A SOP Template for Dishwashing and Sanitization ensures consistent cleaning procedures by outlining specific steps for washing, rinsing, and sanitizing dishes and utensils. This template helps maintain hygiene standards and prevent cross-contamination in food service environments. Clear guidelines within the SOP promote safety and efficiency in daily operations.

Pre-rinse procedures for dirty dishes and utensils.

The SOP details the pre-rinse procedures for dirty dishes and utensils, covering the steps to effectively remove food residue before washing. It emphasizes initial scraping, use of appropriate water temperature, and rinsing techniques to ensure cleanliness and prevent cross-contamination. Proper adherence to these procedures enhances the overall hygiene and efficiency of dishwashing operations in commercial and domestic settings.

Segregation of dishes, glassware, pots, and pans for washing.

This SOP details the segregation of dishes, glassware, pots, and pans for washing, emphasizing the importance of categorizing kitchenware to ensure effective cleaning and sanitation. It covers the proper sorting techniques, handling procedures, and designated washing methods for each type of item to prevent cross-contamination, maintain hygiene standards, and optimize washing efficiency in commercial or domestic kitchens.

Preparation and concentration check for detergent solutions.

This SOP details the preparation and concentration check of detergent solutions, including selecting appropriate detergents, measuring accurate quantities, mixing procedures, ensuring homogeneous solutions, verifying concentration levels through standardized methods, maintaining solution stability, and documenting preparation records. The purpose is to guarantee effective cleaning performance and safety by ensuring detergent solutions are prepared and used at optimal concentrations.

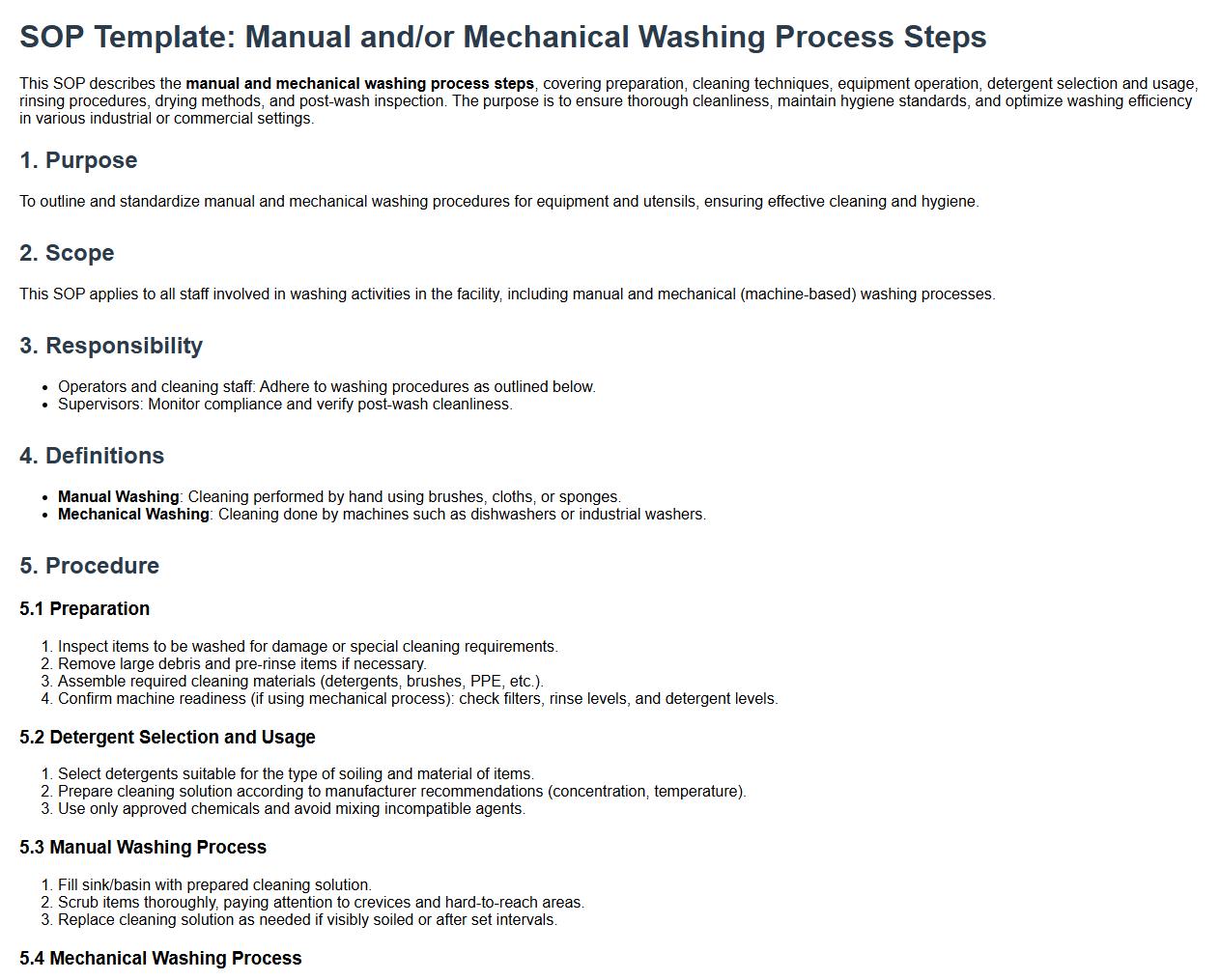

Manual and/or mechanical washing process steps.

This SOP describes the manual and mechanical washing process steps, covering preparation, cleaning techniques, equipment operation, detergent selection and usage, rinsing procedures, drying methods, and post-wash inspection. The purpose is to ensure thorough cleanliness, maintain hygiene standards, and optimize washing efficiency in various industrial or commercial settings.

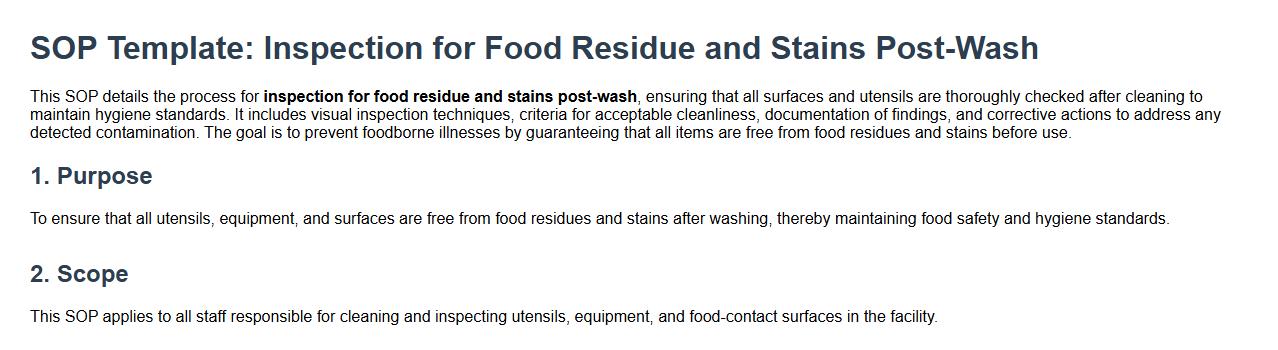

Inspection for food residue and stains post-wash.

This SOP details the process for inspection for food residue and stains post-wash, ensuring that all surfaces and utensils are thoroughly checked after cleaning to maintain hygiene standards. It includes visual inspection techniques, criteria for acceptable cleanliness, documentation of findings, and corrective actions to address any detected contamination. The goal is to prevent foodborne illnesses by guaranteeing that all items are free from food residues and stains before use.

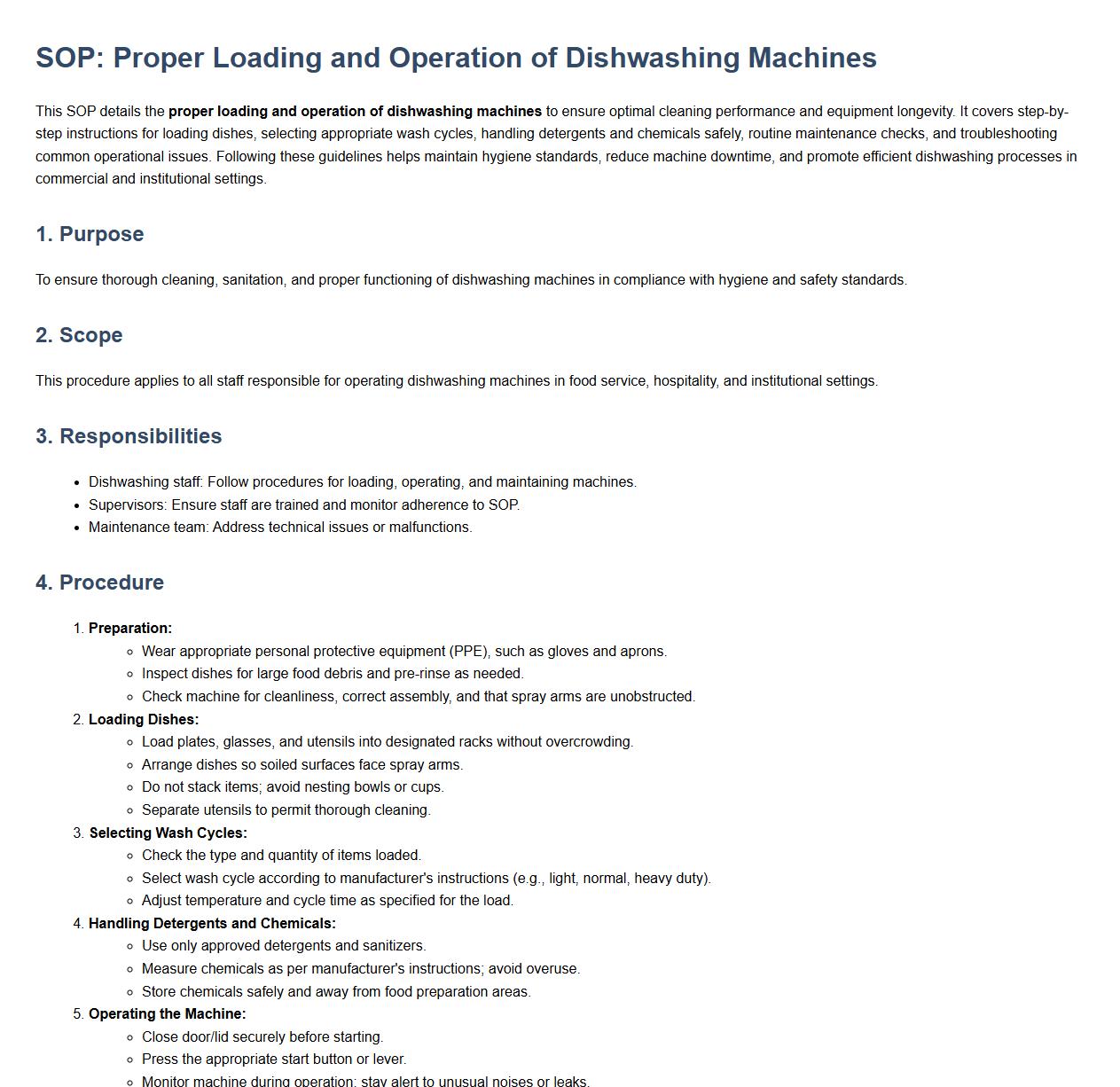

Proper loading and operation of dishwashing machines.

This SOP details the proper loading and operation of dishwashing machines to ensure optimal cleaning performance and equipment longevity. It covers step-by-step instructions for loading dishes, selecting appropriate wash cycles, handling detergents and chemicals safely, routine maintenance checks, and troubleshooting common operational issues. Following these guidelines helps maintain hygiene standards, reduce machine downtime, and promote efficient dishwashing processes in commercial and institutional settings.

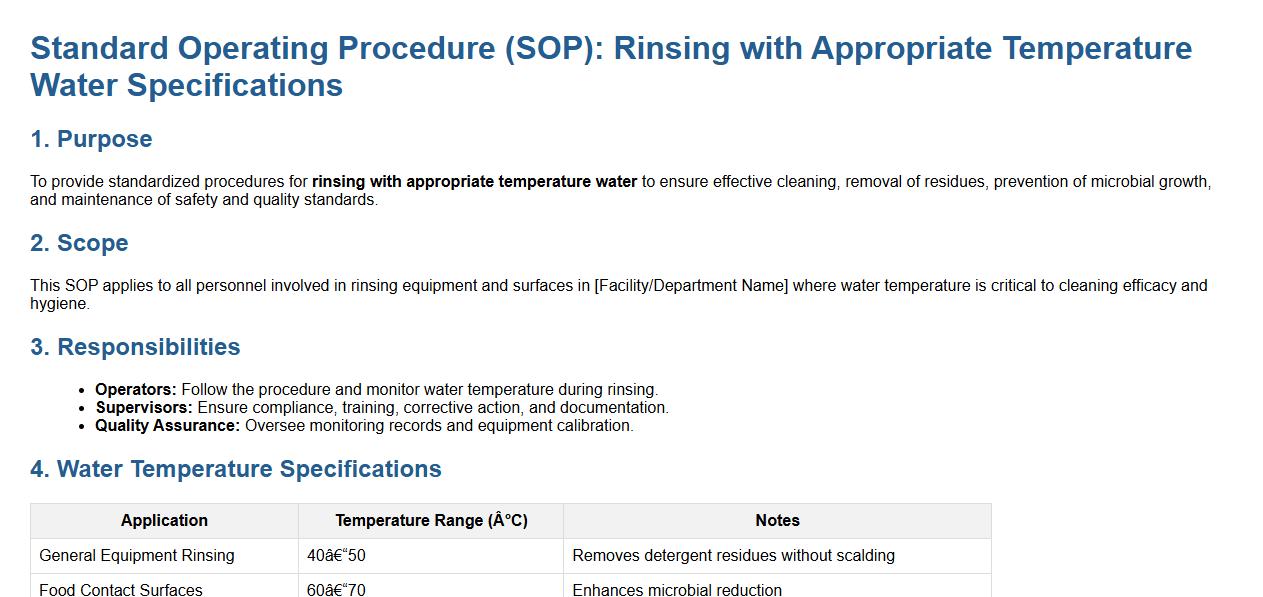

Rinsing with appropriate temperature water specifications.

This SOP details the procedure for rinsing with appropriate temperature water specifications to ensure effective cleaning and hygiene. It specifies the optimal water temperature range for rinsing various equipment and surfaces, emphasizing the importance of temperature control to remove residues, prevent microbial growth, and maintain safety standards. The guideline also includes monitoring techniques, equipment calibration, and corrective actions to maintain consistent water temperature during the rinsing process, ensuring compliance with sanitation protocols and quality assurance requirements.

Sanitizer preparation, dilution, and contact time verification.

This SOP details the procedures for sanitizer preparation, dilution, and contact time verification, ensuring the correct concentration of sanitizing solutions is achieved and maintained for effective microbial control. It includes guidelines for selecting appropriate sanitizers, accurate dilution methods, verification of contact time to maximize disinfection efficacy, safety precautions during handling, and documentation requirements to comply with health and safety standards.

Air-drying and storage of clean dishes and utensils.

This SOP describes the air-drying and storage of clean dishes and utensils, emphasizing proper sanitation practices, preventing contamination, ensuring complete drying to inhibit bacterial growth, and organizing storage areas to maintain cleanliness and accessibility. It aims to uphold food safety standards by detailing step-by-step procedures for handling clean dishware and utensils after washing.

Documentation of cleaning schedules and verification logs.

This SOP details the process for documentation of cleaning schedules and verification logs, ensuring that all cleaning tasks are performed consistently and verified for compliance. It includes establishing routine cleaning schedules, assigning responsibilities, recording completion times, and maintaining verification logs to track the effectiveness of cleaning activities. The purpose is to uphold hygiene standards, facilitate audits, and ensure accountability in cleaning operations.

What are the key steps outlined in the SOP for properly washing and sanitizing dishes?

The SOP emphasizes the importance of pre-rinsing dishes to remove food residues before washing. Dishes must then be washed thoroughly with detergent to eliminate grease and dirt. The final step involves sanitizing the dishes to kill any remaining bacteria and ensure safety.

Which types of sanitizing solutions are approved according to the SOP for dishwashing?

The SOP approves sanitizing solutions such as chlorine-based sanitizers for effective microbial control. Quaternary ammonium compounds (quats) are also commonly permitted for sanitizing purposes. All sanitizers must meet regulatory standards for safety and concentration levels.

According to the SOP, what is the required water temperature for effective sanitization?

The SOP specifies that water temperature must be maintained at a minimum of 171degF (77degC) for hot water sanitization. This temperature ensures proper elimination of harmful microorganisms during the sanitizing process. Alternatively, chemical sanitizers can be used at lower temperatures when conditions are met.

How does the SOP define the frequency for changing dishwashing water and sanitizing solution?

The SOP requires that dishwashing water and sanitizing solutions be changed regularly to maintain effectiveness. Change intervals depend on the level of soil and use but generally occur when water becomes visibly dirty or every two hours. Frequent changing prevents cross-contamination and ensures hygiene.

What is the correct sequence for pre-rinsing, washing, rinsing, and sanitizing as specified in the SOP?

The SOP mandates a strict sequence starting with pre-rinsing to remove loose debris from dishes. This is followed by washing with detergent to clean all surfaces thoroughly. Next, a clean water rinse removes soap residues, and finally, sanitizing ensures dishes are safe for use.