A SOP Template for Food Packaging and Takeout ensures consistent quality and safety by outlining step-by-step procedures for handling, packaging, and delivering food items. This template helps maintain hygiene standards, prevents contamination, and optimizes packaging efficiency to enhance customer satisfaction. Implementing a standardized SOP supports regulatory compliance and streamlines training for staff in food service operations.

Receiving and inspecting raw materials and packaging supplies.

This SOP details the process for receiving and inspecting raw materials and packaging supplies, covering procedures for verifying delivery accuracy, checking material quality and condition, ensuring compliance with specifications, recording discrepancies, and proper storage. The goal is to maintain product quality and ensure efficient inventory management by preventing the acceptance of damaged or non-conforming materials.

Personal hygiene and handwashing protocols for staff.

This SOP establishes personal hygiene and handwashing protocols for staff, detailing proper handwashing techniques, the importance of maintaining personal cleanliness, appropriate use of hand sanitizers, guidelines for wearing clean and suitable attire, and procedures for preventing cross-contamination. The aim is to minimize the risk of infection and ensure a safe and healthy environment for both staff and clients.

Food preparation and portioning standards.

This SOP establishes food preparation and portioning standards to ensure consistency, quality, and safety in meal production. It covers guidelines for ingredient selection, preparation methods, hygiene practices, portion control techniques, and presentation standards. This procedure aims to maintain nutritional value, reduce waste, and deliver uniform servings that meet customer expectations and regulatory requirements.

Packaging materials handling and storage procedures.

This SOP details packaging materials handling and storage procedures, covering proper receiving, inspection, and documentation of packaging materials, safe handling techniques to prevent damage and contamination, organized storage methods to optimize space and accessibility, inventory control to track usage and reorder levels, and compliance with safety and quality standards. The aim is to ensure packaging materials are maintained in optimal condition, facilitating efficient production processes and minimizing waste.

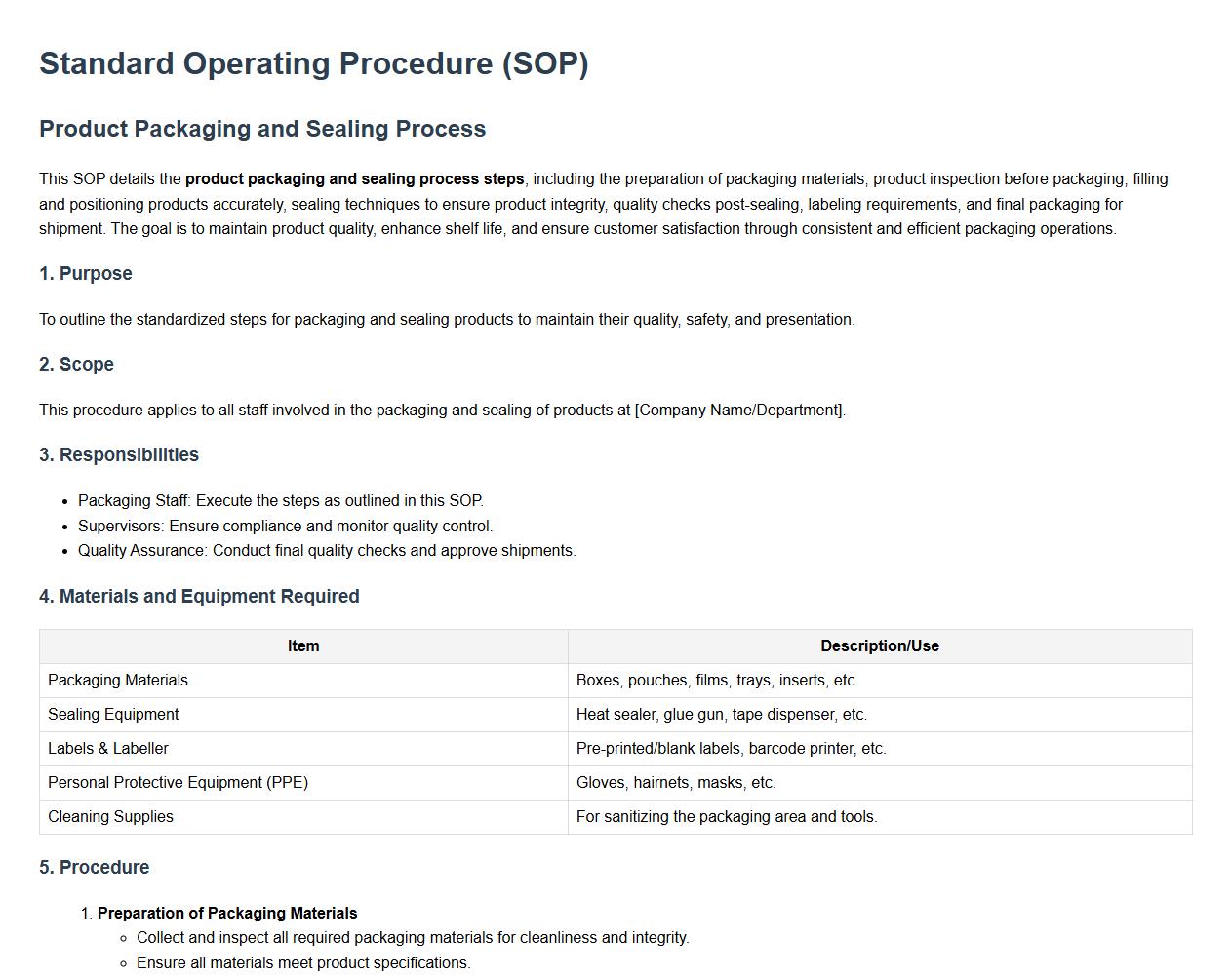

Product packaging and sealing process steps.

This SOP details the product packaging and sealing process steps, including the preparation of packaging materials, product inspection before packaging, filling and positioning products accurately, sealing techniques to ensure product integrity, quality checks post-sealing, labeling requirements, and final packaging for shipment. The goal is to maintain product quality, enhance shelf life, and ensure customer satisfaction through consistent and efficient packaging operations.

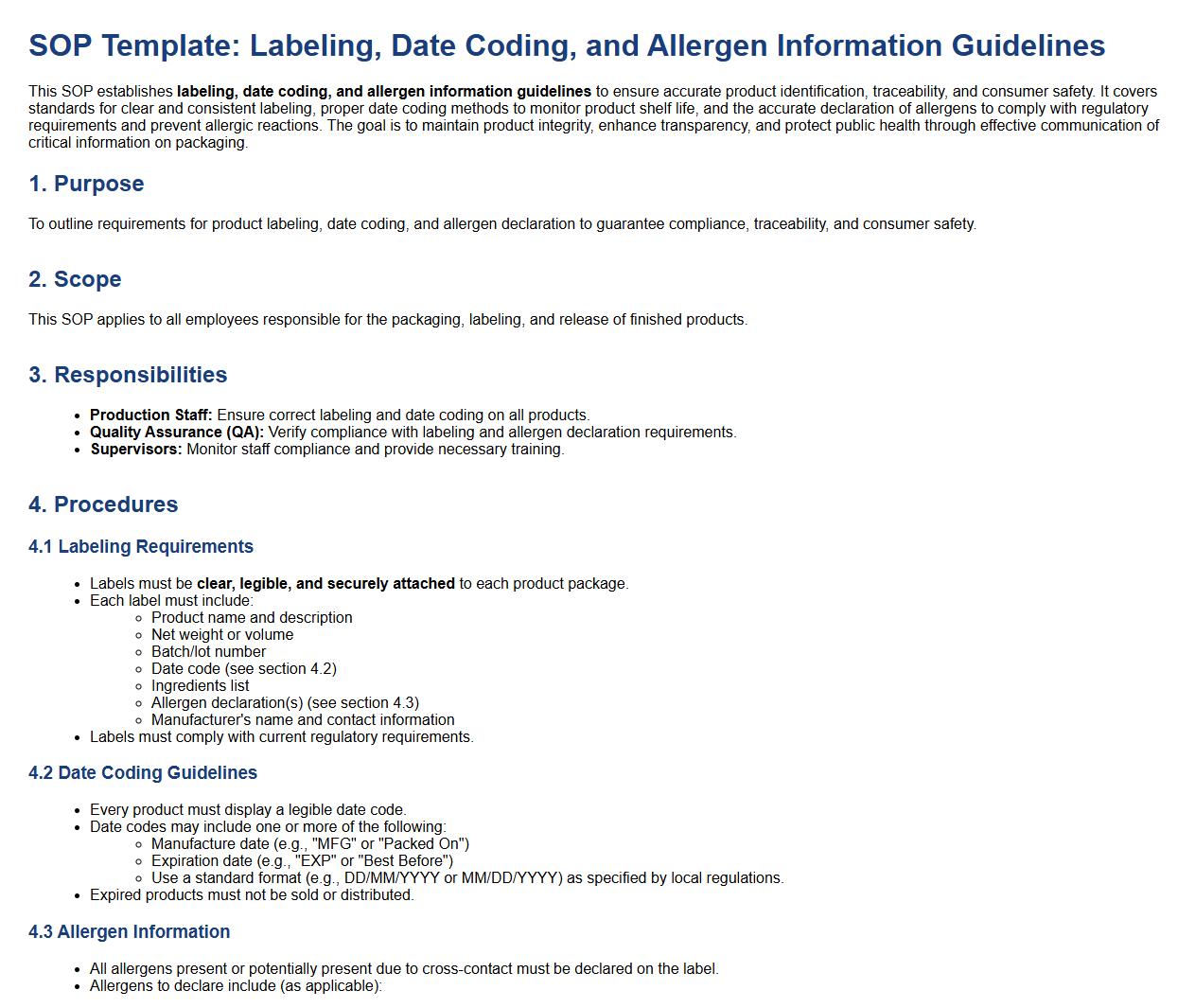

Labeling, date coding, and allergen information guidelines.

This SOP establishes labeling, date coding, and allergen information guidelines to ensure accurate product identification, traceability, and consumer safety. It covers standards for clear and consistent labeling, proper date coding methods to monitor product shelf life, and the accurate declaration of allergens to comply with regulatory requirements and prevent allergic reactions. The goal is to maintain product integrity, enhance transparency, and protect public health through effective communication of critical information on packaging.

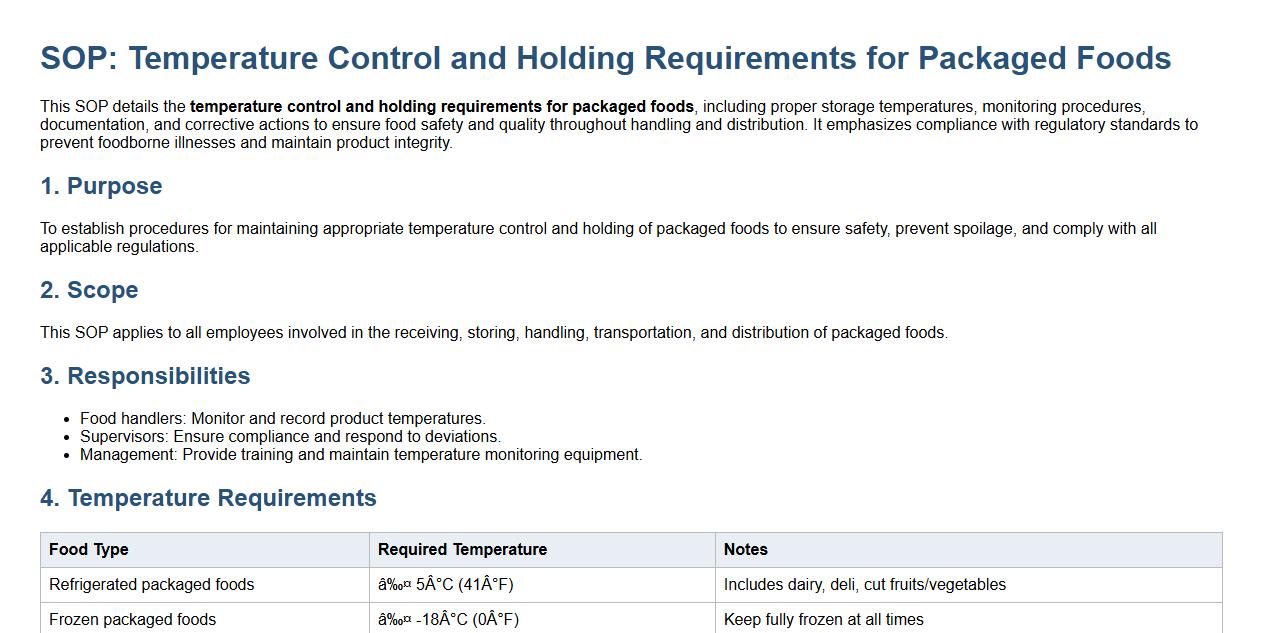

Temperature control and holding requirements for packaged foods.

This SOP details the temperature control and holding requirements for packaged foods, including proper storage temperatures, monitoring procedures, documentation, and corrective actions to ensure food safety and quality throughout handling and distribution. It emphasizes compliance with regulatory standards to prevent foodborne illnesses and maintain product integrity.

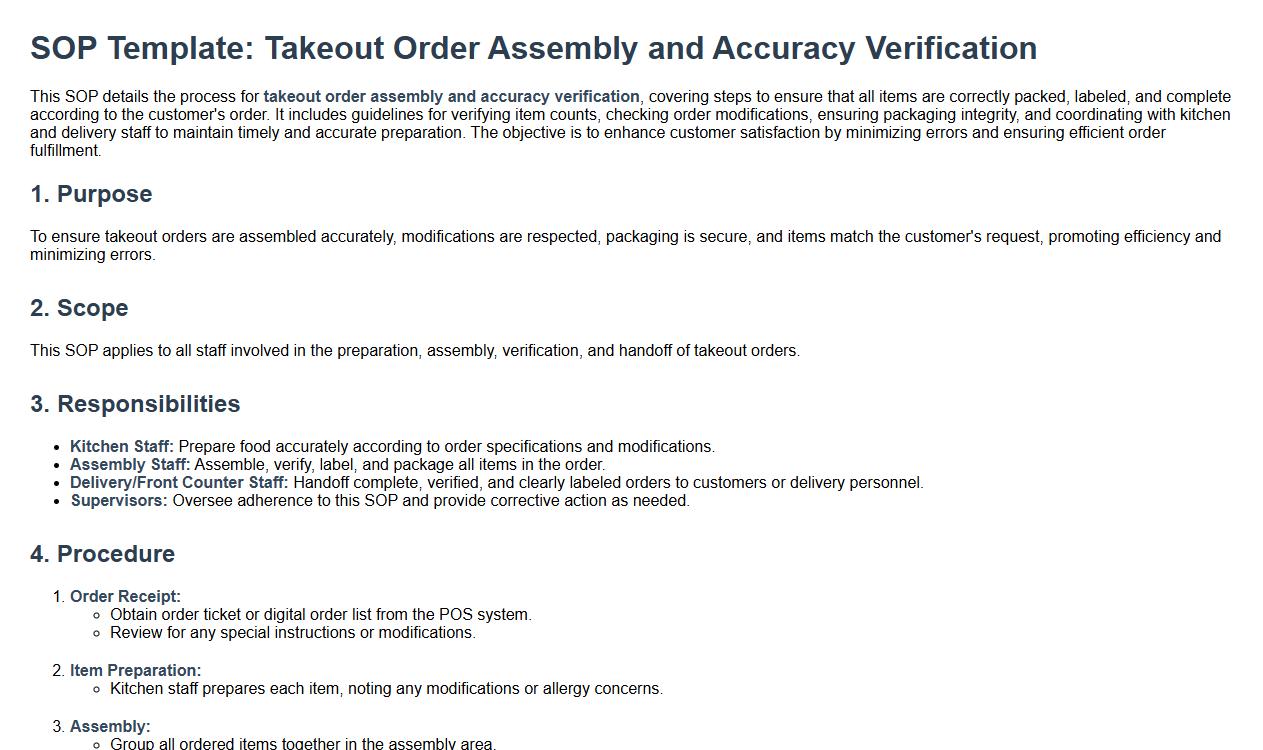

Takeout order assembly and accuracy verification.

This SOP details the process for takeout order assembly and accuracy verification, covering steps to ensure that all items are correctly packed, labeled, and complete according to the customer's order. It includes guidelines for verifying item counts, checking order modifications, ensuring packaging integrity, and coordinating with kitchen and delivery staff to maintain timely and accurate preparation. The objective is to enhance customer satisfaction by minimizing errors and ensuring efficient order fulfillment.

Cleaning and sanitizing equipment and work surfaces.

This SOP details procedures for cleaning and sanitizing equipment and work surfaces, emphasizing the importance of maintaining hygiene standards to prevent contamination and ensure a safe working environment. It covers the selection of appropriate cleaning agents, step-by-step cleaning and sanitizing methods, frequency of cleaning, safety precautions during the process, and proper documentation to verify compliance with health regulations.

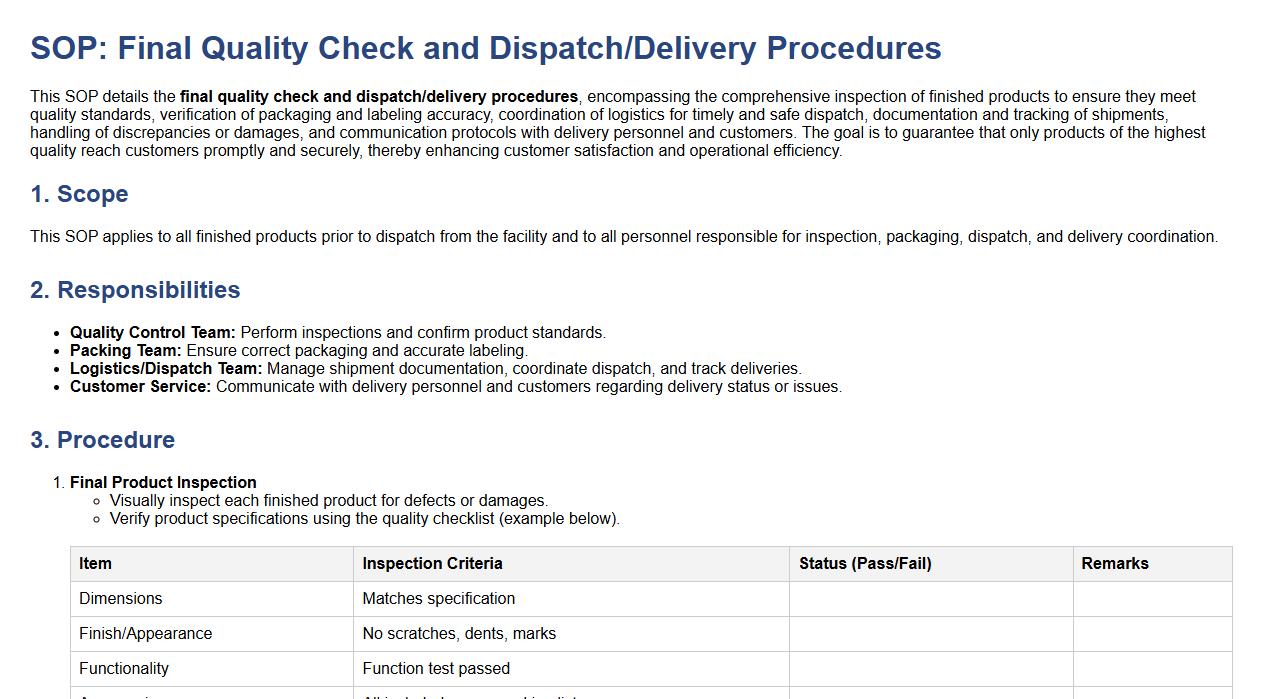

Final quality check and dispatch/delivery procedures.

This SOP details the final quality check and dispatch/delivery procedures, encompassing the comprehensive inspection of finished products to ensure they meet quality standards, verification of packaging and labeling accuracy, coordination of logistics for timely and safe dispatch, documentation and tracking of shipments, handling of discrepancies or damages, and communication protocols with delivery personnel and customers. The goal is to guarantee that only products of the highest quality reach customers promptly and securely, thereby enhancing customer satisfaction and operational efficiency.

What are the critical control points identified in the SOP for food packaging and takeout to ensure food safety?

The critical control points in the SOP include temperature monitoring, cross-contamination prevention, and proper food handling practices. These points ensure food remains safe from preparation through packaging and delivery. Regular checks of these factors help reduce the risk of foodborne illnesses.

How does the SOP define the proper procedures for labeling and dating packaged food items?

The SOP mandates accurate labeling with clear identification of contents and production dates. This ensures traceability and helps maintain food freshness standards. Labels must be legible and applied before storage or distribution.

What sanitation and hygiene standards are outlined in the SOP for staff handling packaging materials?

The SOP emphasizes strict personal hygiene standards including handwashing, use of gloves, and clean uniforms. Staff must sanitize hands before handling packaging to prevent contamination. Packaging materials themselves must be stored in sanitized and pest-free environments.

Which steps does the SOP require for secure sealing and prevention of contamination during food packaging?

The SOP requires secure sealing using tamper-evident materials and sealed containers to protect food integrity. Packaging areas must be sanitized regularly to minimize contamination risks. Staff are trained to avoid direct contact with food surfaces during sealing processes.

What documentation and record-keeping protocols are specified in the SOP for tracking packaged and takeout orders?

The SOP outlines thorough record-keeping protocols including batch numbers, packaging dates, and responsible personnel signatures. These records facilitate traceability and accountability in case of quality control issues. Digital logs or written forms must be maintained and reviewed regularly for compliance.