A SOP Template for Cafe Beverage Preparation ensures consistent quality and safety by outlining standardized steps for brewing, mixing, and serving beverages. This template helps staff follow precise measurements, hygiene protocols, and presentation guidelines to maintain customer satisfaction. Implementing a clear SOP reduces errors and streamlines training for new employees.

Beverage menu and recipe standardization.

This SOP details the process of beverage menu and recipe standardization, ensuring consistency in taste, quality, and presentation across all beverage offerings. It covers the development and documentation of standardized recipes, ingredient specifications, portion control, preparation techniques, and presentation guidelines. The aim is to maintain uniformity, enhance customer satisfaction, and streamline training for staff while optimizing inventory management and cost control.

Daily workstation setup and equipment checks.

This SOP details the process for daily workstation setup and equipment checks, including organizing the workspace, inspecting tools and machinery for proper function, ensuring safety protocols are followed, verifying calibration and cleanliness of equipment, and reporting any malfunctions or hazards. The goal is to maintain a safe, efficient, and productive work environment through systematic daily preparations and inspections.

Ingredient storage, handling, and inventory management.

This SOP details ingredient storage, handling, and inventory management protocols to ensure the proper preservation, safety, and efficient use of ingredients. It includes guidelines for correct storage conditions, handling procedures to prevent contamination and spoilage, systematic inventory tracking, and regular stock rotation. The objective is to maintain ingredient quality, minimize waste, and support smooth production operations through effective inventory oversight.

Espresso machine operation and calibration.

This SOP details the espresso machine operation and calibration process, including proper machine startup and shutdown, routine cleaning and maintenance, grind size adjustment, tamping techniques, temperature and pressure calibration, shot extraction monitoring, and troubleshooting common issues. The objective is to ensure consistent coffee quality, machine longevity, and optimal performance by following standardized procedures for operation and calibration.

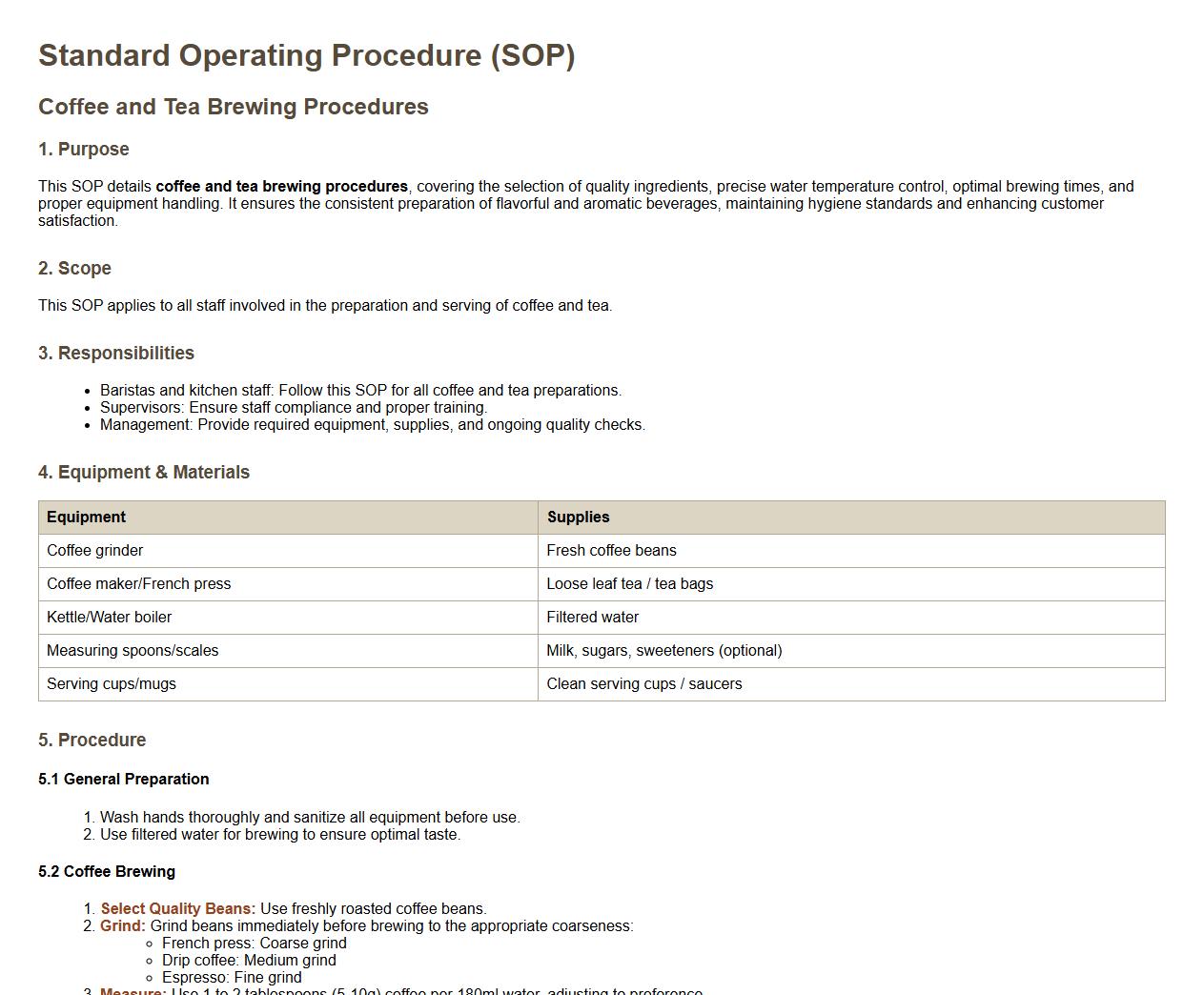

Coffee and tea brewing procedures.

This SOP details coffee and tea brewing procedures, covering the selection of quality ingredients, precise water temperature control, optimal brewing times, and proper equipment handling. It ensures the consistent preparation of flavorful and aromatic beverages, maintaining hygiene standards and enhancing customer satisfaction. The process includes guidelines for grinding coffee beans, steeping tea leaves, and serving techniques to deliver the best coffee and tea experience.

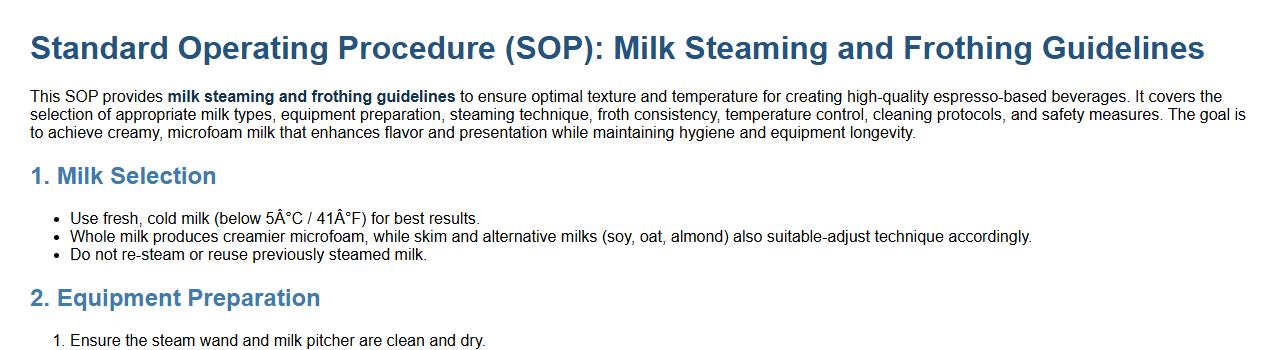

Milk steaming and frothing guidelines.

This SOP provides milk steaming and frothing guidelines to ensure optimal texture and temperature for creating high-quality espresso-based beverages. It covers the selection of appropriate milk types, equipment preparation, steaming technique, froth consistency, temperature control, cleaning protocols, and safety measures. The goal is to achieve creamy, microfoam milk that enhances flavor and presentation while maintaining hygiene and equipment longevity.

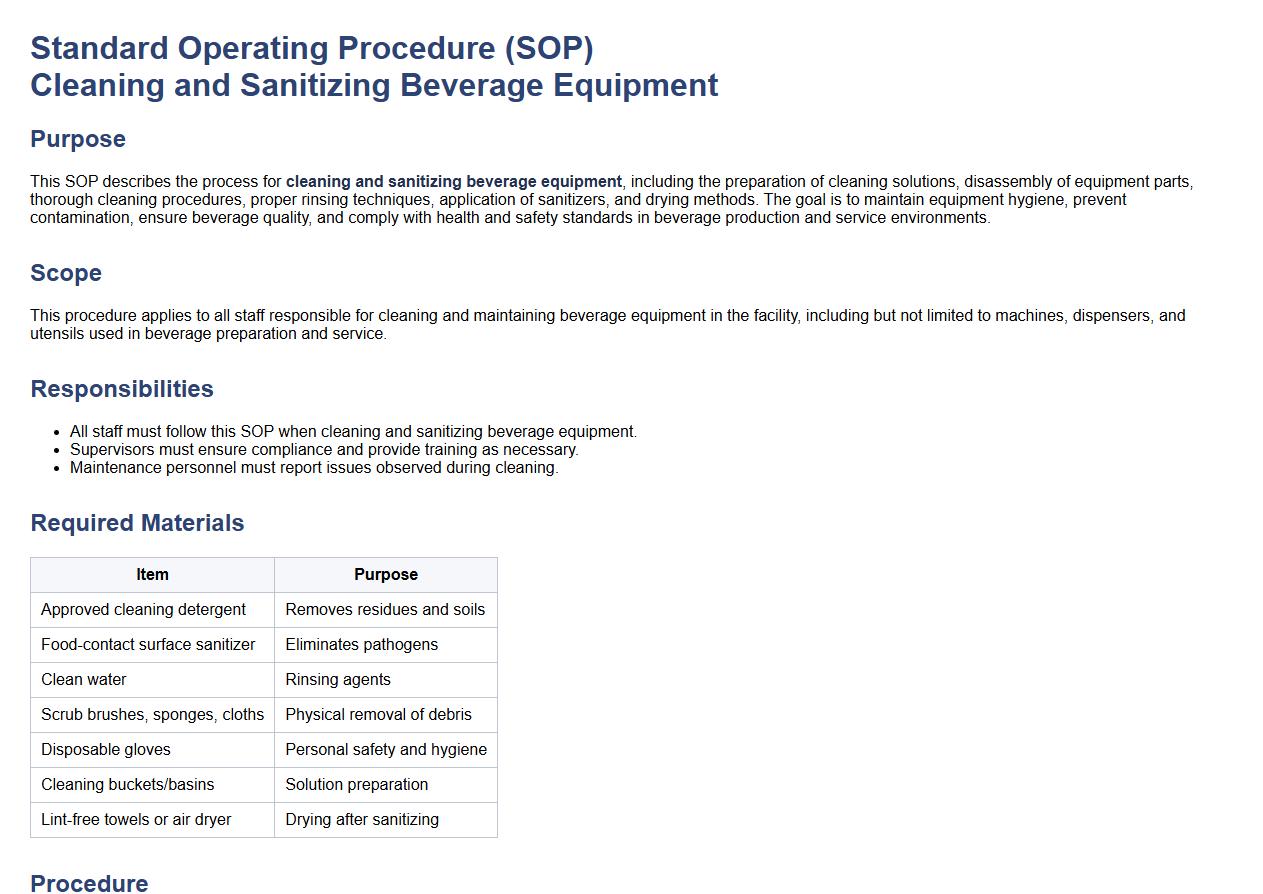

Cleaning and sanitizing beverage equipment.

This SOP describes the process for cleaning and sanitizing beverage equipment, including the preparation of cleaning solutions, disassembly of equipment parts, thorough cleaning procedures, proper rinsing techniques, application of sanitizers, and drying methods. The goal is to maintain equipment hygiene, prevent contamination, ensure beverage quality, and comply with health and safety standards in beverage production and service environments.

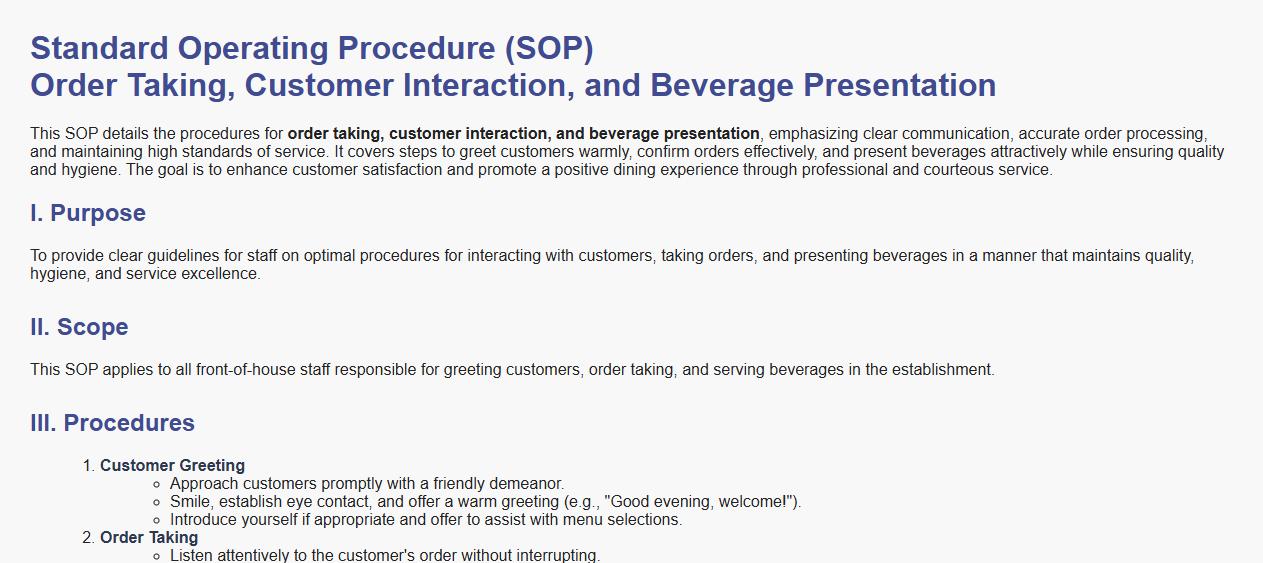

Order taking, customer interaction, and beverage presentation.

This SOP details the procedures for order taking, customer interaction, and beverage presentation, emphasizing clear communication, accurate order processing, and maintaining high standards of service. It covers steps to greet customers warmly, confirm orders effectively, and present beverages attractively while ensuring quality and hygiene. The goal is to enhance customer satisfaction and promote a positive dining experience through professional and courteous service.

Waste management and disposal of used ingredients.

This SOP details the procedures for effective waste management and disposal of used ingredients, covering identification and segregation of waste types, safe handling and storage of waste materials, environmentally responsible disposal methods, compliance with regulatory standards, and documentation of waste disposal activities. The goal is to minimize environmental impact, ensure workplace safety, and maintain hygiene by properly managing and disposing of all used ingredients in the production process.

End-of-shift cleanup and closing procedures.

This SOP details end-of-shift cleanup and closing procedures, including workstation organization, equipment shutdown, waste disposal, inventory checks, safety inspections, and documentation of completed tasks. The goal is to ensure a clean, safe, and secure environment for the next shift, promoting operational efficiency and workplace safety.

Critical Steps for Preparing Each Standard Cafe Beverage

The SOP outlines a systematic procedure to ensure consistency in every cafe beverage. Each step, from ingredient selection to final garnish, is precisely detailed. Adhering strictly to these steps guarantees a high-quality product.

Equipment Cleanliness and Maintenance During Beverage Preparation

The SOP mandates regular cleaning schedules for all equipment and utensils used in beverage preparation. Staff must sanitize machines before and after each use to prevent contamination. Routine maintenance checks are also specified to ensure optimal equipment performance.

Quality Control Checks for Consistent Beverage Taste and Presentation

The SOP includes taste tests and visual inspections at multiple stages of preparation. Baristas must verify temperature, texture, and flavor balance before serving. Presentation standards, such as cup cleanliness and latte art precision, are also enforced.

Health and Safety Guidelines for Staff During Beverage Preparation

The SOP requires staff to follow strict personal hygiene and safety protocols. This includes wearing gloves, hairnets, and avoiding cross-contamination between raw and cooked ingredients. Emergency procedures and safe handling instructions are clearly communicated to all team members.

Portion Sizes and Ingredient Measurements for Each Beverage Type

The SOP specifies exact portion sizes and ingredient quantities to maintain consistency and control costs. Measurements are to be taken using standardized tools or scales for accuracy. This ensures every beverage meets the cafe's quality and taste standards.