A SOP Template for Maintenance Request Handling streamlines the process of logging, assessing, and resolving maintenance issues efficiently. This document ensures consistent communication between staff and maintenance teams, minimizing downtime and improving equipment reliability. Following a clear procedure reduces errors and accelerates response times for all maintenance requests.

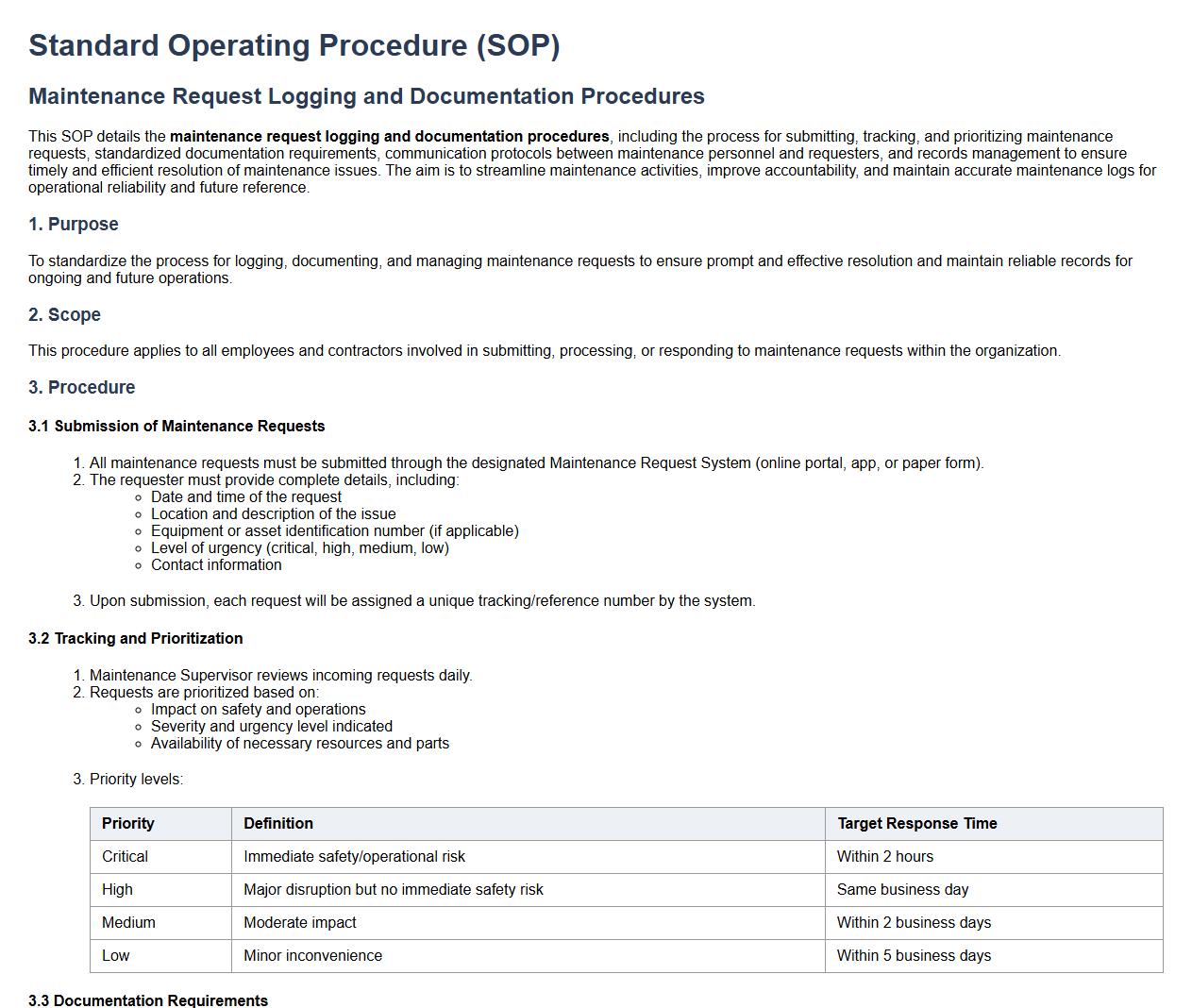

Maintenance request logging and documentation procedures.

This SOP details the maintenance request logging and documentation procedures, including the process for submitting, tracking, and prioritizing maintenance requests, standardized documentation requirements, communication protocols between maintenance personnel and requesters, and records management to ensure timely and efficient resolution of maintenance issues. The aim is to streamline maintenance activities, improve accountability, and maintain accurate maintenance logs for operational reliability and future reference.

Assessment and prioritization of maintenance requests.

This SOP details the assessment and prioritization of maintenance requests, covering the systematic evaluation of reported issues, categorization based on urgency and impact, assignment of priority levels, and scheduling of maintenance tasks. The objective is to ensure efficient allocation of resources, timely resolution of critical repairs, and minimized downtime, thereby maintaining optimal operational performance and safety standards.

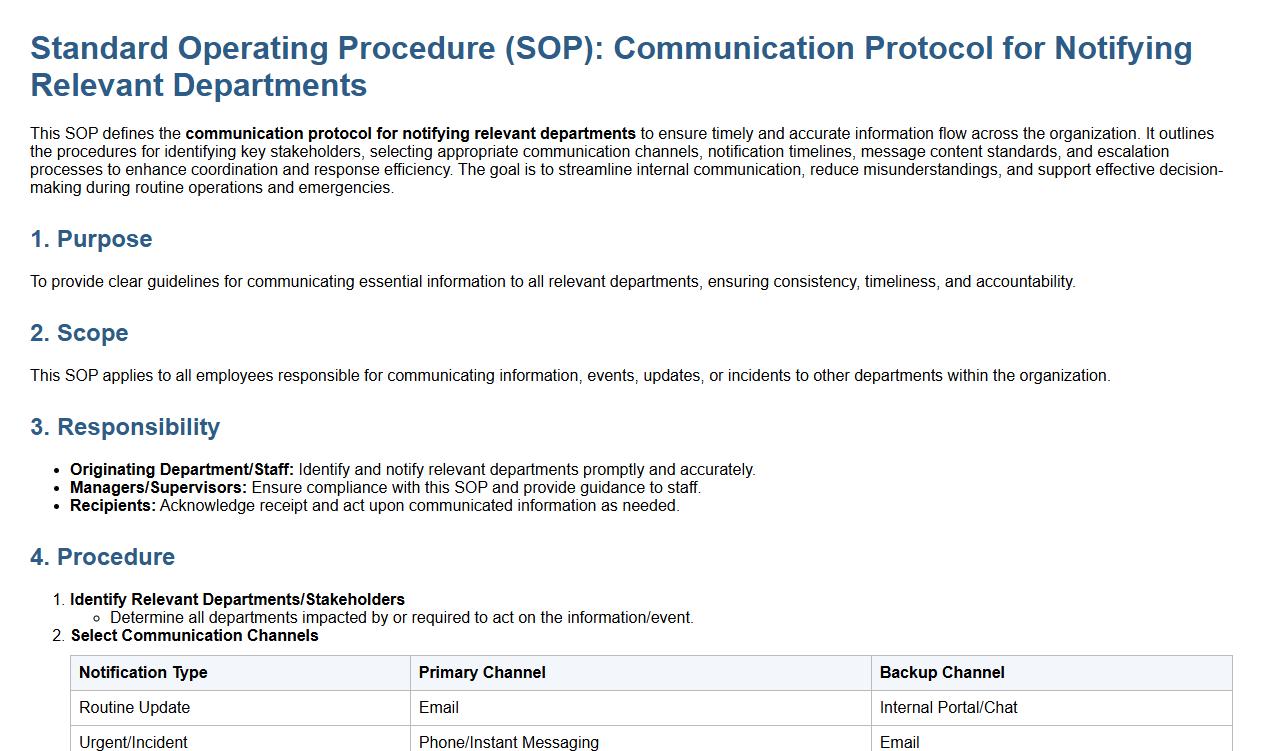

Communication protocol for notifying relevant departments.

This SOP defines the communication protocol for notifying relevant departments to ensure timely and accurate information flow across the organization. It outlines the procedures for identifying key stakeholders, selecting appropriate communication channels, notification timelines, message content standards, and escalation processes to enhance coordination and response efficiency. The goal is to streamline internal communication, reduce misunderstandings, and support effective decision-making during routine operations and emergencies.

Assignment of maintenance tasks to appropriate personnel.

This SOP details the assignment of maintenance tasks to appropriate personnel, ensuring that each task is delegated based on skill level, experience, and availability. It covers the identification of maintenance needs, evaluation of personnel qualifications, task prioritization, communication protocols, and follow-up procedures to guarantee efficient and timely maintenance operations while maintaining safety and quality standards.

Standard workflow for on-site inspection and diagnosis.

This SOP defines the standard workflow for on-site inspection and diagnosis, detailing the systematic process for evaluating equipment, facilities, or systems. It includes preparation and planning, initial assessment, data collection and analysis, identification of issues or defects, diagnosis of root causes, documentation of findings, recommended corrective actions, and communication of results to relevant stakeholders. The purpose is to ensure consistent, accurate, and efficient inspections that enhance operational reliability and safety.

Procurement process for required tools and replacement parts.

This SOP details the procurement process for required tools and replacement parts, encompassing the identification of needs, supplier evaluation and selection, purchase order creation, approval workflows, receiving and inspection procedures, inventory updating, and payment processing. The objective is to ensure timely acquisition of quality tools and parts while maintaining cost-effectiveness and compliance with company policies.

Repair and resolution reporting guidelines.

This SOP details the repair and resolution reporting guidelines, which include the standardized process for identifying, documenting, and reporting equipment or system malfunctions, the steps for timely communication of issues to the maintenance team, criteria for prioritizing repairs based on urgency and impact, methods for tracking repair progress and completion, and protocols for validating and closing repair requests. The goal is to ensure efficient resolution of problems, minimize downtime, and maintain operational continuity through clear and consistent reporting practices.

Quality assurance checks after maintenance completion.

This SOP details the process for quality assurance checks after maintenance completion, ensuring all maintenance tasks meet established standards and operational requirements. It covers inspection protocols, verification of repairs or adjustments, documentation of findings, clear communication with relevant teams, and follow-up actions to address any discrepancies. The goal is to guarantee equipment reliability, safety, and optimal performance following maintenance activities.

Close-out and feedback collection process.

This SOP details the close-out and feedback collection process, outlining steps for project completion, documentation finalization, stakeholder feedback gathering, performance evaluation, and lessons learned documentation. The procedure ensures thorough project closure, enhances future project planning, and promotes continuous improvement through structured feedback integration.

Archiving maintenance records and follow-up scheduling.

This SOP details the process of archiving maintenance records and follow-up scheduling, including systematic documentation of completed maintenance tasks, secure storage of records for easy retrieval, regular review of archived data to ensure completeness, and setting up timely follow-up appointments to maintain equipment efficiency and compliance. The goal is to enhance maintenance tracking, ensure accountability, and facilitate proactive upkeep through organized record-keeping and scheduled interventions.

What are the required steps for submitting a maintenance request according to the SOP?

To submit a maintenance request, the requester must fill out a standardized form detailing the issue. This form should be submitted through the designated platform or sent directly to the maintenance department. Proper documentation ensures that requests are logged and prioritized correctly.

Who is responsible for approving and assigning maintenance requests as per the SOP?

The maintenance supervisor is responsible for approving all incoming requests. Upon approval, the supervisor assigns tasks to the appropriate maintenance personnel based on urgency and expertise. This step ensures efficient allocation of resources and timely resolution.

What is the expected timeline for response and resolution outlined in the SOP?

The SOP mandates an initial response within 24 hours of request submission. Resolution timelines vary based on the severity of the issue but generally aim for completion within 3 to 5 business days. Adhering to these timelines is crucial for maintaining operational efficiency.

How should status updates and communications be documented during the maintenance process?

All status updates must be recorded in the maintenance tracking system in real-time. Communication between the requester and maintenance team should be clear and documented to maintain transparency. Proper record-keeping facilitates accountability and historical tracking.

What procedures are in place for emergency maintenance situations within the SOP?

In emergency scenarios, immediate notification to the emergency response team is required. The SOP prioritizes rapid dispatch of technical staff to mitigate risks and restore functionality. Emergency protocols ensure safety and minimize downtime effectively.