A SOP Template for Cleaning and Sanitizing Food Areas outlines standardized procedures to ensure all surfaces and equipment are thoroughly cleaned and disinfected. This template helps maintain hygiene standards, prevent contamination, and comply with food safety regulations. Clear instructions and scheduled tasks improve consistency and accountability in food production environments.

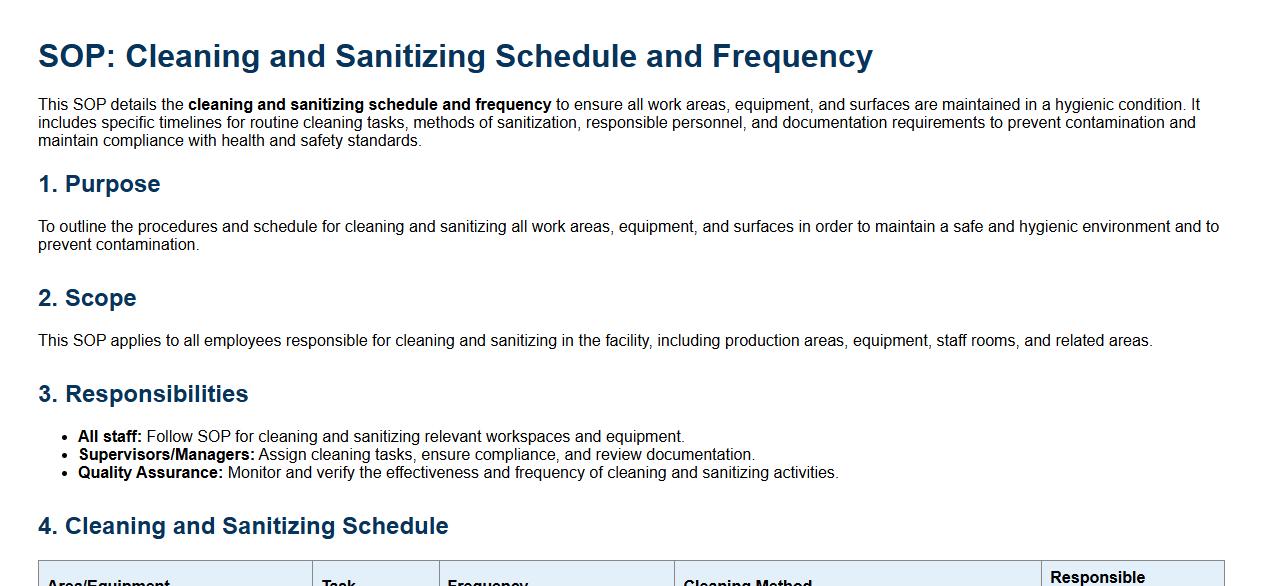

Cleaning and sanitizing schedule and frequency.

This SOP details the cleaning and sanitizing schedule and frequency to ensure all work areas, equipment, and surfaces are maintained in a hygienic condition. It includes specific timelines for routine cleaning tasks, methods of sanitization, responsible personnel, and documentation requirements to prevent contamination and maintain compliance with health and safety standards.

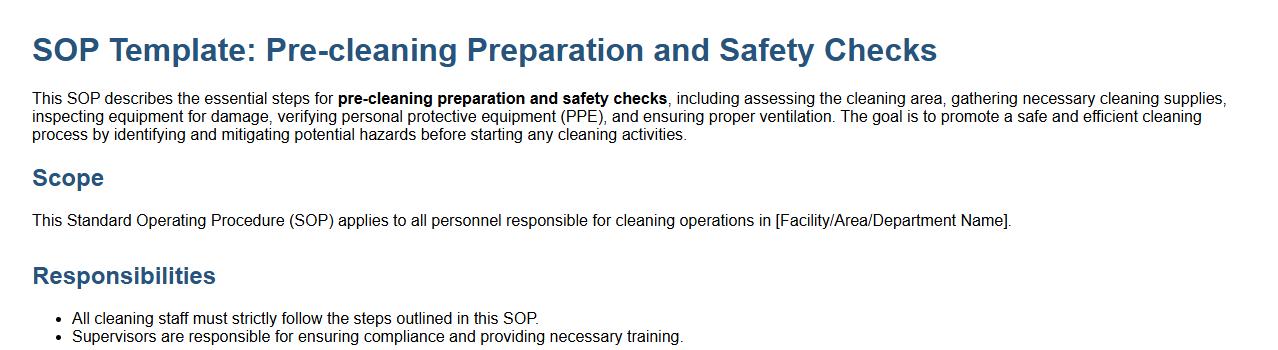

Pre-cleaning preparation and safety checks.

This SOP describes the essential steps for pre-cleaning preparation and safety checks, including assessing the cleaning area, gathering necessary cleaning supplies, inspecting equipment for damage, verifying personal protective equipment (PPE), and ensuring proper ventilation. The goal is to promote a safe and efficient cleaning process by identifying and mitigating potential hazards before starting any cleaning activities.

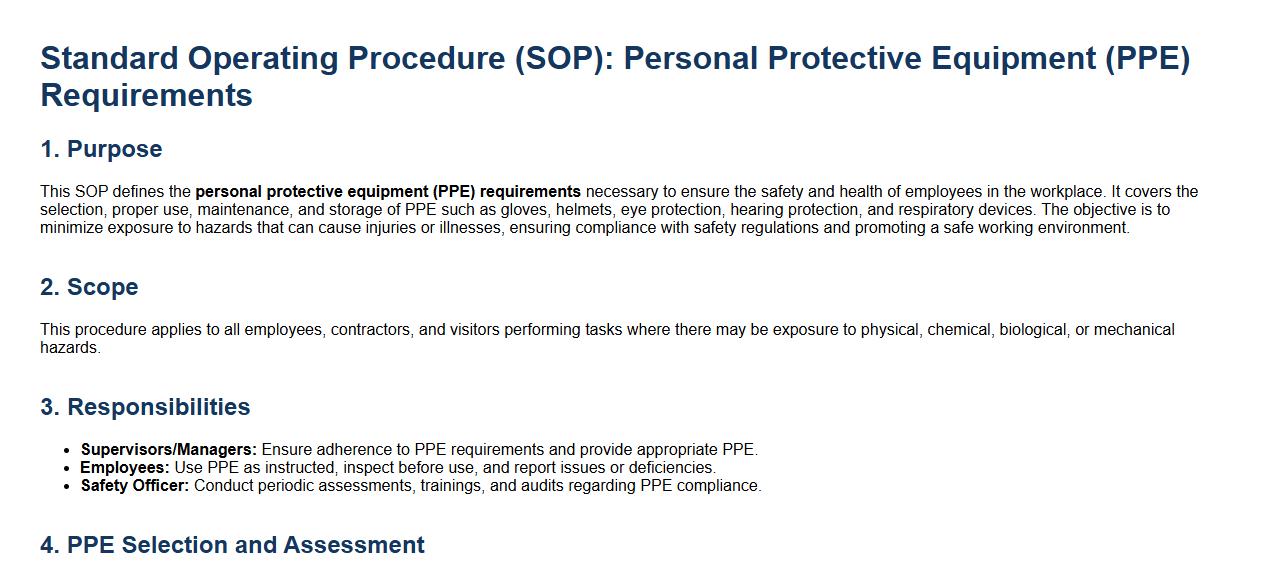

Personal protective equipment (PPE) requirements.

This SOP defines the personal protective equipment (PPE) requirements necessary to ensure the safety and health of employees in the workplace. It covers the selection, proper use, maintenance, and storage of PPE such as gloves, helmets, eye protection, hearing protection, and respiratory devices. The objective is to minimize exposure to hazards that can cause injuries or illnesses, ensuring compliance with safety regulations and promoting a safe working environment.

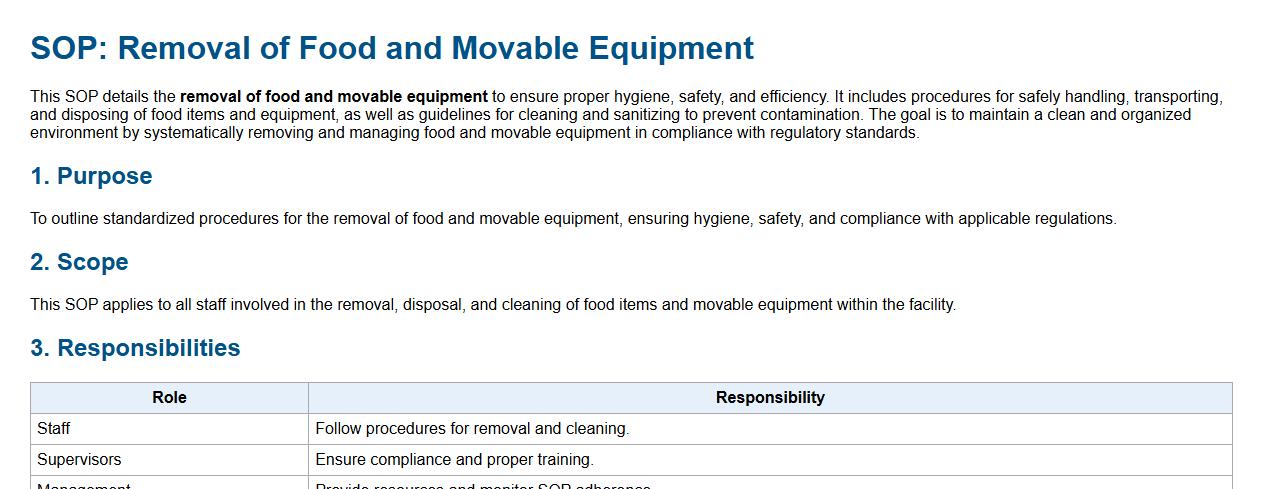

Removal of food and movable equipment.

This SOP details the removal of food and movable equipment to ensure proper hygiene, safety, and efficiency. It includes procedures for safely handling, transporting, and disposing of food items and equipment, as well as guidelines for cleaning and sanitizing to prevent contamination. The goal is to maintain a clean and organized environment by systematically removing and managing food and movable equipment in compliance with regulatory standards.

Selection and use of approved cleaning agents.

This SOP details the selection and use of approved cleaning agents, covering criteria for choosing effective and safe cleaning products, proper handling and storage practices, application methods for different surfaces and equipment, safety precautions to protect workers and the environment, and protocols for disposal of cleaning agents. The aim is to ensure efficient cleaning while minimizing health risks and environmental impact.

Step-by-step cleaning procedures for all surfaces.

This SOP details the step-by-step cleaning procedures for all surfaces, ensuring thorough sanitation and maintenance of cleanliness. It covers the preparation of cleaning supplies, use of appropriate cleaning agents, systematic cleaning techniques for various surface types, proper rinsing and drying methods, and safety precautions to prevent contamination and maintain hygiene standards. Adhering to these procedures helps create a safe and sanitary environment in all operational areas.

Rinsing and inspection after cleaning.

This SOP details the process for rinsing and inspection after cleaning to ensure all surfaces and equipment are free from cleaning agents, residues, and contaminants. It includes steps for thoroughly rinsing cleaned items with appropriate water pressure, performing visual and tactile inspections to verify cleanliness, and identifying any areas requiring re-cleaning. The goal is to maintain hygiene standards, prevent cross-contamination, and ensure the safety and quality of products or environments.

Application of appropriate sanitizers with contact time.

This SOP details the application of appropriate sanitizers with contact time, emphasizing the selection of suitable sanitizing agents, correct dilution and preparation methods, proper application techniques, and adherence to recommended contact times to ensure effective microbial control. The objective is to maintain hygiene standards, prevent contamination, and ensure safety in both industrial and domestic environments by following established sanitization protocols.

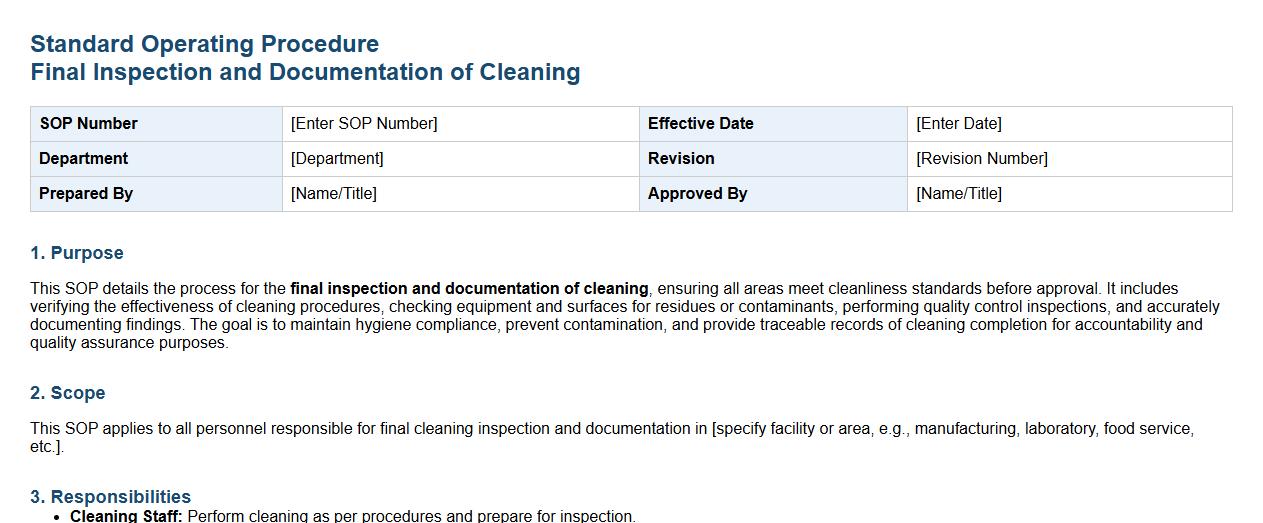

Final inspection and documentation of cleaning.

This SOP details the process for the final inspection and documentation of cleaning, ensuring all areas meet cleanliness standards before approval. It includes verifying the effectiveness of cleaning procedures, checking equipment and surfaces for residues or contaminants, performing quality control inspections, and accurately documenting findings. The goal is to maintain hygiene compliance, prevent contamination, and provide traceable records of cleaning completion for accountability and quality assurance purposes.

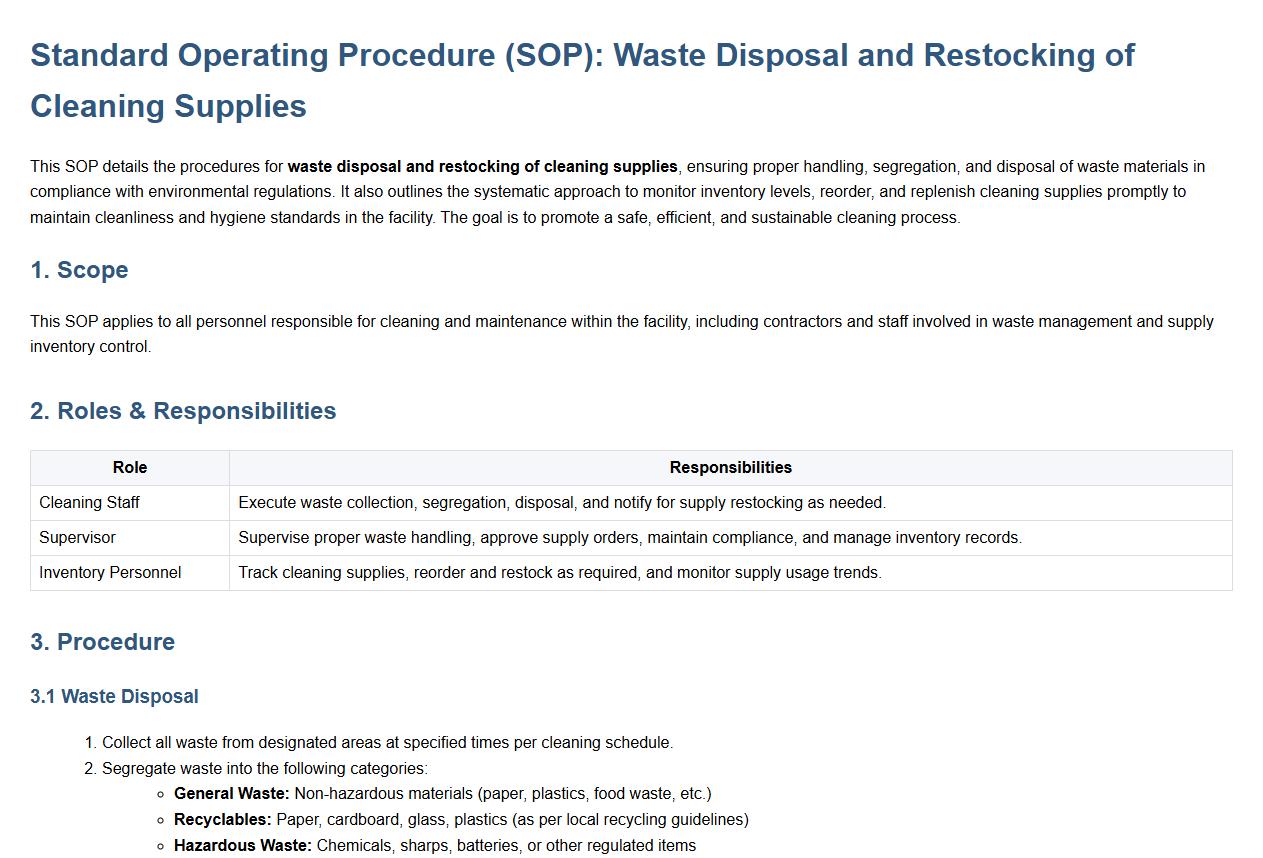

Waste disposal and restocking of cleaning supplies.

This SOP details the procedures for waste disposal and restocking of cleaning supplies, ensuring proper handling, segregation, and disposal of waste materials in compliance with environmental regulations. It also outlines the systematic approach to monitor inventory levels, reorder, and replenish cleaning supplies promptly to maintain cleanliness and hygiene standards in the facility. The goal is to promote a safe, efficient, and sustainable cleaning process.

Key Steps in Cleaning and Sanitizing Food Areas

The SOP emphasizes a systematic approach starting with the removal of food debris and waste from all surfaces. Following this, surfaces must be thoroughly cleaned using appropriate detergents to remove grease and residues. The final step involves sanitizing the areas to eliminate harmful microorganisms and ensure food safety.

Approved Cleaning Agents and Sanitizers

The SOP specifies the use of food-grade detergents that effectively break down organic matter without leaving harmful residues. For sanitizing, only approved sanitizers such as chlorine-based or quaternary ammonium compounds are authorized. These agents must meet regulatory standards to ensure they are safe for use in food preparation environments.

Frequency and Timing for Cleaning Food Preparation Surfaces

The SOP outlines that high-contact surfaces must be cleaned and sanitized at regular intervals, often between tasks or every few hours during continuous operation. It mandates that cleaning be performed immediately after any contamination or when switching between different food types. Scheduled deep cleans are required daily to maintain hygiene standards.

Required Personal Protective Equipment (PPE)

Employees must wear appropriate PPE such as gloves, aprons, and sometimes face masks to prevent contamination and protect themselves from chemicals. The SOP highlights the importance of proper PPE use during both cleaning and sanitizing processes. PPE serves as a critical barrier to maintain both worker safety and food area hygiene.

Verification and Documentation Methods

The SOP requires routine visual inspections and the use of microbial testing to verify cleanliness and effective sanitization. All cleaning activities must be documented in logs, detailing date, time, area cleaned, and personnel responsible. This thorough documentation ensures accountability and helps maintain compliance with food safety regulations.