A SOP Template for Food Allergen Management provides a structured framework to identify, control, and prevent food allergen contamination in food production processes. It outlines specific procedures for allergen handling, cleaning, labeling, and staff training to ensure consumer safety and regulatory compliance. Implementing this template helps minimize the risk of allergen cross-contact and supports consistent quality control across all operational stages.

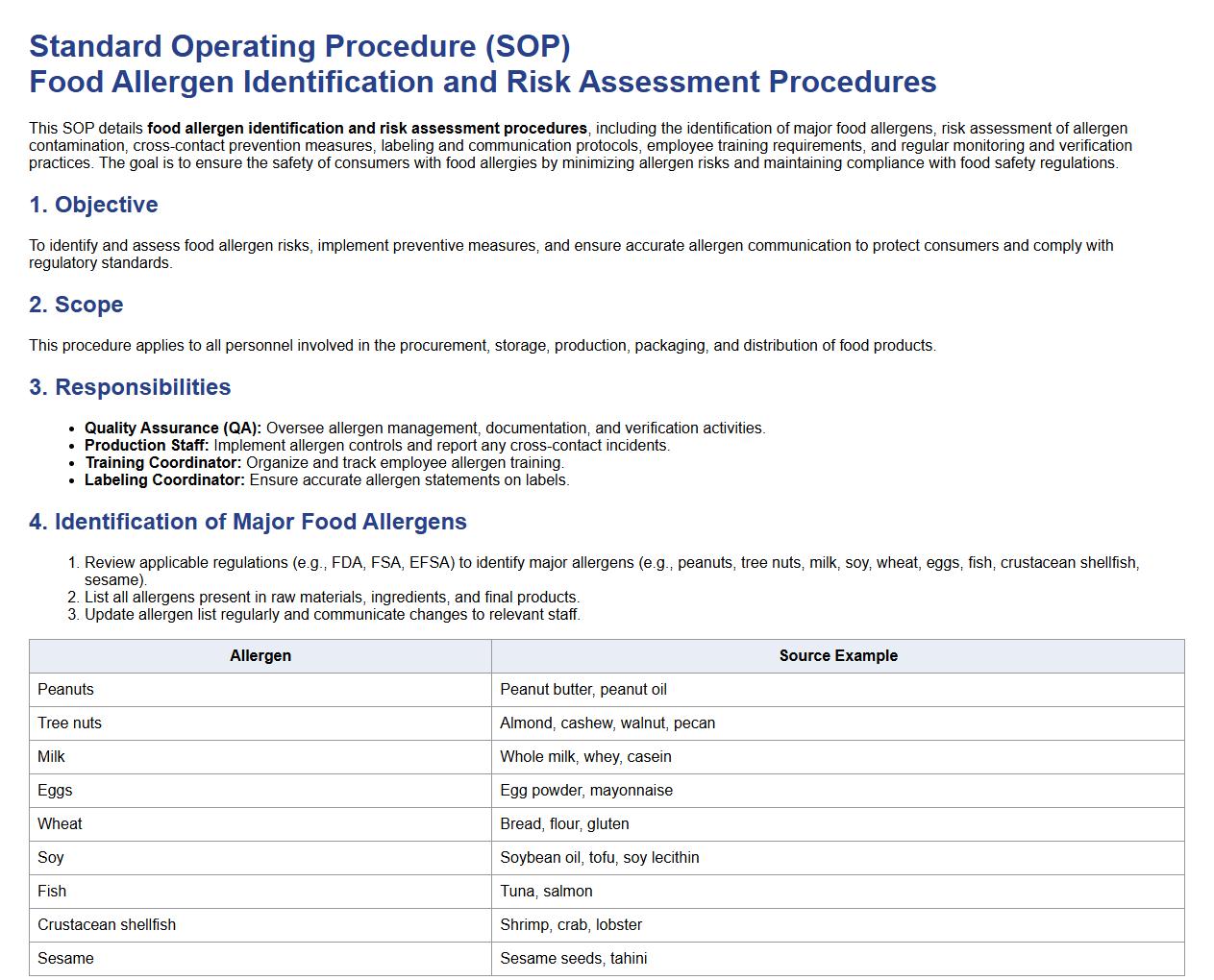

Food allergen identification and risk assessment procedures.

This SOP details food allergen identification and risk assessment procedures, including the identification of major food allergens, risk assessment of allergen contamination, cross-contact prevention measures, labeling and communication protocols, employee training requirements, and regular monitoring and verification practices. The goal is to ensure the safety of consumers with food allergies by minimizing allergen risks and maintaining compliance with food safety regulations.

Raw material and supplier allergen verification protocols.

This SOP details raw material and supplier allergen verification protocols to ensure the safety and compliance of incoming materials. It covers supplier qualification, allergen risk assessment, documentation review, testing procedures, and ongoing monitoring to prevent allergen cross-contamination. The protocol aims to maintain product integrity, protect consumer health, and adhere to regulatory requirements by verifying allergen information accurately before raw material acceptance.

Allergen segregation during receiving, storage, and processing.

This SOP details the procedures for allergen segregation during receiving, storage, and processing to prevent cross-contamination and ensure product safety. It covers identification of allergenic ingredients upon receipt, dedicated storage areas with clear labeling, segregation protocols during handling and processing, cleaning and sanitation practices, employee training on allergen awareness, and documentation requirements. The goal is to protect consumers with allergies by maintaining strict control measures throughout the supply chain and production line.

Cross-contact prevention practices and zoning guidelines.

This SOP details cross-contact prevention practices and zoning guidelines designed to minimize the risk of allergen contamination in food production or handling areas. It includes protocols for identifying allergenic ingredients, establishing and maintaining designated zones for allergen and non-allergen handling, proper cleaning and sanitation procedures, employee training and hygiene practices, and routine monitoring and verification methods. The objective is to ensure product safety and protect consumers with food allergies by preventing inadvertent allergen cross-contact.

Cleaning and sanitation methods for allergen control.

This SOP details effective cleaning and sanitation methods for allergen control, focusing on the systematic removal of allergens from surfaces and equipment to prevent cross-contact. It includes procedures for identifying allergen hazards, selecting appropriate cleaning agents and tools, establishing cleaning schedules, and verifying cleanliness through proper inspection and testing. The goal is to maintain a safe environment for individuals with allergies by minimizing allergen presence and ensuring compliance with food safety standards.

Employee training on allergen awareness and handling.

This SOP details the employee training on allergen awareness and handling, focusing on educating staff about common allergens, proper identification of allergenic ingredients, cross-contact prevention techniques, safe food preparation practices, cleaning and sanitizing protocols, emergency response for allergic reactions, and ongoing training requirements. The goal is to enhance employee knowledge and skills to prevent allergen contamination and protect customers with food allergies, ensuring a safe dining experience for all.

Product labeling and allergen declaration requirements.

This SOP defines the product labeling and allergen declaration requirements, ensuring accurate identification of product contents, compliance with regulatory standards, and clear communication of allergen information to consumers. It covers label design, mandatory information inclusion, allergen identification and declaration, language and format guidelines, label review and approval processes, and procedures for label amendments and updates. The goal is to safeguard consumer health by preventing allergen-related risks and ensuring transparency in product labeling.

Verification and validation of allergen control measures.

This SOP details the verification and validation of allergen control measures, including procedures for monitoring allergen sources, assessing cleaning and sanitation effectiveness, conducting allergen testing and analysis, documenting compliance with allergen control protocols, training staff on allergen management, and implementing corrective actions when deviations are identified. The goal is to ensure that allergen risk is minimized throughout the production process, safeguarding consumer health and maintaining regulatory compliance.

Handling allergen-related incidents and product recalls.

This SOP details the procedures for handling allergen-related incidents and product recalls, including identification and assessment of allergen contamination risks, immediate containment and notification protocols, communication strategies with regulatory bodies and customers, product traceability and recall execution, staff training on allergen management, and documentation and review processes. The goal is to ensure consumer safety and regulatory compliance by effectively managing allergen incidents and minimizing public health risks.

Documentation, monitoring, and record-keeping of allergen management activities.

This SOP details the documentation, monitoring, and record-keeping of allergen management activities, ensuring accurate tracking of allergen control measures, verification of compliance with safety standards, regular review of allergen risks, and maintenance of comprehensive records. The goal is to support effective allergen management, enhance food safety, and enable traceability in case of allergen-related incidents.

Criteria for Identification and Classification of Food Allergens in SOP

The SOP for Food Allergen Management uses scientific and regulatory standards to identify food allergens. It classifies allergens based on their potential to cause adverse allergic reactions in sensitive individuals. This ensures that all high-risk allergens are properly labeled and managed during production.

Procedures for Preventing Cross-Contact of Allergens

The SOP outlines strict cleaning and segregation protocols to prevent cross-contact of allergens. It mandates the use of dedicated equipment or thorough cleaning when switching between allergen-containing and allergen-free products. These preventive measures minimize the risk of allergen contamination in finished products.

Record-Keeping and Documentation Processes

The SOP requires comprehensive documentation of allergen control measures at each stage of production. This includes recording ingredient sourcing, cleaning schedules, and audits to ensure compliance. Maintaining accurate records facilitates traceability and accountability in allergen management.

Staff Training Requirements for Food Allergen Management

Staff must receive regular training on allergen awareness and safe handling practices as specified in the SOP. Training covers identification of allergens, cross-contact risks, and emergency response protocols. This ensures that all personnel are competent in minimizing allergen hazards.

Incident Response and Corrective Actions for Allergen Exposure

The SOP details a clear incident response plan for unintended allergen exposure or contamination. It includes immediate containment, product recall procedures, and root cause analysis. Corrective actions are implemented promptly to prevent recurrence and protect consumer safety.