A SOP Template for Office Supply Management provides a structured framework to efficiently track, order, and maintain office supplies ensuring minimal disruptions. It outlines specific roles, approval processes, and inventory monitoring techniques to optimize resource use and prevent shortages. This template enhances accountability and streamlines procurement workflows for consistent operational support.

Office supply ordering and requisition procedures.

This SOP details the office supply ordering and requisition procedures, encompassing the process for identifying supply needs, submitting requisition requests, approval workflows, vendor selection and order placement, tracking deliveries, and inventory management. The objective is to ensure timely procurement of necessary office supplies, maintain adequate stock levels, control costs, and streamline the ordering process to support efficient office operations.

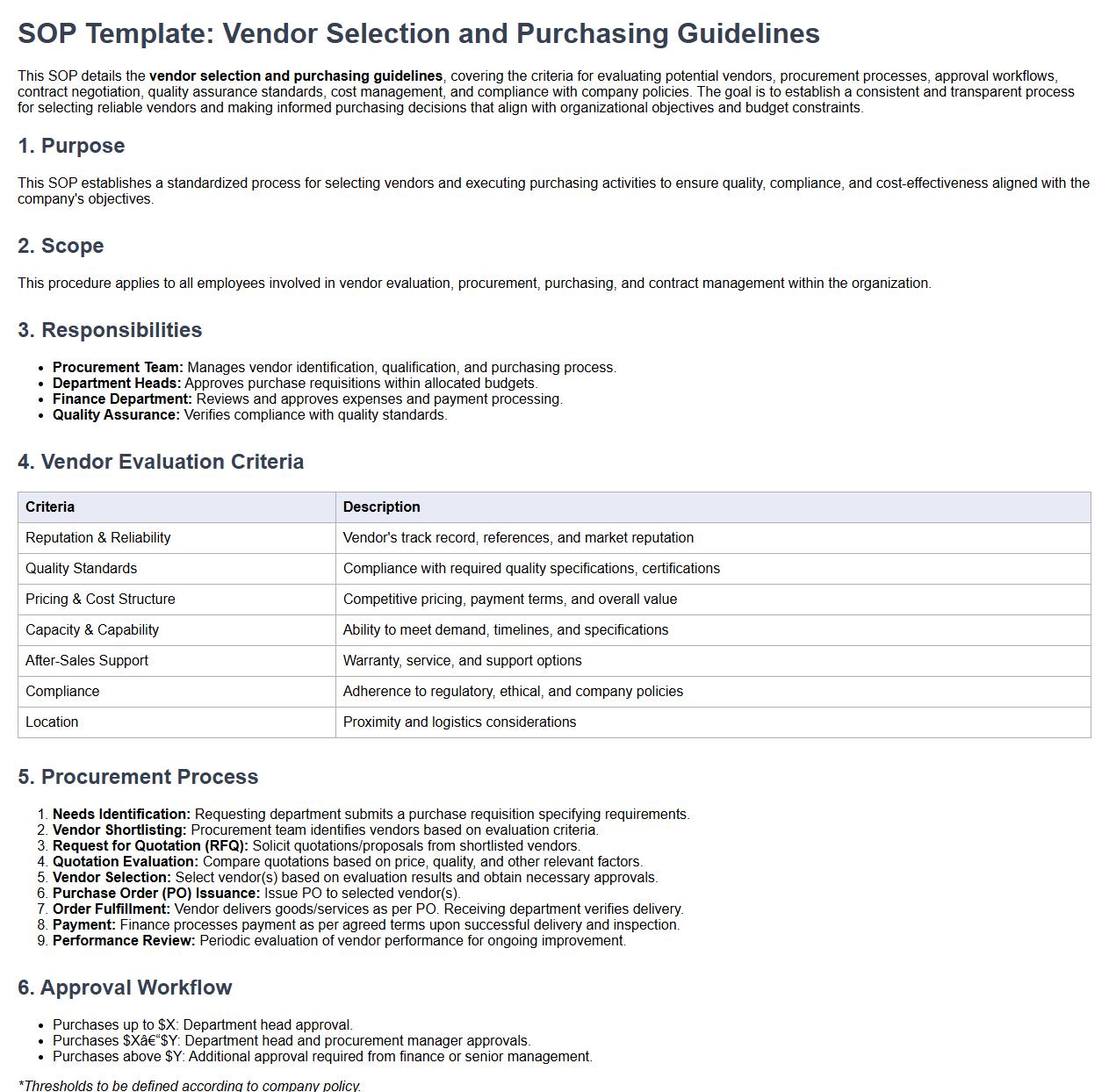

Vendor selection and purchasing guidelines.

This SOP details the vendor selection and purchasing guidelines, covering the criteria for evaluating potential vendors, procurement processes, approval workflows, contract negotiation, quality assurance standards, cost management, and compliance with company policies. The goal is to establish a consistent and transparent process for selecting reliable vendors and making informed purchasing decisions that align with organizational objectives and budget constraints.

Receiving and inspection of office supplies.

This SOP details the receiving and inspection of office supplies, covering procedures for verifying delivered items against purchase orders, checking for damages or discrepancies, proper documentation of received goods, and ensuring that all supplies meet quality standards before distribution. The goal is to maintain accurate inventory records, prevent supply shortages, and ensure that only approved office materials are accepted for use.

Inventory tracking and stock level monitoring.

This SOP establishes inventory tracking and stock level monitoring processes to ensure accurate recording, management, and control of stock levels. It covers procedures for regular stock counts, real-time inventory updates, discrepancy resolution, reorder point determination, and reporting. The goal is to maintain optimal inventory levels, prevent stockouts or overstocking, and support efficient supply chain operations.

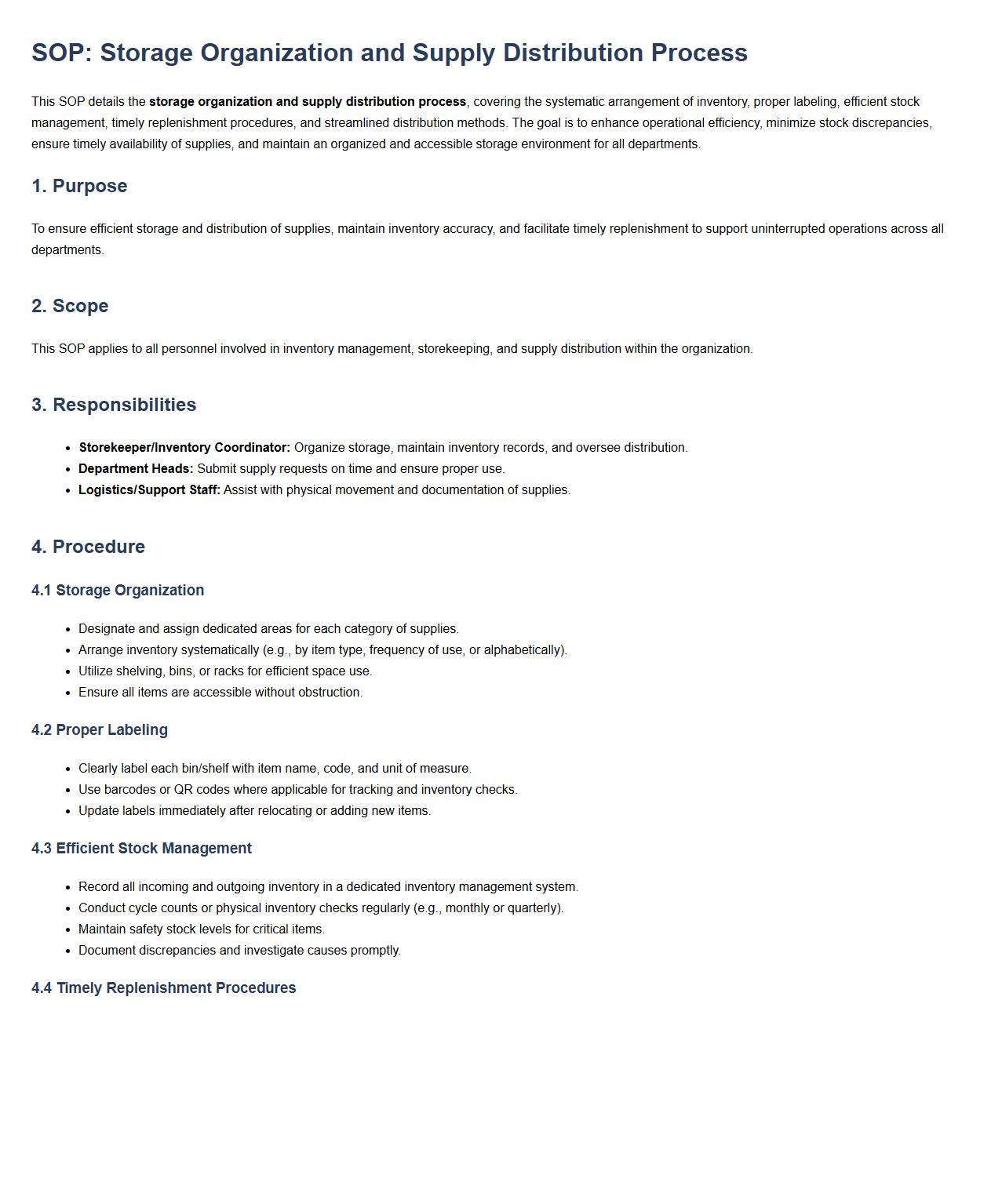

Storage organization and supply distribution process.

This SOP details the storage organization and supply distribution process, covering the systematic arrangement of inventory, proper labeling, efficient stock management, timely replenishment procedures, and streamlined distribution methods. The goal is to enhance operational efficiency, minimize stock discrepancies, ensure timely availability of supplies, and maintain an organized and accessible storage environment for all departments.

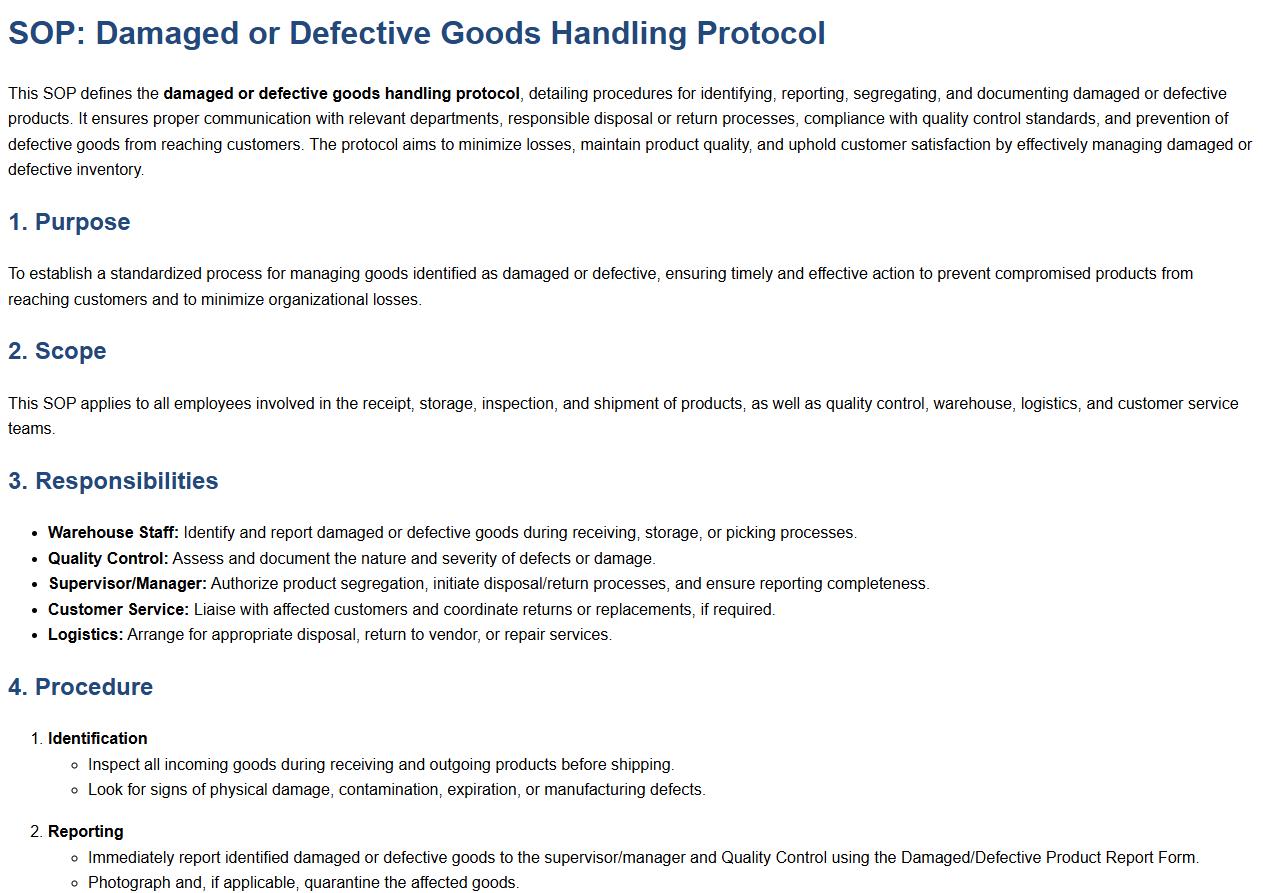

Damaged or defective goods handling protocol.

This SOP defines the damaged or defective goods handling protocol, detailing procedures for identifying, reporting, segregating, and documenting damaged or defective products. It ensures proper communication with relevant departments, responsible disposal or return processes, compliance with quality control standards, and prevention of defective goods from reaching customers. The protocol aims to minimize losses, maintain product quality, and uphold customer satisfaction by effectively managing damaged or defective inventory.

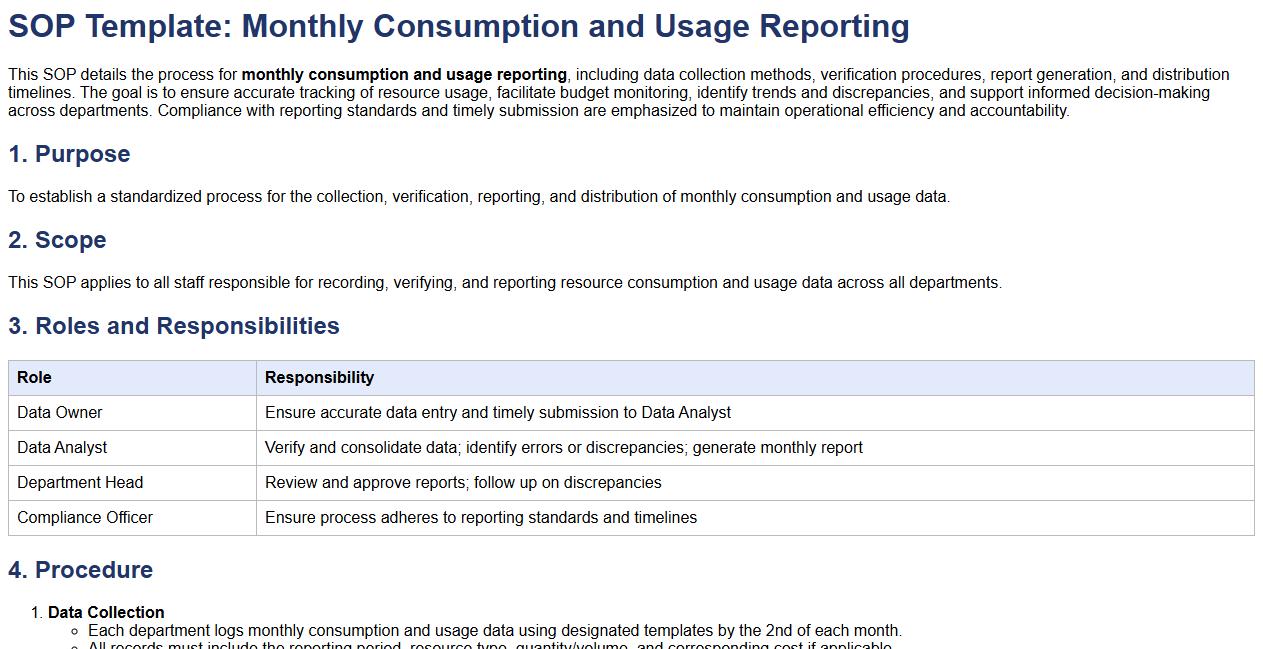

Monthly consumption and usage reporting.

This SOP details the process for monthly consumption and usage reporting, including data collection methods, verification procedures, report generation, and distribution timelines. The goal is to ensure accurate tracking of resource usage, facilitate budget monitoring, identify trends and discrepancies, and support informed decision-making across departments. Compliance with reporting standards and timely submission are emphasized to maintain operational efficiency and accountability.

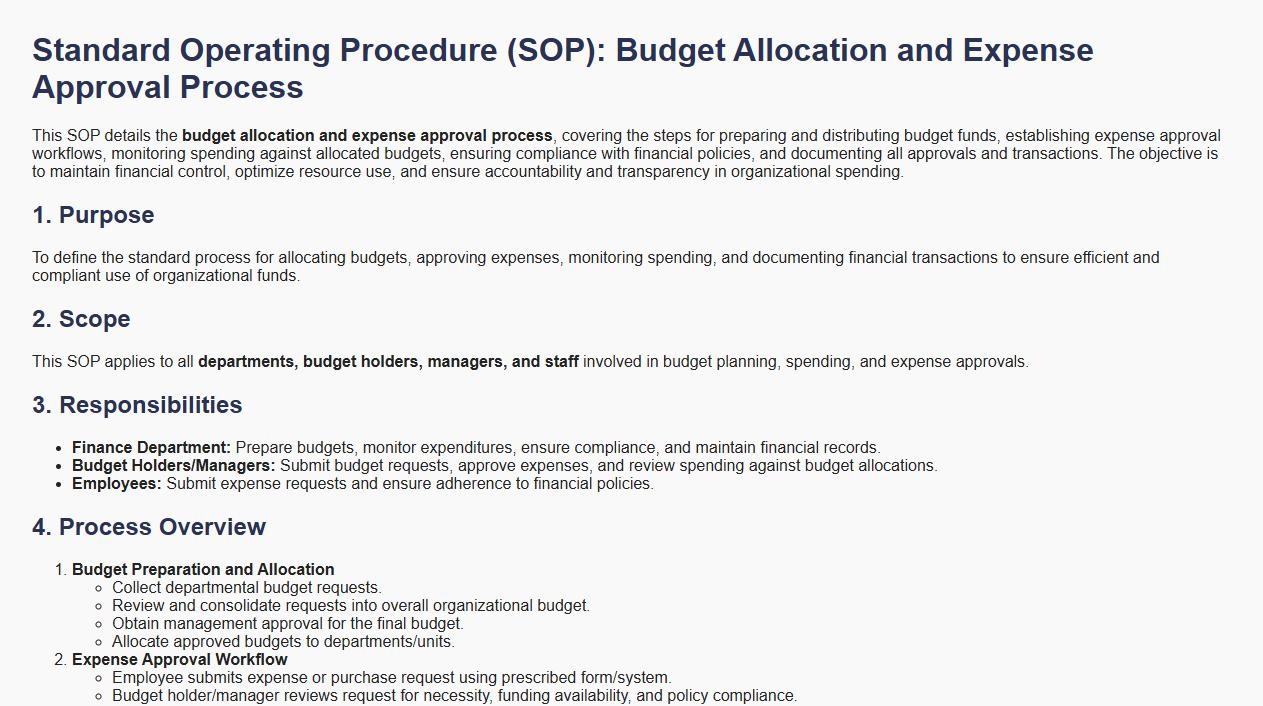

Budget allocation and expense approval process.

This SOP details the budget allocation and expense approval process, covering the steps for preparing and distributing budget funds, establishing expense approval workflows, monitoring spending against allocated budgets, ensuring compliance with financial policies, and documenting all approvals and transactions. The objective is to maintain financial control, optimize resource use, and ensure accountability and transparency in organizational spending.

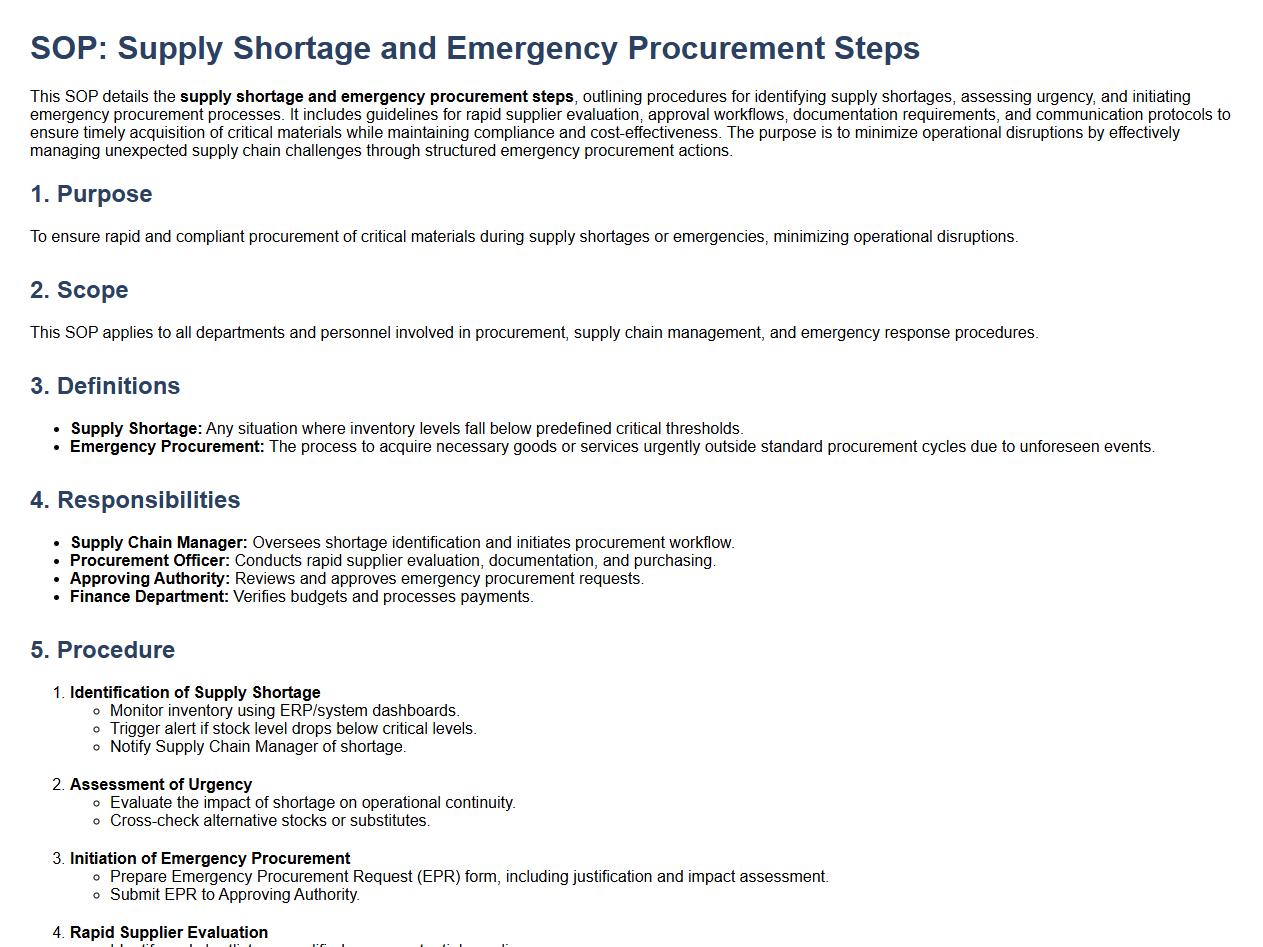

Supply shortage and emergency procurement steps.

This SOP details the supply shortage and emergency procurement steps, outlining procedures for identifying supply shortages, assessing urgency, and initiating emergency procurement processes. It includes guidelines for rapid supplier evaluation, approval workflows, documentation requirements, and communication protocols to ensure timely acquisition of critical materials while maintaining compliance and cost-effectiveness. The purpose is to minimize operational disruptions by effectively managing unexpected supply chain challenges through structured emergency procurement actions.

Disposal and recycling of obsolete or excess supplies.

This SOP details the proper procedures for the disposal and recycling of obsolete or excess supplies, including identification, segregation, and categorization of items, environmentally responsible disposal methods, recycling processes, compliance with regulatory requirements, documentation and tracking, and guidelines for minimizing waste. The aim is to ensure efficient resource management while promoting sustainability and reducing environmental impact.

What key steps must be followed for requesting and approving office supply orders according to the SOP?

The first key step is submitting a formal request form detailing the required office supplies. Following submission, the request must undergo an approval process by the designated supervisor or manager. Once approved, the order is processed and tracked until the supplies are delivered.

Which documentation is required for inventory tracking and supply issuance under this SOP?

The SOP mandates maintaining an inventory log that records all incoming and outgoing supplies. Each issuance requires a sign-out sheet signed by the recipient to ensure accountability. Additionally, periodic inventory reconciliation reports are required to verify stock levels.

Who is responsible for maintaining and reconciling office supply stock as per the protocol?

The designated office supply coordinator holds primary responsibility for stock maintenance. This individual must periodically conduct inventory audits to identify discrepancies. Reconciliation activities ensure accurate records and timely reordering of supplies.

What procedures are outlined for handling urgent or special office supply requests?

The SOP specifies that urgent requests require immediate notification to the supply manager for expedited approval. Special orders must include detailed justification and approval before procurement. These requests are prioritized to ensure minimal disruption to office operations.

How does the SOP address the management and disposal of obsolete or damaged office supplies?

The SOP outlines that obsolete or damaged items should be segregated and documented separately from usable stock. Disposal must be conducted in accordance with environmental and company guidelines. Proper documentation ensures transparency and compliance during the disposal process.