A SOP Template for Food Quality Control provides a structured framework to ensure consistent monitoring and assessment of food safety and quality standards. It outlines specific procedures, responsibilities, and criteria to maintain compliance with regulatory requirements and enhance product reliability. Utilizing this template helps organizations streamline quality control processes and minimize risks associated with food contamination or defects.

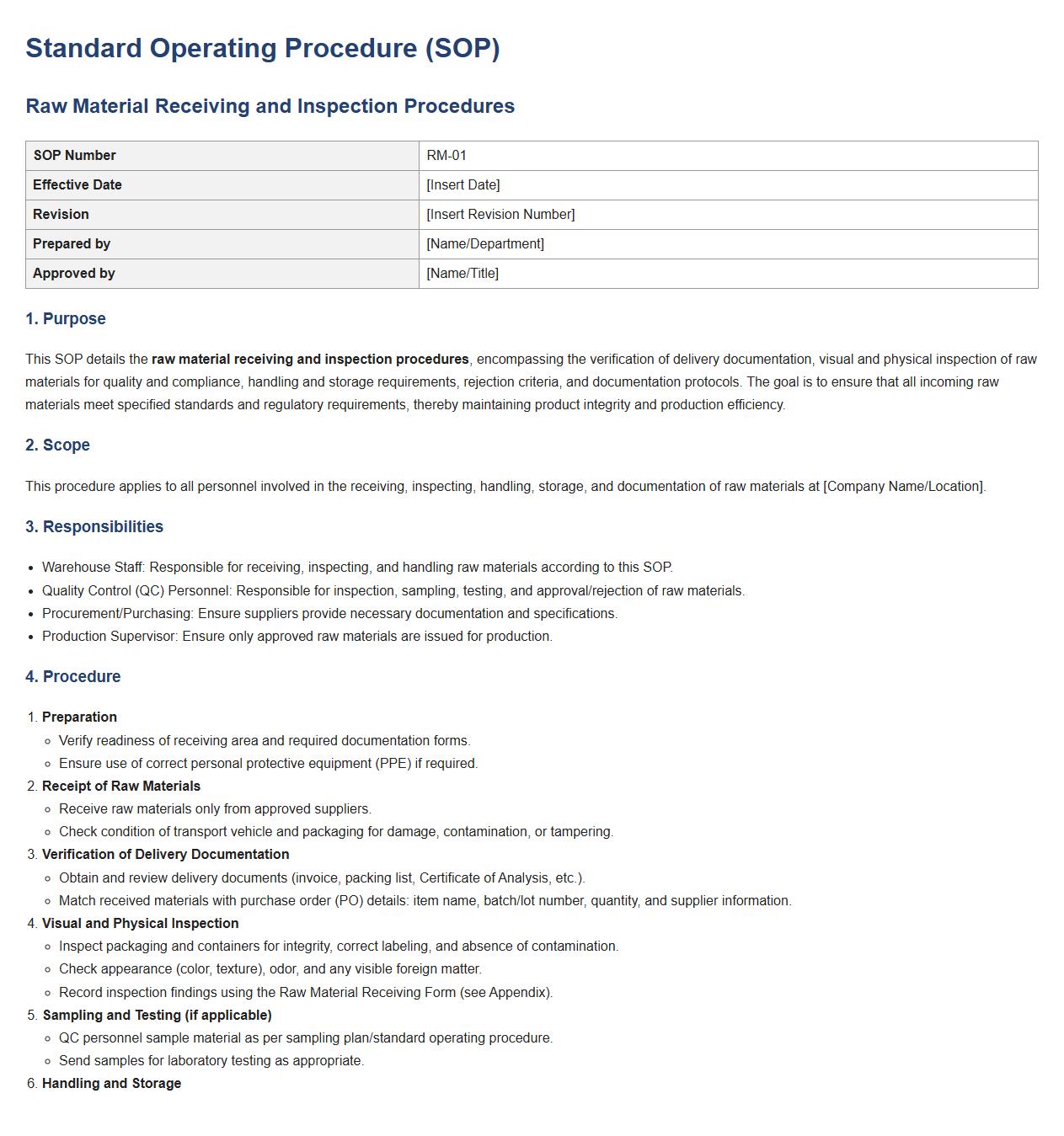

Raw material receiving and inspection procedures.

This SOP details the raw material receiving and inspection procedures, encompassing the verification of delivery documentation, visual and physical inspection of raw materials for quality and compliance, handling and storage requirements, rejection criteria, and documentation protocols. The goal is to ensure that all incoming raw materials meet specified standards and regulatory requirements, thereby maintaining product integrity and production efficiency.

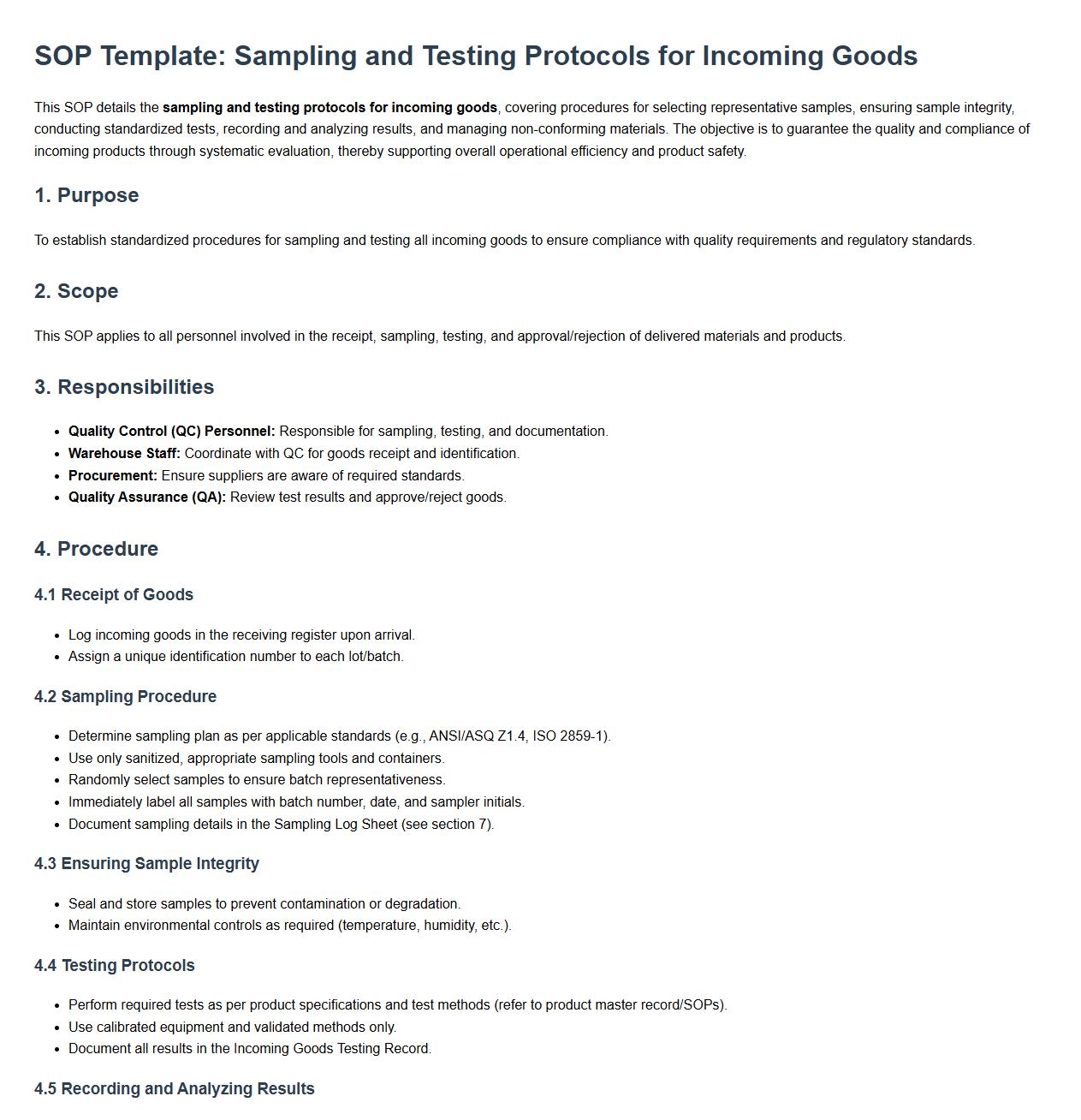

Sampling and testing protocols for incoming goods.

This SOP details the sampling and testing protocols for incoming goods, covering procedures for selecting representative samples, ensuring sample integrity, conducting standardized tests, recording and analyzing results, and managing non-conforming materials. The objective is to guarantee the quality and compliance of incoming products through systematic evaluation, thereby supporting overall operational efficiency and product safety.

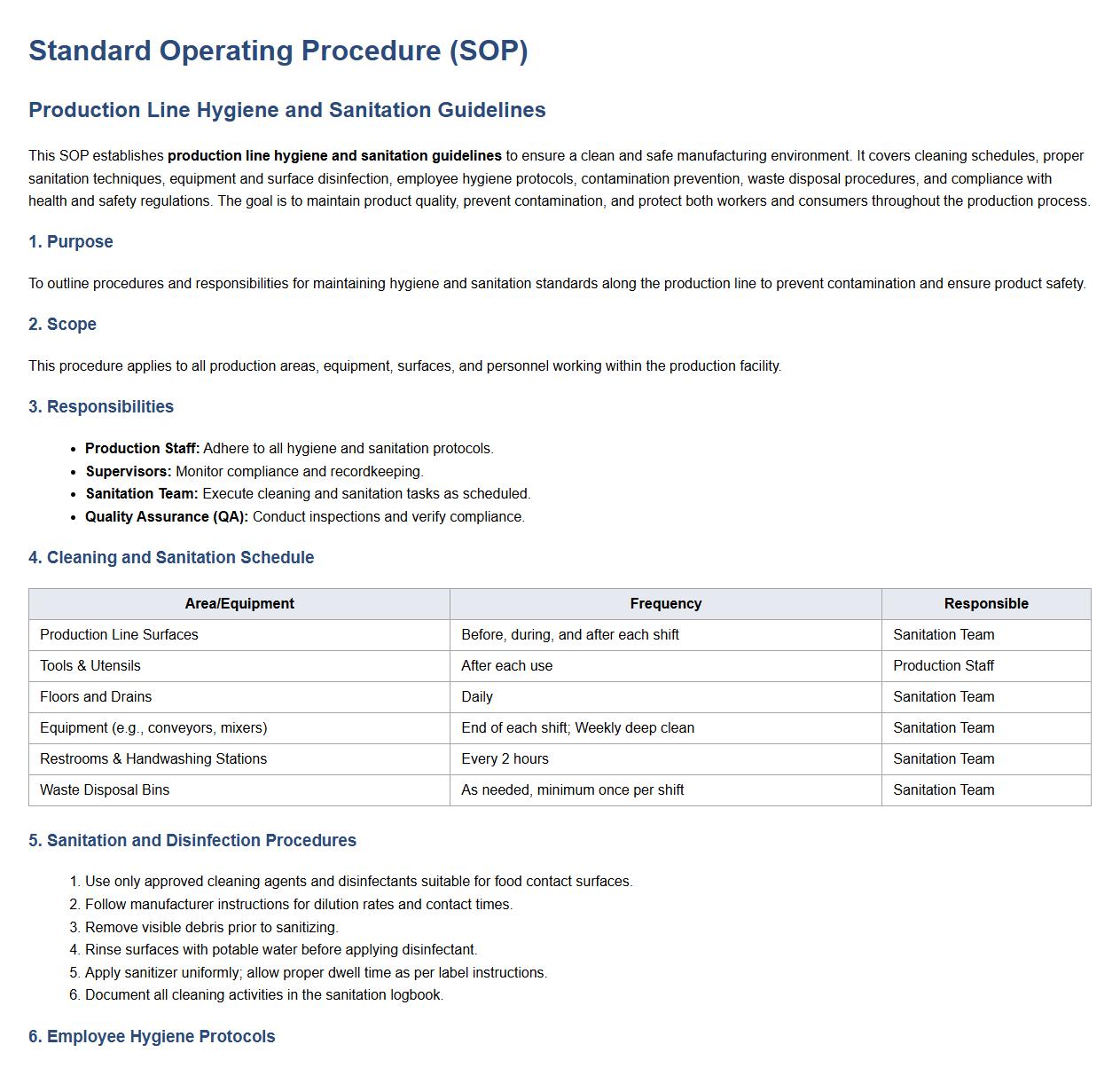

Production line hygiene and sanitation guidelines.

This SOP establishes production line hygiene and sanitation guidelines to ensure a clean and safe manufacturing environment. It covers cleaning schedules, proper sanitation techniques, equipment and surface disinfection, employee hygiene protocols, contamination prevention, waste disposal procedures, and compliance with health and safety regulations. The goal is to maintain product quality, prevent contamination, and protect both workers and consumers throughout the production process.

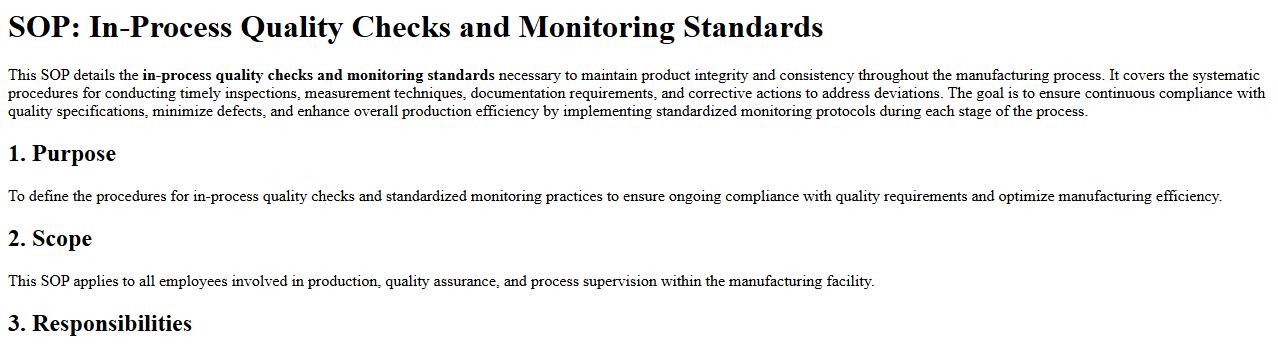

In-process quality checks and monitoring standards.

This SOP details the in-process quality checks and monitoring standards necessary to maintain product integrity and consistency throughout the manufacturing process. It covers the systematic procedures for conducting timely inspections, measurement techniques, documentation requirements, and corrective actions to address deviations. The goal is to ensure continuous compliance with quality specifications, minimize defects, and enhance overall production efficiency by implementing standardized monitoring protocols during each stage of the process.

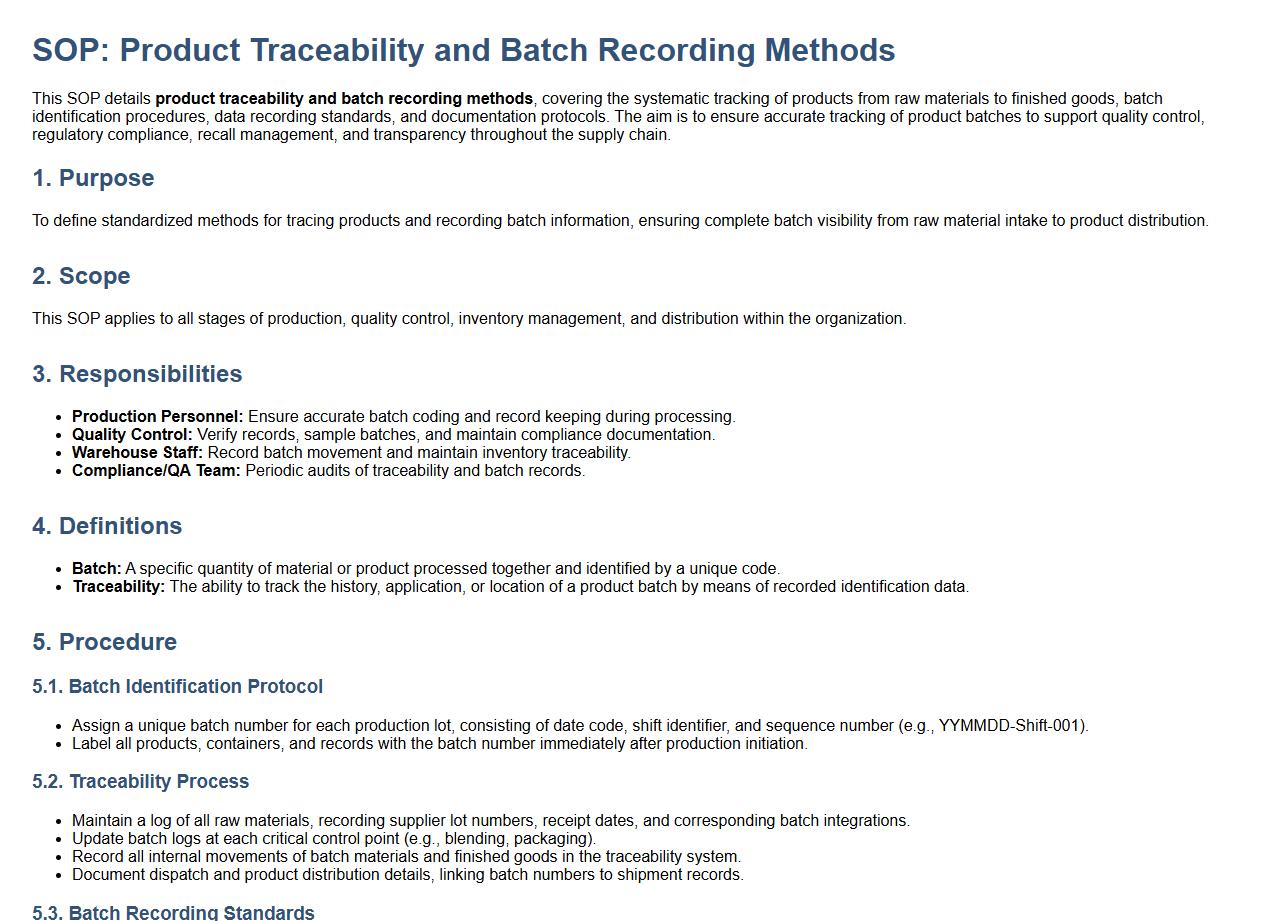

Product traceability and batch recording methods.

This SOP details product traceability and batch recording methods, covering the systematic tracking of products from raw materials to finished goods, batch identification procedures, data recording standards, and documentation protocols. The aim is to ensure accurate tracking of product batches to support quality control, regulatory compliance, recall management, and transparency throughout the supply chain.

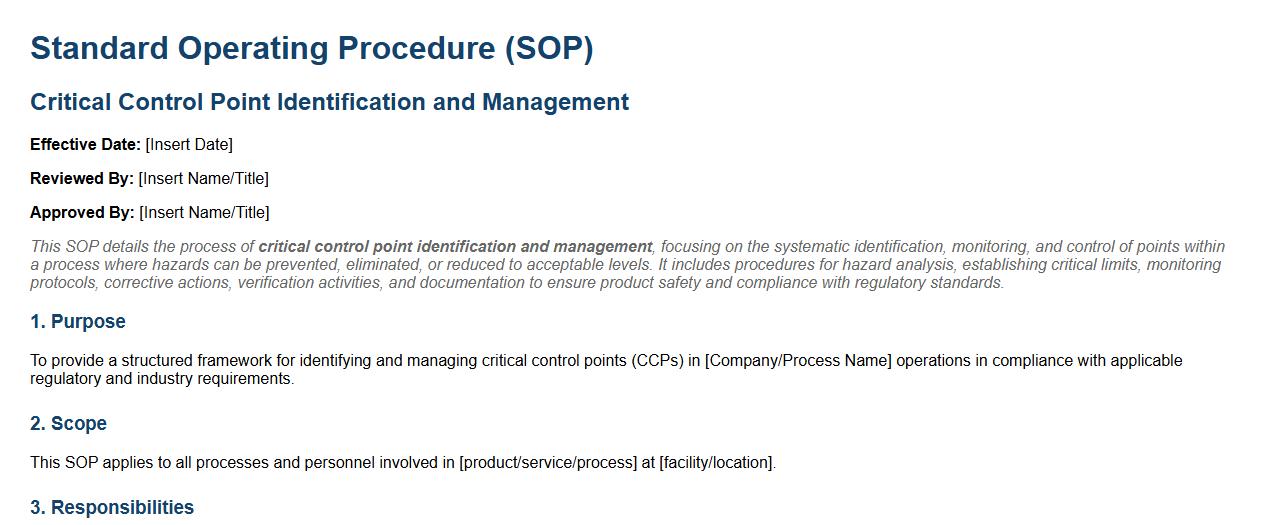

Critical control point identification and management.

This SOP details the process of critical control point identification and management, focusing on the systematic identification, monitoring, and control of points within a process where hazards can be prevented, eliminated, or reduced to acceptable levels. It includes procedures for hazard analysis, establishing critical limits, monitoring protocols, corrective actions, verification activities, and documentation to ensure product safety and compliance with regulatory standards.

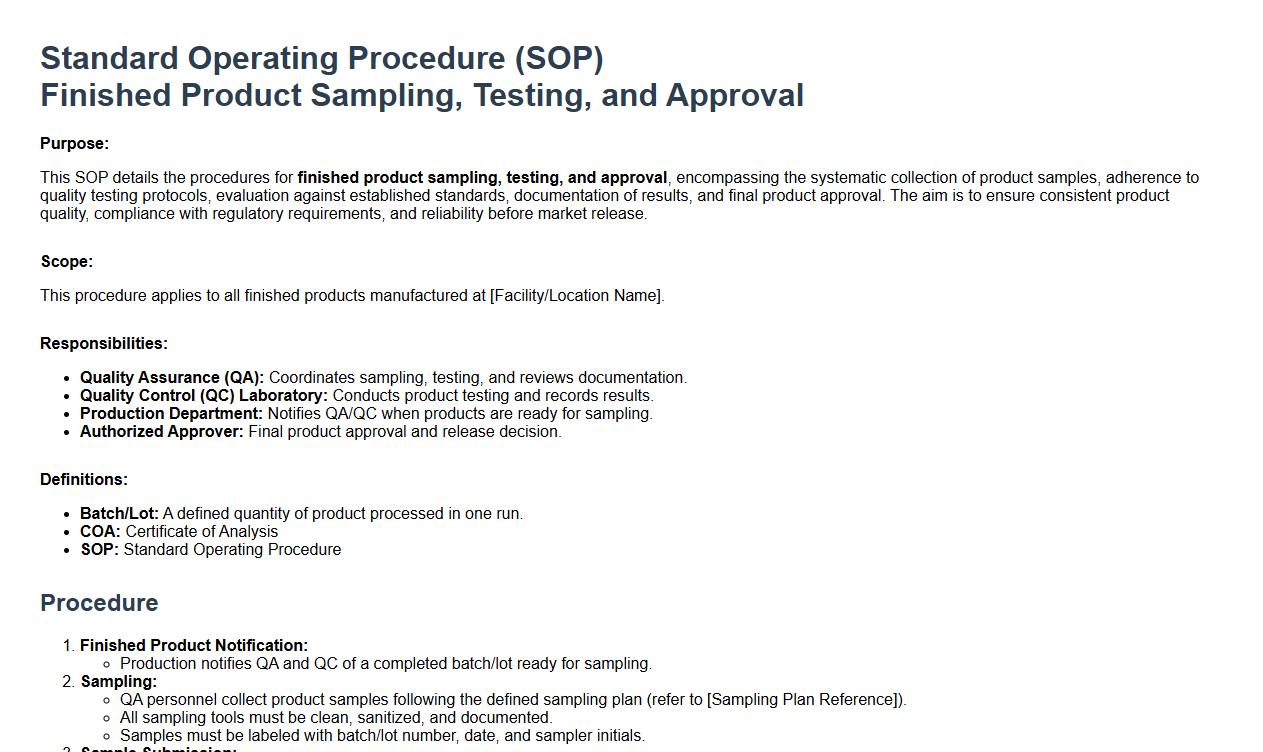

Finished product sampling, testing, and approval.

This SOP details the procedures for finished product sampling, testing, and approval, encompassing the systematic collection of product samples, adherence to quality testing protocols, evaluation against established standards, documentation of results, and final product approval. The aim is to ensure consistent product quality, compliance with regulatory requirements, and reliability before market release.

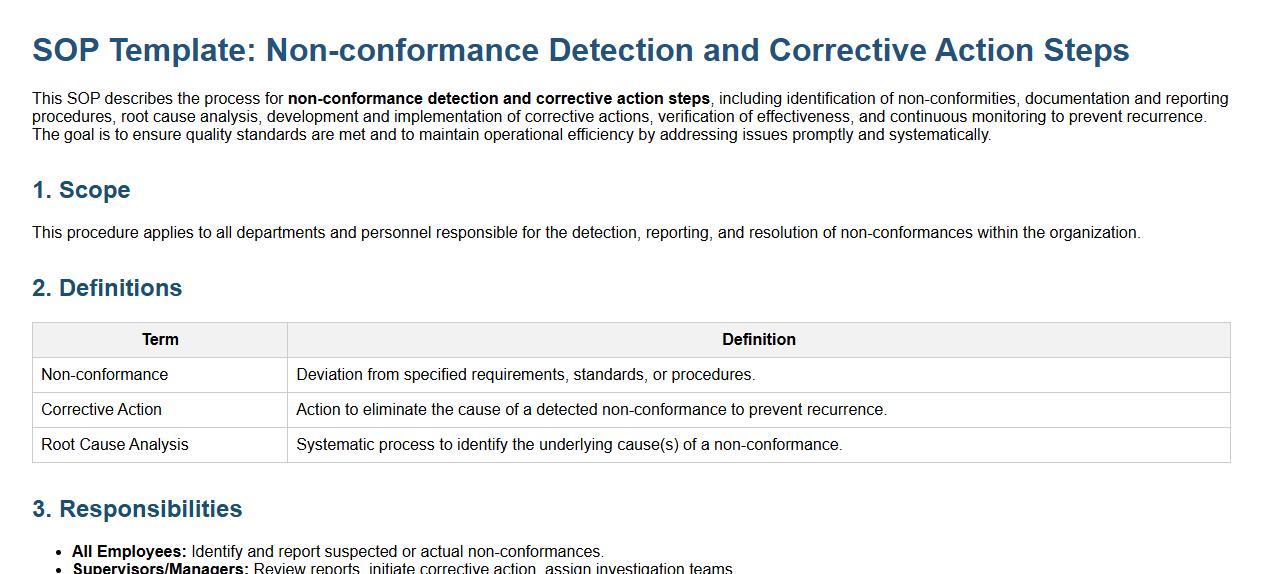

Non-conformance detection and corrective action steps.

This SOP describes the process for non-conformance detection and corrective action steps, including identification of non-conformities, documentation and reporting procedures, root cause analysis, development and implementation of corrective actions, verification of effectiveness, and continuous monitoring to prevent recurrence. The goal is to ensure quality standards are met and to maintain operational efficiency by addressing issues promptly and systematically.

Storage and handling procedures for raw and finished goods.

This SOP details the storage and handling procedures for raw and finished goods, covering proper storage conditions, inventory management, handling techniques to prevent damage, contamination control, and safety protocols. It ensures the integrity and quality of materials throughout the supply chain by minimizing risks associated with improper storage and handling practices.

Documentation, record-keeping, and reporting requirements.

This SOP details the documentation, record-keeping, and reporting requirements essential for maintaining accurate and timely records. It covers the processes for documenting operational activities, storing records securely, and generating reports in compliance with regulatory standards. The goal is to ensure transparency, accountability, and easy retrieval of information for audits, performance monitoring, and continuous improvement.

What are the critical control points identified in the SOP for food quality control?

The SOP defines critical control points (CCPs) as stages in the food production process where hazards can be prevented, eliminated, or reduced to safe levels. Common CCPs include cooking temperatures, cooling times, and hygiene practices during handling. Identifying these points ensures consistent monitoring and risk management to maintain food safety.

How does the SOP define and document acceptable food quality standards?

The SOP establishes acceptable food quality standards based on regulatory guidelines and internal benchmarks for taste, texture, appearance, and safety. These standards are documented through detailed specifications and quality checklists. This documentation enables objective evaluation and consistent adherence to quality requirements.

Which steps does the SOP outline for handling non-conforming food products?

The SOP requires immediate segregation and identification of non-conforming products to prevent their distribution. It outlines procedures for corrective actions such as reprocessing, disposal, or supplier notification. All actions taken must be documented thoroughly to support traceability and continuous improvement in food quality management.

What sampling and testing procedures are specified in the SOP for quality assurance?

The SOP specifies systematic sampling methods to collect representative food samples at predefined intervals and critical points. Laboratory testing includes microbiological, chemical, and sensory analyses to verify product compliance with standards. Results from these tests guide adjustments and validation of the quality assurance process.

How does the SOP mandate record-keeping and reporting of food quality inspections?

The SOP mandates comprehensive record-keeping of all inspections, test results, and corrective actions using standardized forms and digital systems. Reporting protocols require timely communication of findings to relevant personnel and management. This ensures transparency, accountability, and aids in continuous monitoring of food quality.