A SOP Template for Fast Food Service Operations ensures consistent quality and efficiency by outlining step-by-step procedures for food preparation, customer service, and hygiene standards. It helps employees follow standardized practices, reducing errors and maintaining food safety compliance. Implementing this template improves operational flow and enhances customer satisfaction in fast food establishments.

Customer order taking and point-of-sale procedures.

This SOP defines the standard processes for customer order taking and point-of-sale procedures, including accurate order entry, handling customer inquiries, processing payments, issuing receipts, managing returns and exchanges, and maintaining transaction records. The goal is to ensure efficient, accurate, and courteous service that enhances customer satisfaction and supports seamless sales operations.

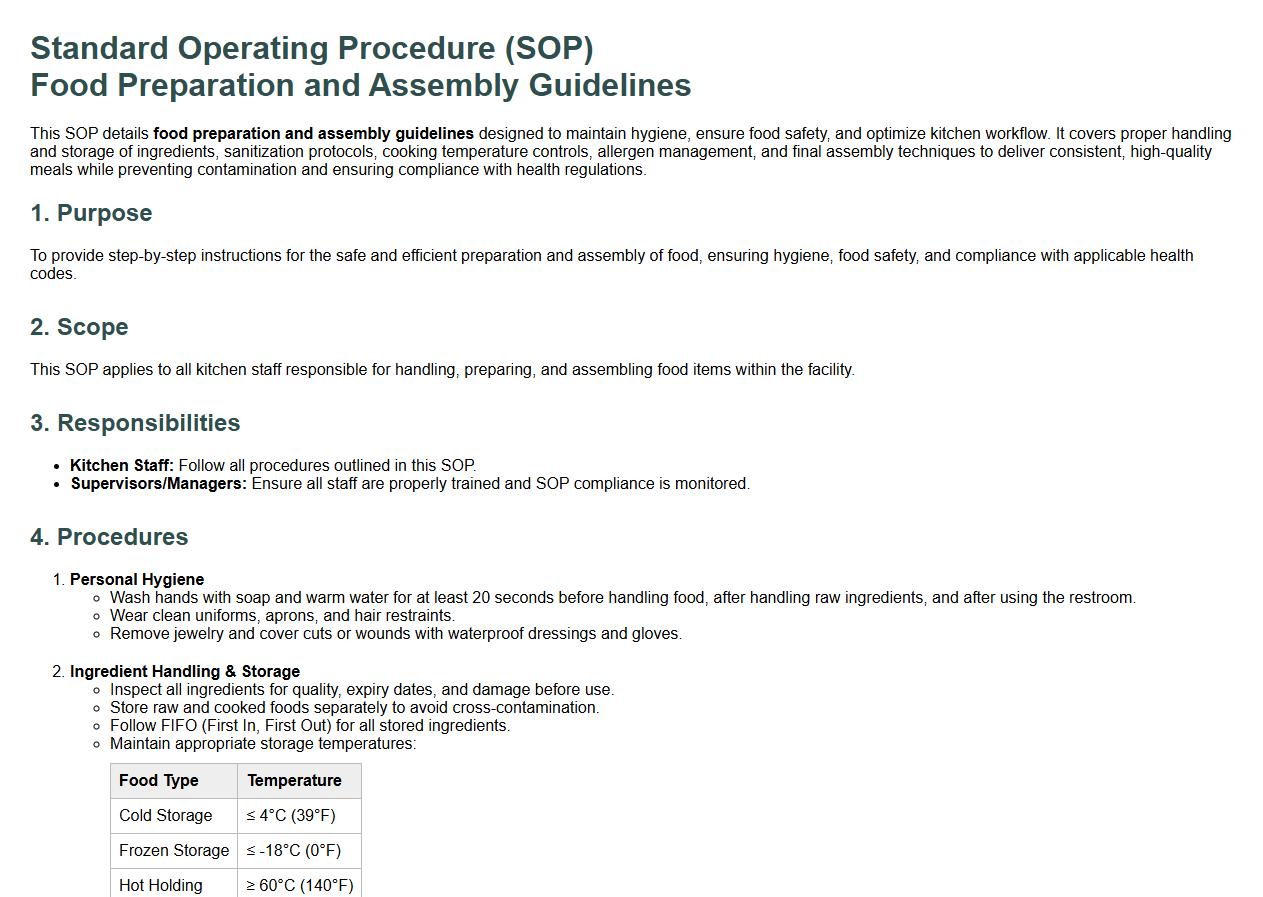

Food preparation and assembly guidelines.

This SOP details food preparation and assembly guidelines designed to maintain hygiene, ensure food safety, and optimize kitchen workflow. It covers proper handling and storage of ingredients, sanitization protocols, cooking temperature controls, allergen management, and final assembly techniques to deliver consistent, high-quality meals while preventing contamination and ensuring compliance with health regulations.

Quality control and food safety checks.

This SOP details the procedures for quality control and food safety checks, covering inspection protocols, sampling methods, contamination prevention, compliance with food safety standards, documentation requirements, corrective actions, and continuous monitoring. The objective is to ensure that all food products meet the highest standards of quality and safety to protect consumer health and maintain regulatory compliance.

Sanitization and cleaning protocols.

This SOP establishes sanitization and cleaning protocols designed to maintain a hygienic environment by detailing proper cleaning procedures, selection and use of disinfectants, frequency of cleaning tasks, equipment sanitation, waste disposal methods, and employee responsibilities. The objective is to prevent contamination, reduce the risk of infection, and ensure compliance with health and safety standards.

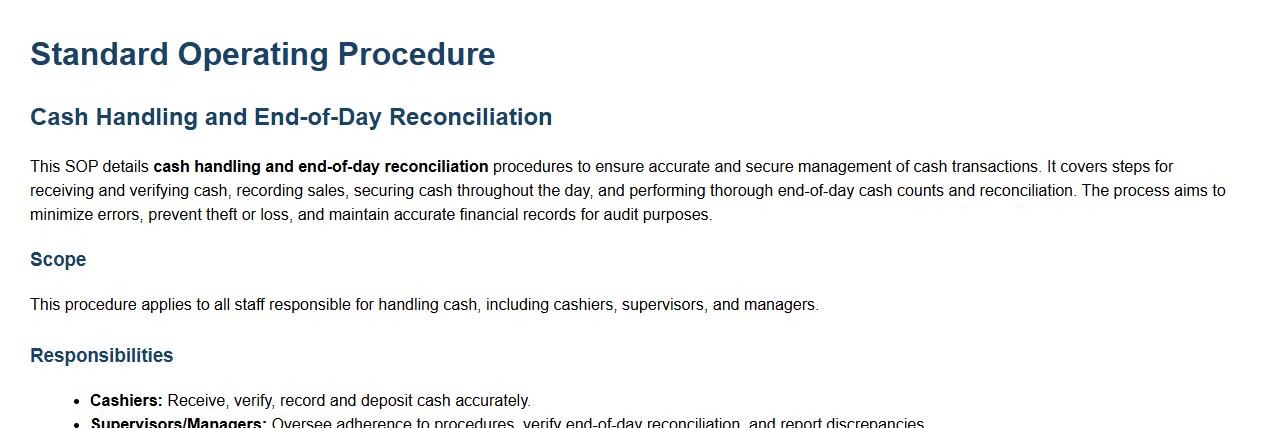

Cash handling and end-of-day reconciliation.

This SOP details cash handling and end-of-day reconciliation procedures to ensure accurate and secure management of cash transactions. It covers steps for receiving and verifying cash, recording sales, securing cash throughout the day, and performing thorough end-of-day cash counts and reconciliation. The process aims to minimize errors, prevent theft or loss, and maintain accurate financial records for audit purposes.

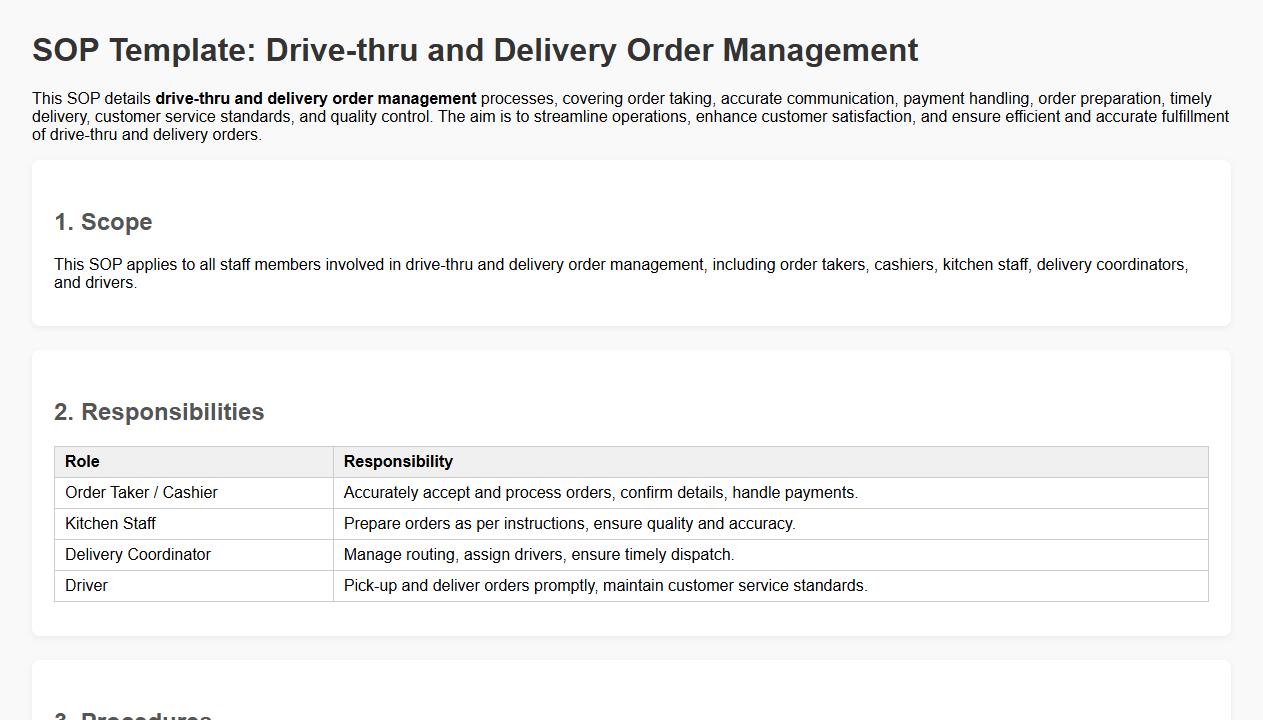

Drive-thru and delivery order management.

This SOP details drive-thru and delivery order management processes, covering order taking, accurate communication, payment handling, order preparation, timely delivery, customer service standards, and quality control. The aim is to streamline operations, enhance customer satisfaction, and ensure efficient and accurate fulfillment of drive-thru and delivery orders.

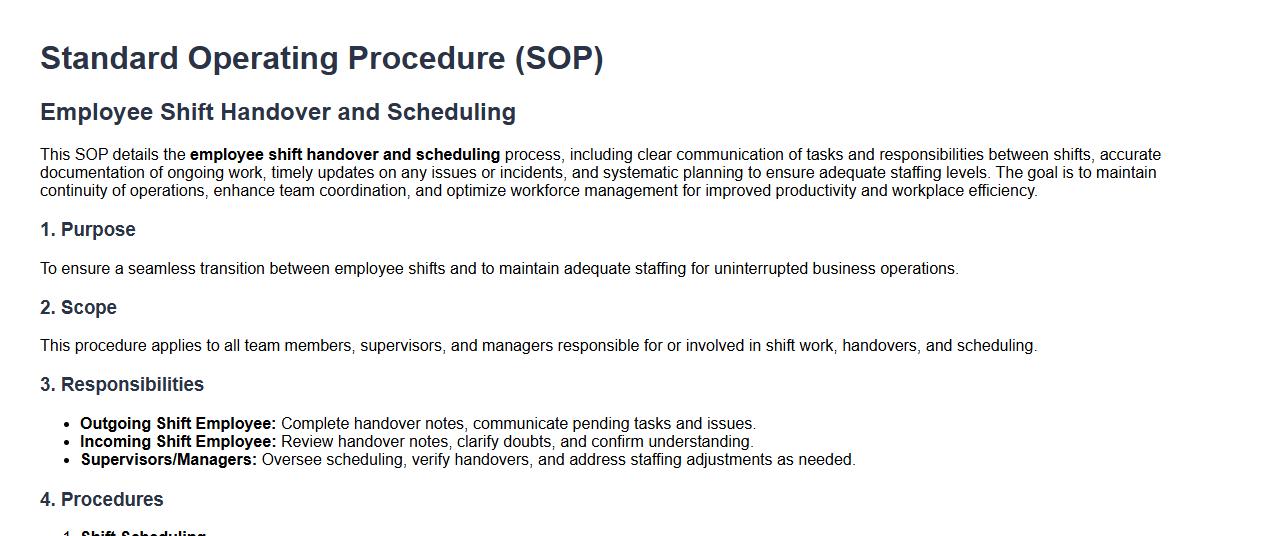

Employee shift handover and scheduling.

This SOP details the employee shift handover and scheduling process, including clear communication of tasks and responsibilities between shifts, accurate documentation of ongoing work, timely updates on any issues or incidents, and systematic planning to ensure adequate staffing levels. The goal is to maintain continuity of operations, enhance team coordination, and optimize workforce management for improved productivity and workplace efficiency.

Inventory tracking and stock replenishment.

This SOP details inventory tracking and stock replenishment processes to maintain optimal stock levels, prevent shortages, and reduce excess inventory. It covers systematic recording of stock movements, regular stock audits, automated alerts for low stock, and efficient ordering procedures. The goal is to ensure accurate inventory data, timely restocking, and streamlined supply chain operations for improved business continuity and customer satisfaction.

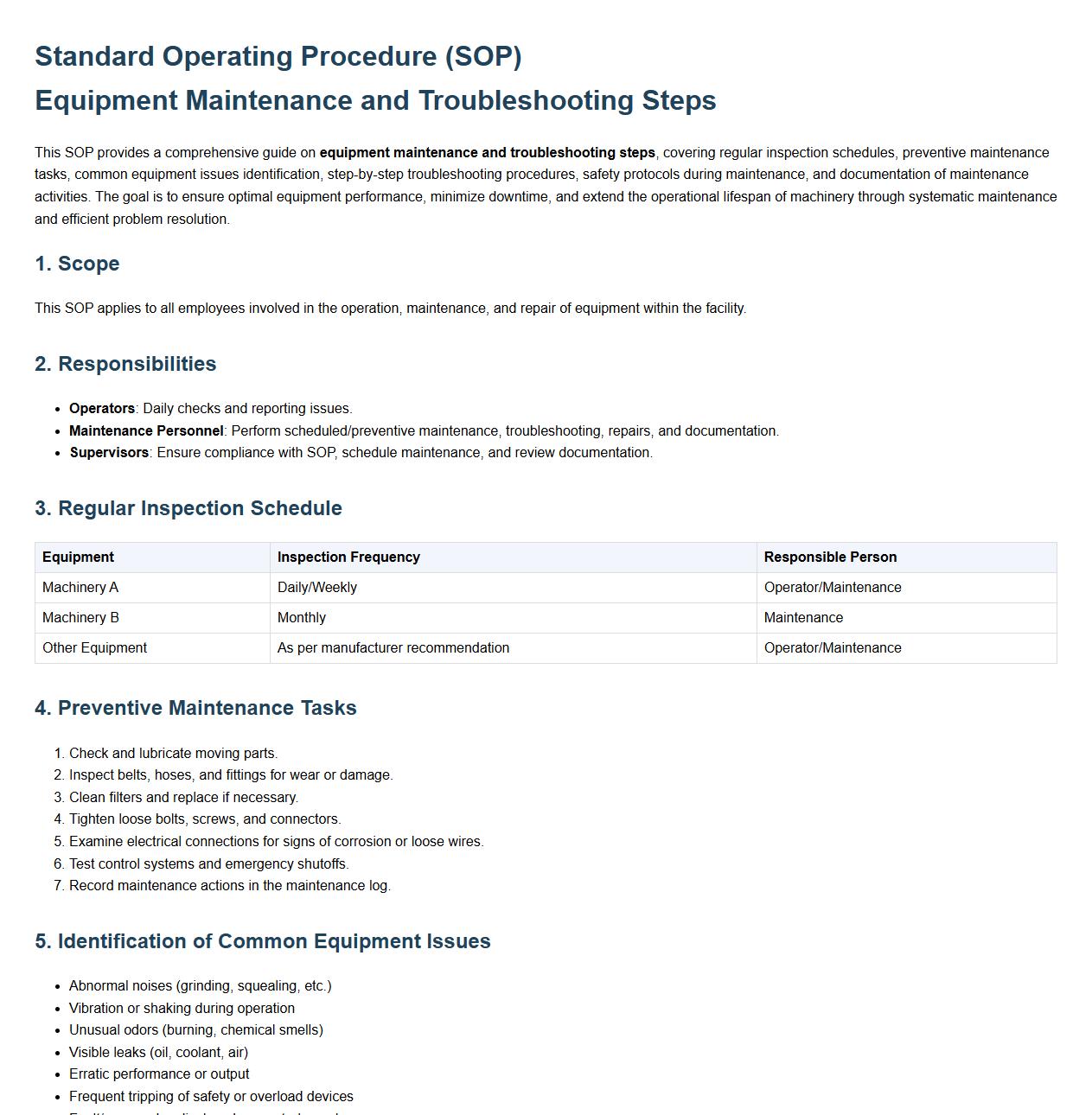

Equipment maintenance and troubleshooting steps.

This SOP provides a comprehensive guide on equipment maintenance and troubleshooting steps, covering regular inspection schedules, preventive maintenance tasks, common equipment issues identification, step-by-step troubleshooting procedures, safety protocols during maintenance, and documentation of maintenance activities. The goal is to ensure optimal equipment performance, minimize downtime, and extend the operational lifespan of machinery through systematic maintenance and efficient problem resolution.

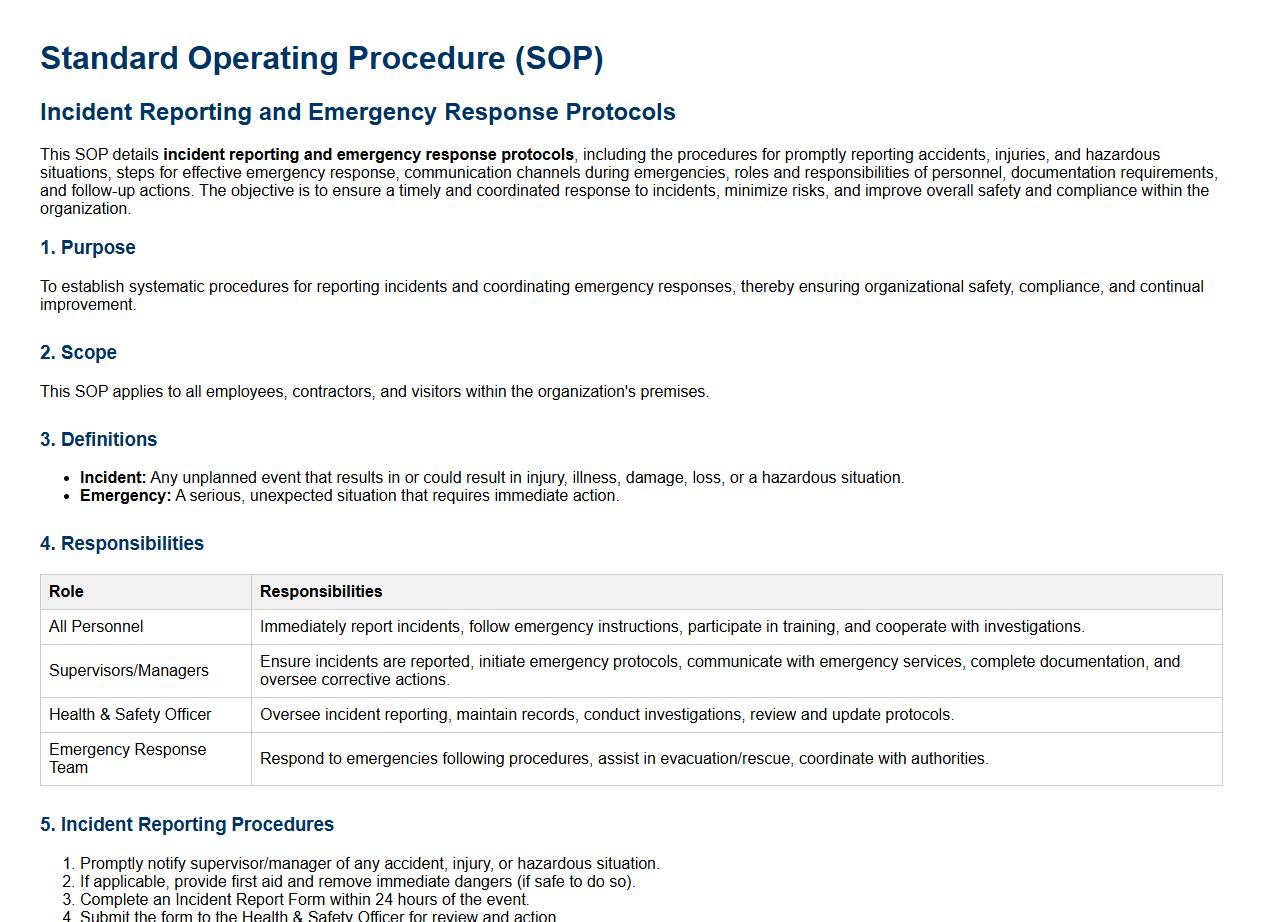

Incident reporting and emergency response protocols.

This SOP details incident reporting and emergency response protocols, including the procedures for promptly reporting accidents, injuries, and hazardous situations, steps for effective emergency response, communication channels during emergencies, roles and responsibilities of personnel, documentation requirements, and follow-up actions. The objective is to ensure a timely and coordinated response to incidents, minimize risks, and improve overall safety and compliance within the organization.

What are the primary steps outlined in the SOP for handling customer orders in the fast food service?

The SOP emphasizes the importance of precise order taking through clear communication with customers. Orders must be entered quickly and accurately into the system to ensure efficiency. Finally, the preparation and delivery of the order are conducted with a focus on timeliness and quality assurance.

How does the SOP address hygiene and sanitation protocols for food preparation areas?

The SOP mandates regular cleaning and sanitizing of all food preparation surfaces before, during, and after shifts. Staff are required to follow strict handwashing procedures to prevent contamination. Additionally, the use of gloves and hairnets is enforced to maintain a hygienic environment.

What procedures does the SOP specify for managing peak service hours and high customer volume?

During peak hours, the SOP outlines the deployment of additional staff to ensure smooth workflow and reduce wait times. It also recommends prioritizing tasks with clear communication and coordination among team members for maximum efficiency. The use of pre-preparation techniques is encouraged to handle the increase in order volume.

How does the SOP guide the process of food storage and inventory control?

The SOP requires strict adherence to proper storage temperatures and labeling of all food items to ensure freshness and safety. Regular inventory checks are scheduled to track stock levels and minimize waste. The FIFO (First In, First Out) method is implemented to rotate stock efficiently.

What are the SOP's instructions for resolving customer complaints and service recovery?

The SOP directs staff to respond promptly and empathetically to customer complaints, aiming to resolve issues effectively. Documentation of complaints is essential to identify patterns and improve service. When necessary, appropriate compensation or corrective actions are offered to ensure complete customer satisfaction.