A SOP Template for Facility Maintenance Services provides a standardized framework to ensure consistent and efficient maintenance operations. It outlines step-by-step procedures, safety protocols, and quality standards to optimize facility upkeep and minimize downtime. This template helps organizations maintain equipment reliability while enhancing compliance with regulatory requirements.

Scheduled preventive maintenance planning.

This SOP details the process for scheduled preventive maintenance planning, encompassing the systematic scheduling, monitoring, and execution of maintenance tasks to ensure optimal equipment performance and longevity. It includes defining maintenance intervals, assigning responsibilities, tracking maintenance activities, and documenting outcomes to minimize downtime, prevent unexpected failures, and enhance operational efficiency.

Work order request and assignment procedures.

This SOP details the work order request and assignment procedures, covering the process for submitting work order requests, evaluating and prioritizing tasks, assigning work orders to appropriate personnel, tracking progress, and ensuring timely completion. The goal is to streamline workflow management, enhance communication, and ensure efficient use of resources for all maintenance and operational tasks.

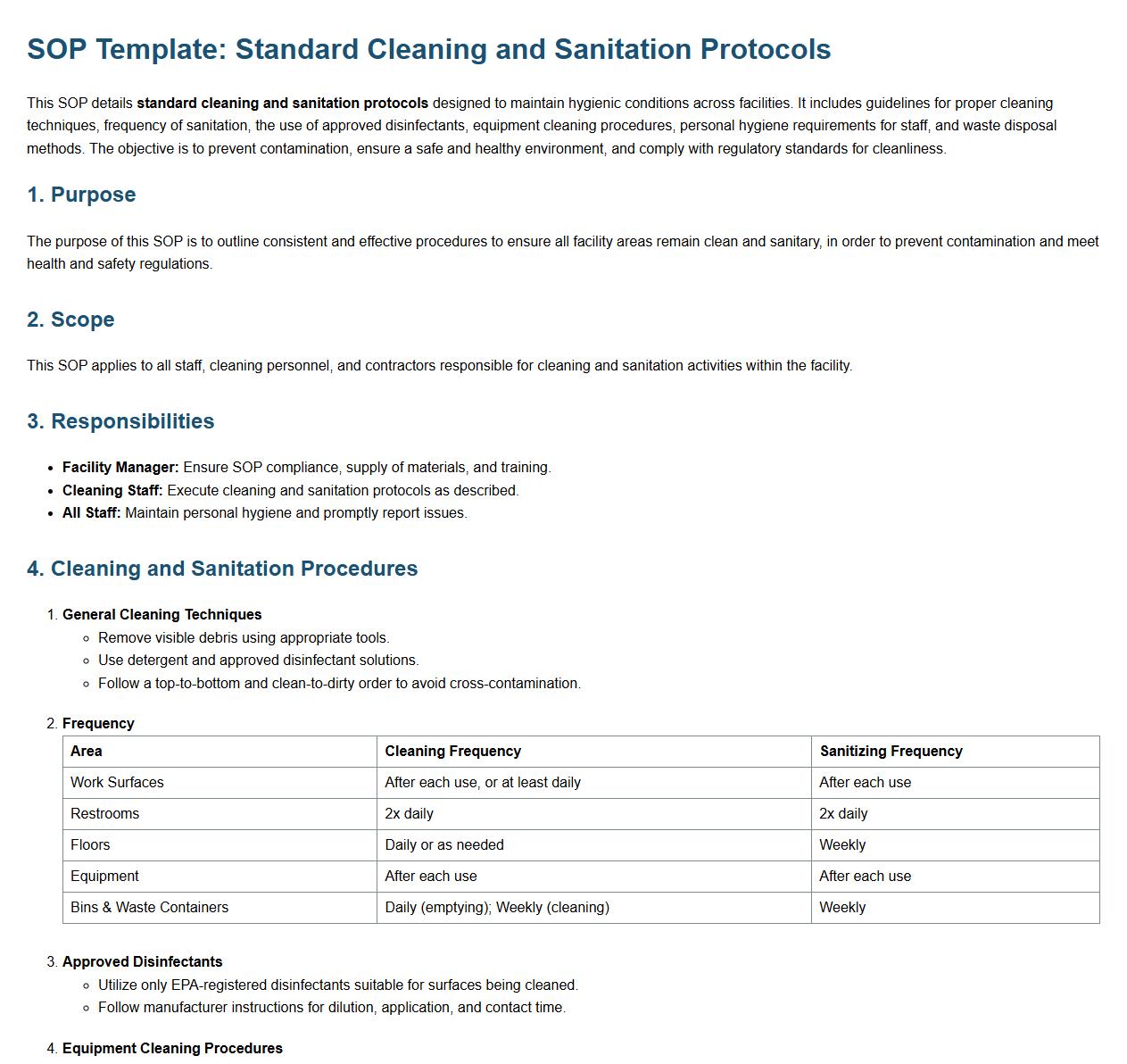

Standard cleaning and sanitation protocols.

This SOP details standard cleaning and sanitation protocols designed to maintain hygienic conditions across facilities. It includes guidelines for proper cleaning techniques, frequency of sanitation, the use of approved disinfectants, equipment cleaning procedures, personal hygiene requirements for staff, and waste disposal methods. The objective is to prevent contamination, ensure a safe and healthy environment, and comply with regulatory standards for cleanliness.

Inspection and audit checklists for facility areas.

This SOP details the procedures for developing and utilizing inspection and audit checklists for facility areas, ensuring comprehensive assessments of compliance, safety, and operational efficiency. The document covers checklist design, area-specific criteria, inspection frequency, documentation standards, corrective action protocols, and continuous improvement processes to maintain facility integrity and regulatory adherence.

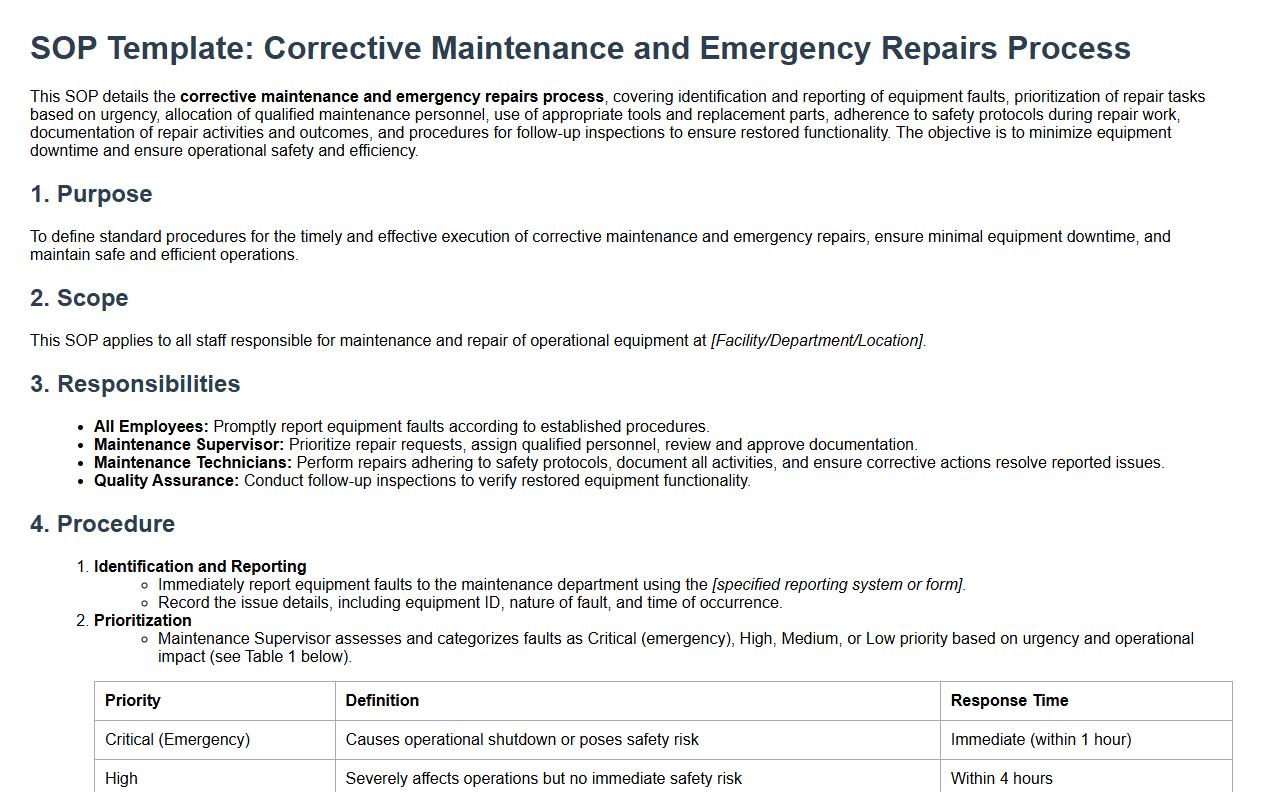

Corrective maintenance and emergency repairs process.

This SOP details the corrective maintenance and emergency repairs process, covering identification and reporting of equipment faults, prioritization of repair tasks based on urgency, allocation of qualified maintenance personnel, use of appropriate tools and replacement parts, adherence to safety protocols during repair work, documentation of repair activities and outcomes, and procedures for follow-up inspections to ensure restored functionality. The objective is to minimize equipment downtime and ensure operational safety and efficiency.

Inventory management for tools and spare parts.

This SOP details inventory management for tools and spare parts, covering procedures for accurate tracking, storage, and maintenance of inventory items. It includes guidelines for recording tool and spare part usage, regular stock audits, reorder point establishment, supplier coordination, and documentation standards to prevent shortages and overstocking. The goal is to ensure efficient inventory control, minimize downtime, and support operational continuity through systematic management practices.

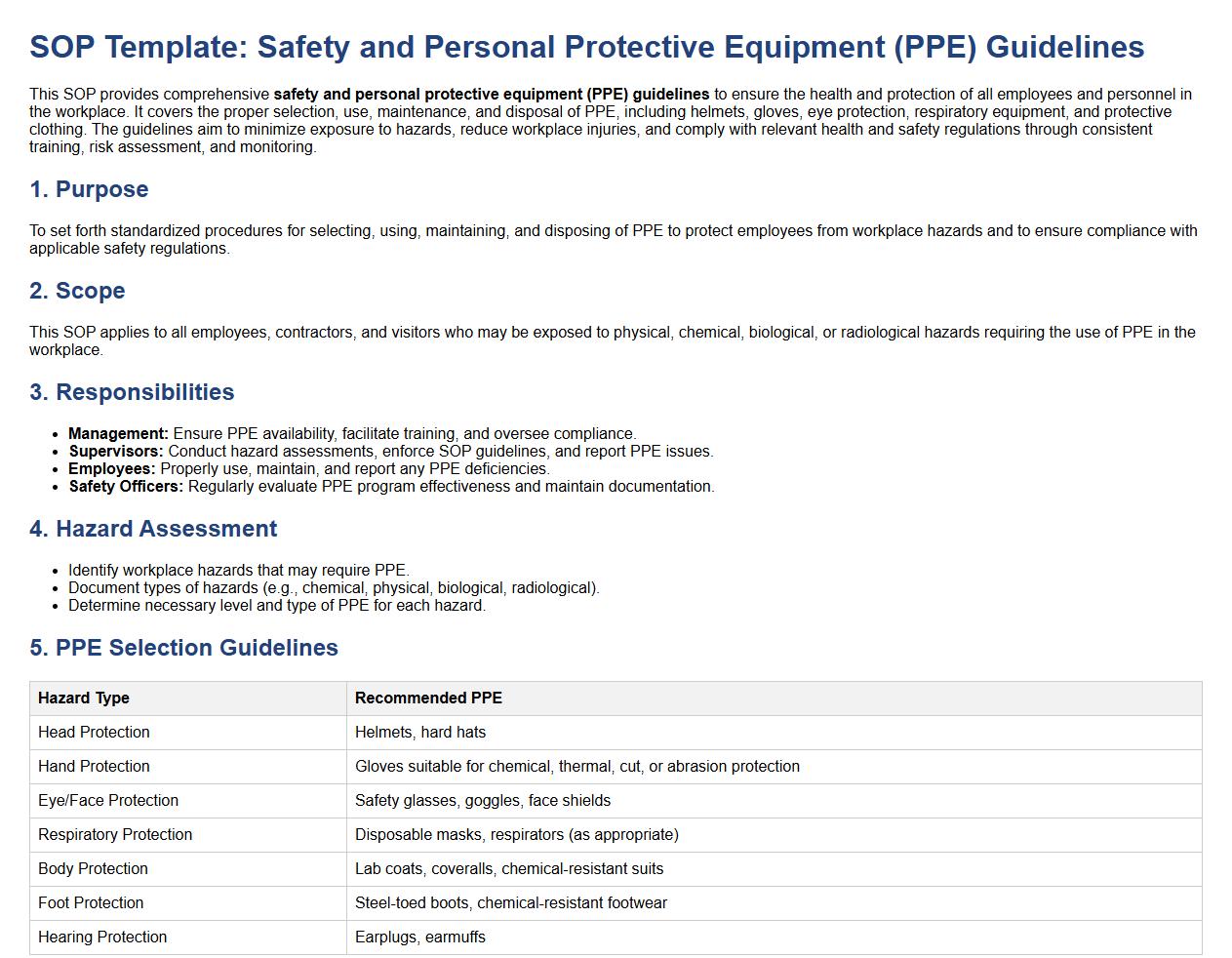

Safety and personal protective equipment (PPE) guidelines.

This SOP provides comprehensive safety and personal protective equipment (PPE) guidelines to ensure the health and protection of all employees and personnel in the workplace. It covers the proper selection, use, maintenance, and disposal of PPE, including helmets, gloves, eye protection, respiratory equipment, and protective clothing. The guidelines aim to minimize exposure to hazards, reduce workplace injuries, and comply with relevant health and safety regulations through consistent training, risk assessment, and monitoring.

Contractor and vendor coordination procedures.

This SOP details contractor and vendor coordination procedures, covering contractor selection and vetting, communication protocols, scheduling and work coordination, compliance with safety and quality standards, documentation and contract management, performance monitoring and evaluation, issue resolution, and reporting requirements. The goal is to ensure seamless collaboration, maintain project timelines, uphold safety standards, and achieve quality outcomes through effective management of external contractors and vendors.

Staff training and competency requirements.

This SOP details staff training and competency requirements, focusing on onboarding new employees, continuous skill development, mandatory training sessions, competency assessments, documentation of training records, and compliance with industry standards. The objective is to ensure all staff possess the necessary knowledge and skills to perform their duties effectively, safely, and in alignment with organizational goals.

Documentation, reporting, and compliance record-keeping.

This SOP defines the process for documentation, reporting, and compliance record-keeping, including accurate data collection, timely submission of reports, maintenance of compliance logs, audit preparation, and record retention protocols. The aim is to ensure transparency, regulatory adherence, and efficient tracking of operational activities within the organization.

What are the primary objectives outlined in the SOP for Facility Maintenance Services?

The primary objectives of the SOP for Facility Maintenance Services focus on ensuring a safe, functional, and efficient environment. It aims to minimize downtime and extend the lifespan of facility assets through timely and effective maintenance. Additionally, the SOP emphasizes compliance with health, safety, and environmental regulations.

Which roles and responsibilities are specified for personnel involved in facility maintenance?

The SOP clearly defines roles and responsibilities for facility maintenance personnel, including technicians, supervisors, and managers. Each role is tasked with distinct duties such as conducting inspections, performing repairs, and documenting activities. Accountability and communication channels are established to maintain high-quality service and operational efficiency.

What procedures are established for reporting and addressing maintenance requests?

The SOP mandates a standardized procedure for reporting and addressing maintenance requests to ensure timely responses. Requests must be submitted through an authorized system or form and prioritized based on urgency and impact. This structured approach guarantees efficient handling and resolution of maintenance issues.

How does the SOP define the process for routine, preventive, and emergency maintenance tasks?

The SOP outlines specific protocols for routine, preventive, and emergency maintenance tasks to maintain operational continuity. Routine tasks are scheduled regularly, preventive maintenance is planned based on equipment condition, and emergency procedures are activated immediately to address critical issues. This systematic process ensures reliability and safety of all facility systems.

What record-keeping and documentation requirements are mandated by the SOP for completed maintenance activities?

The SOP requires comprehensive record-keeping and documentation of all completed maintenance activities to support accountability and auditing. Records must include work performed, materials used, personnel involved, and timestamps. Proper documentation facilitates tracking trends, planning future maintenance, and ensuring compliance with regulatory standards.