A SOP Template for Safe Food Temperature Monitoring provides a standardized procedure to ensure consistent and accurate measurement of food temperatures. It outlines step-by-step instructions for using thermometers, recording data, and identifying corrective actions to maintain food safety. This template helps prevent foodborne illnesses by ensuring proper temperature control throughout food handling processes.

Temperature monitoring equipment calibration and validation.

This SOP details the procedures for temperature monitoring equipment calibration and validation, ensuring accuracy and reliability of temperature measurements. It covers the selection of calibration standards, calibration frequency, validation techniques, documentation requirements, and corrective actions for equipment found out of tolerance. The goal is to maintain equipment performance within specified limits to support quality control and regulatory compliance.

Routine temperature checks schedule and documentation.

This SOP details the routine temperature checks schedule and documentation process, outlining the frequency and timing of temperature monitoring, proper methods for accurate measurement, required documentation forms, and record-keeping protocols. The goal is to ensure consistent and reliable temperature monitoring to maintain safety, detect potential health issues early, and comply with regulatory standards.

Receiving and storage temperature requirements for foods.

This SOP details the receiving and storage temperature requirements for foods, outlining protocols for verifying temperature upon delivery, maintaining optimal storage temperatures to ensure food safety, preventing temperature abuse during handling and storage, and monitoring practices to avoid spoilage and contamination. The purpose is to maintain food quality, prevent bacterial growth, and ensure compliance with food safety regulations throughout the receiving and storage processes.

Procedures for hot and cold holding of prepared foods.

This SOP details procedures for hot and cold holding of prepared foods, ensuring food safety by maintaining proper temperatures to prevent bacterial growth. It covers guidelines for monitoring and controlling holding temperatures, equipment usage, safe storage practices, temperature recording and verification, and corrective actions if food temperatures fall outside safe ranges. The aim is to preserve food quality and prevent foodborne illnesses during service and storage.

Guidelines for food preparation and cooling times.

This SOP provides detailed guidelines for food preparation and cooling times to ensure food safety and prevent microbial growth. It covers proper cooking temperatures, time limits for cooling cooked foods, best practices for rapid cooling, and storage requirements. Adherence to these guidelines helps maintain food quality, reduce the risk of foodborne illnesses, and comply with health regulations.

Corrective actions for temperature violations.

This SOP details corrective actions for temperature violations, including identification of temperature deviations, immediate response procedures, equipment inspection and calibration, documentation and reporting of incidents, employee training on temperature control, and preventive measures to avoid recurrence. The goal is to ensure product safety and quality by maintaining proper temperature standards and promptly addressing any violations.

Temperature log maintenance and record retention.

This SOP details the procedures for temperature log maintenance and record retention, including accurate recording of temperature readings, regular monitoring schedules, proper documentation methods, secure storage of records, compliance with regulatory requirements, routine audits, and retention timelines. The aim is to ensure precise temperature tracking for safety, quality control, and regulatory compliance across various operational environments.

Staff training on safe temperature monitoring practices.

This SOP describes staff training on safe temperature monitoring practices, emphasizing the importance of accurate temperature measurement, proper use of monitoring equipment, adherence to safety protocols, regular calibration and maintenance of devices, documentation and reporting of temperature readings, and corrective actions in case of deviations. The goal is to ensure staff competence in maintaining optimal temperature conditions to safeguard product quality and safety.

Cleaning and sanitizing of temperature monitoring equipment.

This SOP details the procedures for cleaning and sanitizing temperature monitoring equipment to ensure accurate readings and prevent contamination. It covers the selection of appropriate cleaning agents, step-by-step cleaning methods, sanitization techniques, equipment maintenance schedules, and safety precautions to protect both personnel and equipment. The goal is to maintain the reliability and hygiene of temperature monitoring devices used in various environments.

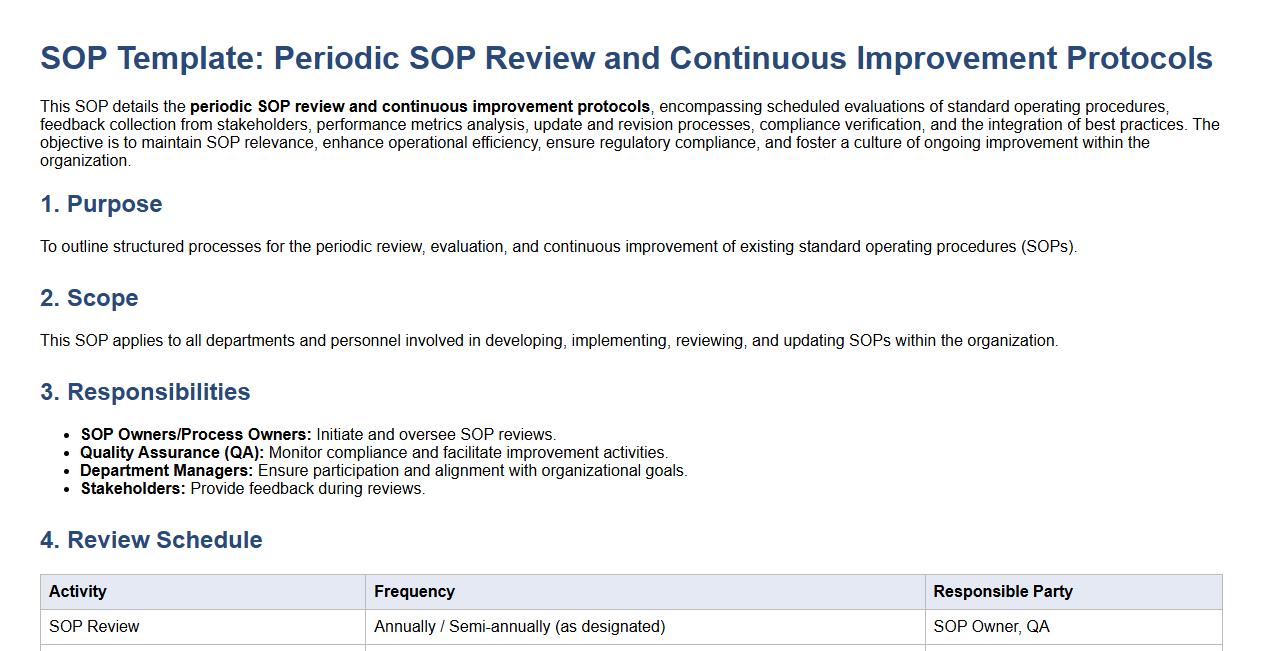

Periodic SOP review and continuous improvement protocols.

This SOP details the periodic SOP review and continuous improvement protocols, encompassing scheduled evaluations of standard operating procedures, feedback collection from stakeholders, performance metrics analysis, update and revision processes, compliance verification, and the integration of best practices. The objective is to maintain SOP relevance, enhance operational efficiency, ensure regulatory compliance, and foster a culture of ongoing improvement within the organization.

What are the required temperature ranges for storing different types of perishable foods as per the SOP?

The SOP mandates strict adherence to specific temperature ranges to ensure food safety. Perishable foods such as dairy and meats must be stored between 0degC and 4degC to prevent bacterial growth. Frozen items require temperatures at or below -18degC to maintain quality and safety.

Which equipment and tools must be used for accurate food temperature monitoring according to the SOP?

The SOP requires the use of calibrated digital thermometers and data loggers for precise temperature readings. Infrared thermometers are also specified for surface temperature checks without contamination risk. Proper maintenance and regular calibration of these tools are essential for accurate monitoring.

What is the documented procedure for recording and reporting temperature discrepancies or violations?

The SOP outlines a formal process involving immediate recording of the deviation in a temperature log. Any violation must be reported to the designated supervisor within one hour for prompt action. A corrective action report must be filed and reviewed for compliance and future prevention.

Who is responsible for conducting and logging routine food temperature checks based on the SOP?

The SOP assigns responsibility to trained food safety personnel or designated staff members for performing routine temperature checks. These individuals must log readings accurately and verify equipment functionality daily. Accountability is emphasized to uphold food safety standards throughout operations.

What corrective actions are mandated by the SOP when food temperatures fall outside of safe limits?

When temperatures fall outside safe parameters, the SOP mandates immediate removal of affected food items from service or storage. The food must be evaluated for spoilage and either discarded or reprocessed following safety guidelines. Additionally, preventive measures and retraining must be implemented to avoid recurrence of temperature violations.