A SOP Template for Inventory Management in Restaurants provides a structured guide to streamline stock control processes, ensuring accuracy and consistency. It outlines step-by-step procedures for tracking inventory levels, ordering supplies, and minimizing waste to maintain optimal kitchen operations. Implementing this template enhances efficiency and helps prevent stockouts or overstock situations.

Receiving and inspection of inventory deliveries.

This SOP details the receiving and inspection of inventory deliveries, including procedures for verifying shipment accuracy, inspecting goods for quality and damage, documenting discrepancies, proper handling and storage of received items, and communication with suppliers. The goal is to ensure that all inventory deliveries meet the required standards and are accurately recorded to maintain efficient inventory management and prevent operational disruptions.

Proper documentation and logging of incoming inventory.

This SOP defines the procedures for proper documentation and logging of incoming inventory, ensuring accurate tracking of all received materials, verification against purchase orders, timely entry into inventory management systems, and maintaining clear records for auditing and accountability purposes.

Storage guidelines for perishable and non-perishable items.

This SOP provides comprehensive storage guidelines for perishable and non-perishable items, covering proper temperature control, humidity management, shelf life monitoring, and contamination prevention. It emphasizes organized storage practices, labeling, and rotation methods such as FIFO (First In, First Out) to maintain product quality, safety, and minimize waste. These guidelines ensure efficient inventory management and compliance with health and safety standards in various storage environments.

Inventory stock rotation and FIFO (First-In, First-Out) procedures.

This SOP details the inventory stock rotation and FIFO (First-In, First-Out) procedures, establishing systematic methods for organizing, managing, and rotating stock to ensure older inventory is used before newer supplies. It covers stock identification, tracking, shelf life management, proper storage techniques, regular audits, and documentation practices to minimize waste, prevent product obsolescence, and maintain optimal inventory accuracy and efficiency in stock handling.

Daily inventory usage tracking and recording.

This SOP details the process for daily inventory usage tracking and recording, ensuring accurate monitoring of stock levels, timely updates in inventory management systems, verification of usage against requisitions, identification of discrepancies, and proper documentation for accountability. Its purpose is to maintain optimal inventory control, prevent stockouts or overstocking, and support efficient resource planning and procurement.

Periodic inventory counts and reconciliation.

This SOP details the process for conducting periodic inventory counts and reconciliation, including scheduling regular inventory audits, accurate counting procedures, comparing physical stock with inventory records, identifying and investigating discrepancies, updating inventory management systems, and reporting findings to management. The goal is to maintain accurate inventory levels, prevent stock loss, and ensure financial accuracy.

Handling and disposal of expired or spoiled items.

This SOP details the proper handling and disposal of expired or spoiled items, including identification, segregation, safe removal, environmental compliance, and documentation procedures. It aims to prevent contamination, ensure workplace safety, and adhere to regulatory standards by managing expired or spoiled materials effectively.

Security measures for inventory storage areas.

This SOP details security measures for inventory storage areas, encompassing access control protocols, surveillance system implementation, regular inventory audits, proper lighting and signage, employee training on security policies, and emergency response procedures. The goal is to safeguard inventory from theft, damage, and unauthorized access, ensuring accurate stock management and a secure storage environment.

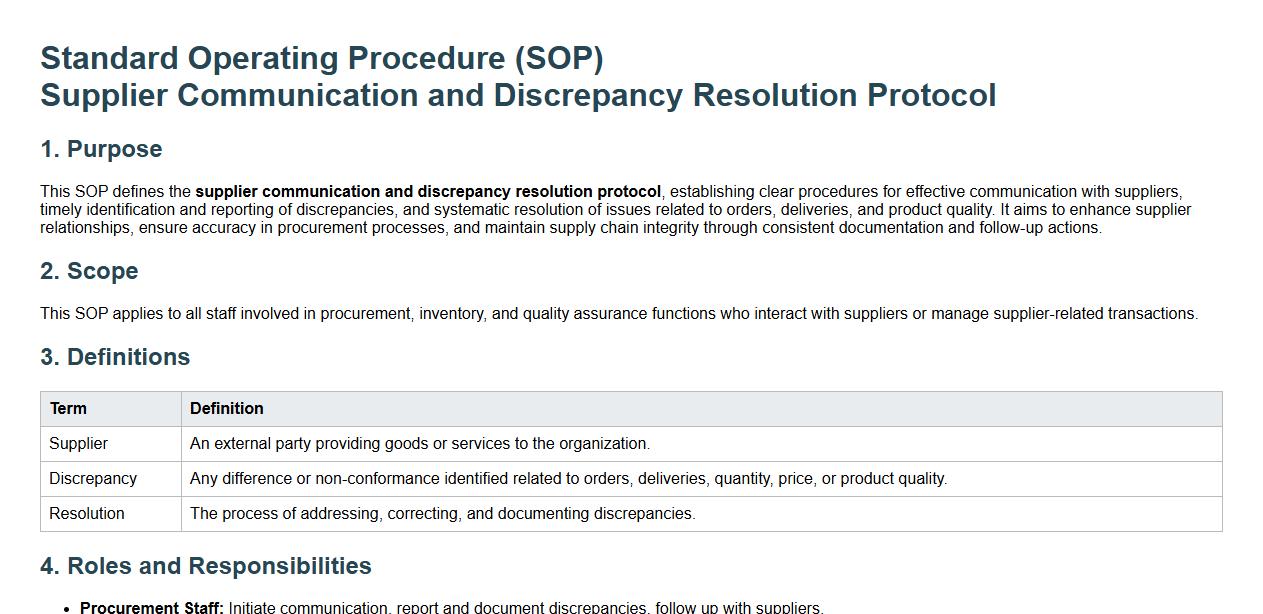

Supplier communication and discrepancy resolution protocol.

This SOP defines the supplier communication and discrepancy resolution protocol, establishing clear procedures for effective communication with suppliers, timely identification and reporting of discrepancies, and systematic resolution of issues related to orders, deliveries, and product quality. It aims to enhance supplier relationships, ensure accuracy in procurement processes, and maintain supply chain integrity through consistent documentation and follow-up actions.

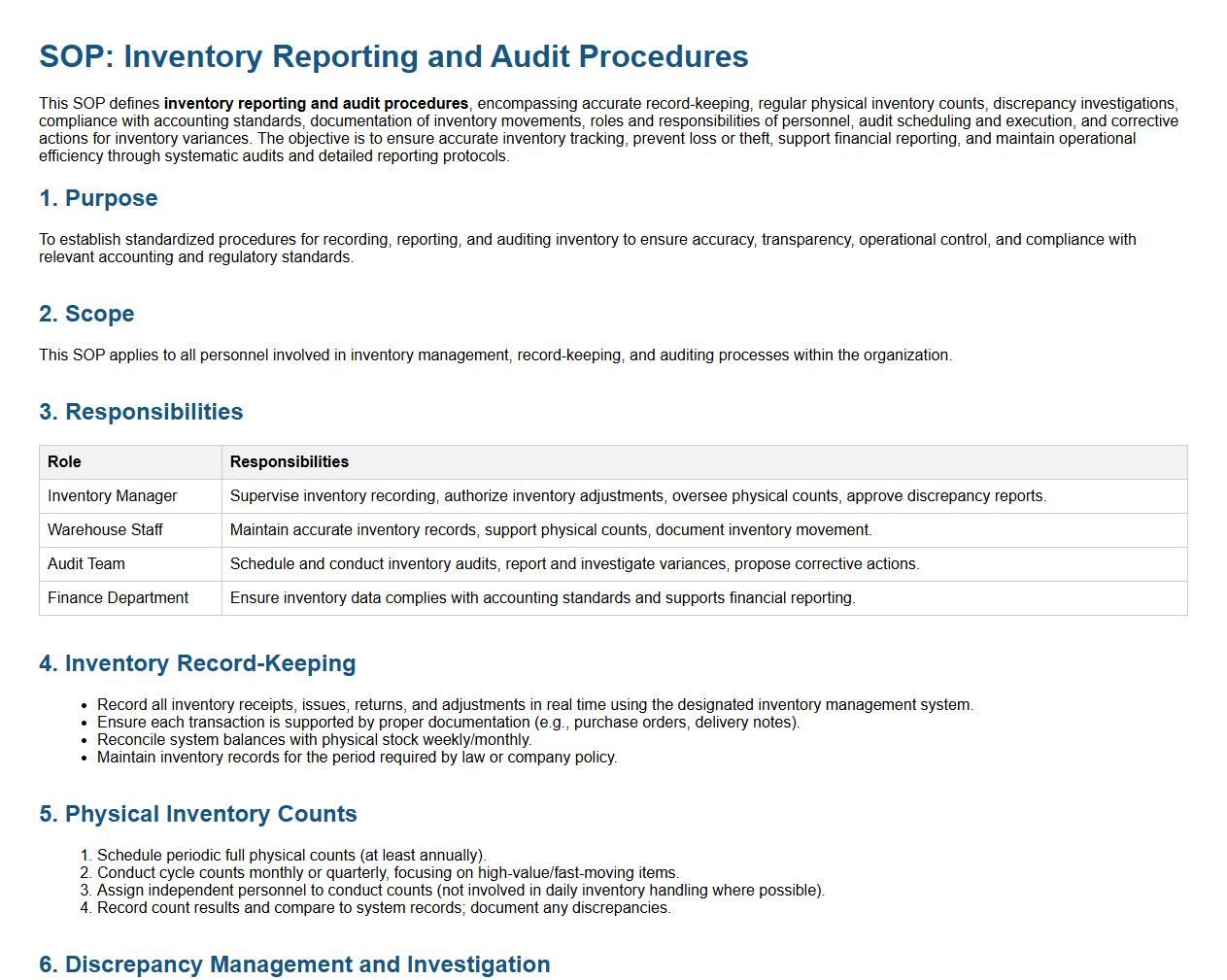

Inventory reporting and audit procedures.

This SOP defines inventory reporting and audit procedures, encompassing accurate record-keeping, regular physical inventory counts, discrepancy investigations, compliance with accounting standards, documentation of inventory movements, roles and responsibilities of personnel, audit scheduling and execution, and corrective actions for inventory variances. The objective is to ensure accurate inventory tracking, prevent loss or theft, support financial reporting, and maintain operational efficiency through systematic audits and detailed reporting protocols.

Key Steps in Receiving and Inspecting Inventory

The SOP emphasizes the importance of thorough inspection when receiving inventory to ensure product quality and accuracy. Staff must verify the delivery against purchase orders to confirm correct items and quantities. Any discrepancies or damages are to be documented immediately to maintain inventory integrity.

Procedure for Recording and Tracking Stock Levels

The SOP outlines a systematic approach for real-time stock recording using inventory management software or manual logs. Accurate tracking of quantities is crucial to prevent stockouts or overstocking issues. Regular updates help in maintaining a reliable overview of available inventory at all times.

Handling Perishable vs. Non-Perishable Inventory

The SOP recommends different strategies for perishable and non-perishable items to maximize shelf life and reduce waste. Perishable goods require immediate refrigeration and first-in-first-out (FIFO) usage to maintain freshness. Non-perishable items can be stored longer but should be rotated periodically to avoid expiration.

Protocols for Inventory Discrepancy Resolution

The SOP mandates prompt investigation of any inventory discrepancies to identify causes such as theft, miscounting, or supplier errors. Staff must report differences to management and document findings in discrepancy reports. Corrective actions are then implemented to prevent recurrence and ensure accurate inventory records.

Documentation and Reporting Requirements

The SOP specifies comprehensive documentation of all inventory activities including receipts, inspections, adjustments, and discrepancies. Regular reports must be generated to provide management with insights on stock levels and trends. Proper record-keeping facilitates audits and supports informed decision-making in inventory management.