A SOP Template for Food Safety Management provides a standardized framework to ensure compliance with food safety regulations and maintain hygiene standards. This template outlines critical procedures for handling, storing, and preparing food to prevent contamination and ensure consumer safety. It serves as an essential tool for training staff and maintaining consistent quality in food operations.

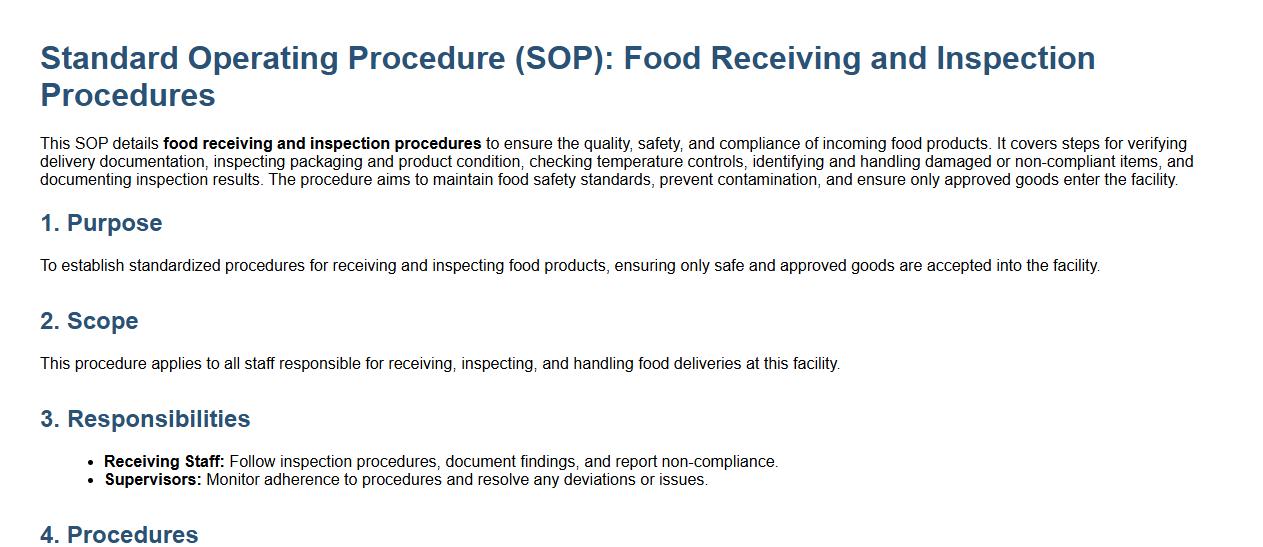

Food receiving and inspection procedures.

This SOP details food receiving and inspection procedures to ensure the quality, safety, and compliance of incoming food products. It covers steps for verifying delivery documentation, inspecting packaging and product condition, checking temperature controls, identifying and handling damaged or non-compliant items, and documenting inspection results. The procedure aims to maintain food safety standards, prevent contamination, and ensure only approved goods enter the facility.

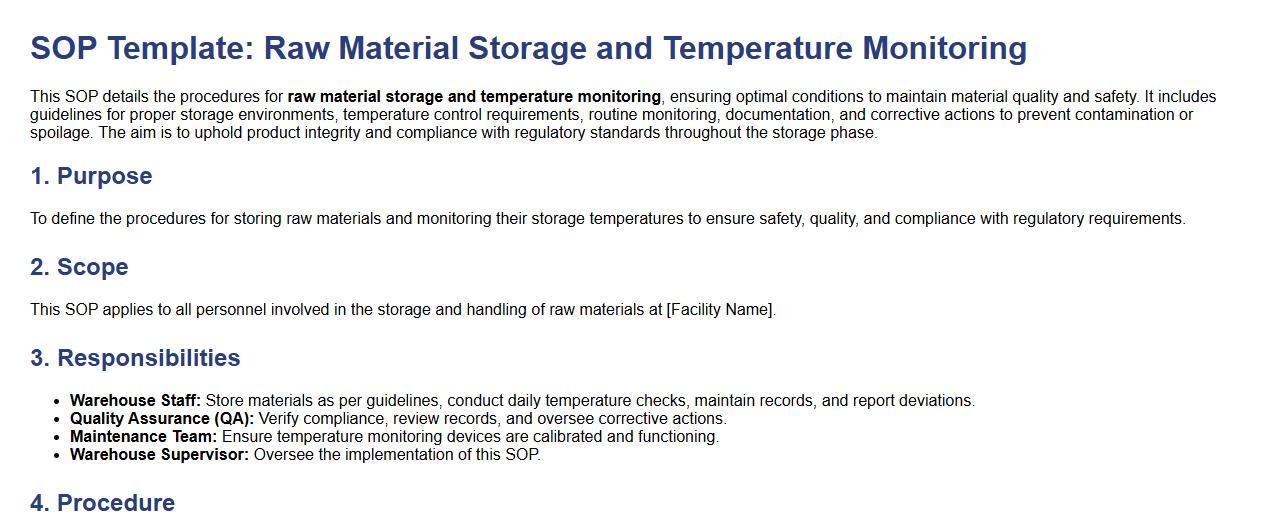

Raw material storage and temperature monitoring.

This SOP details the procedures for raw material storage and temperature monitoring, ensuring optimal conditions to maintain material quality and safety. It includes guidelines for proper storage environments, temperature control requirements, routine monitoring, documentation, and corrective actions to prevent contamination or spoilage. The aim is to uphold product integrity and compliance with regulatory standards throughout the storage phase.

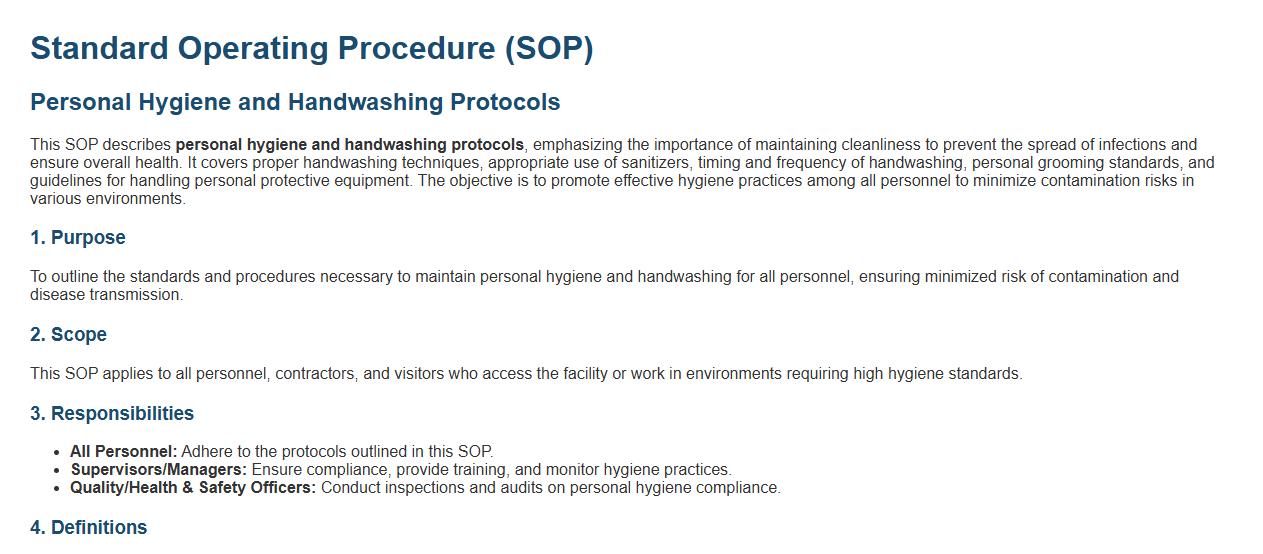

Personal hygiene and handwashing protocols.

This SOP describes personal hygiene and handwashing protocols, emphasizing the importance of maintaining cleanliness to prevent the spread of infections and ensure overall health. It covers proper handwashing techniques, appropriate use of sanitizers, timing and frequency of handwashing, personal grooming standards, and guidelines for handling personal protective equipment. The objective is to promote effective hygiene practices among all personnel to minimize contamination risks in various environments.

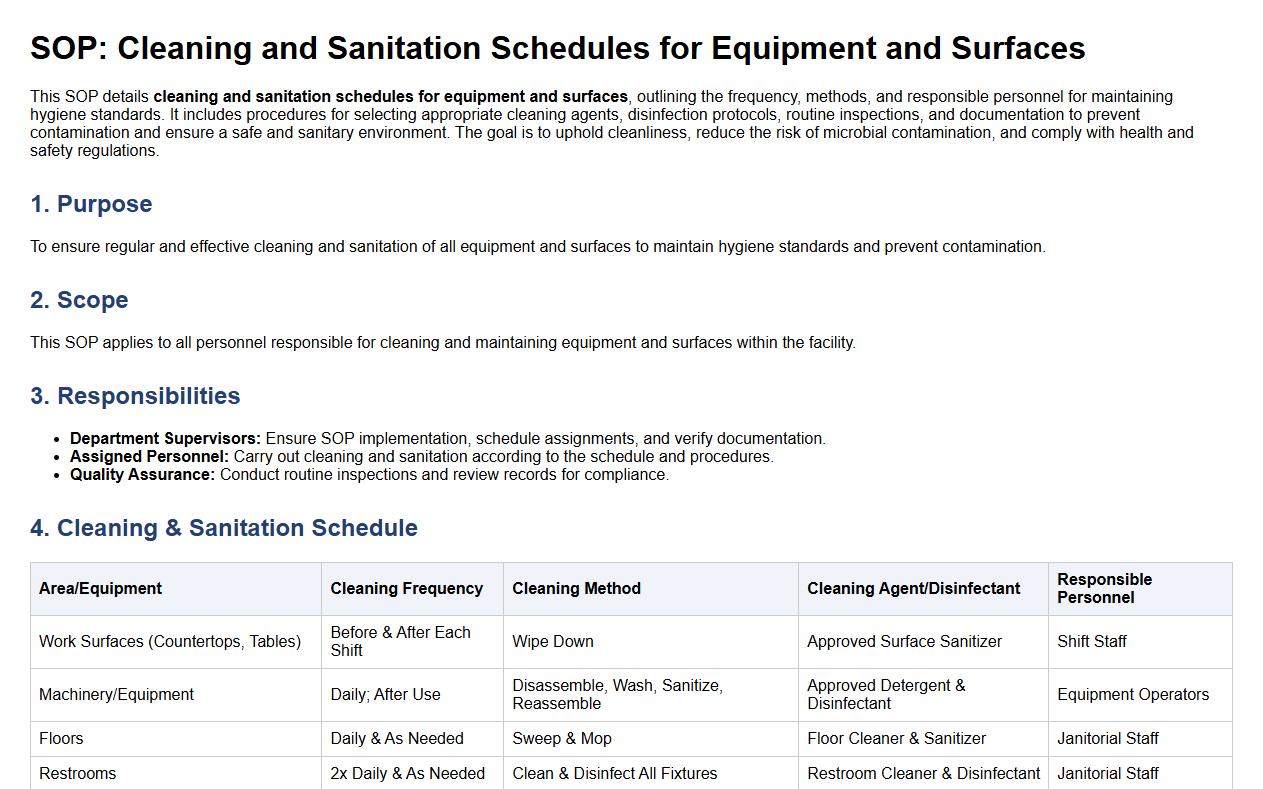

Cleaning and sanitation schedules for equipment and surfaces.

This SOP details cleaning and sanitation schedules for equipment and surfaces, outlining the frequency, methods, and responsible personnel for maintaining hygiene standards. It includes procedures for selecting appropriate cleaning agents, disinfection protocols, routine inspections, and documentation to prevent contamination and ensure a safe and sanitary environment. The goal is to uphold cleanliness, reduce the risk of microbial contamination, and comply with health and safety regulations.

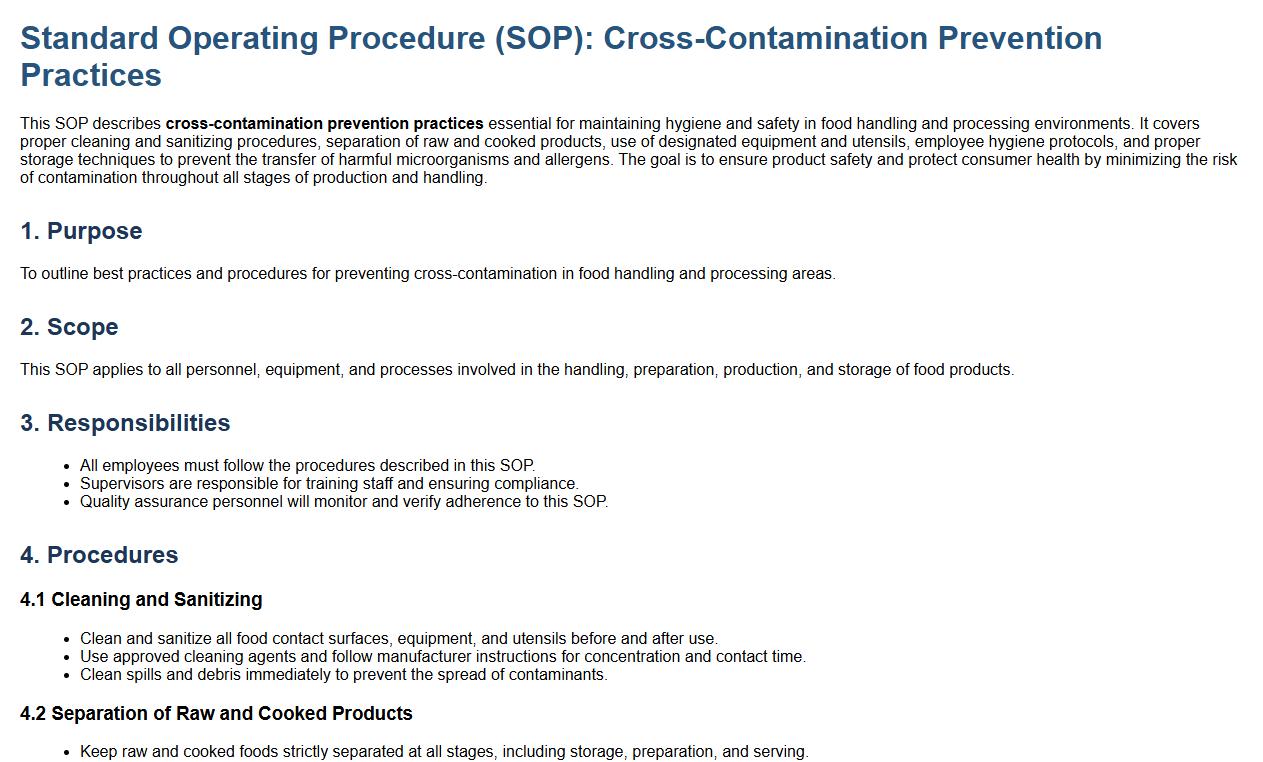

Cross-contamination prevention practices.

This SOP describes cross-contamination prevention practices essential for maintaining hygiene and safety in food handling and processing environments. It covers proper cleaning and sanitizing procedures, separation of raw and cooked products, use of designated equipment and utensils, employee hygiene protocols, and proper storage techniques to prevent the transfer of harmful microorganisms and allergens. The goal is to ensure product safety and protect consumer health by minimizing the risk of contamination throughout all stages of production and handling.

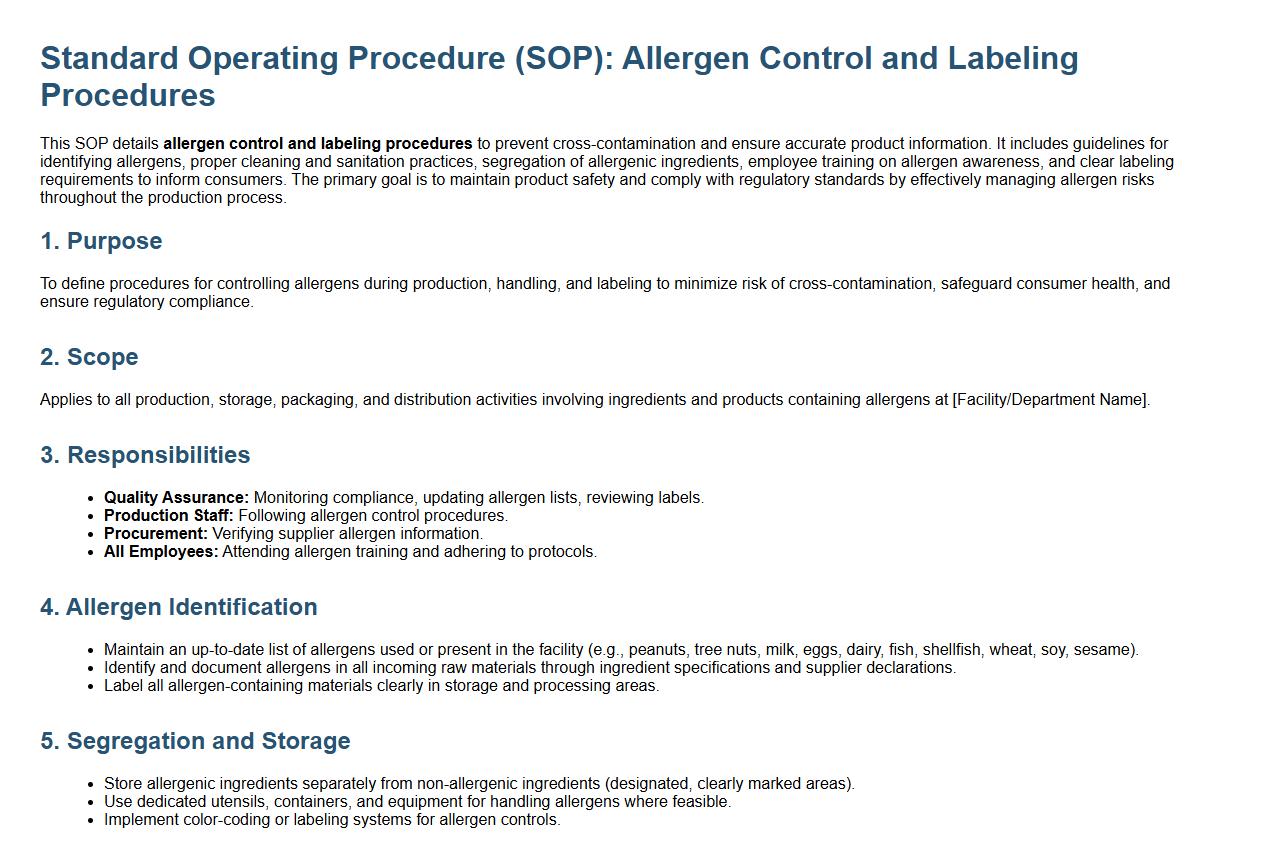

Allergen control and labeling procedures.

This SOP details allergen control and labeling procedures to prevent cross-contamination and ensure accurate product information. It includes guidelines for identifying allergens, proper cleaning and sanitation practices, segregation of allergenic ingredients, employee training on allergen awareness, and clear labeling requirements to inform consumers. The primary goal is to maintain product safety and comply with regulatory standards by effectively managing allergen risks throughout the production process.

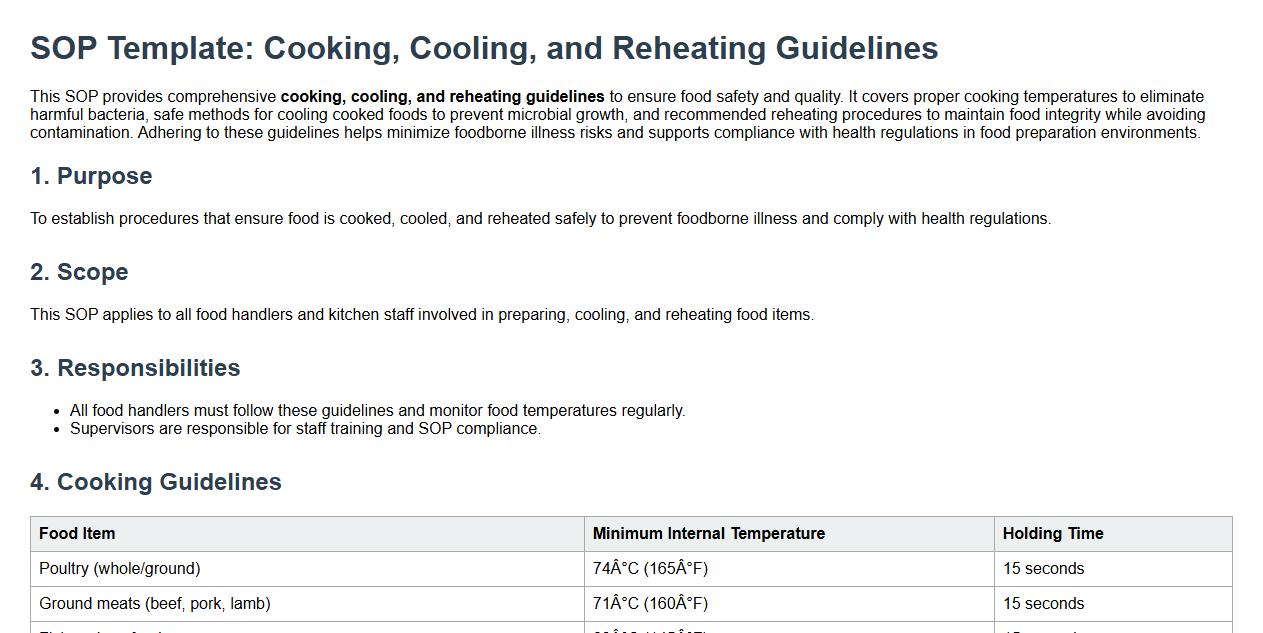

Cooking, cooling, and reheating guidelines.

This SOP provides comprehensive cooking, cooling, and reheating guidelines to ensure food safety and quality. It covers proper cooking temperatures to eliminate harmful bacteria, safe methods for cooling cooked foods to prevent microbial growth, and recommended reheating procedures to maintain food integrity while avoiding contamination. Adhering to these guidelines helps minimize foodborne illness risks and supports compliance with health regulations in food preparation environments.

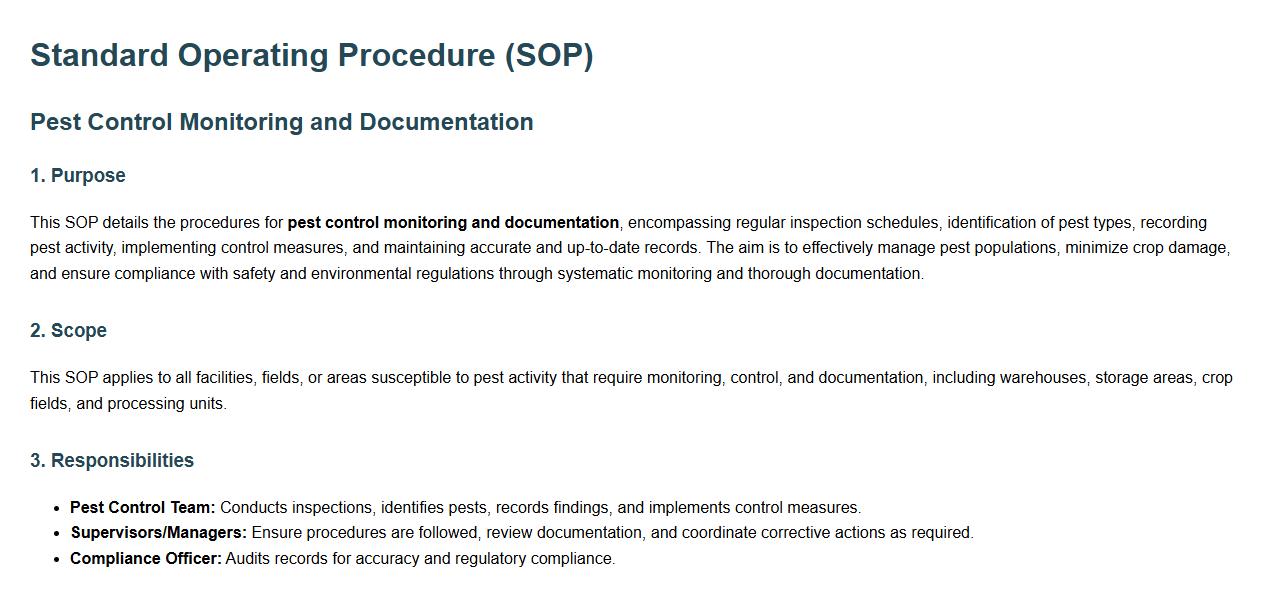

Pest control monitoring and documentation.

This SOP details the procedures for pest control monitoring and documentation, encompassing regular inspection schedules, identification of pest types, recording pest activity, implementing control measures, and maintaining accurate and up-to-date records. The aim is to effectively manage pest populations, minimize crop damage, and ensure compliance with safety and environmental regulations through systematic monitoring and thorough documentation.

Product traceability and recall procedures.

This SOP establishes product traceability and recall procedures to ensure efficient tracking of products through all stages of production, distribution, and sale. It details methods for maintaining accurate records, identifying and isolating affected batches, communicating with stakeholders, and executing timely product recalls to protect consumer safety and comply with regulatory requirements. This procedure aims to minimize risks, prevent further distribution of compromised products, and uphold brand integrity.

Record-keeping and food safety audit processes.

This SOP details the record-keeping and food safety audit processes essential for maintaining compliance with food safety regulations and ensuring product quality. It covers systematic documentation of food safety data, routine audit procedures, corrective actions, and continuous monitoring to uphold hygiene standards and traceability throughout the food production cycle.

What are the critical control points identified in the SOP for Food Safety Management?

The critical control points (CCPs) in the SOP focus on key stages where potential hazards can be prevented, eliminated, or reduced. These typically include receiving, storage, preparation, cooking, cooling, and serving processes. Proper monitoring and verification at each CCP ensure food safety compliance throughout the food handling process.

How does the SOP define procedures for handling and storing perishable food items?

The SOP emphasizes strict temperature control during the handling and storage of perishable foods to prevent bacterial growth. It mandates the use of designated refrigeration units and encourages the first-in, first-out (FIFO) inventory method. Proper packaging and separation from raw items are also highlighted to avoid cross-contamination.

What documentation and recordkeeping requirements are specified in the SOP?

The SOP requires detailed recordkeeping of all food safety activities including temperature logs, cleaning schedules, and monitoring checklists. Documentation must be accurate, up-to-date, and reviewed regularly to ensure compliance. These records support traceability and provide evidence during audits or inspections.

How are hygiene and sanitation practices described in the SOP for staff?

The SOP outlines strict personal hygiene guidelines such as regular handwashing, use of protective clothing, and health monitoring for staff. It also defines routine sanitation procedures for equipment, surfaces, and utensils to maintain a clean environment. Training and supervision of staff hygiene practices are key components to uphold food safety standards.

What corrective actions are outlined in the SOP in case of food safety non-compliance?

In case of non-compliance, the SOP specifies immediate corrective actions such as discarding affected food, re-cleaning contaminated areas, and retraining personnel. It mandates investigation into root causes to prevent recurrence and documentation of all corrective steps taken. These actions ensure continuous improvement and protect consumer health.