A SOP Template for Maintenance Requests streamlines the process of reporting and handling maintenance issues efficiently. It outlines clear steps for submitting requests, prioritizing tasks, and documenting resolutions to ensure timely and organized maintenance management. Using this template improves communication between staff and maintenance teams, reducing downtime and enhancing operational productivity.

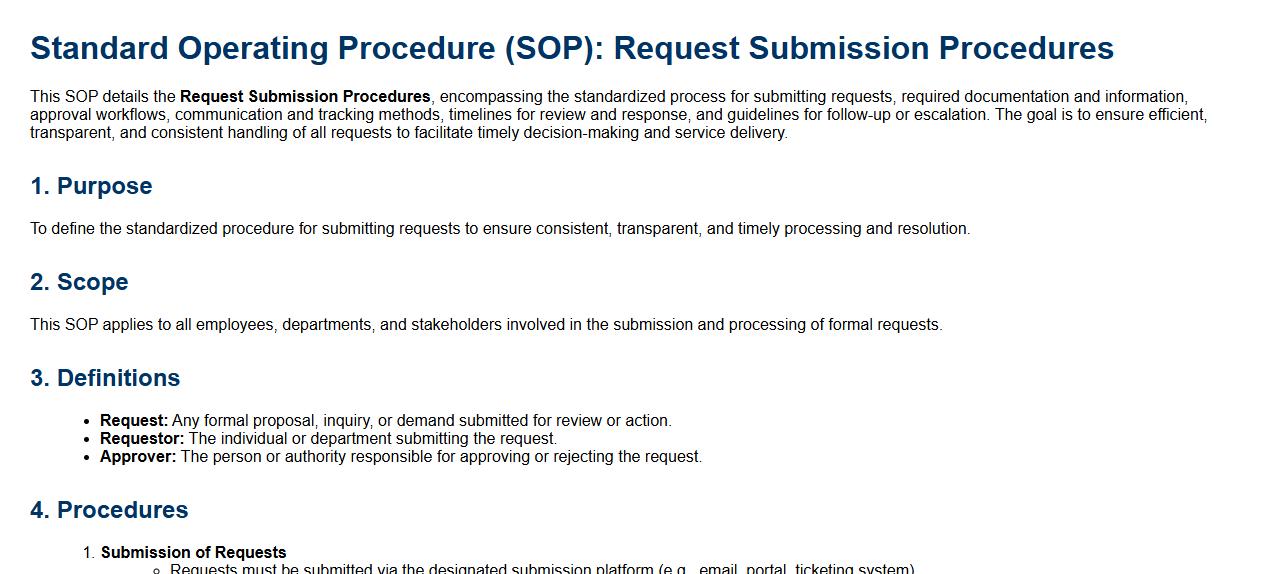

Request Submission Procedures.

This SOP details the Request Submission Procedures, encompassing the standardized process for submitting requests, required documentation and information, approval workflows, communication and tracking methods, timelines for review and response, and guidelines for follow-up or escalation. The goal is to ensure efficient, transparent, and consistent handling of all requests to facilitate timely decision-making and service delivery.

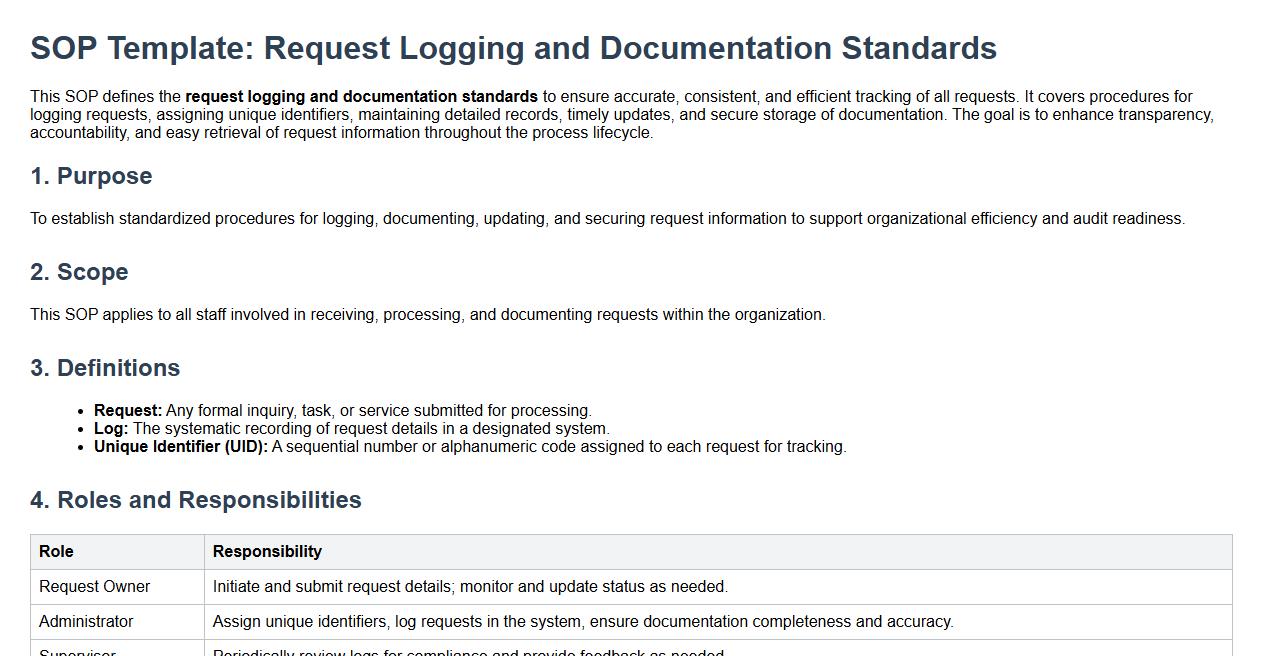

Request Logging and Documentation Standards.

This SOP defines the request logging and documentation standards to ensure accurate, consistent, and efficient tracking of all requests. It covers procedures for logging requests, assigning unique identifiers, maintaining detailed records, timely updates, and secure storage of documentation. The goal is to enhance transparency, accountability, and easy retrieval of request information throughout the process lifecycle.

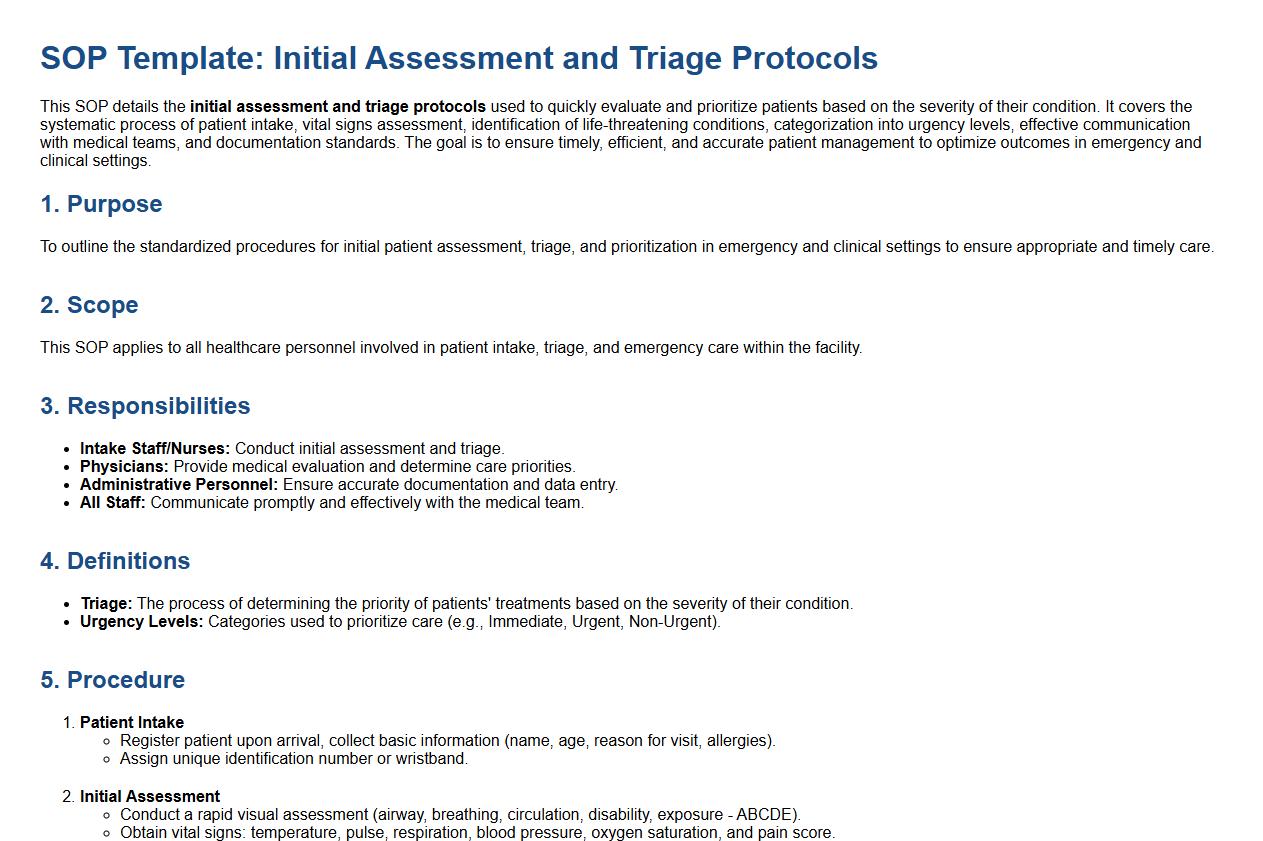

Initial Assessment and Triage Protocols.

This SOP details the initial assessment and triage protocols used to quickly evaluate and prioritize patients based on the severity of their condition. It covers the systematic process of patient intake, vital signs assessment, identification of life-threatening conditions, categorization into urgency levels, effective communication with medical teams, and documentation standards. The goal is to ensure timely, efficient, and accurate patient management to optimize outcomes in emergency and clinical settings.

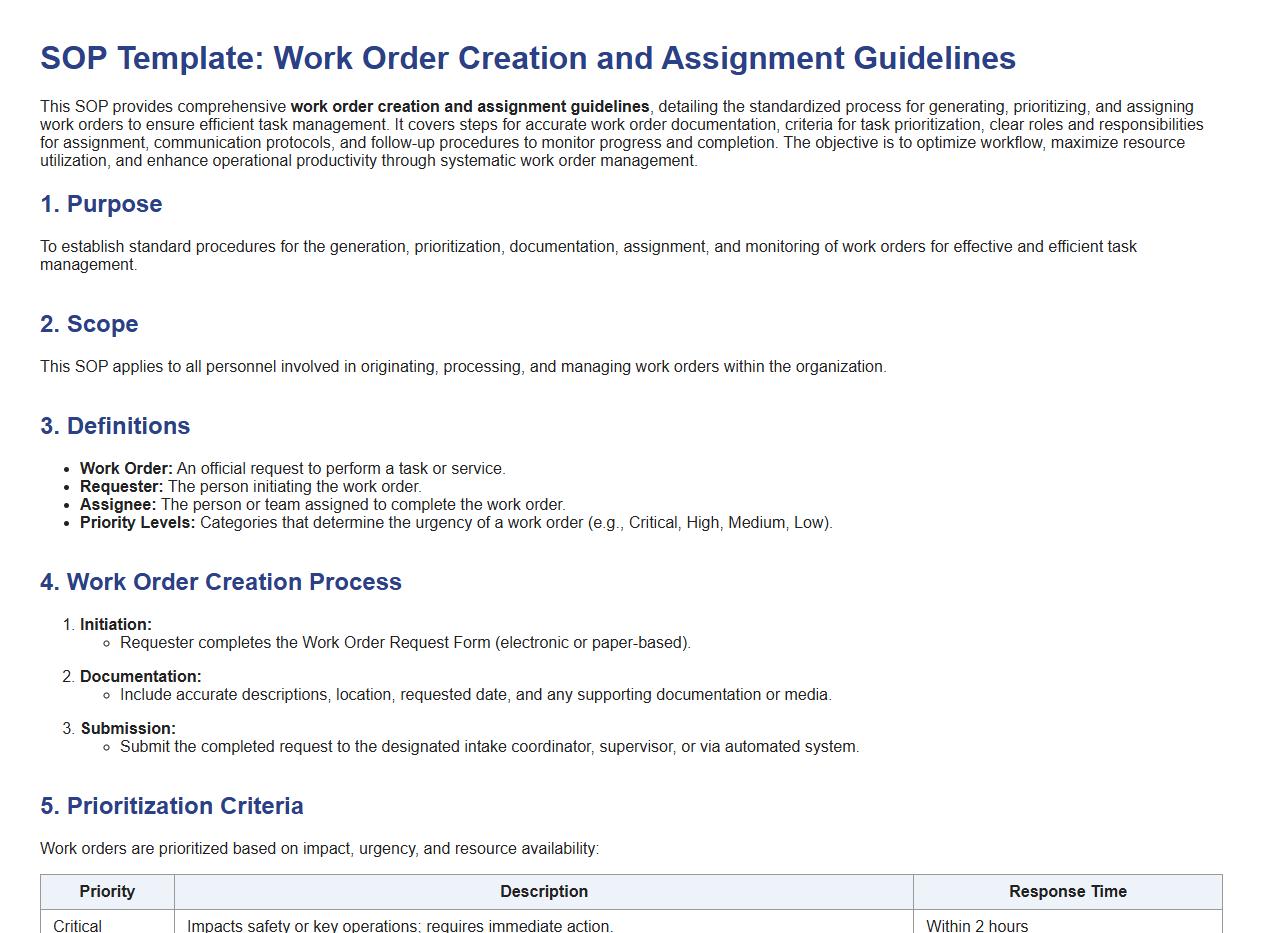

Work Order Creation and Assignment Guidelines.

This SOP provides comprehensive work order creation and assignment guidelines, detailing the standardized process for generating, prioritizing, and assigning work orders to ensure efficient task management. It covers steps for accurate work order documentation, criteria for task prioritization, clear roles and responsibilities for assignment, communication protocols, and follow-up procedures to monitor progress and completion. The objective is to optimize workflow, maximize resource utilization, and enhance operational productivity through systematic work order management.

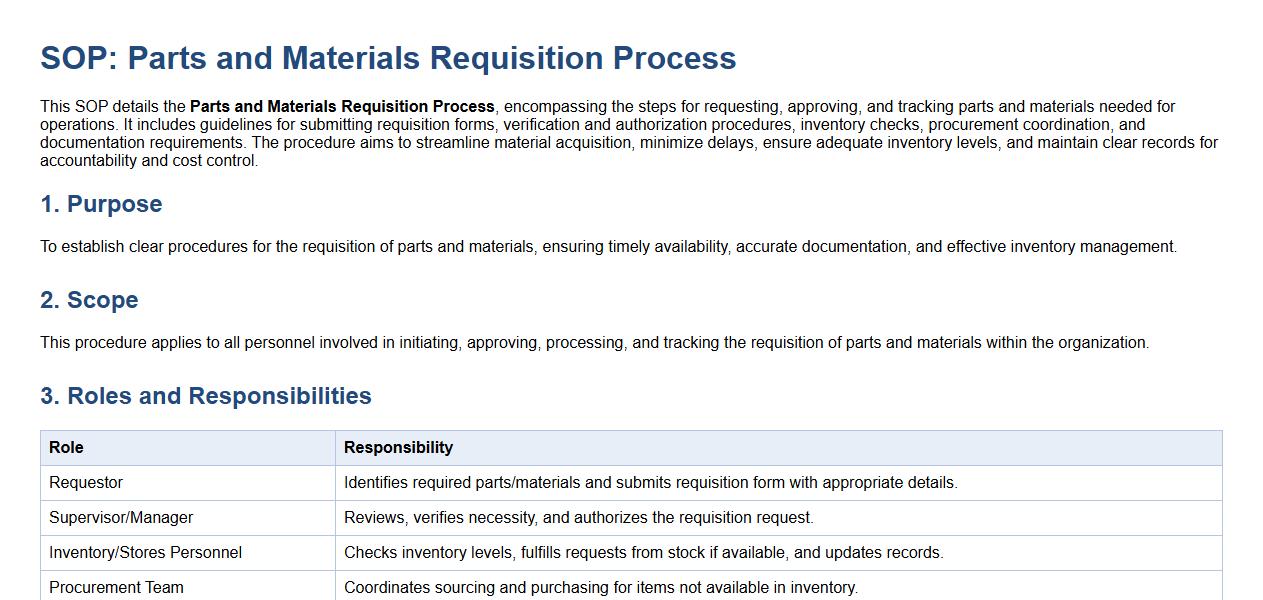

Parts and Materials Requisition Process.

This SOP details the Parts and Materials Requisition Process, encompassing the steps for requesting, approving, and tracking parts and materials needed for operations. It includes guidelines for submitting requisition forms, verification and authorization procedures, inventory checks, procurement coordination, and documentation requirements. The procedure aims to streamline material acquisition, minimize delays, ensure adequate inventory levels, and maintain clear records for accountability and cost control.

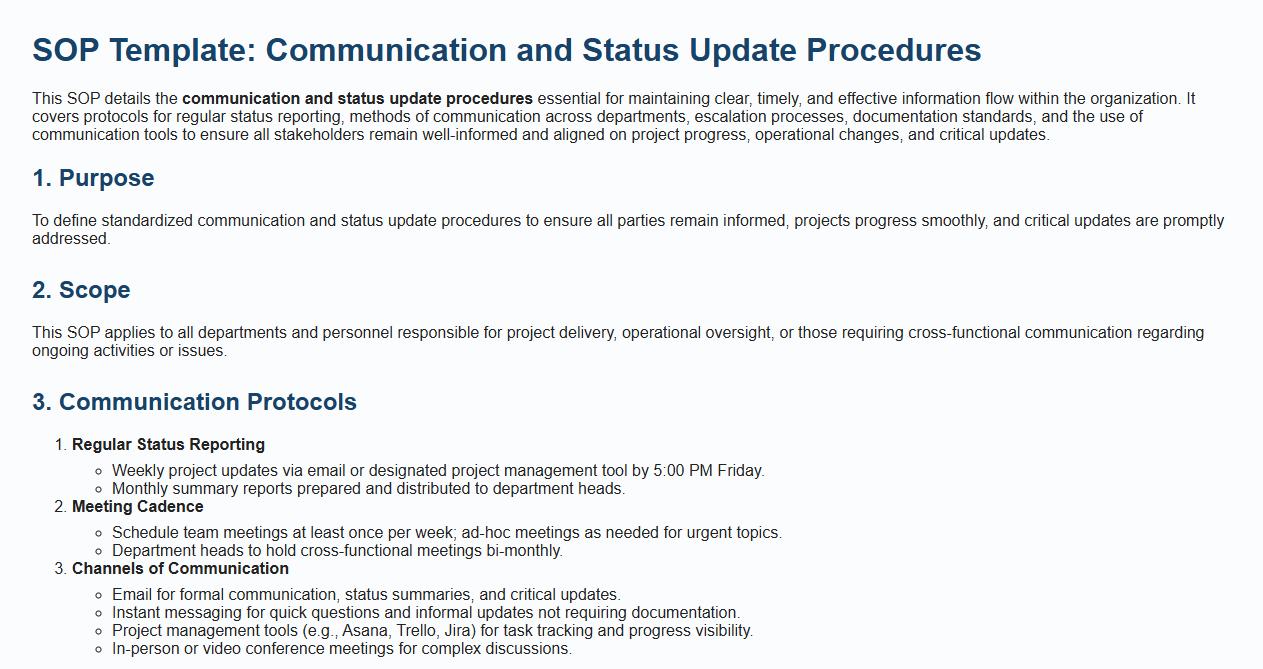

Communication and Status Update Procedures.

This SOP details the communication and status update procedures essential for maintaining clear, timely, and effective information flow within the organization. It covers protocols for regular status reporting, methods of communication across departments, escalation processes, documentation standards, and the use of communication tools to ensure all stakeholders remain well-informed and aligned on project progress, operational changes, and critical updates.

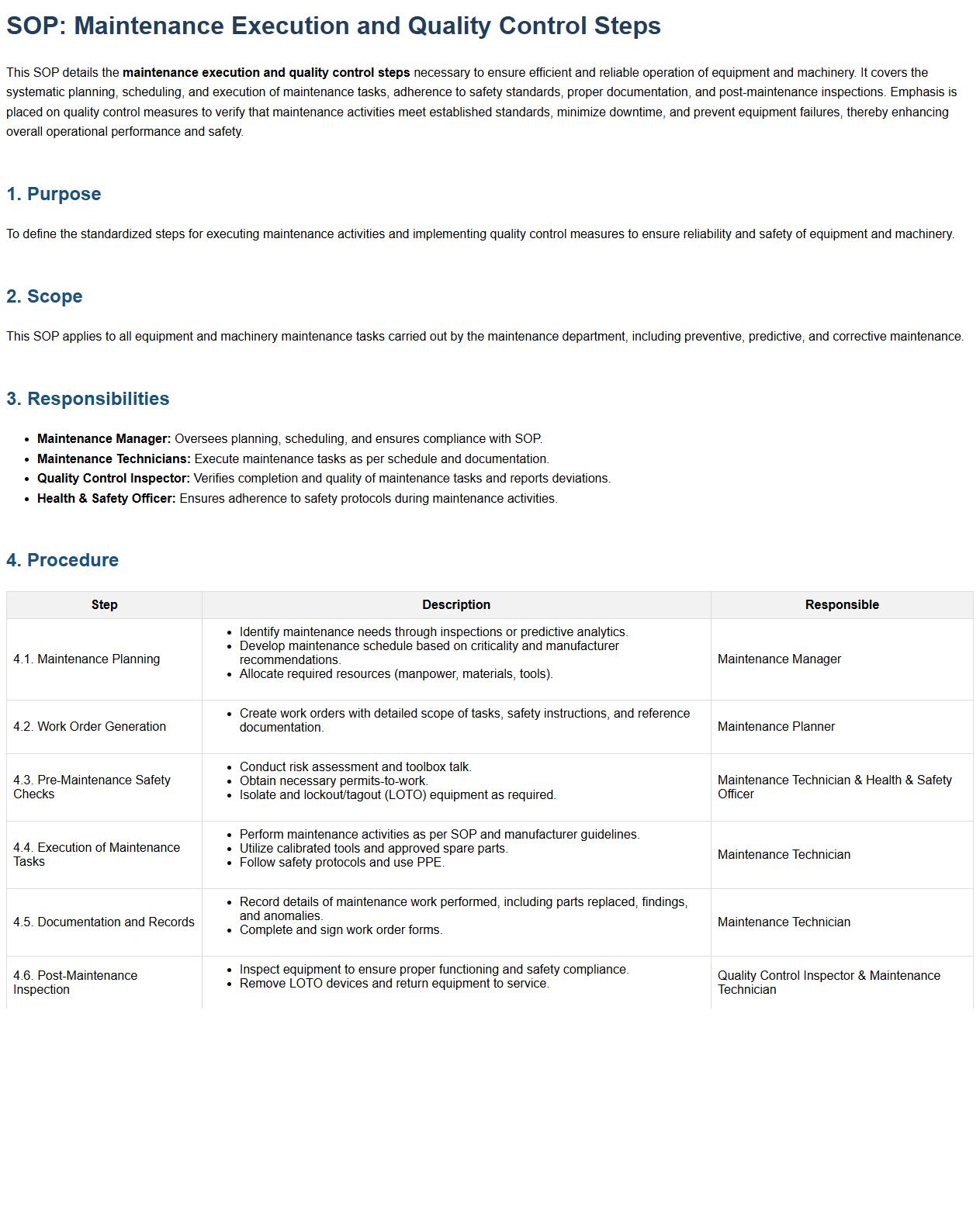

Maintenance Execution and Quality Control Steps.

This SOP details the maintenance execution and quality control steps necessary to ensure efficient and reliable operation of equipment and machinery. It covers the systematic planning, scheduling, and execution of maintenance tasks, adherence to safety standards, proper documentation, and post-maintenance inspections. Emphasis is placed on quality control measures to verify that maintenance activities meet established standards, minimize downtime, and prevent equipment failures, thereby enhancing overall operational performance and safety.

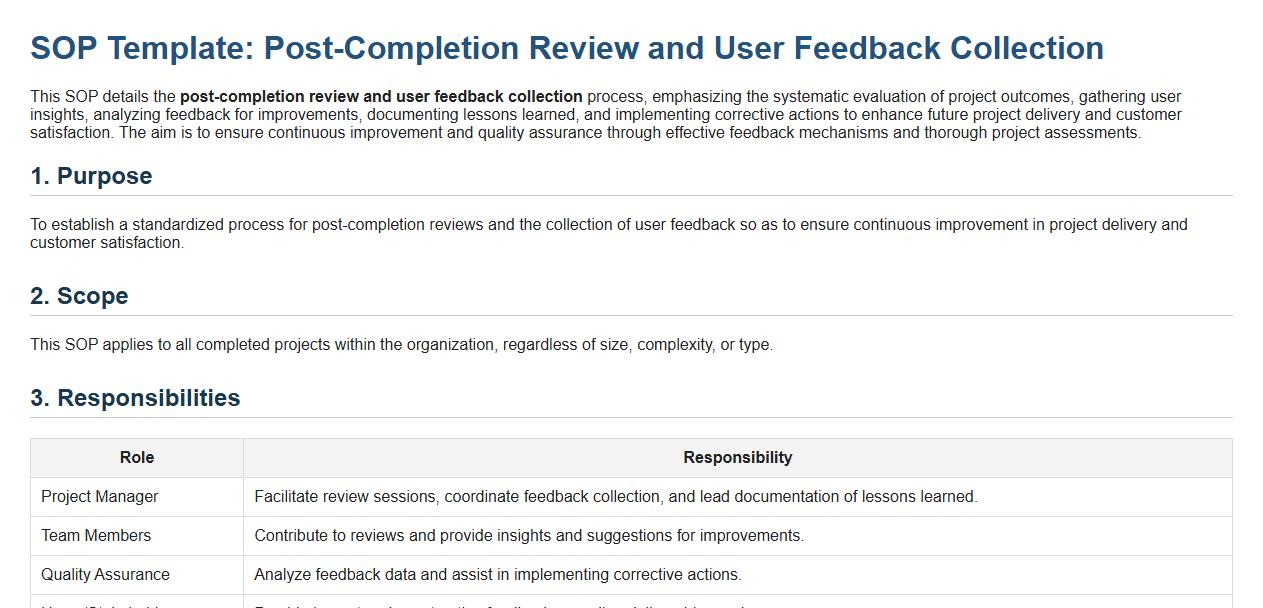

Post-Completion Review and User Feedback Collection.

This SOP details the post-completion review and user feedback collection process, emphasizing the systematic evaluation of project outcomes, gathering user insights, analyzing feedback for improvements, documenting lessons learned, and implementing corrective actions to enhance future project delivery and customer satisfaction. The aim is to ensure continuous improvement and quality assurance through effective feedback mechanisms and thorough project assessments.

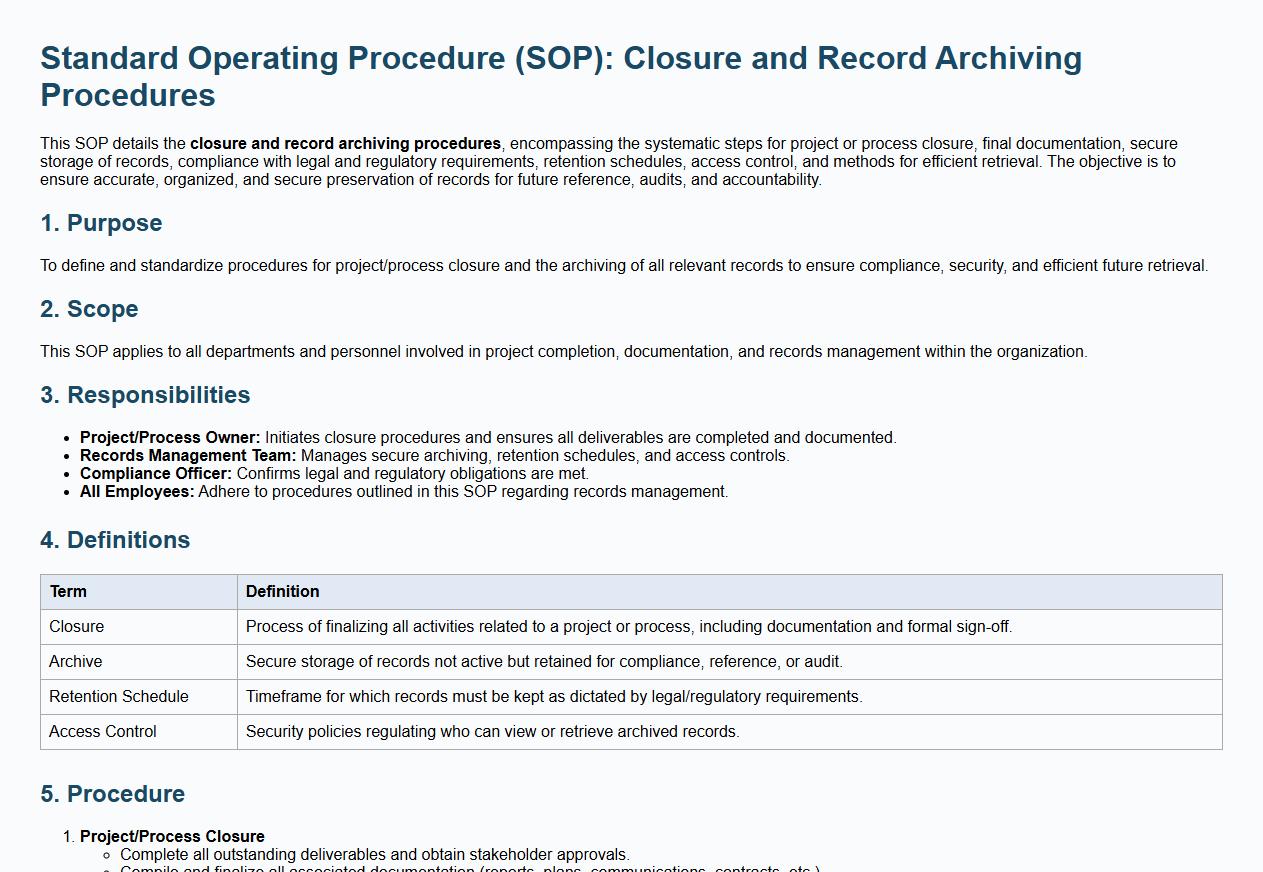

Closure and Record Archiving Procedures.

This SOP details the closure and record archiving procedures, encompassing the systematic steps for project or process closure, final documentation, secure storage of records, compliance with legal and regulatory requirements, retention schedules, access control, and methods for efficient retrieval. The objective is to ensure accurate, organized, and secure preservation of records for future reference, audits, and accountability.

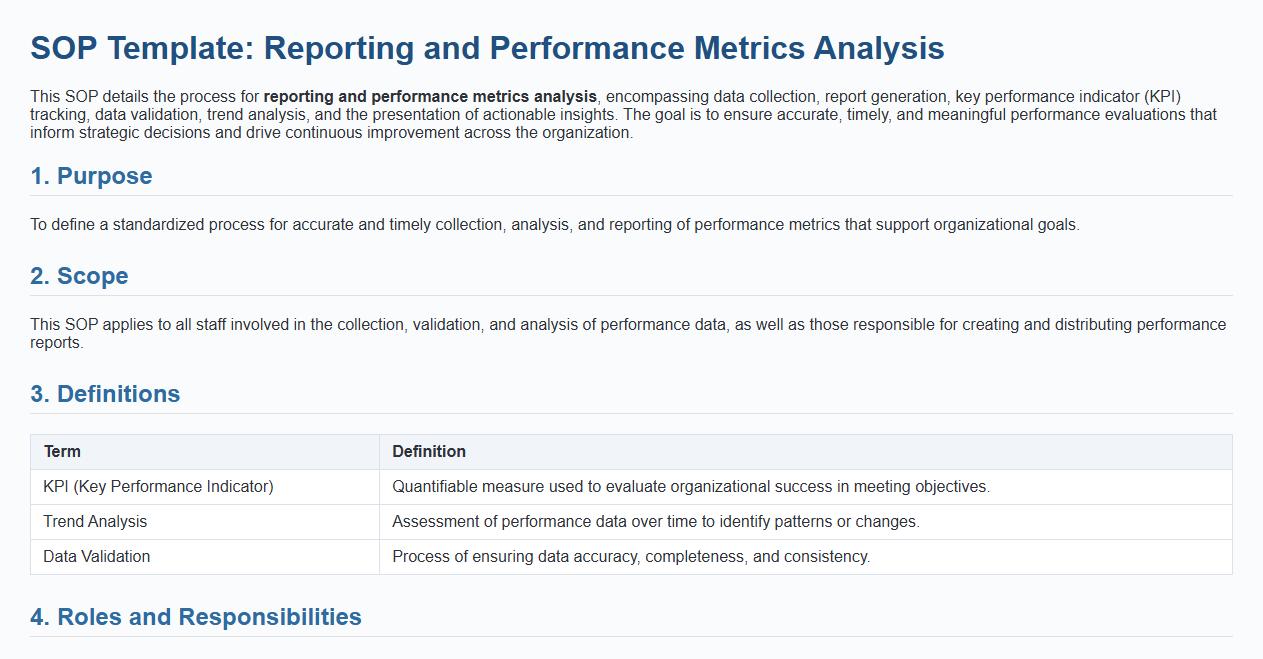

Reporting and Performance Metrics Analysis.

This SOP details the process for reporting and performance metrics analysis, encompassing data collection, report generation, key performance indicator (KPI) tracking, data validation, trend analysis, and the presentation of actionable insights. The goal is to ensure accurate, timely, and meaningful performance evaluations that inform strategic decisions and drive continuous improvement across the organization.

What are the required steps outlined in the SOP for submitting a maintenance request?

The SOP requires submitting a maintenance request form detailing the issue clearly and accurately. The request must be submitted through the designated system or platform to ensure proper logging. Additionally, the requester should provide all necessary contact information for follow-up communication.

Who is authorized to approve and prioritize maintenance requests according to the SOP?

Facility managers or designated supervisors are authorized to approve and prioritize maintenance requests. They assess the urgency and impact of each request before assigning priority levels. Only authorized personnel have the authority to reclassify or escalate requests.

How does the SOP define categories or types of maintenance requests (e.g., urgent, routine)?

The SOP categorizes maintenance requests into urgent, semi-urgent, and routine based on potential risk and operational impact. Urgent requests involve immediate hazards or disruptions requiring swift action. Routine requests pertain to non-critical issues scheduled for regular maintenance windows.

What documentation and tracking processes are specified in the maintenance request SOP?

The SOP mandates that every maintenance request is logged in a centralized tracking system with detailed documentation. Status updates and resolution notes must be recorded promptly to maintain transparency. Regular reports are generated to monitor progress and compliance with service level agreements.

What are the escalation procedures in the SOP if a maintenance request is not addressed within the specified timeframe?

If a maintenance request is not resolved on time, the SOP requires immediate escalation to higher management or the maintenance department head. Follow-up communications must be documented to ensure accountability. Repeated delays trigger a formal review to improve process efficiency.