A SOP Template for Food Storage provides a standardized framework to ensure proper handling, organization, and preservation of food items. This template outlines critical procedures such as temperature control, labeling, and rotation to maintain food safety and quality. Following these guidelines helps minimize contamination risks and extends the shelf life of stored products.

Temperature and humidity control monitoring.

This SOP establishes guidelines for temperature and humidity control monitoring, detailing the procedures for accurately measuring and regulating environmental conditions to ensure optimal storage and operational efficiency. It covers the use of monitoring equipment, data recording, maintenance of control systems, and corrective actions to maintain specified temperature and humidity levels, thereby preserving product quality and ensuring compliance with regulatory standards.

Receiving and inspection of food items.

This SOP details the receiving and inspection of food items, including guidelines for verifying delivery accuracy, checking the condition and quality of food products, ensuring proper temperature control during transport, identifying signs of contamination or damage, documenting discrepancies or defects, and establishing protocols for acceptance or rejection of shipments. The objective is to maintain food safety, prevent contamination, and ensure that only high-quality ingredients enter the production or storage areas.

Proper food segregation and storage organization.

This SOP details proper food segregation and storage organization, focusing on techniques to prevent cross-contamination, maintain food quality, and ensure compliance with health standards. It covers the classification of food types, designated storage areas, temperature control requirements, labeling protocols, and routine monitoring practices to promote safe, efficient, and hygienic food handling throughout the storage process.

First-In-First-Out (FIFO) inventory management.

This SOP details the First-In-First-Out (FIFO) inventory management process, ensuring that the oldest stock is used or sold before newer inventory. It covers procedures for organizing inventory, tracking product expiration dates, regular stock rotation, minimizing waste, and maintaining accurate records. The goal is to optimize inventory turnover, reduce spoilage, and maintain product quality across storage and distribution operations.

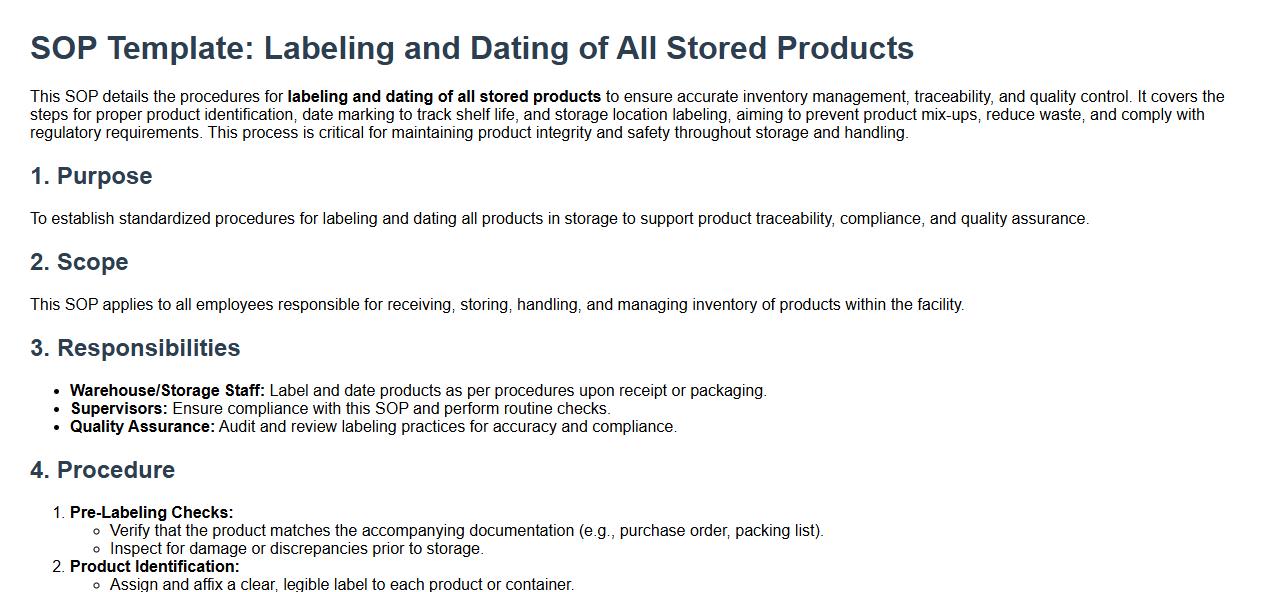

Labeling and dating of all stored products.

This SOP details the procedures for labeling and dating of all stored products to ensure accurate inventory management, traceability, and quality control. It covers the steps for proper product identification, date marking to track shelf life, and storage location labeling, aiming to prevent product mix-ups, reduce waste, and comply with regulatory requirements. This process is critical for maintaining product integrity and safety throughout storage and handling.

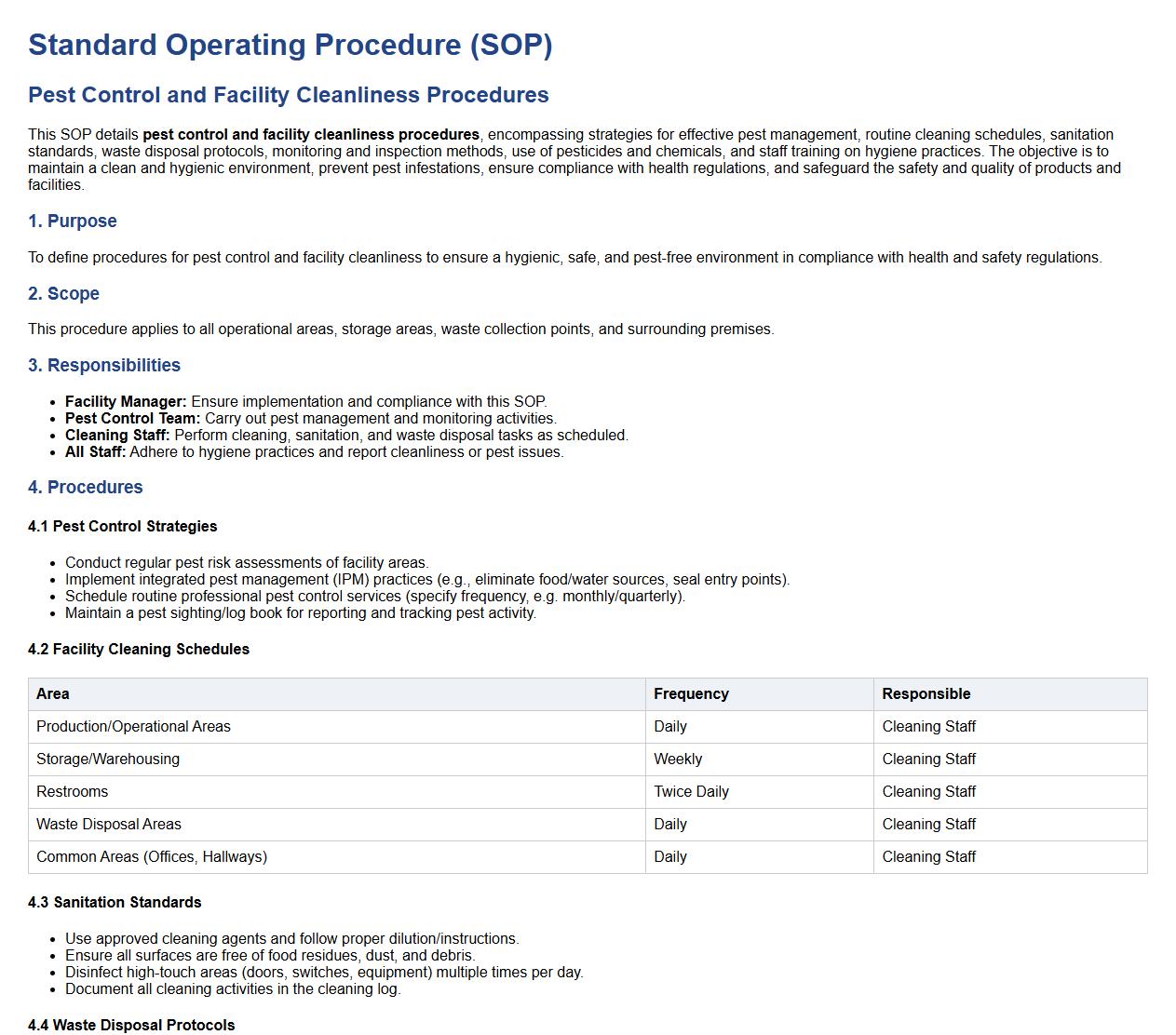

Pest control and facility cleanliness procedures.

This SOP details pest control and facility cleanliness procedures, encompassing strategies for effective pest management, routine cleaning schedules, sanitation standards, waste disposal protocols, monitoring and inspection methods, use of pesticides and chemicals, and staff training on hygiene practices. The objective is to maintain a clean and hygienic environment, prevent pest infestations, ensure compliance with health regulations, and safeguard the safety and quality of products and facilities.

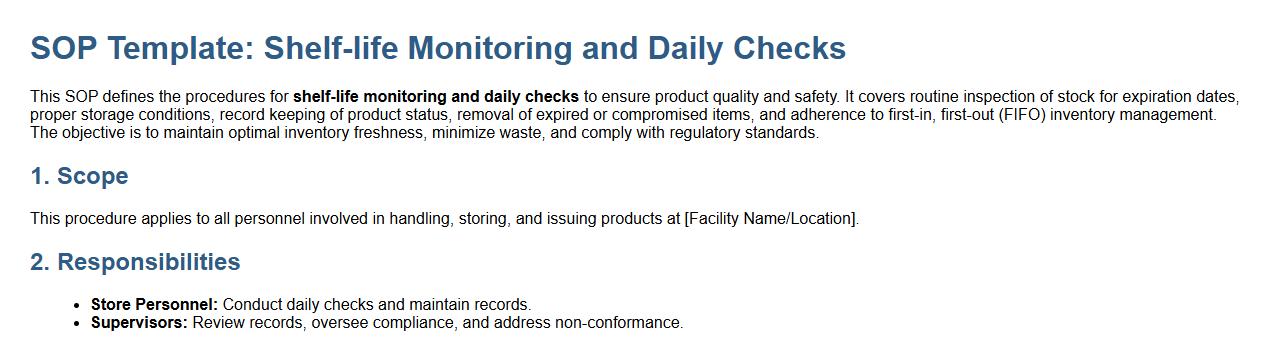

Shelf-life monitoring and daily checks.

This SOP defines the procedures for shelf-life monitoring and daily checks to ensure product quality and safety. It covers routine inspection of stock for expiration dates, proper storage conditions, record keeping of product status, removal of expired or compromised items, and adherence to first-in, first-out (FIFO) inventory management. The objective is to maintain optimal inventory freshness, minimize waste, and comply with regulatory standards.

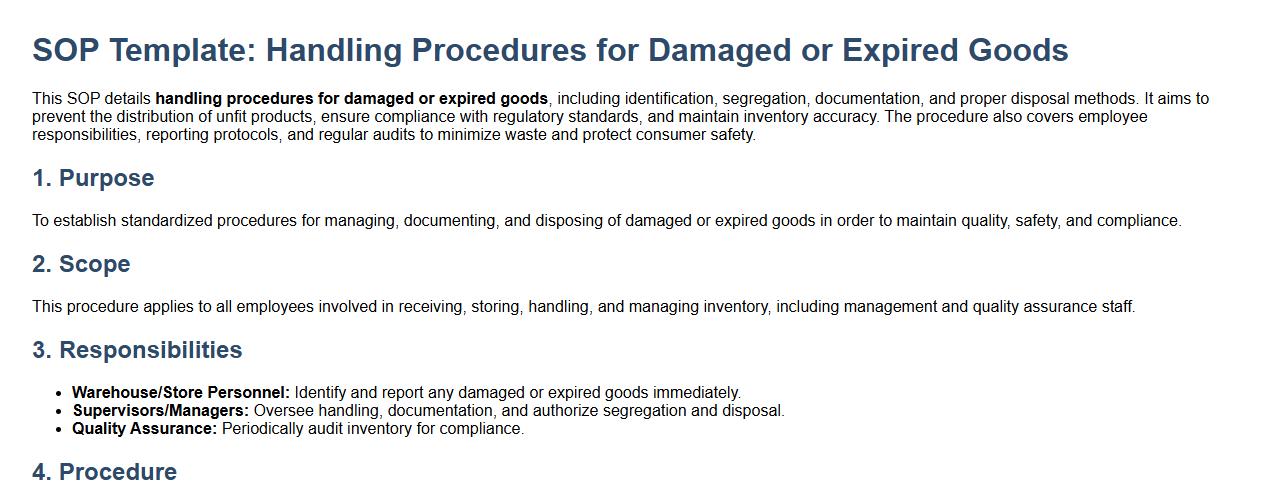

Handling procedures for damaged or expired goods.

This SOP details handling procedures for damaged or expired goods, including identification, segregation, documentation, and proper disposal methods. It aims to prevent the distribution of unfit products, ensure compliance with regulatory standards, and maintain inventory accuracy. The procedure also covers employee responsibilities, reporting protocols, and regular audits to minimize waste and protect consumer safety.

Personal hygiene and food handling rules for staff.

This SOP establishes personal hygiene and food handling rules for staff to ensure food safety and prevent contamination. It covers proper handwashing techniques, appropriate use of protective clothing, guidelines for handling and storing food, protocols for managing illness and injuries among staff, and procedures for maintaining a clean and sanitary work environment. Adhering to these rules helps protect consumers, maintain product quality, and comply with health regulations.

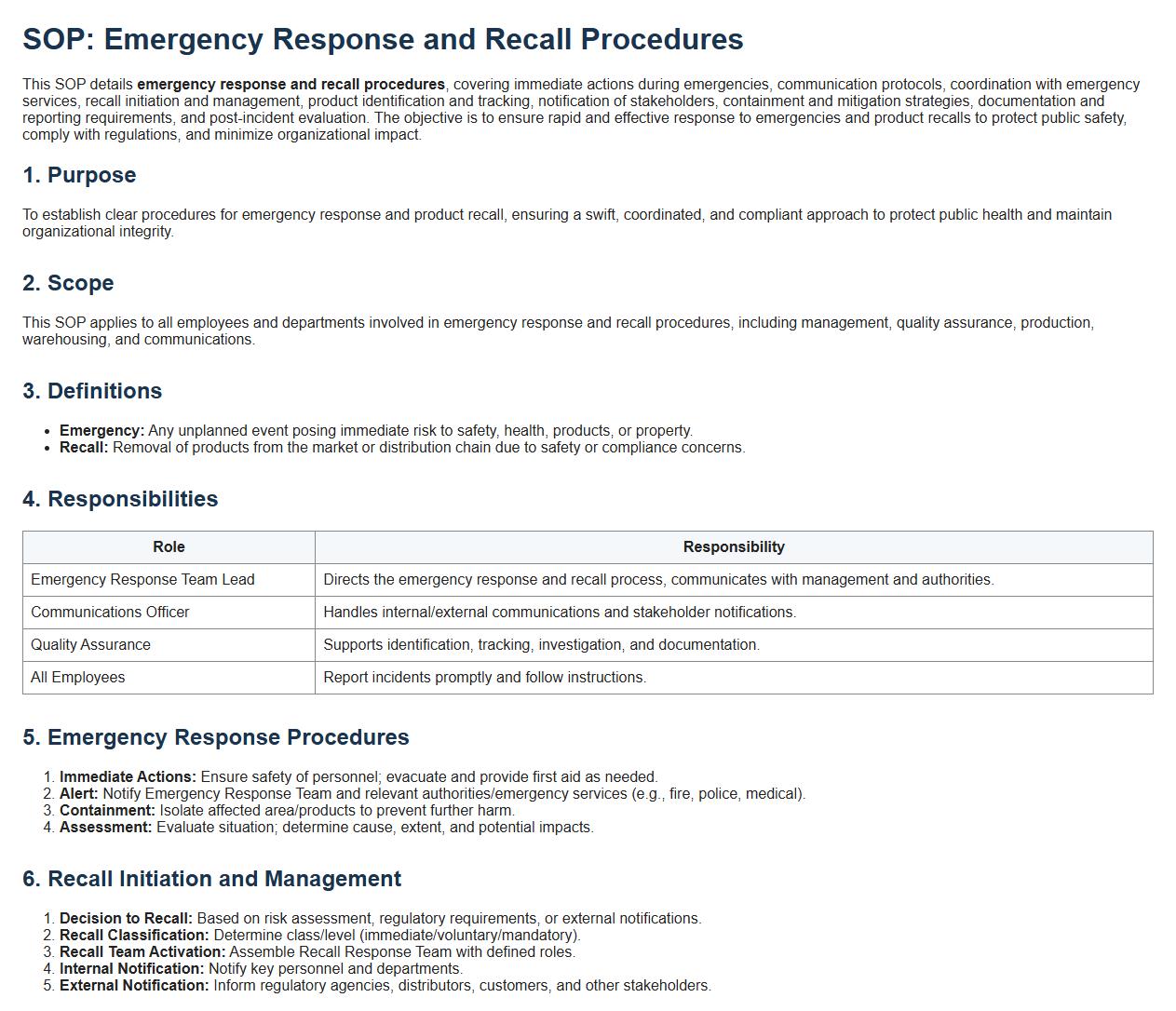

Emergency response and recall procedures.

This SOP details emergency response and recall procedures, covering immediate actions during emergencies, communication protocols, coordination with emergency services, recall initiation and management, product identification and tracking, notification of stakeholders, containment and mitigation strategies, documentation and reporting requirements, and post-incident evaluation. The objective is to ensure rapid and effective response to emergencies and product recalls to protect public safety, comply with regulations, and minimize organizational impact.

Temperature Requirements for Storing Perishable vs Non-Perishable Foods

The SOP mandates strict temperature controls for different food types to ensure safety and quality. Perishable foods must be stored at temperatures below 5degC to inhibit bacterial growth. Non-perishable foods require a dry, cool environment typically between 10degC and 21degC to maintain shelf life.

Organization and Labeling of Stored Food Items

The SOP emphasizes clear organization and systematic labeling for all food items to enable easy identification and traceability. Foods are grouped by category, and labels must include the item name, storage date, and expiration date. Proper organization reduces the risk of cross-contamination and spoilage.

Procedures for Checking and Documenting Food Expiration Dates

Regular monitoring is critical as outlined in the SOP, requiring staff to check expiration dates daily. Any items nearing or past their expiry must be documented and removed promptly. Records of these checks are maintained to ensure compliance and food safety audits.

Hygienic Practices Mandated When Handling and Transferring Food

The SOP mandates wearing gloves, washing hands thoroughly, and using clean tools when handling food to prevent contamination. Food must be transferred using sanitized containers and equipment. These hygiene protocols protect against foodborne illnesses during storage transitions.

Corrective Actions for Spoiled or Contaminated Food

The SOP defines immediate removal and disposal procedures for any spoiled or contaminated food items. Staff must isolate these items and log the incident for quality control purposes. Corrective measures include investigating causes to prevent future occurrences and ensure food safety.