A SOP Template for Equipment Checkout provides a standardized procedure for tracking and managing the use of company assets. This template ensures clear guidelines for equipment issuance, return, and condition verification to maintain accountability. It helps prevent loss, damage, and misuse by documenting each step in the checkout process.

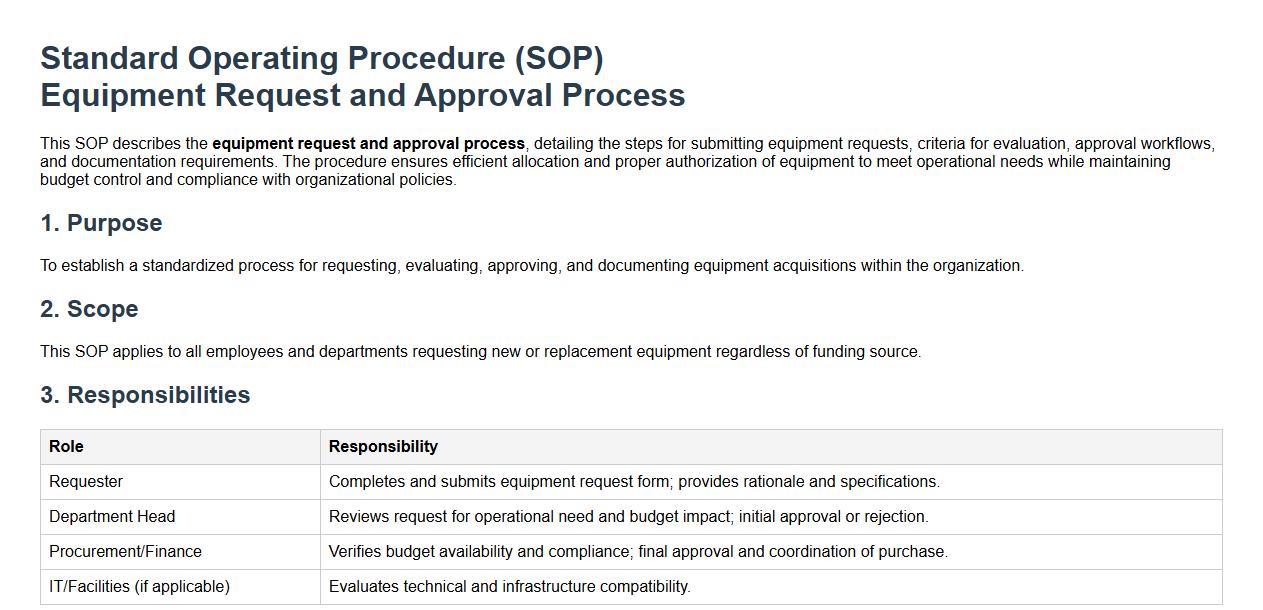

Equipment request and approval process.

This SOP describes the equipment request and approval process, detailing the steps for submitting equipment requests, criteria for evaluation, approval workflows, and documentation requirements. The procedure ensures efficient allocation and proper authorization of equipment to meet operational needs while maintaining budget control and compliance with organizational policies.

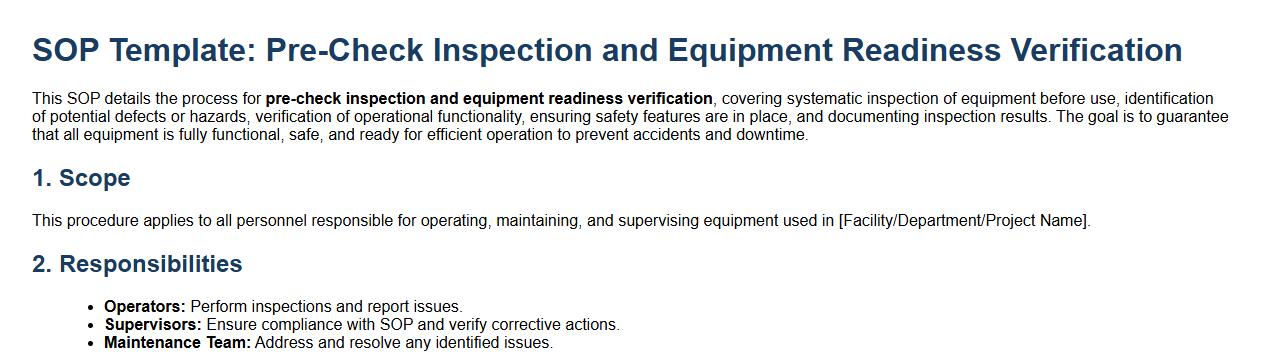

Pre-check inspection and equipment readiness verification.

This SOP details the process for pre-check inspection and equipment readiness verification, covering systematic inspection of equipment before use, identification of potential defects or hazards, verification of operational functionality, ensuring safety features are in place, and documenting inspection results. The goal is to guarantee that all equipment is fully functional, safe, and ready for efficient operation to prevent accidents and downtime.

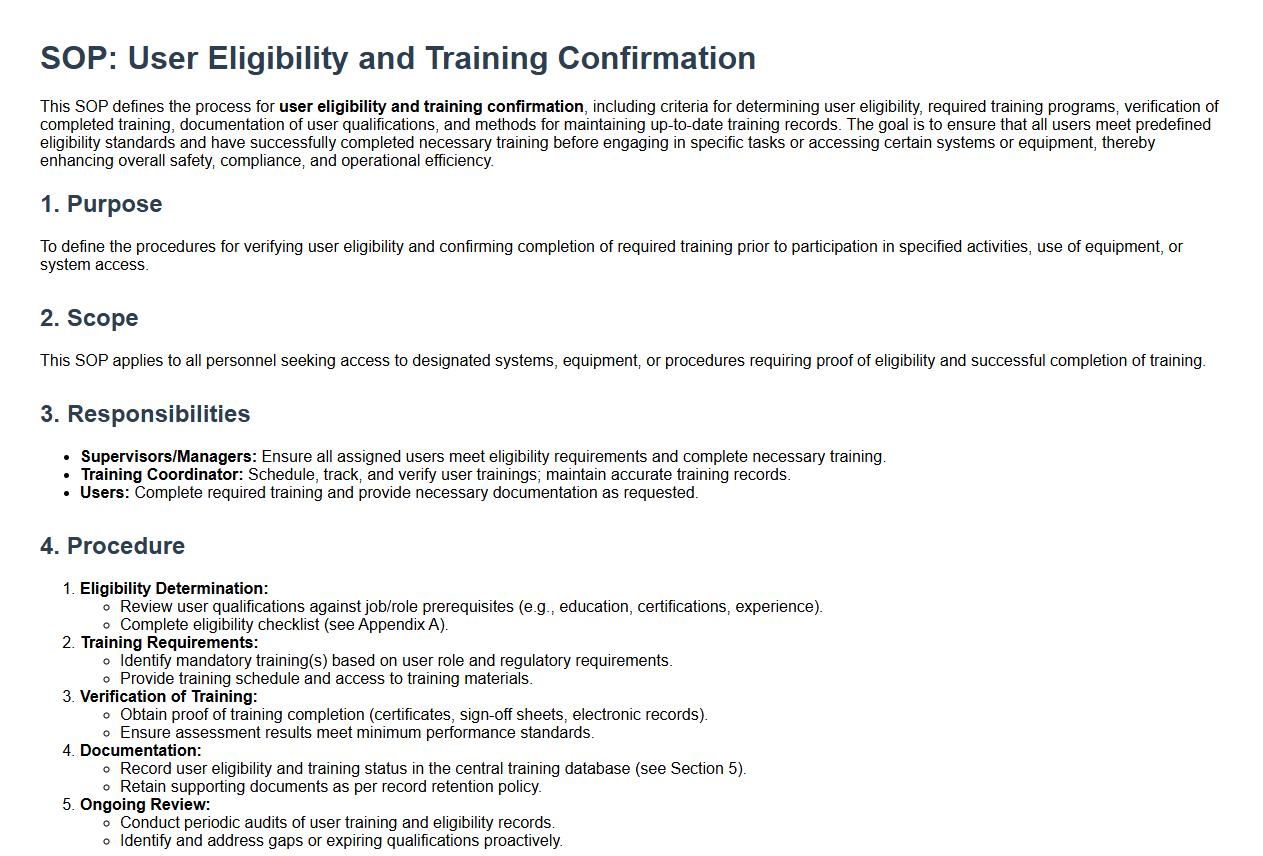

User eligibility and training confirmation.

This SOP defines the process for user eligibility and training confirmation, including criteria for determining user eligibility, required training programs, verification of completed training, documentation of user qualifications, and methods for maintaining up-to-date training records. The goal is to ensure that all users meet predefined eligibility standards and have successfully completed necessary training before engaging in specific tasks or accessing certain systems or equipment, thereby enhancing overall safety, compliance, and operational efficiency.

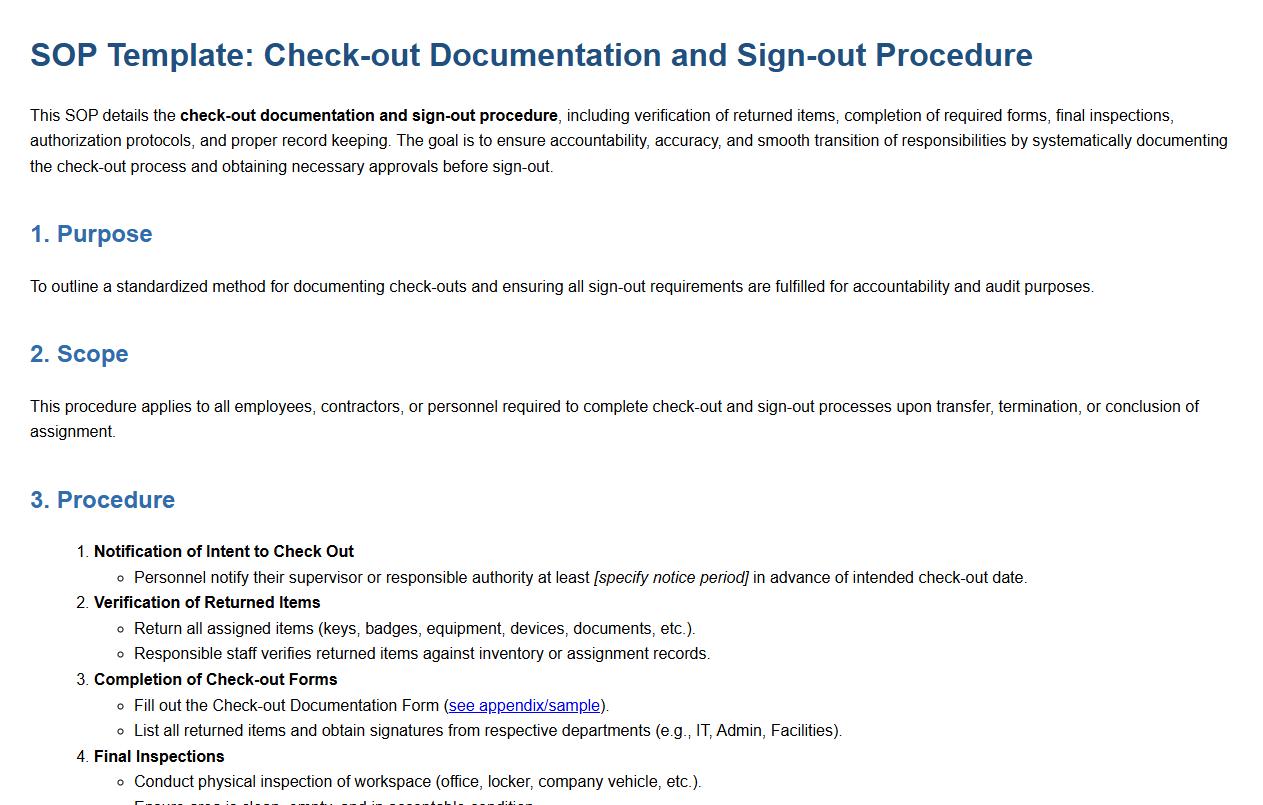

Check-out documentation and sign-out procedure.

This SOP details the check-out documentation and sign-out procedure, including verification of returned items, completion of required forms, final inspections, authorization protocols, and proper record keeping. The goal is to ensure accountability, accuracy, and smooth transition of responsibilities by systematically documenting the check-out process and obtaining necessary approvals before sign-out.

Issuing of safety gear and operation instructions.

This SOP defines the process for issuing of safety gear and operation instructions, ensuring that all personnel receive the appropriate protective equipment and clear, comprehensive guidance on its correct usage. It covers criteria for gear allocation, documentation requirements, training on operational procedures, and compliance monitoring, aiming to enhance workplace safety and minimize risks associated with equipment operation.

Timeframe for equipment loan and expected return date.

This SOP defines the timeframe for equipment loan and expected return date, establishing clear guidelines for borrowing, duration limits, and scheduled return to ensure efficient equipment management and availability. It aims to prevent conflicts, maintain accountability, and optimize resource utilization by specifying loan periods, renewal policies, and consequences for late returns.

On-site usage guidelines and accountability.

This SOP defines on-site usage guidelines and accountability, covering the proper use of facilities and equipment, access control protocols, user responsibilities, tracking and reporting usage, maintenance and cleanliness standards, and compliance with safety regulations. The objective is to ensure efficient resource utilization, maintain operational integrity, and uphold accountability among all personnel accessing and using on-site assets.

Reporting and logging any malfunctions or damages during use.

This SOP details the process for reporting and logging any malfunctions or damages during use of equipment and machinery. It includes guidelines for immediate identification, accurate documentation, timely communication to relevant personnel, and proper follow-up actions to ensure repairs are conducted promptly. The goal is to maintain operational efficiency, prevent accidents, and extend the lifespan of assets through systematic tracking and resolution of issues.

Check-in procedure and post-use inspection.

This SOP details the check-in procedure and post-use inspection to ensure proper tracking and maintenance of equipment or facilities. It includes steps for verifying user identity, logging usage times, inspecting equipment condition before and after use, identifying and reporting damages or malfunctions, and ensuring that all items are cleaned and stored appropriately. The goal is to maintain safety, functionality, and accountability for all checked-out resources.

Sanitization, maintenance scheduling, and equipment storage after return.

This SOP details sanitization, maintenance scheduling, and equipment storage after return, focusing on thorough cleaning protocols to prevent contamination, systematic scheduling of maintenance tasks to ensure equipment functionality, and proper storage practices to protect equipment integrity and prolong lifespan. Adhering to these procedures ensures optimal equipment performance, safety, and compliance with operational standards.

What key criteria must be met before equipment can be checked out according to the SOP?

Before equipment can be checked out, the SOP mandates a thorough verification of the user's credentials and training. Equipment must be inspected for any damages or malfunctions to ensure safety and operational readiness. Additionally, the requested use and duration must align with the authorized purposes outlined in the SOP.

Which personnel are authorized to approve and record equipment checkout as per the protocol?

Only designated supervisors or managers with appropriate training are authorized to approve equipment checkouts. These personnel are responsible for accurately recording all checkout details in the official log. This ensures accountability and traceability of the equipment usage within the organization's operational framework.

What are the required documentation and tracking procedures for equipment checkout in the SOP?

The SOP requires comprehensive documentation including the user's information, equipment serial number, checkout time, and expected return date. All checkouts must be entered into a centralized equipment tracking system to maintain an up-to-date inventory status. This process is critical to prevent loss and ensure efficient equipment management.

How does the SOP address lost, damaged, or overdue equipment during checkout?

The SOP outlines immediate reporting protocols for any lost, damaged, or overdue equipment to the authorized personnel. Investigations and corrective actions must be initiated promptly to mitigate risks and financial impacts. Furthermore, users may face penalties or restrictions as specified within the SOP to enforce compliance.

What steps must be followed for returning equipment to ensure compliance with the SOP?

Upon return, equipment must undergo a detailed inspection to verify condition and functionality against the checkout records. The return must be formally logged in the tracking system with any noted discrepancies documented. Adhering to these steps ensures proper equipment maintenance and accountability according to the SOP.