A SOP Template for Retail Stock Replenishment streamlines the process of maintaining optimal inventory levels by outlining clear procedures for ordering, receiving, and restocking products. This template ensures consistency and efficiency, reducing stockouts and overstock situations. It serves as a crucial guide for retail staff to follow standardized steps that support smooth inventory management and customer satisfaction.

Stock level monitoring and gap analysis procedures.

This SOP describes the stock level monitoring and gap analysis procedures, including methods for regularly tracking inventory levels, identifying discrepancies between actual and desired stock quantities, analyzing causes of stock gaps, and implementing corrective actions. The goal is to maintain optimal stock availability, reduce stockouts and overstock situations, and improve overall inventory management efficiency.

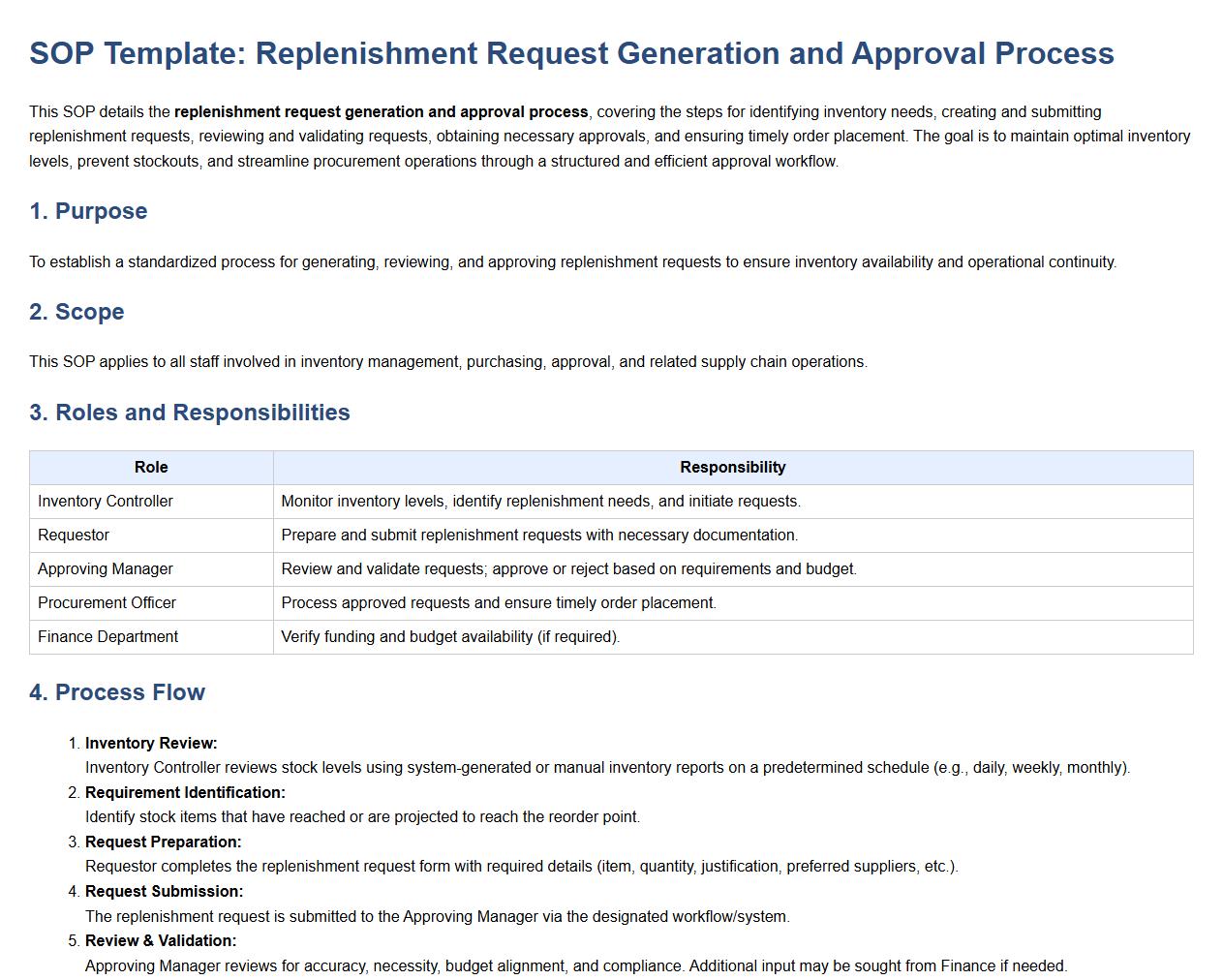

Replenishment request generation and approval process.

This SOP details the replenishment request generation and approval process, covering the steps for identifying inventory needs, creating and submitting replenishment requests, reviewing and validating requests, obtaining necessary approvals, and ensuring timely order placement. The goal is to maintain optimal inventory levels, prevent stockouts, and streamline procurement operations through a structured and efficient approval workflow.

Guidelines for receiving and inspecting deliveries.

This SOP provides guidelines for receiving and inspecting deliveries, covering procedures for verifying shipment accuracy, checking for damage, ensuring compliance with order specifications, documenting discrepancies, and proper handling of received goods. The goal is to maintain quality control, prevent errors, and ensure timely and accurate processing of all incoming deliveries.

Stock rotation and FIFO (First-In-First-Out) practices.

This SOP establishes stock rotation and FIFO (First-In-First-Out) practices to ensure inventory freshness, reduce waste, and optimize stock management. It includes procedures for organizing and managing stock, prioritizing the use of older inventory before newer stock, proper labeling and storage techniques, regular inventory checks, and staff training on FIFO principles. The goal is to maintain product quality, minimize spoilage, and improve operational efficiency through effective stock control.

Shelf and display restocking protocols.

This SOP details shelf and display restocking protocols, encompassing inventory management, product handling, restocking procedures, quality control, safety measures, and presentation standards. Its purpose is to maintain optimal product availability, enhance store aesthetics, ensure customer satisfaction, and promote efficient and safe restocking processes.

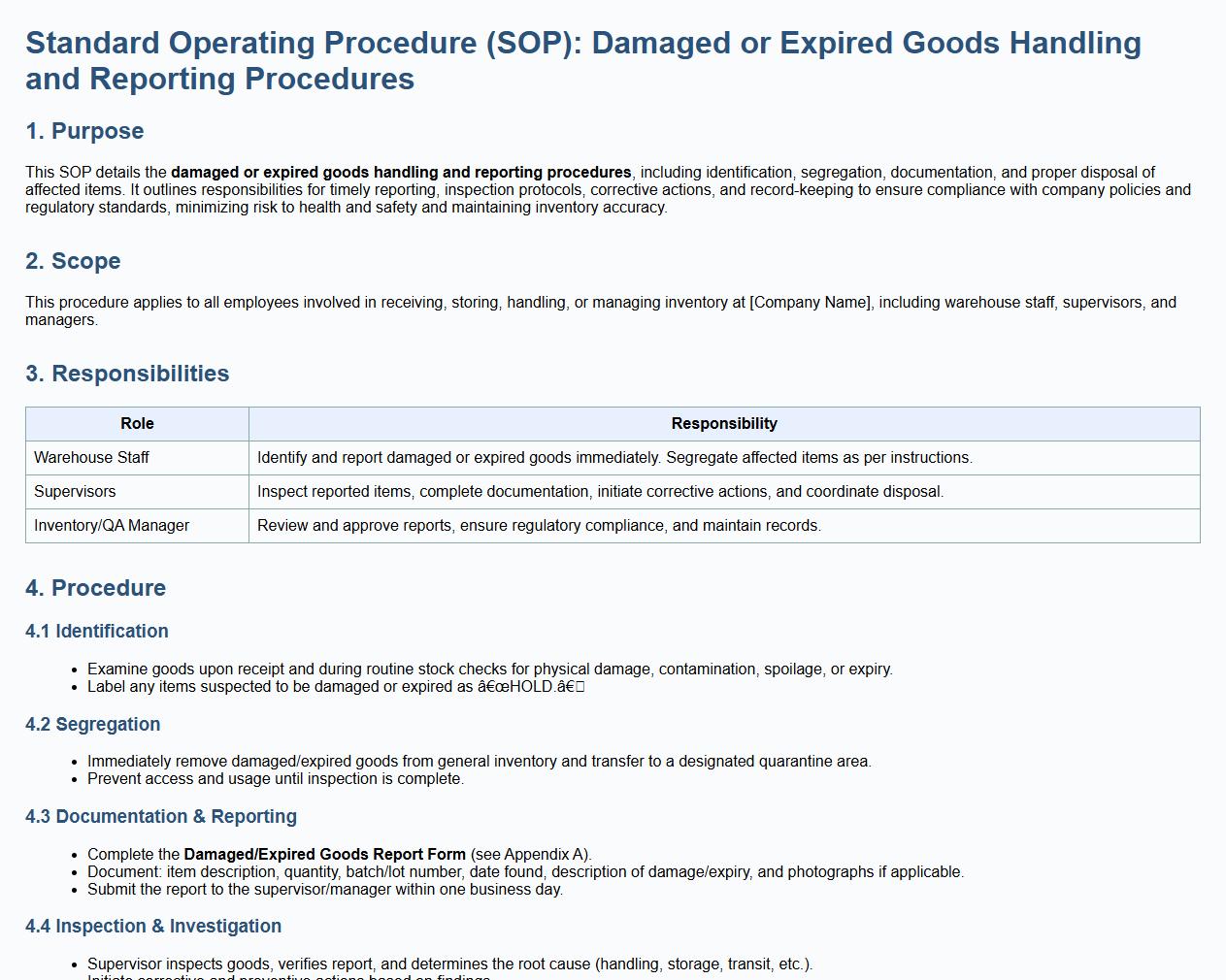

Damaged or expired goods handling and reporting procedures.

This SOP details the damaged or expired goods handling and reporting procedures, including identification, segregation, documentation, and proper disposal of affected items. It outlines responsibilities for timely reporting, inspection protocols, corrective actions, and record-keeping to ensure compliance with company policies and regulatory standards, minimizing risk to health and safety and maintaining inventory accuracy.

Inventory count reconciliation and discrepancy resolution.

This SOP details the process for inventory count reconciliation and discrepancy resolution, including accurate physical counting methods, comparing counts to recorded inventory data, identifying and investigating discrepancies, implementing corrective actions, and maintaining detailed documentation. The goal is to ensure inventory accuracy, prevent stock losses, and improve overall inventory management efficiency.

Communication procedures with suppliers and warehouse.

This SOP details communication procedures with suppliers and warehouse, establishing clear guidelines for effective information exchange regarding order placements, delivery schedules, inventory updates, and issue resolution. It aims to enhance coordination, minimize errors, and ensure timely supply chain operations through standardized communication channels and protocols.

Store cleanliness and safety during replenishment activities.

This SOP ensures store cleanliness and safety during replenishment activities by outlining procedures for maintaining a clean and hazard-free environment while restocking shelves. It covers proper handling and storage of products, cleaning protocols before and after replenishment, use of personal protective equipment, safe stacking techniques, and immediate clean-up of spills or debris. The goal is to protect employees and customers by preventing accidents, contamination, and ensuring a well-organized, safe store environment.

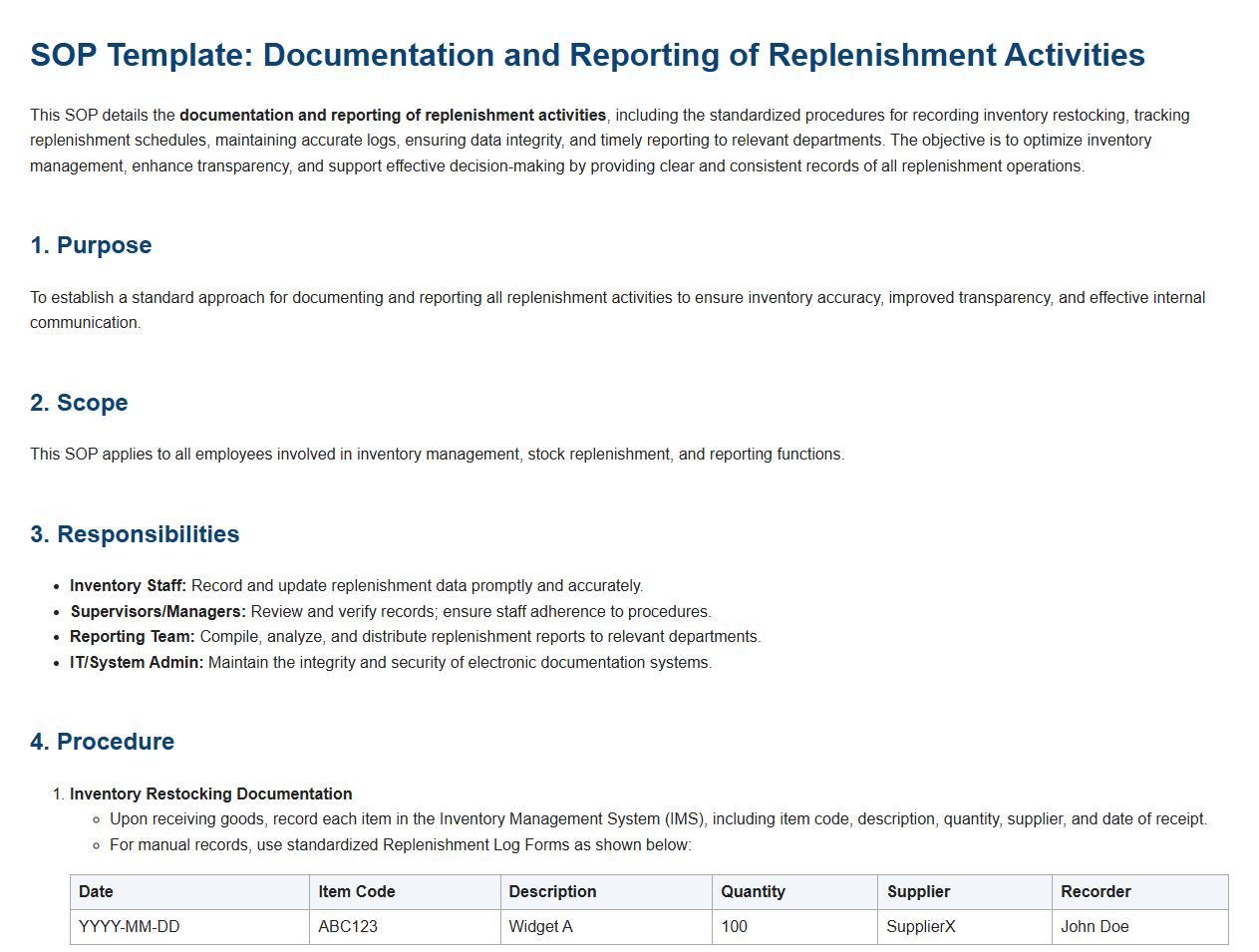

Documentation and reporting of replenishment activities.

This SOP details the documentation and reporting of replenishment activities, including the standardized procedures for recording inventory restocking, tracking replenishment schedules, maintaining accurate logs, ensuring data integrity, and timely reporting to relevant departments. The objective is to optimize inventory management, enhance transparency, and support effective decision-making by providing clear and consistent records of all replenishment operations.

What is the primary objective of the Retail Stock Replenishment SOP?

The primary objective of the Retail Stock Replenishment SOP is to ensure timely and efficient restocking of products to maintain optimal inventory levels. It aims to minimize stockouts and overstock situations by providing clear guidelines for inventory management. Ultimately, this SOP supports continuous product availability to meet customer demand consistently.

Which roles and departments are responsible for initiating and verifying stock replenishment?

The Inventory Management Team and the Store Replenishment Department are primarily responsible for initiating stock replenishment. Additionally, the Purchasing Department verifies replenishment requests to ensure accuracy and feasibility. Cross-department collaboration ensures the replenishment process is both effective and well-monitored.

What criteria trigger the commencement of a stock replenishment cycle according to the SOP?

Stock replenishment cycles are triggered when inventory levels fall below the predefined reorder threshold. Sales velocity, historical data, and seasonal demand forecasts also influence the initiation of replenishment. These criteria help maintain a balance between supply and demand to avoid stock discrepancies.

What standard documentation and systems are required during the replenishment process?

The SOP mandates the use of inventory management software and standardized replenishment forms to document stock movements accurately. Electronic data interchange (EDI) systems are often incorporated for seamless communication between suppliers and retail stores. Proper documentation ensures traceability and accountability throughout the replenishment cycle.

How does the SOP define the escalation procedure for discrepancies or stock shortages during replenishment?

The SOP outlines a clear escalation protocol where discrepancies or stock shortages must be reported immediately to the Retail Manager. If unresolved, issues are escalated further to the Supply Chain Director for prompt resolution. This structured escalation ensures quick corrective actions to maintain supply chain integrity.