A SOP Template for Professional Maintenance Services provides a structured framework to ensure consistent and efficient execution of maintenance tasks. It outlines step-by-step procedures, safety protocols, and quality standards to optimize service delivery and minimize downtime. This template enhances communication, accountability, and compliance within maintenance teams.

Work order initiation and scheduling procedures.

This SOP details the work order initiation and scheduling procedures, covering the process of creating, prioritizing, and assigning work orders, scheduling tasks efficiently, resource allocation, and monitoring progress. The objective is to streamline maintenance and operational workflows, ensuring timely and organized completion of all work orders to enhance productivity and minimize downtime.

Client communication and service request handling.

This SOP details effective client communication and service request handling, covering procedures for receiving, documenting, and responding to client inquiries and service requests promptly. It emphasizes clear, professional communication, tracking and prioritizing requests, coordinating with relevant departments, and ensuring timely resolution and follow-up. The aim is to enhance client satisfaction, maintain transparency, and streamline service delivery through consistent and efficient communication practices.

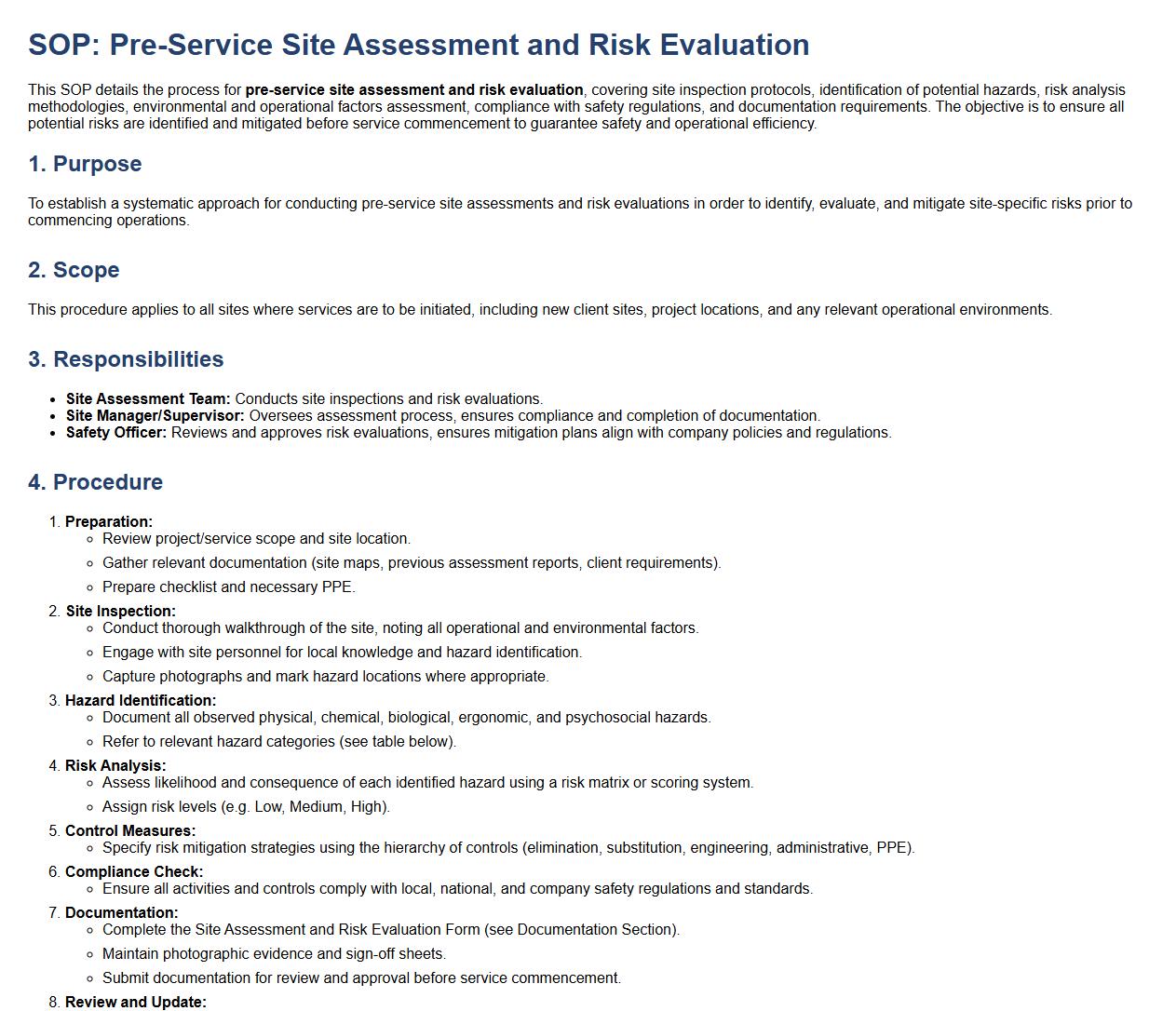

Pre-service site assessment and risk evaluation.

This SOP details the process for pre-service site assessment and risk evaluation, covering site inspection protocols, identification of potential hazards, risk analysis methodologies, environmental and operational factors assessment, compliance with safety regulations, and documentation requirements. The objective is to ensure all potential risks are identified and mitigated before service commencement to guarantee safety and operational efficiency.

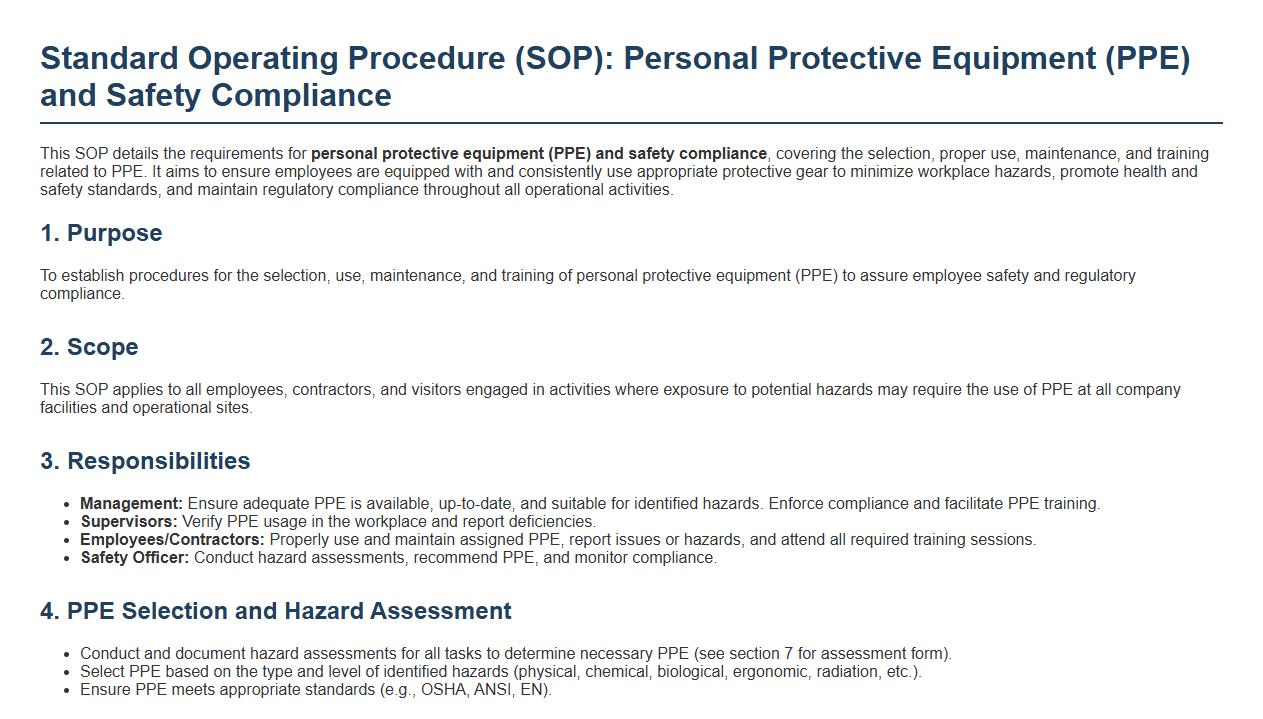

Personal protective equipment (PPE) and safety compliance.

This SOP details the requirements for personal protective equipment (PPE) and safety compliance, covering the selection, proper use, maintenance, and training related to PPE. It aims to ensure employees are equipped with and consistently use appropriate protective gear to minimize workplace hazards, promote health and safety standards, and maintain regulatory compliance throughout all operational activities.

Standardized equipment and tool usage guidelines.

This SOP establishes standardized equipment and tool usage guidelines to ensure consistent, safe, and efficient operation across all work areas. It covers proper selection, handling, maintenance, and storage of tools and equipment, emphasizing user safety, equipment longevity, and compliance with relevant regulations. The objective is to minimize accidents, reduce downtime, and promote best practices for all personnel involved in equipment usage.

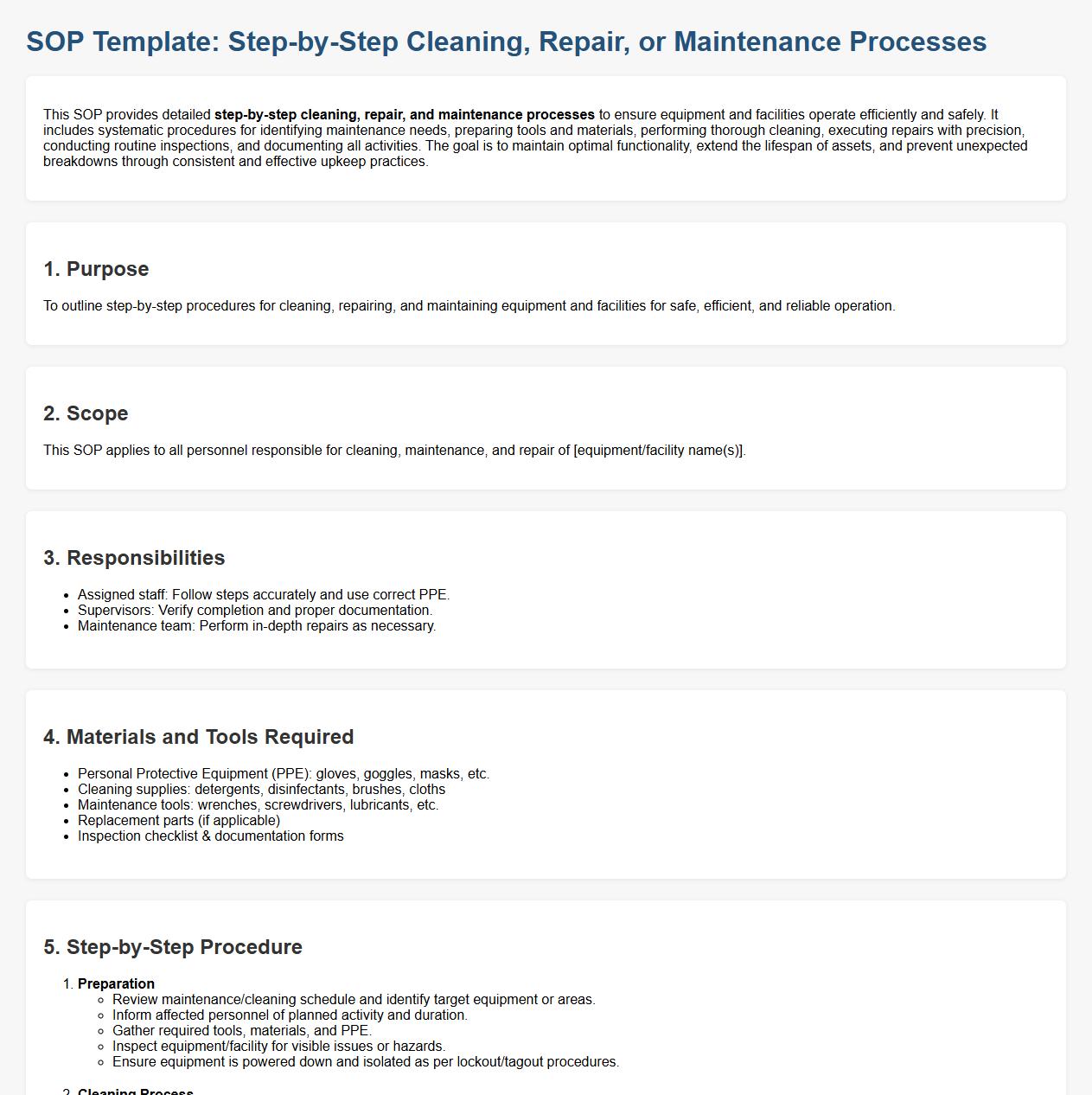

Step-by-step cleaning, repair, or maintenance processes.

This SOP provides detailed step-by-step cleaning, repair, and maintenance processes to ensure equipment and facilities operate efficiently and safely. It includes systematic procedures for identifying maintenance needs, preparing tools and materials, performing thorough cleaning, executing repairs with precision, conducting routine inspections, and documenting all activities. The goal is to maintain optimal functionality, extend the lifespan of assets, and prevent unexpected breakdowns through consistent and effective upkeep practices.

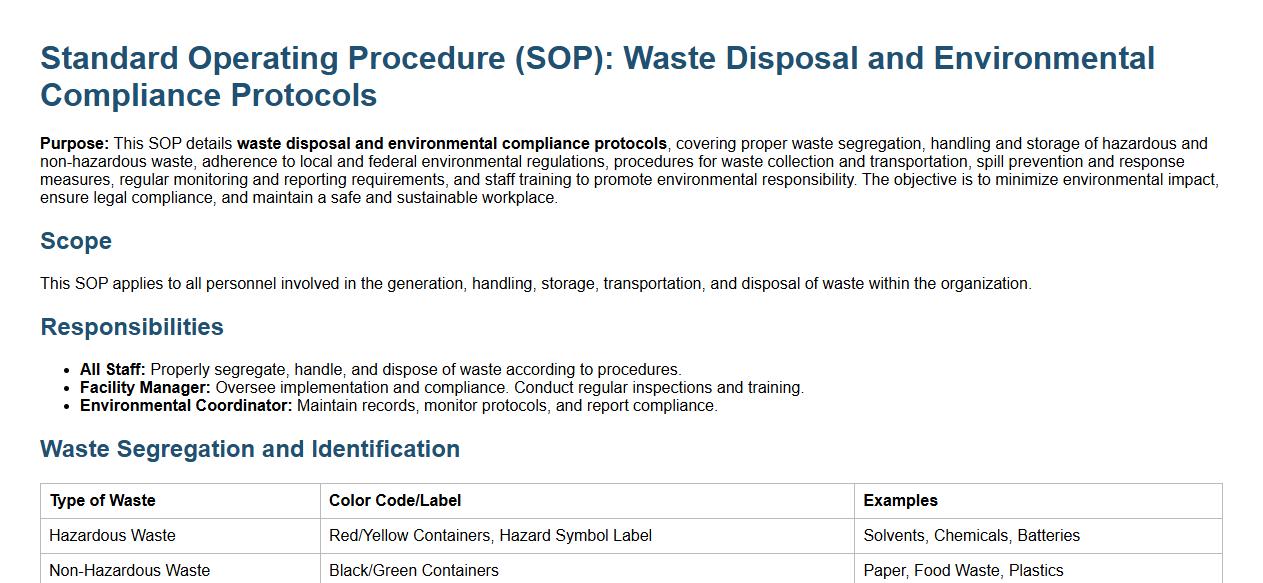

Waste disposal and environmental compliance protocols.

This SOP details waste disposal and environmental compliance protocols, covering proper waste segregation, handling and storage of hazardous and non-hazardous waste, adherence to local and federal environmental regulations, procedures for waste collection and transportation, spill prevention and response measures, regular monitoring and reporting requirements, and staff training to promote environmental responsibility. The objective is to minimize environmental impact, ensure legal compliance, and maintain a safe and sustainable workplace.

Quality control inspections and service verification.

This SOP details the process for quality control inspections and service verification, encompassing systematic evaluation of product standards, adherence to service protocols, identification of defects or non-compliance, documentation of inspection results, corrective action procedures, staff responsibilities during inspections, and continuous improvement measures. The objective is to maintain high-quality standards, ensure customer satisfaction, and guarantee that all services meet established industry regulations and company policies.

Incident reporting and escalation procedures.

This SOP details the incident reporting and escalation procedures designed to ensure timely identification, documentation, and communication of workplace incidents. It includes steps for immediate reporting, assessment of severity, notification of appropriate personnel, and escalation protocols to management or emergency services. The goal is to promote a safe work environment by enabling prompt response, investigation, and corrective actions to prevent recurrence and comply with regulatory requirements.

Post-service documentation and client feedback collection.

This SOP details the process for post-service documentation and client feedback collection, including accurate and timely recording of service details, ensuring completeness of service reports, methods for soliciting client feedback, handling and analyzing feedback data, and integrating insights into service improvement strategies. The goal is to maintain high service quality, enhance client satisfaction, and support continuous improvement through systematic documentation and effective feedback management.

What are the defined roles and responsibilities of personnel according to the SOP for Professional Maintenance Services?

The SOP defines the roles and responsibilities of maintenance personnel to ensure clear accountability throughout the maintenance process. Each team member is assigned specific tasks to maintain efficiency and compliance with organizational standards. Proper role assignment ensures that all maintenance activities are performed by qualified individuals.

What specific procedures must be followed for scheduled and emergency maintenance tasks as per the SOP?

The SOP outlines detailed procedures that must be followed for both scheduled and emergency maintenance tasks to guarantee systematic and safe operations. Scheduled maintenance requires adherence to a predefined timetable, while emergency tasks demand quick response actions according to safety guidelines. Following these procedures minimizes downtime and enhances equipment reliability.

What tools, equipment, and materials are required and approved for use in the SOP for Professional Maintenance Services?

The SOP specifies the approved tools, equipment, and materials to ensure consistency and safety in maintenance activities. Only authorized and calibrated instruments should be used to maintain standards and reduce work hazards. This list helps in procuring and verifying equipment readiness before maintenance tasks begin.

What quality assurance measures and safety compliance protocols are mandated by the SOP?

The SOP mandates stringent quality assurance measures and safety compliance protocols to uphold operational integrity and protect personnel. Regular inspections, audits, and adherence to industry safety standards are integral parts of the process. Compliance ensures maintenance work is performed without risks and meets regulatory requirements.

How are maintenance service records documented, reviewed, and stored as specified in the SOP?

Documentation, review, and storage of maintenance service records are systematically managed according to the SOP to provide transparency and traceability. Records must be accurately maintained, periodically reviewed for effectiveness, and securely stored to support audits and future maintenance planning. Proper record management enhances accountability and continuous improvement.