A SOP Template for Food Inventory Management ensures consistent procedures for tracking, storing, and rotating food supplies to minimize waste and maintain quality. It outlines step-by-step instructions for inventory checks, recording stock levels, and handling expired products. Following this template helps streamline operations and ensures compliance with food safety standards.

Food receiving and inspection procedures.

This SOP details the food receiving and inspection procedures to ensure all incoming food products meet safety, quality, and regulatory standards. It covers the steps for verifying delivery documentation, inspecting packaging integrity, checking temperature controls, assessing product quality and freshness, identifying potential contaminants or damages, and recording inspection findings. The goal is to prevent contamination, ensure compliance with food safety regulations, and maintain product consistency from delivery to storage.

Proper storage and organization methods.

This SOP details proper storage and organization methods to maximize space efficiency, ensure easy accessibility, maintain inventory accuracy, and promote a safe working environment. It covers guidelines for categorizing items, labeling systems, optimal shelving and container use, regular inventory checks, and cleanliness standards to prevent damage and enhance overall operational workflow.

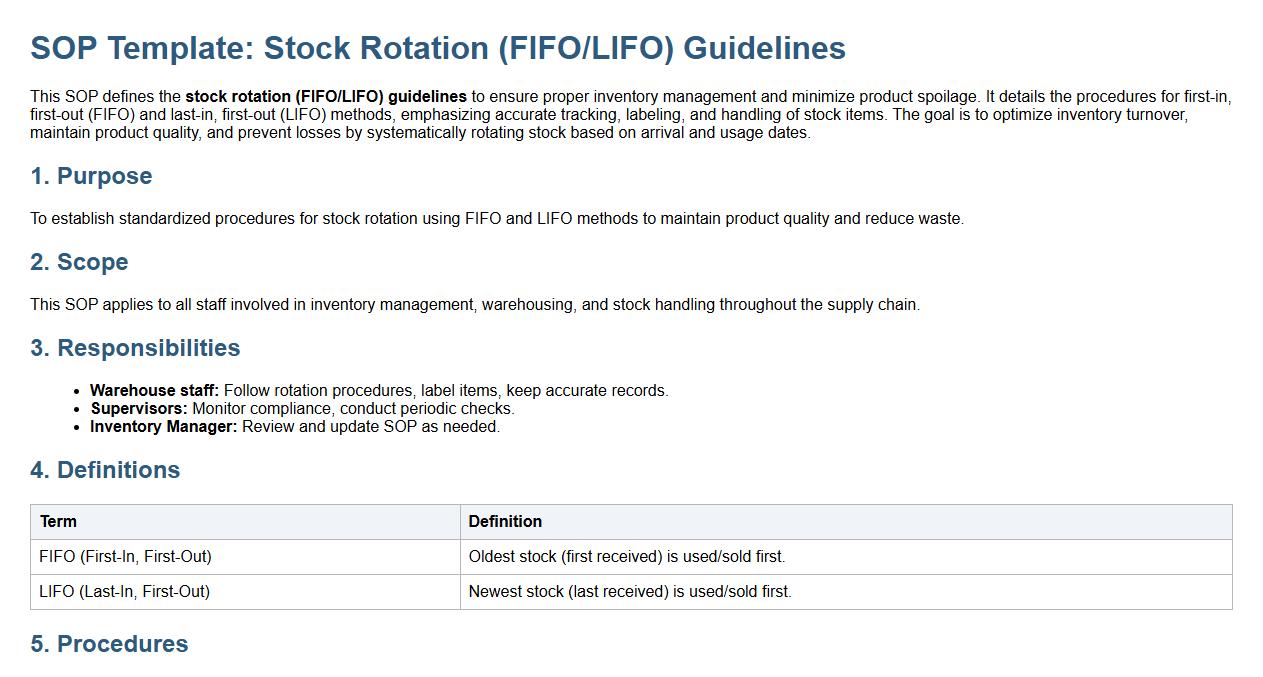

Stock rotation (FIFO/LIFO) guidelines.

This SOP defines the stock rotation (FIFO/LIFO) guidelines to ensure proper inventory management and minimize product spoilage. It details the procedures for first-in, first-out (FIFO) and last-in, first-out (LIFO) methods, emphasizing accurate tracking, labeling, and handling of stock items. The goal is to optimize inventory turnover, maintain product quality, and prevent losses by systematically rotating stock based on arrival and usage dates.

Temperature control and monitoring protocols.

This SOP details the temperature control and monitoring protocols vital for maintaining optimal environmental conditions. It covers procedures for accurate temperature measurement, equipment calibration, monitoring schedules, setting temperature thresholds, and responding to deviations. The objective is to ensure product quality, safety, and compliance with regulatory standards by implementing consistent and effective temperature management practices.

Inventory tracking and documentation process.

This SOP establishes the inventory tracking and documentation process, detailing accurate recording, monitoring, and management of stock levels. It includes procedures for item identification, data entry, regular audits, discrepancy resolution, and reporting to ensure efficient inventory control and minimize loss. The goal is to maintain up-to-date inventory records, support operational planning, and optimize resource allocation through systematic documentation and tracking.

Procedures for damaged or expired goods handling.

This SOP details the procedures for damaged or expired goods handling, encompassing the identification, segregation, documentation, and proper disposal or return of such products. It ensures compliance with safety and quality standards, minimizes inventory discrepancies, and prevents the distribution of unsuitable goods. The process includes employee responsibilities, reporting mechanisms, and regulatory adherence to maintain product integrity and protect consumer health.

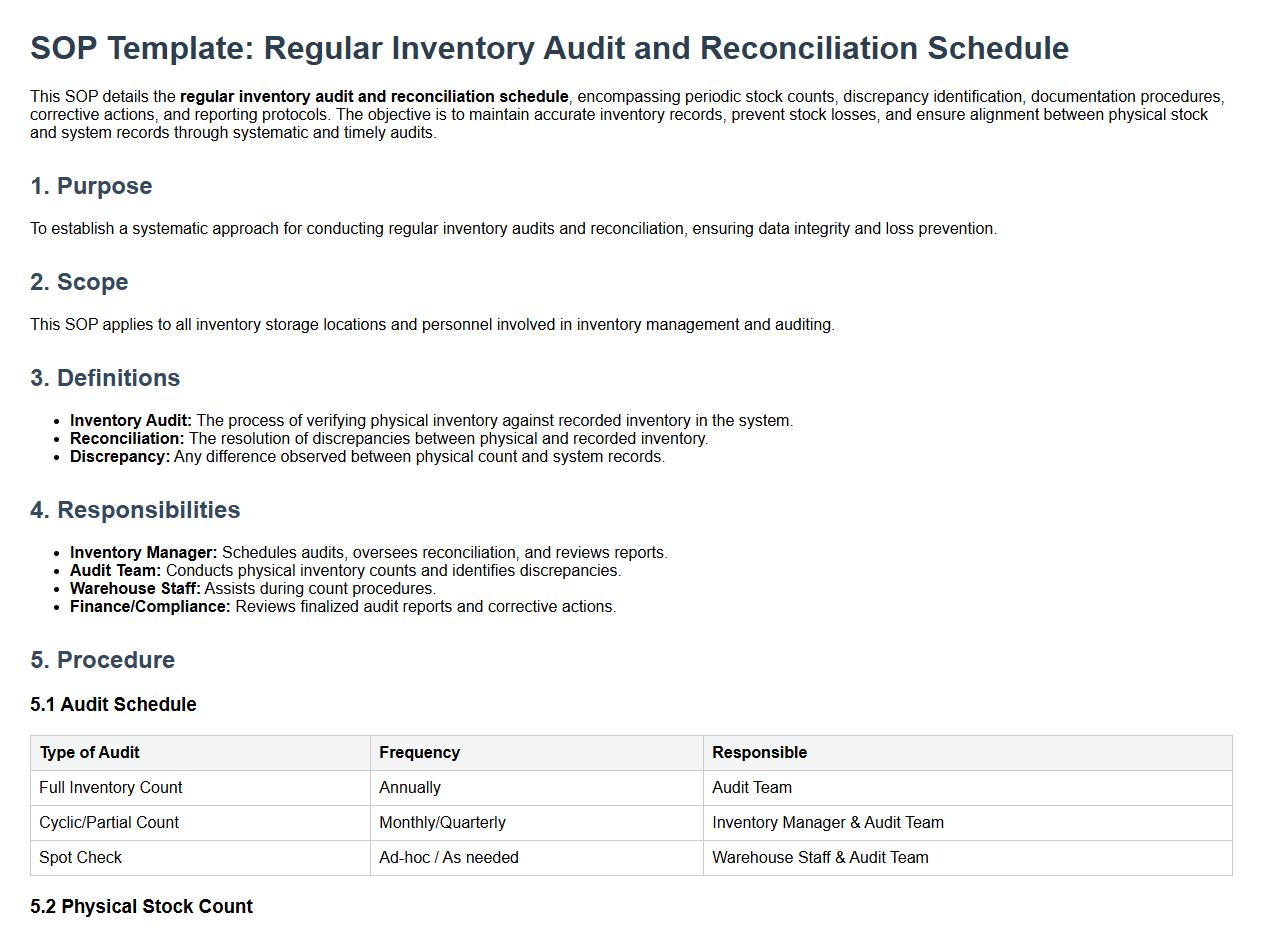

Regular inventory audit and reconciliation schedule.

This SOP details the regular inventory audit and reconciliation schedule, encompassing periodic stock counts, discrepancy identification, documentation procedures, corrective actions, and reporting protocols. The objective is to maintain accurate inventory records, prevent stock losses, and ensure alignment between physical stock and system records through systematic and timely audits.

Contamination prevention and food safety standards.

This SOP details contamination prevention and food safety standards, covering hygiene protocols, cross-contamination controls, proper food handling procedures, cleaning and sanitization requirements, temperature control measures, pest management, employee training, and monitoring and documentation processes. The objective is to maintain high food quality and safety, ensuring compliance with regulatory standards and protecting consumer health by preventing contamination throughout the food production and handling chain.

Issuing and requisitioning inventory practices.

This SOP details the issuing and requisitioning inventory practices to ensure accurate tracking and management of inventory items. It covers procedures for requesting inventory, verifying stock levels, authorizing requisitions, issuing materials, recording transactions, and maintaining inventory control to prevent shortages, overstock, and discrepancies. The objective is to streamline inventory flow, improve accountability, and support operational efficiency.

Cleaning and sanitation requirements for storage areas.

This SOP details the cleaning and sanitation requirements for storage areas, emphasizing proper cleaning techniques, frequency of sanitation, approved cleaning agents, and waste disposal procedures. It aims to maintain hygienic storage conditions, prevent contamination, and ensure compliance with health and safety standards to protect stored products and personnel.

What is the primary objective of the Food Inventory Management SOP?

The primary objective of the Food Inventory Management SOP is to maintain accurate and up-to-date records of all food stock. It aims to minimize waste and reduce the risk of spoilage through systematic tracking. Ensuring food safety and regulatory compliance is also a fundamental goal of the SOP.

Which procedures are outlined for receiving and inspecting food items?

The SOP requires a thorough inspection of all incoming food items to verify quality and quantity against purchase orders. Temperature checks and packaging condition assessments are integral to the receiving process. Any discrepancies or damages must be documented immediately for corrective action.

How does the SOP define the process for recording inventory counts and discrepancies?

Inventory counts must be recorded accurately using standardized forms or digital tools as specified by the SOP. Any discrepancies, such as missing or excess items, should be noted and investigated promptly. The process includes regular audits to ensure consistent inventory accuracy.

What methods are established for storing food items to ensure safety and quality?

The SOP mandates storing food items at specified temperatures and in designated storage areas to prevent contamination. Proper labeling and rotation based on the first-in, first-out (FIFO) principle are required to maintain freshness. Storage conditions are monitored regularly to uphold quality standards.

What are the documented protocols for handling expired or damaged food inventory?

Expired or damaged food items must be segregated immediately upon identification to prevent cross-contamination. The SOP outlines a clear process for documenting and disposing of such items safely and in compliance with health regulations. Regular review of inventory helps in early detection and proper management of unsuitable stock.