A SOP Template for Food Safety and Hygiene provides a structured framework to ensure consistent adherence to hygiene standards and food safety protocols within food handling environments. This template outlines critical procedures such as cleaning schedules, personal hygiene practices, and cross-contamination prevention measures. Utilizing this standardized document helps organizations maintain compliance with health regulations and safeguard consumer health effectively.

Personnel hygiene and sanitation protocols.

This SOP defines personnel hygiene and sanitation protocols, covering handwashing procedures, use of personal protective equipment (PPE), proper attire and grooming standards, cleanliness of workstations, waste disposal methods, employee health monitoring, and guidelines for preventing contamination. The objective is to maintain a hygienic environment that minimizes the risk of infection, ensures food safety, and promotes overall workplace health and safety.

Food handling and processing procedures.

This SOP details food handling and processing procedures, encompassing hygiene standards, proper food storage, sanitation practices, temperature control, cross-contamination prevention, equipment cleaning protocols, and quality assurance measures. The goal is to maintain food safety, ensure product integrity, and comply with regulatory requirements throughout the entire food processing workflow.

Cleaning and sanitizing equipment instructions.

This SOP details the cleaning and sanitizing equipment instructions, including the selection of appropriate cleaning agents, step-by-step equipment disassembly, thorough washing procedures, effective sanitizing methods to eliminate harmful microorganisms, proper rinsing techniques, and safe drying practices. The purpose is to maintain equipment hygiene, prevent contamination, and ensure operational efficiency in compliance with health and safety standards.

Raw material receiving and inspection guidelines.

This SOP establishes raw material receiving and inspection guidelines to ensure that all incoming materials meet quality and safety standards. It covers procedures for verifying delivery documentation, inspecting materials for damage or contamination, measuring quantities, and handling discrepancies or non-conformities. The goal is to maintain the integrity of the production process by accepting only compliant raw materials and promptly addressing any issues to prevent disruptions and ensure product quality.

Cold storage and temperature monitoring processes.

This SOP describes cold storage and temperature monitoring processes, focusing on maintaining optimal temperature conditions to ensure product quality and safety. It includes guidelines for proper storage practices, temperature control equipment operation, routine temperature monitoring and recording, calibration of sensors and devices, handling temperature deviations, and documentation protocols. The goal is to prevent spoilage, contamination, and ensure regulatory compliance by consistently maintaining the cold chain throughout storage and handling.

Allergen control and cross-contamination prevention.

This SOP details allergen control and cross-contamination prevention strategies, focusing on identifying allergenic ingredients, segregating allergenic materials, implementing cleaning protocols, training staff on allergen awareness, monitoring cross-contact risks, labeling products accurately, and establishing emergency response plans for allergen exposure. The goal is to protect consumers with allergies and ensure food safety by minimizing the risk of cross-contamination throughout all stages of production and handling.

Pest control and facility monitoring.

This SOP outlines pest control and facility monitoring procedures, including identification and prevention of pest infestations, regular inspection schedules, use of safe and effective pest management techniques, maintenance of facility hygiene, monitoring environmental conditions, documentation of pest activity and control measures, and compliance with regulatory standards to ensure a clean and pest-free environment.

Product packaging and labeling requirements.

This SOP details the product packaging and labeling requirements essential for ensuring compliance with regulatory standards and enhancing brand consistency. It covers guidelines for packaging materials, labeling information accuracy, safety warnings, batch numbers, expiration dates, and barcoding. The procedure aims to guarantee product integrity, consumer safety, and facilitate efficient inventory management and traceability throughout the supply chain.

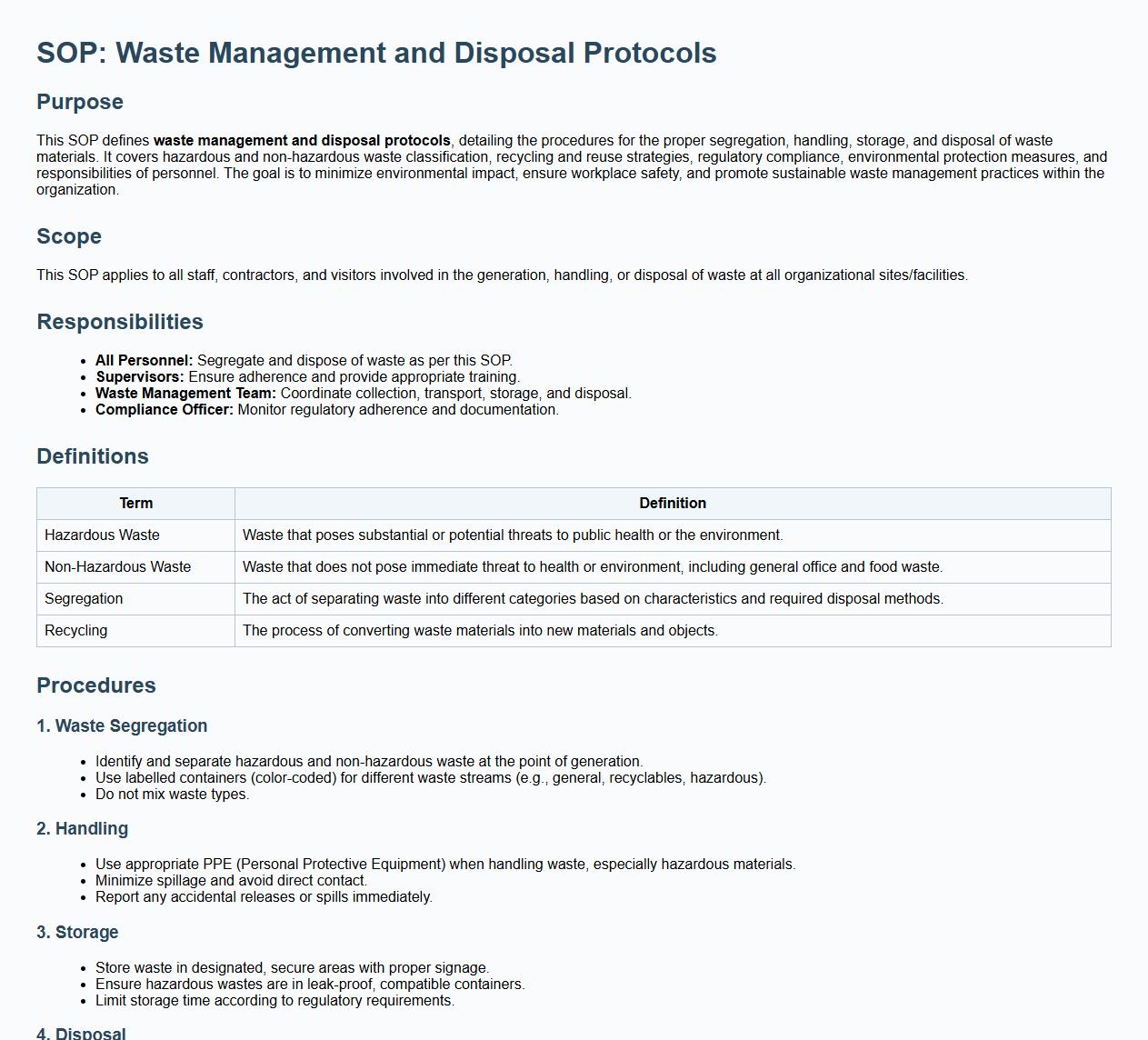

Waste management and disposal protocols.

This SOP defines waste management and disposal protocols, detailing the procedures for the proper segregation, handling, storage, and disposal of waste materials. It covers hazardous and non-hazardous waste classification, recycling and reuse strategies, regulatory compliance, environmental protection measures, and responsibilities of personnel. The goal is to minimize environmental impact, ensure workplace safety, and promote sustainable waste management practices within the organization.

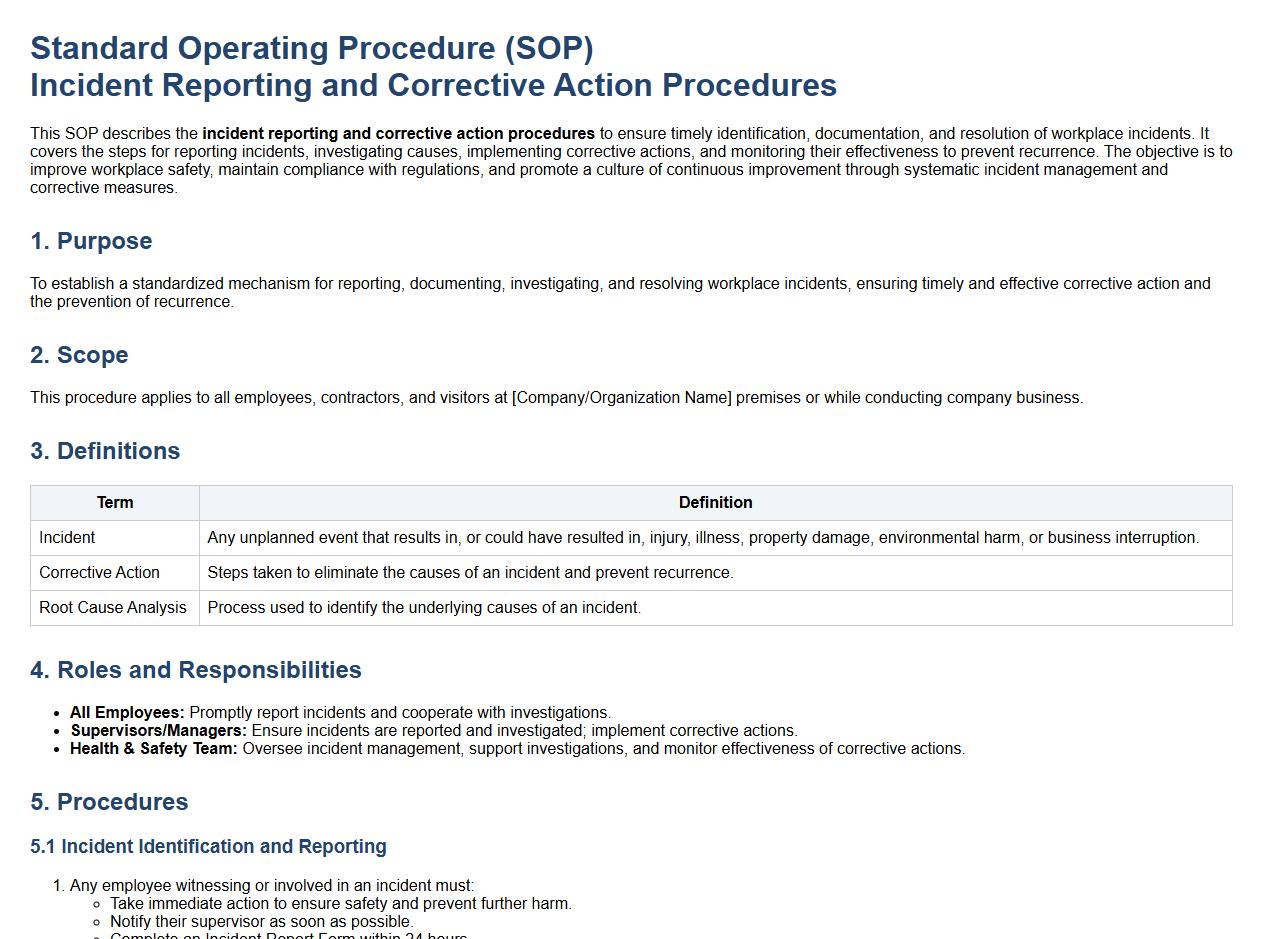

Incident reporting and corrective action procedures.

This SOP describes the incident reporting and corrective action procedures to ensure timely identification, documentation, and resolution of workplace incidents. It covers the steps for reporting incidents, investigating causes, implementing corrective actions, and monitoring their effectiveness to prevent recurrence. The objective is to improve workplace safety, maintain compliance with regulations, and promote a culture of continuous improvement through systematic incident management and corrective measures.

What are the critical personal hygiene practices required by the SOP for all food handlers?

The SOP mandates strict adherence to handwashing protocols before and after handling food, after using the restroom, and after any activity that contaminates hands. Food handlers must wear clean uniforms, hairnets, and gloves to prevent contamination. Additionally, personal hygiene such as avoiding jewelry and maintaining short, clean nails is emphasized to ensure food safety.

Which cleaning and sanitation procedures must be routinely documented according to the SOP?

The SOP requires routine documentation of all cleaning and sanitation activities, including cleaning schedules, materials used, and responsible personnel. Detailed records ensure accountability and traceability in food safety management. These documents help verify compliance during audits and inspections.

How does the SOP define safe food storage temperatures and requirements?

The SOP specifies maintaining cold foods at <=4degC and hot foods at >=60degC to prevent bacterial growth, with regular temperature monitoring. Proper storage also includes separation of raw and cooked foods to avoid cross-contamination. Clear labeling of expiration dates and proper rotation using FIFO (First In, First Out) are critical for ensuring food quality and safety.

What actions does the SOP mandate in case of suspected food contamination?

Upon suspicion of food contamination, the SOP requires immediate quarantine and segregation of the affected items to prevent distribution. The incident must be reported to a supervisor or food safety manager for further investigation. Contaminated food should be discarded safely, and the source of contamination identified to prevent recurrence.

What are the SOP's protocols for handling and disposing of food waste?

The SOP outlines using designated bins for food waste, ensuring they are covered and emptied regularly to inhibit pest attraction. Food waste must be disposed of in compliance with local regulations and sanitary guidelines. Staff should clean waste containers frequently to maintain hygienic conditions in the food handling area.