A SOP Template for Facility Maintenance Requests streamlines the process of reporting and addressing maintenance issues in facilities. It ensures consistent documentation, timely communication, and efficient resolution by outlining clear steps for submitting, reviewing, and tracking requests. This template enhances operational efficiency and minimizes downtime through standardized procedures.

Maintenance request submission process.

This SOP details the maintenance request submission process, outlining the steps for identifying, documenting, and reporting maintenance issues. It includes guidelines for submitting maintenance requests, prioritizing tasks, communicating with the maintenance team, tracking request status, and ensuring timely resolution. The goal is to streamline maintenance operations, minimize equipment downtime, and enhance overall facility management efficiency.

Request acknowledgment and logging procedures.

This SOP details the request acknowledgment and logging procedures, covering the initial receipt of requests, timely acknowledgment to requestors, systematic logging of all incoming requests, tracking and monitoring request statuses, and maintaining accurate records for accountability and follow-up. The goal is to ensure efficient communication, transparency, and organized handling of all requests within the organization.

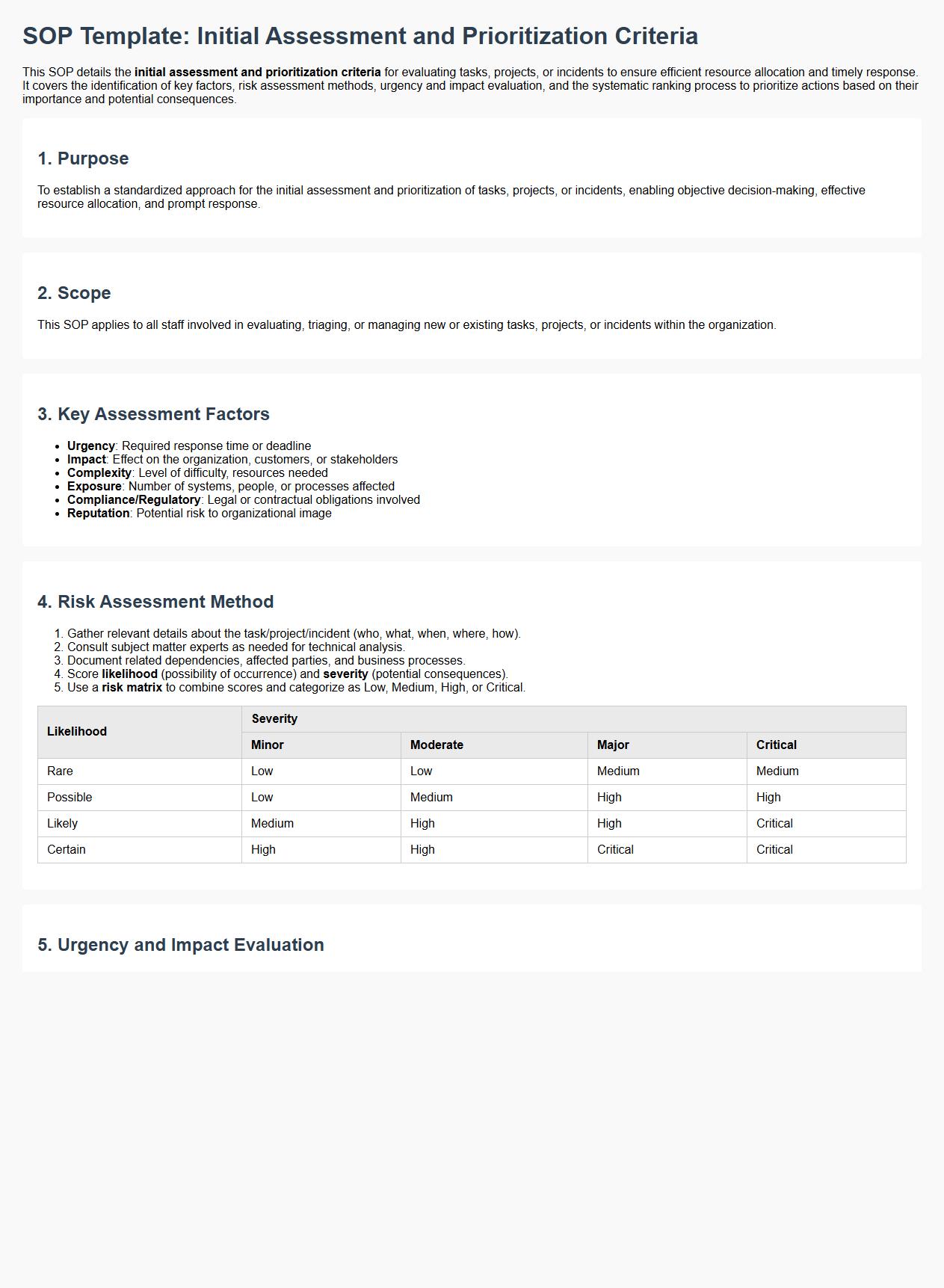

Initial assessment and prioritization criteria.

This SOP details the initial assessment and prioritization criteria for evaluating tasks, projects, or incidents to ensure efficient resource allocation and timely response. It covers the identification of key factors, risk assessment methods, urgency and impact evaluation, and the systematic ranking process to prioritize actions based on their importance and potential consequences.

Assignment of maintenance staff or contractor.

This SOP details the assignment of maintenance staff or contractors to ensure effective planning, selection, and allocation of personnel for maintenance tasks. It covers criteria for selecting qualified staff or contractors, defining roles and responsibilities, scheduling assignments, communication protocols, compliance with safety and quality standards, and documentation requirements. The goal is to optimize maintenance operations, enhance equipment reliability, and maintain a safe working environment.

Detailed troubleshooting and diagnosis steps.

This SOP provides detailed troubleshooting and diagnosis steps to effectively identify and resolve technical issues. It covers systematic approaches to problem detection, analysis of symptoms, use of diagnostic tools, verification of system components, and documentation of findings. The goal is to ensure accurate fault identification, minimize downtime, and maintain optimal system performance through structured problem-solving techniques.

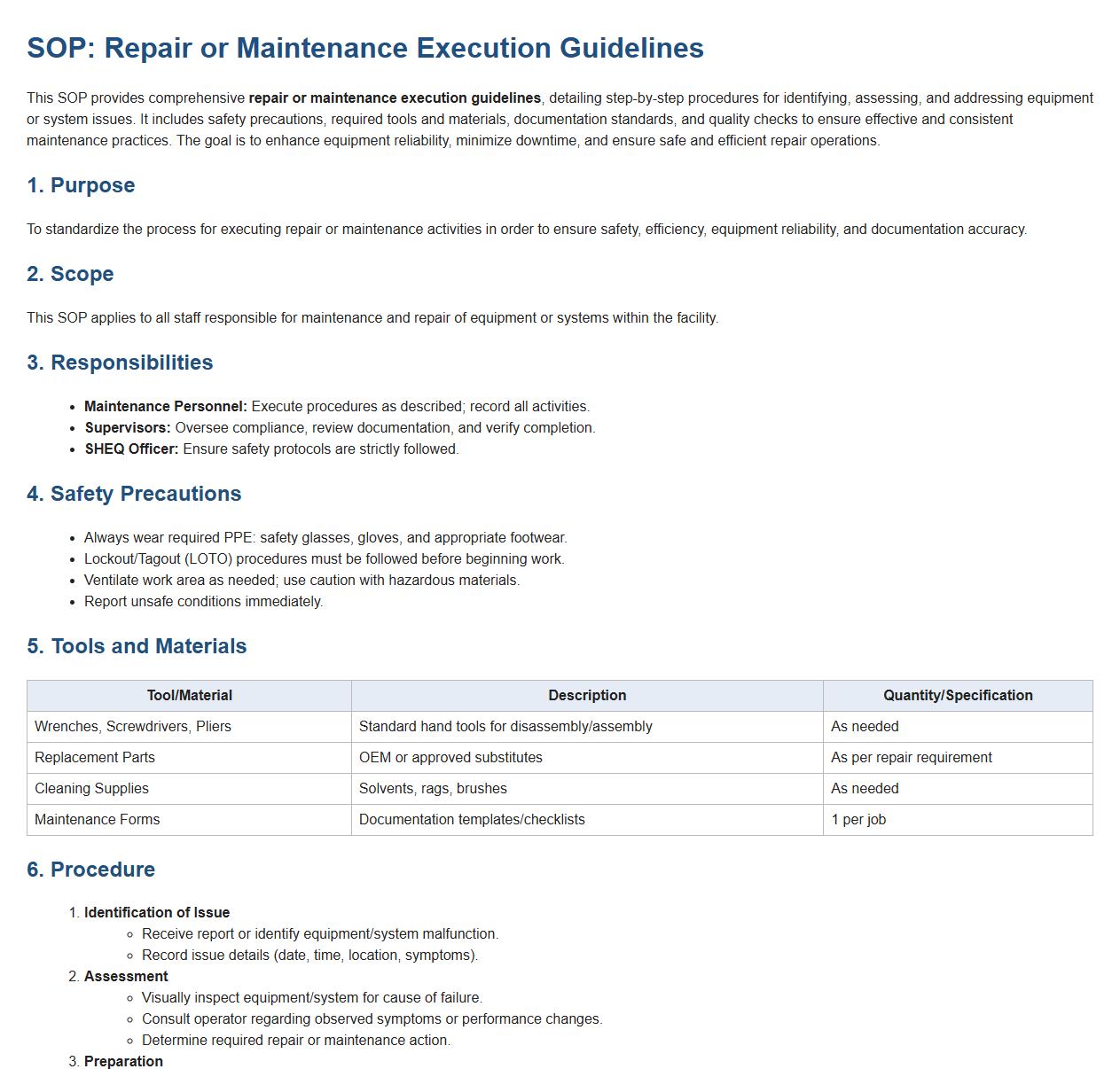

Repair or maintenance execution guidelines.

This SOP provides comprehensive repair or maintenance execution guidelines, detailing step-by-step procedures for identifying, assessing, and addressing equipment or system issues. It includes safety precautions, required tools and materials, documentation standards, and quality checks to ensure effective and consistent maintenance practices. The goal is to enhance equipment reliability, minimize downtime, and ensure safe and efficient repair operations.

Quality control and completion verification process.

This SOP details the quality control and completion verification process, encompassing systematic inspection procedures, adherence to project specifications, defect identification and rectification, documentation of compliance, final approval protocols, and post-completion review. Its goal is to ensure that all deliverables meet established standards and client requirements before project closure, thereby guaranteeing product excellence and customer satisfaction.

Communication and update protocols with requester.

This SOP defines communication and update protocols with requester, outlining clear procedures for maintaining consistent, timely, and transparent communication throughout project or service delivery. It includes guidelines for initial contact, regular status updates, handling inquiries and feedback, escalation processes, and final confirmation. The aim is to ensure effective collaboration, manage expectations, and enhance satisfaction by providing accurate and proactive information exchanges between service providers and requesters.

Post-maintenance review and documentation.

This SOP details the process for post-maintenance review and documentation, encompassing the systematic evaluation of maintenance activities, verification of repair quality, assessment of equipment performance post-maintenance, identification of any residual issues, and thorough recording of findings. The purpose is to ensure maintenance tasks are completed effectively, enhance equipment reliability, facilitate continuous improvement, and maintain accurate historical records for future reference.

Maintenance request closure and record archiving.

This SOP defines the process for maintenance request closure and record archiving, covering the verification of completed work, final approval, documentation updates, and secure storage of maintenance records. It ensures that all maintenance activities are properly closed, documented, and archived for future reference, compliance, and audit purposes.

Key Steps for Submitting a Facility Maintenance Request According to the SOP

The first step is to complete the standardized maintenance request form with detailed information about the issue. Next, the request must be submitted through the designated facility management system or to the assigned department. Lastly, confirmation of receipt is required to ensure the request is logged and tracked properly.

Personnel or Departments Responsible for Reviewing and Approving Maintenance Requests

The maintenance supervisor or facility manager holds primary responsibility for reviewing all submitted maintenance requests. Additionally, department heads may be involved in approving requests that impact specific operational areas. The approval step ensures the feasibility and prioritization of the maintenance tasks before execution.

Defined Response and Completion Timeframes in the SOP for Various Maintenance Issues

The SOP categorizes maintenance issues by priority, setting clear response and completion timeframes for each type. For example, high-priority repairs require responses within 2 hours and completion within 24 hours. Routine maintenance requests typically have longer timeframes, such as 3 days for response and up to a week for completion.

Identification and Escalation of Emergency Maintenance Requests Under SOP Procedures

Emergency maintenance requests must be clearly marked as urgent or critical upon submission to trigger immediate attention. The SOP instructs personnel to escalate these requests directly to emergency response teams or senior management. Prompt escalation ensures swift resolution to minimize risk and operational disruption.

Documentation and Follow-Up Actions Required Upon Completion of a Maintenance Request

Once maintenance is completed, a detailed completion report documenting the work performed and any recommendations must be submitted. Follow-up actions include verification of issue resolution and update of maintenance logs in the facility management system. This documentation supports accountability and helps track recurring problems for future prevention.