A SOP Template for Inventory Management in Food Service provides a structured framework to ensure accurate tracking and control of stock levels, reducing waste and preventing shortages. It outlines standardized procedures for receiving, storing, and rotating food items, maintaining quality and safety standards. This template enhances efficiency and accountability in managing food inventory within the service industry.

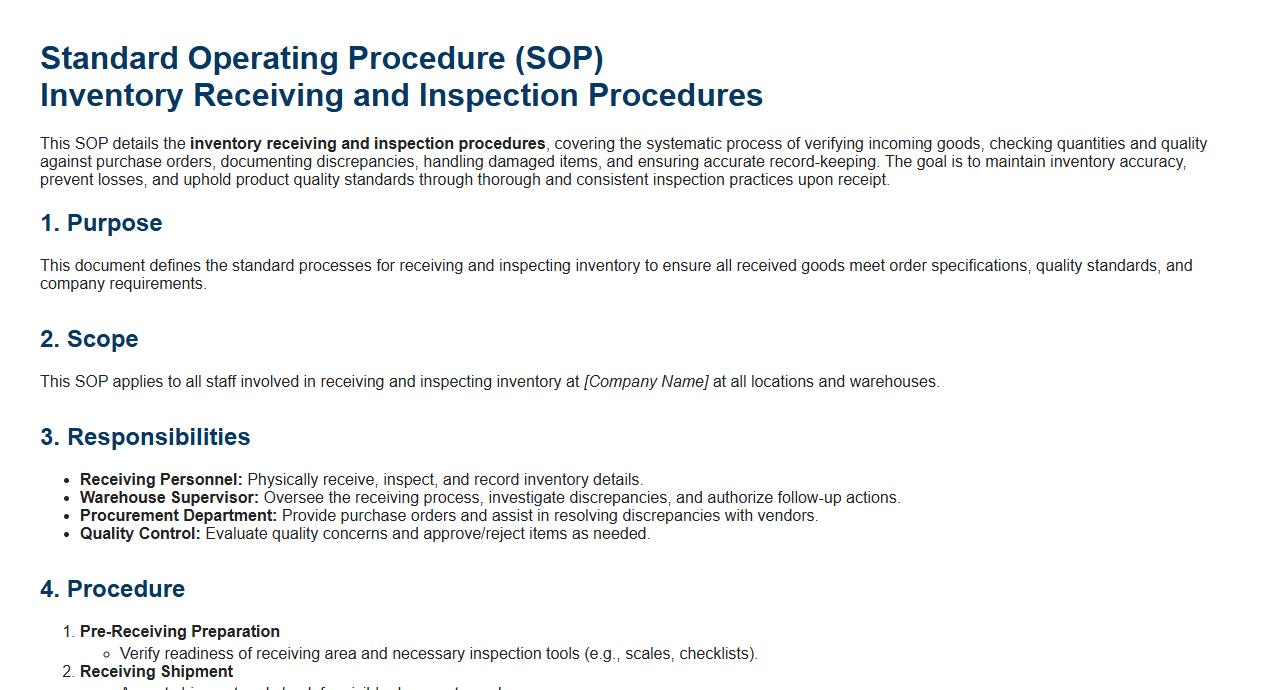

Inventory receiving and inspection procedures.

This SOP details the inventory receiving and inspection procedures, covering the systematic process of verifying incoming goods, checking quantities and quality against purchase orders, documenting discrepancies, handling damaged items, and ensuring accurate record-keeping. The goal is to maintain inventory accuracy, prevent losses, and uphold product quality standards through thorough and consistent inspection practices upon receipt.

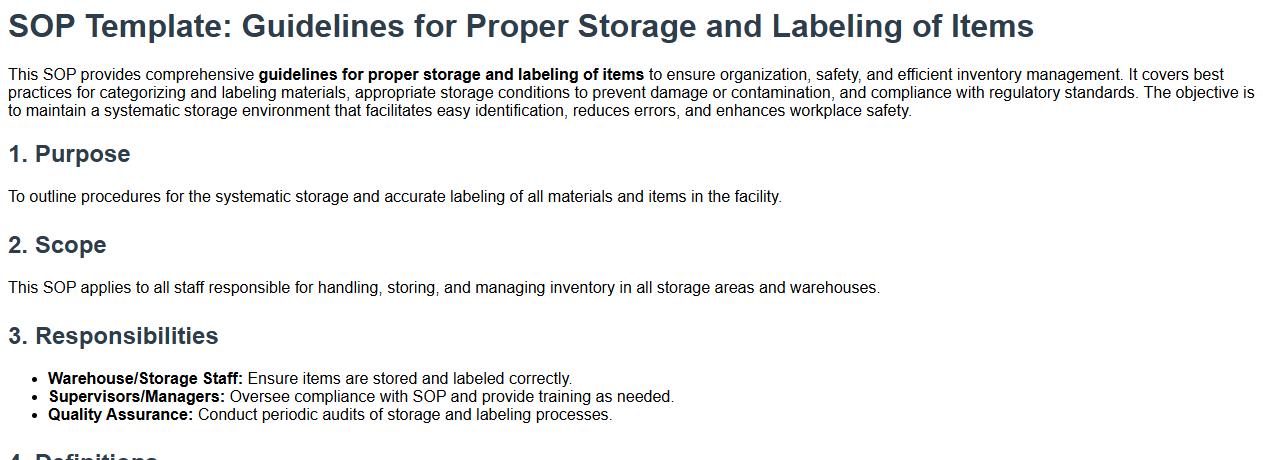

Guidelines for proper storage and labeling of items.

This SOP provides comprehensive guidelines for proper storage and labeling of items to ensure organization, safety, and efficient inventory management. It covers best practices for categorizing and labeling materials, appropriate storage conditions to prevent damage or contamination, and compliance with regulatory standards. The objective is to maintain a systematic storage environment that facilitates easy identification, reduces errors, and enhances workplace safety.

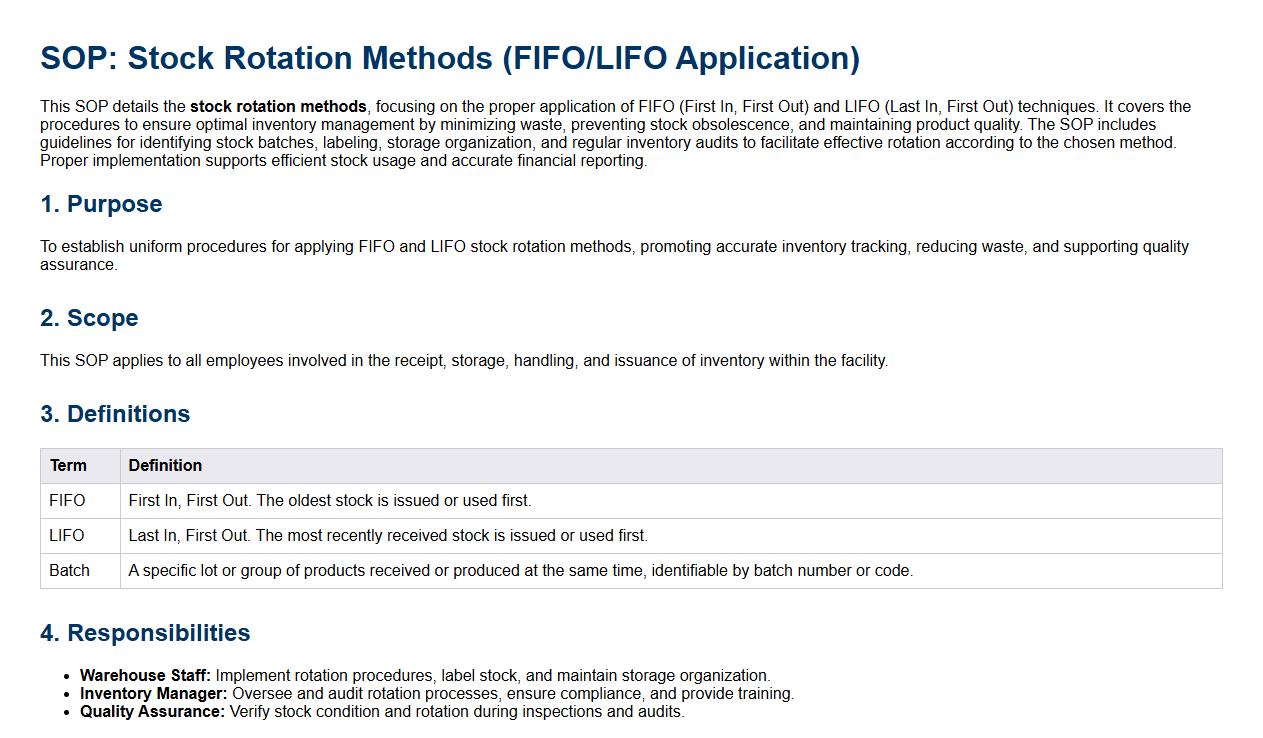

Stock rotation methods (FIFO/LIFO application).

This SOP details the stock rotation methods, focusing on the proper application of FIFO (First In, First Out) and LIFO (Last In, First Out) techniques. It covers the procedures to ensure optimal inventory management by minimizing waste, preventing stock obsolescence, and maintaining product quality. The SOP includes guidelines for identifying stock batches, labeling, storage organization, and regular inventory audits to facilitate effective rotation according to the chosen method. Proper implementation supports efficient stock usage and accurate financial reporting.

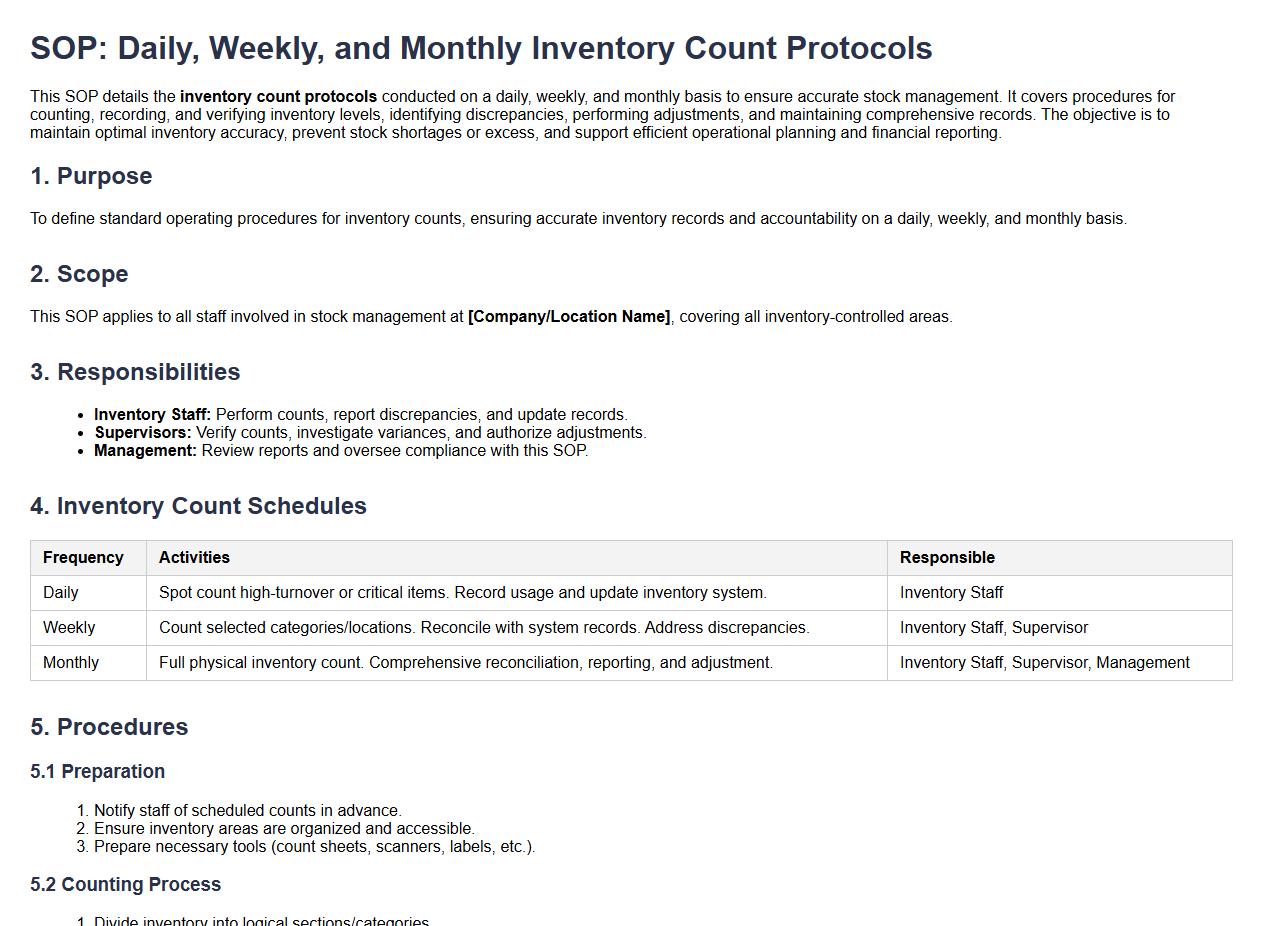

Daily, weekly, and monthly inventory count protocols.

This SOP details the inventory count protocols conducted on a daily, weekly, and monthly basis to ensure accurate stock management. It covers procedures for counting, recording, and verifying inventory levels, identifying discrepancies, performing adjustments, and maintaining comprehensive records. The objective is to maintain optimal inventory accuracy, prevent stock shortages or excess, and support efficient operational planning and financial reporting.

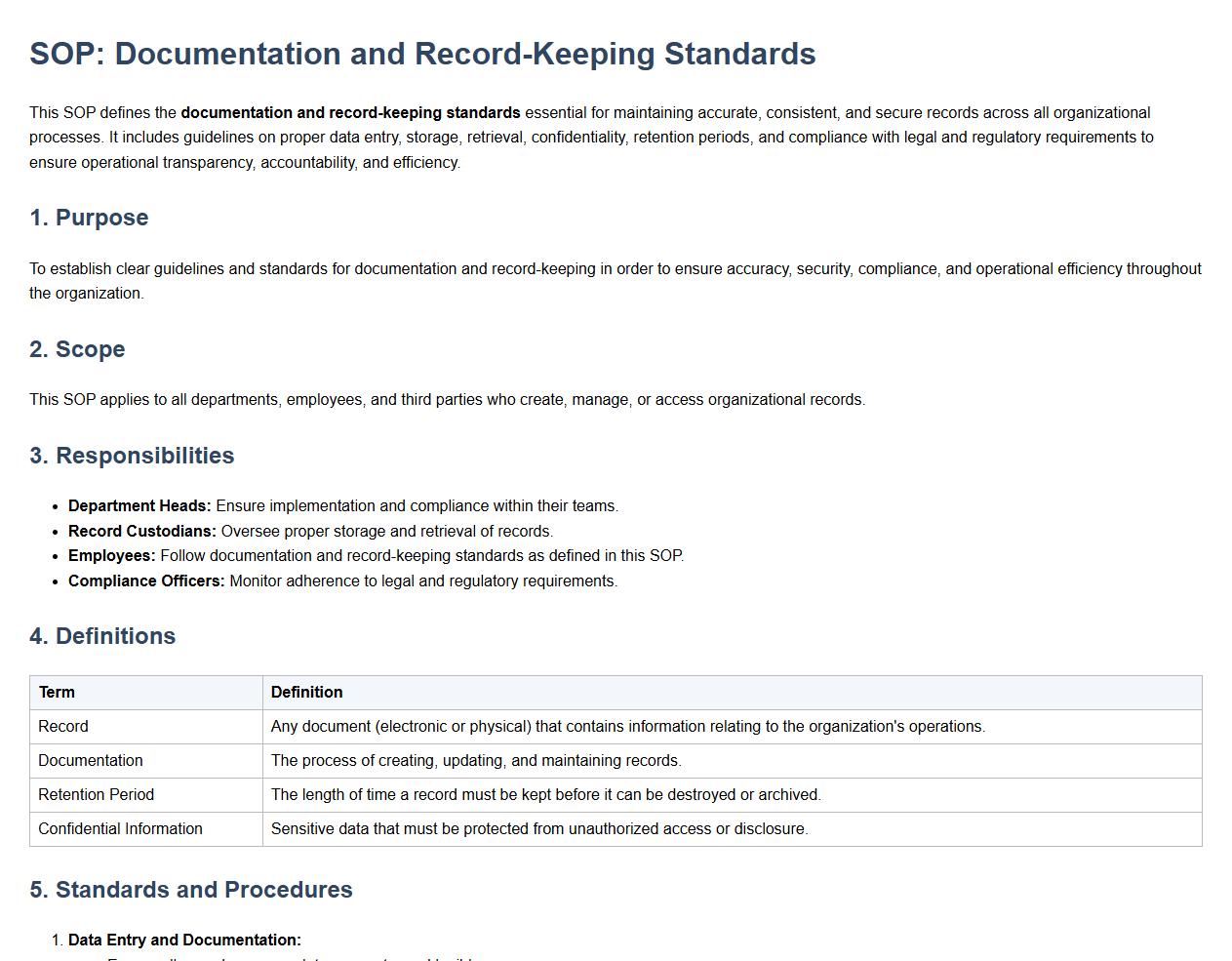

Documentation and record-keeping standards.

This SOP defines the documentation and record-keeping standards essential for maintaining accurate, consistent, and secure records across all organizational processes. It includes guidelines on proper data entry, storage, retrieval, confidentiality, retention periods, and compliance with legal and regulatory requirements to ensure operational transparency, accountability, and efficiency.

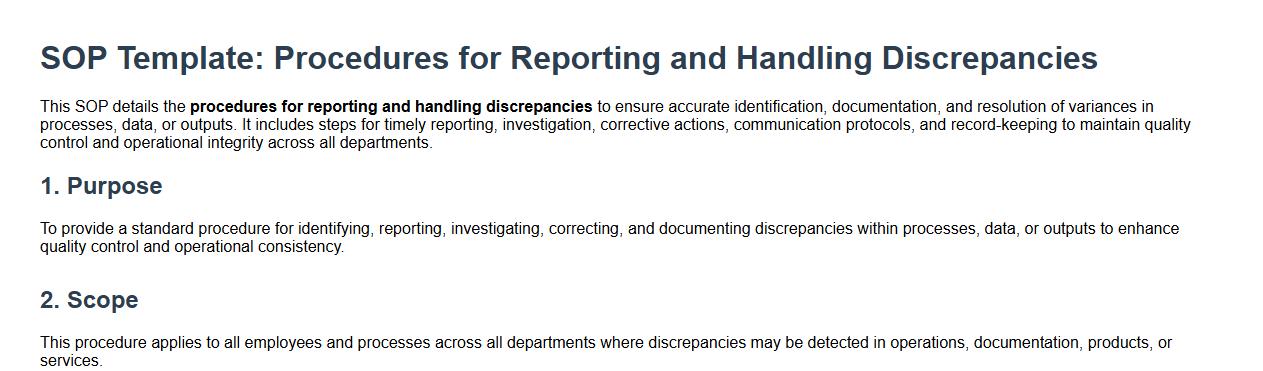

Procedures for reporting and handling discrepancies.

This SOP details the procedures for reporting and handling discrepancies to ensure accurate identification, documentation, and resolution of variances in processes, data, or outputs. It includes steps for timely reporting, investigation, corrective actions, communication protocols, and record-keeping to maintain quality control and operational integrity across all departments.

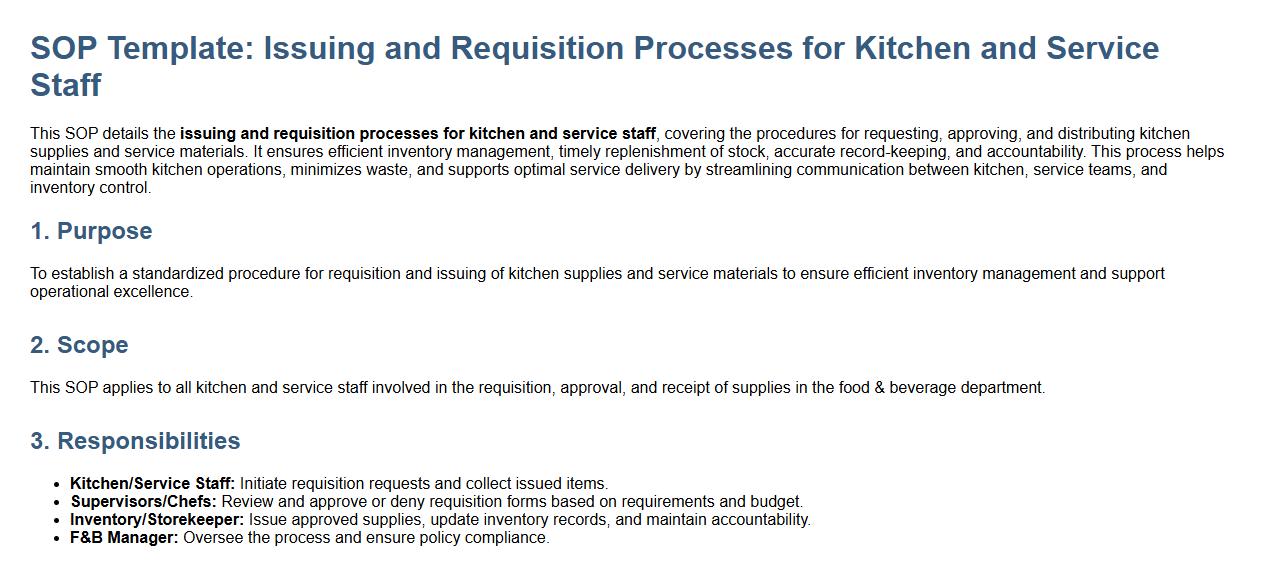

Issuing and requisition processes for kitchen and service staff.

This SOP details the issuing and requisition processes for kitchen and service staff, covering the procedures for requesting, approving, and distributing kitchen supplies and service materials. It ensures efficient inventory management, timely replenishment of stock, accurate record-keeping, and accountability. This process helps maintain smooth kitchen operations, minimizes waste, and supports optimal service delivery by streamlining communication between kitchen, service teams, and inventory control.

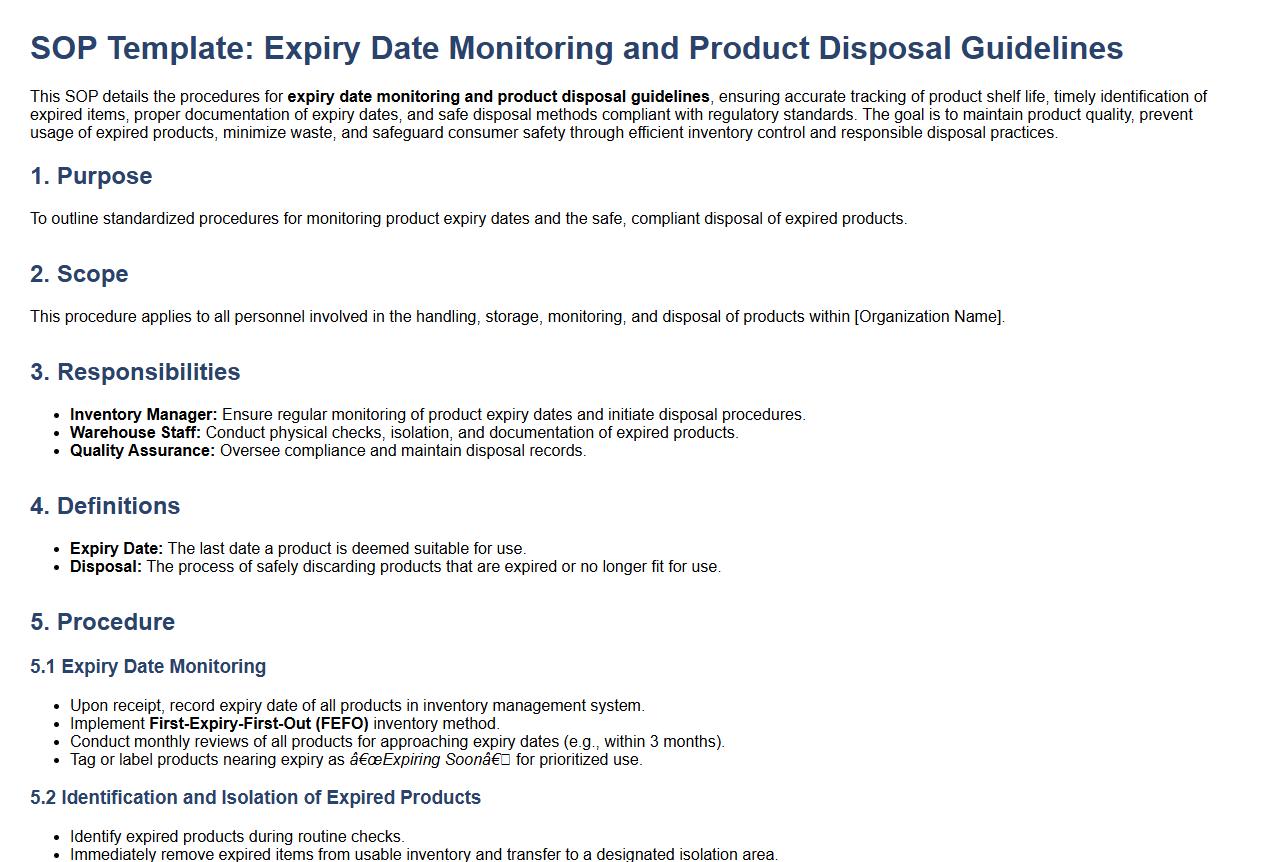

Expiry date monitoring and product disposal guidelines.

This SOP details the procedures for expiry date monitoring and product disposal guidelines, ensuring accurate tracking of product shelf life, timely identification of expired items, proper documentation of expiry dates, and safe disposal methods compliant with regulatory standards. The goal is to maintain product quality, prevent usage of expired products, minimize waste, and safeguard consumer safety through efficient inventory control and responsible disposal practices.

Security measures for inventory storage areas.

This SOP details security measures for inventory storage areas, encompassing access control protocols, surveillance system implementation, inventory monitoring, employee training on security practices, and emergency response plans to prevent theft, damage, and unauthorized access, ensuring the safety and integrity of stored assets.

Reordering thresholds and supplier communication protocols.

This SOP details the processes for managing reordering thresholds and supplier communication protocols, including setting inventory reorder points, monitoring stock levels, initiating reorder requests, maintaining supplier contact information, establishing communication timelines, coordinating order confirmations, and handling discrepancies or delays. The purpose is to ensure timely replenishment of inventory, minimize stockouts, and maintain strong supplier relationships through effective and consistent communication strategies.

What are the main objectives of the SOP for Inventory Management in Food Service?

The primary objectives of the SOP for Inventory Management in Food Service focus on ensuring accurate tracking of all food items. It aims to minimize waste by implementing proper stock control techniques. Additionally, it ensures compliance with health and safety standards throughout the inventory process.

Which procedures are outlined for receiving, storing, and rotating food inventory?

The SOP details strict procedures for receiving deliveries, including verifying quantities and inspecting quality. It prescribes optimal storage conditions to preserve freshness and prevent contamination. Moreover, it enforces the FIFO (First In, First Out) method for food rotation to reduce spoilage.

How does the SOP specify tracking inventory levels and recording usage?

The SOP requires the use of standardized inventory tracking systems to monitor stock levels accurately. It mandates regular updates of consumption records to maintain real-time inventory data. This process helps in forecasting demand and avoiding stockouts or overordering.

What security and quality assurance measures are included in the SOP?

Security measures include controlled access to inventory storage areas to prevent theft or tampering. Quality assurance involves regular inspections and audits to maintain food safety standards. The SOP also emphasizes proper temperature control and hygiene protocols to uphold product quality.

What roles and responsibilities are defined for staff regarding inventory management?

The SOP assigns specific roles such as inventory clerks, kitchen staff, and supervisors to ensure accountability. Each staff member is responsible for following proper handling, recording, and reporting procedures. Training is emphasized to maintain a consistent standard of inventory management practices.