A SOP template for restaurant inventory management streamlines the process of tracking and controlling food and supplies, ensuring accuracy and reducing waste. It outlines standardized steps for receiving, storing, and auditing stock, helping staff maintain consistent quality and cost-efficiency. Implementing this template enhances organization and supports timely reordering to avoid shortages.

Inventory receiving and inspection procedures.

This SOP details inventory receiving and inspection procedures, covering the systematic process for receiving goods, verifying shipment accuracy, performing quality inspections, documenting discrepancies, and ensuring proper storage of inventory. The aim is to maintain accurate inventory records, prevent stock issues, and ensure that all received items meet company standards for quantity and quality.

Proper storage and organization guidelines.

This SOP provides detailed proper storage and organization guidelines to ensure efficient use of space, maintain safety standards, and facilitate easy access to materials and equipment. It covers categorizing items, labeling, shelving techniques, inventory management, and regular maintenance practices aimed at optimizing storage areas and preventing clutter, damage, or accidents.

Daily inventory tracking and updating.

This SOP details the process for daily inventory tracking and updating, including accurate recording of stock levels, monitoring product usage, identifying discrepancies, and ensuring timely data entry. The goal is to maintain up-to-date inventory records to optimize stock management, reduce errors, prevent shortages, and support efficient operational workflows.

Par stock and reorder level monitoring.

This SOP details the procedures for par stock and reorder level monitoring, including the establishment of optimal inventory levels, regular stock assessments, identification of reorder points, timely placement of purchase orders, and accurate record-keeping. The objective is to maintain adequate inventory to prevent stockouts and overstocking, ensuring smooth operations and cost-effective inventory management.

Waste management and spoilage recording.

This SOP details the procedures for waste management and spoilage recording, encompassing the proper segregation, handling, and disposal of waste materials, systematic documentation of spoilage incidents, regular monitoring to minimize waste generation, compliance with environmental regulations, and strategies for sustainable waste reduction. The goal is to maintain a safe and environmentally responsible operation by effectively tracking and managing waste and spoilage throughout the process.

Supplier communication and order placement protocol.

This SOP details the supplier communication and order placement protocol, covering procedures for effective supplier engagement, communication channels, order requisition and approval processes, documentation standards, delivery scheduling, and follow-up actions. Its goal is to streamline procurement activities, ensure timely and accurate order fulfillment, maintain supplier relationships, and optimize inventory management through clear and consistent communication practices.

Inventory reconciliation and discrepancy resolution.

This SOP details the process for inventory reconciliation and discrepancy resolution, including regular inventory audits, identification of discrepancies, investigation procedures, documentation and reporting, corrective actions, and preventive measures. The goal is to maintain accurate inventory records, minimize stock variances, and ensure efficient inventory management across all departments.

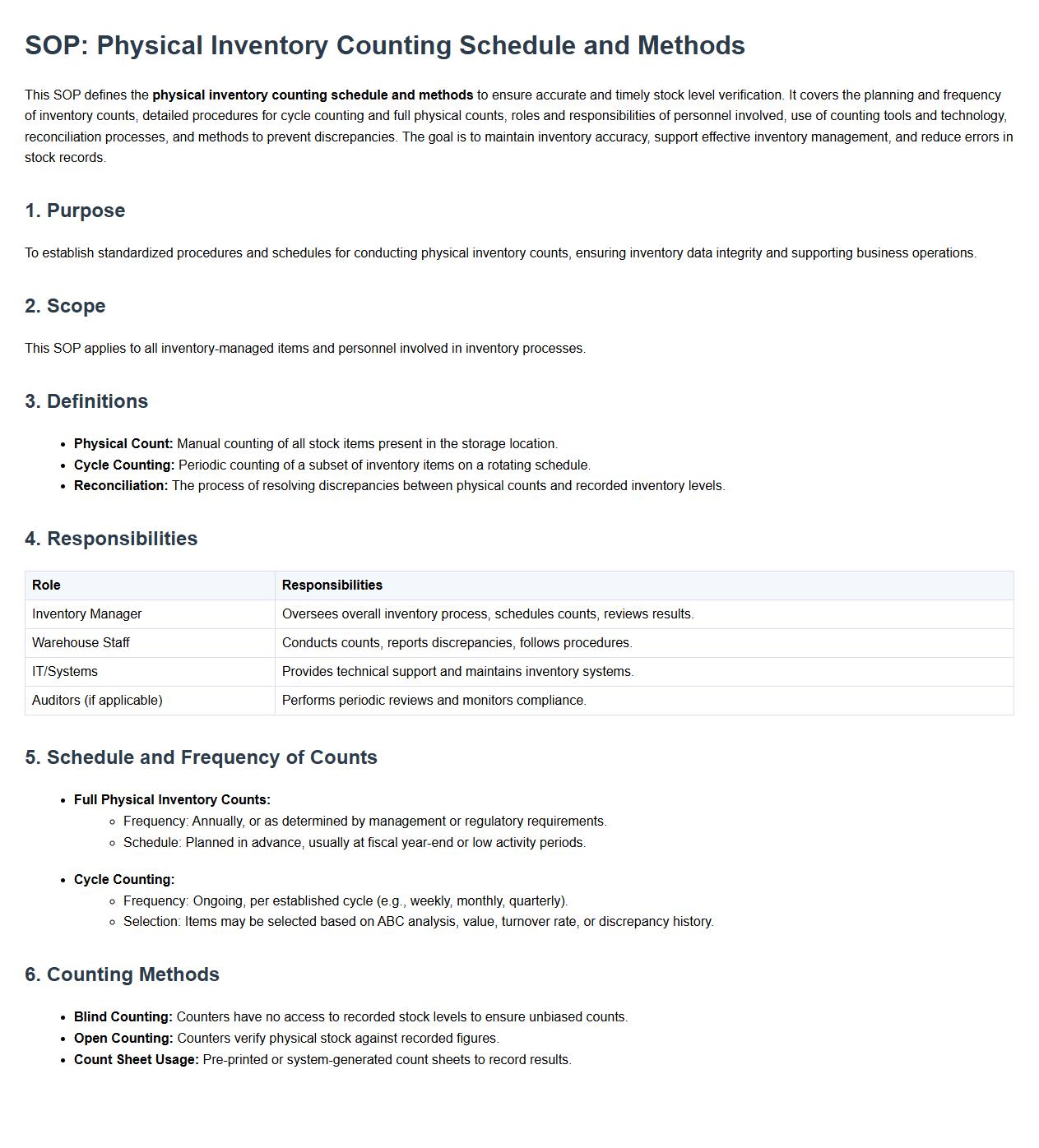

Physical inventory counting schedule and methods.

This SOP defines the physical inventory counting schedule and methods to ensure accurate and timely stock level verification. It covers the planning and frequency of inventory counts, detailed procedures for cycle counting and full physical counts, roles and responsibilities of personnel involved, use of counting tools and technology, reconciliation processes, and methods to prevent discrepancies. The goal is to maintain inventory accuracy, support effective inventory management, and reduce errors in stock records.

Security measures for inventory areas.

This SOP details security measures for inventory areas, encompassing access control protocols, monitoring systems, inventory tracking, employee responsibilities, incident reporting procedures, and periodic security audits. The objective is to safeguard inventory from theft, damage, and unauthorized access, ensuring the integrity and accountability of stock within the facility.

Documentation and reporting standards for inventory movement.

This SOP defines documentation and reporting standards for inventory movement, detailing the procedures for accurate recording, tracking, and reporting of inventory transactions. It includes guidelines for maintaining inventory logs, reconciliation processes, verification of stock levels, timely reporting of discrepancies, and use of standardized forms and digital tools. The objective is to ensure transparency, accuracy, and accountability in inventory management to support operational efficiency and audit compliance.

What procedures ensure accurate tracking and recording of incoming inventory items in the SOP?

The SOP mandates the use of a standardized receiving log to capture all details of incoming inventory items. Each item must be verified against the purchase order for accuracy and quality before acceptance. Additionally, real-time data entry into the inventory management system is required to maintain up-to-date stock records.

How does the SOP define roles and responsibilities for conducting regular inventory checks?

The SOP clearly assigns designated personnel to perform periodic inventory audits, specifying their duties in detail. It emphasizes accountability by requiring supervisors to review and approve audit results. Regular cross-verification by multiple staff members is also recommended to ensure inventory accuracy.

What methods are outlined in the SOP for identifying and managing expired or damaged stock?

The SOP requires routine inspection of inventory items for signs of expiration or damage, using visual checks and barcode scanning. Expired or compromised items must be segregated and labeled accordingly to prevent accidental use. The process also includes documenting these items and arranging for proper disposal or return.

How does the SOP specify reordering processes and minimum stock level guidelines?

The SOP establishes clear minimum stock thresholds that trigger automatic reorder alerts within the inventory system. Reordering procedures include approval protocols and supplier communication guidelines to ensure timely replenishment. This approach helps maintain consistent stock levels and prevent shortages.

What documentation or reporting requirements are mandated by the SOP for inventory discrepancies?

The SOP requires immediate completion of an inventory discrepancy report whenever mismatches are detected. This report must include detailed information on the nature of the discrepancy, affected items, and corrective actions taken. Furthermore, all reports are to be reviewed by management to ensure compliance and mitigate future errors.