A SOP Template for Food Storage and Labeling provides a standardized method to ensure proper handling, storage, and identification of food products. It outlines clear procedures for maintaining food safety, preventing contamination, and complying with regulatory requirements. This template helps organizations improve consistency, reduce errors, and maintain quality control in food management processes.

Food receiving inspection procedures.

This SOP details food receiving inspection procedures to ensure the quality and safety of incoming food products. It includes verifying supplier documentation, checking product temperature, inspecting packaging integrity, assessing product appearance and condition, verifying labeling and expiration dates, and recording inspection results. The goal is to prevent contamination, spoilage, and ensure compliance with food safety standards before acceptance and storage.

Product segregation and storage allocation.

This SOP details the procedures for product segregation and storage allocation, emphasizing the systematic separation of products based on type, quality, and regulatory requirements to prevent contamination and ensure traceability. It includes guidelines for identifying storage zones, assigning designated areas for different product categories, labeling and documentation protocols, and maintaining optimal storage conditions. The objective is to optimize inventory management, facilitate efficient retrieval, and uphold product integrity throughout the storage period.

Temperature and humidity control monitoring.

This SOP details the procedures for temperature and humidity control monitoring to ensure optimal environmental conditions. It includes guidelines for calibrating and maintaining monitoring equipment, regular data recording and analysis, threshold setting for alerts, and corrective actions to maintain product quality and safety. Proper monitoring helps prevent equipment failure, reduce energy costs, and maintain compliance with regulatory standards.

FIFO (First-In, First-Out) inventory rotation system.

This SOP describes the FIFO (First-In, First-Out) inventory rotation system, which ensures that older stock is used or sold before newer stock to maintain product freshness, reduce waste, and minimize inventory obsolescence. It includes procedures for labeling, storing, tracking, and rotating inventory items, as well as documentation and monitoring practices to optimize stock management and improve operational efficiency.

Proper labeling guidelines (expiry, production dates, allergens).

This SOP details proper labeling guidelines encompassing accurate representation of expiry dates, production dates, and allergen information. It ensures compliance with regulatory requirements, enhances consumer safety by providing clear and precise product information, and minimizes risks associated with allergen exposure. The guidelines cover label design, placement, font size, and mandatory content to guarantee consistency and readability across all product packaging.

Cross-contamination prevention measures.

This SOP details cross-contamination prevention measures to minimize the risk of contaminating food products, surfaces, and equipment in food handling and processing environments. It covers hygiene practices, proper cleaning and sanitization protocols, segregation of raw and cooked foods, use of protective clothing, employee training, and monitoring procedures to uphold food safety standards and protect consumer health.

Daily storage area cleanliness protocols.

This SOP defines the daily storage area cleanliness protocols to maintain a safe, organized, and efficient storage environment. It includes step-by-step procedures for cleaning and sanitizing storage surfaces, organizing items to prevent contamination, inspecting for pests or hazards, proper waste disposal, and documentation of maintenance activities. This ensures compliance with health and safety standards while promoting operational efficiency and preventing damage or spoilage of stored materials.

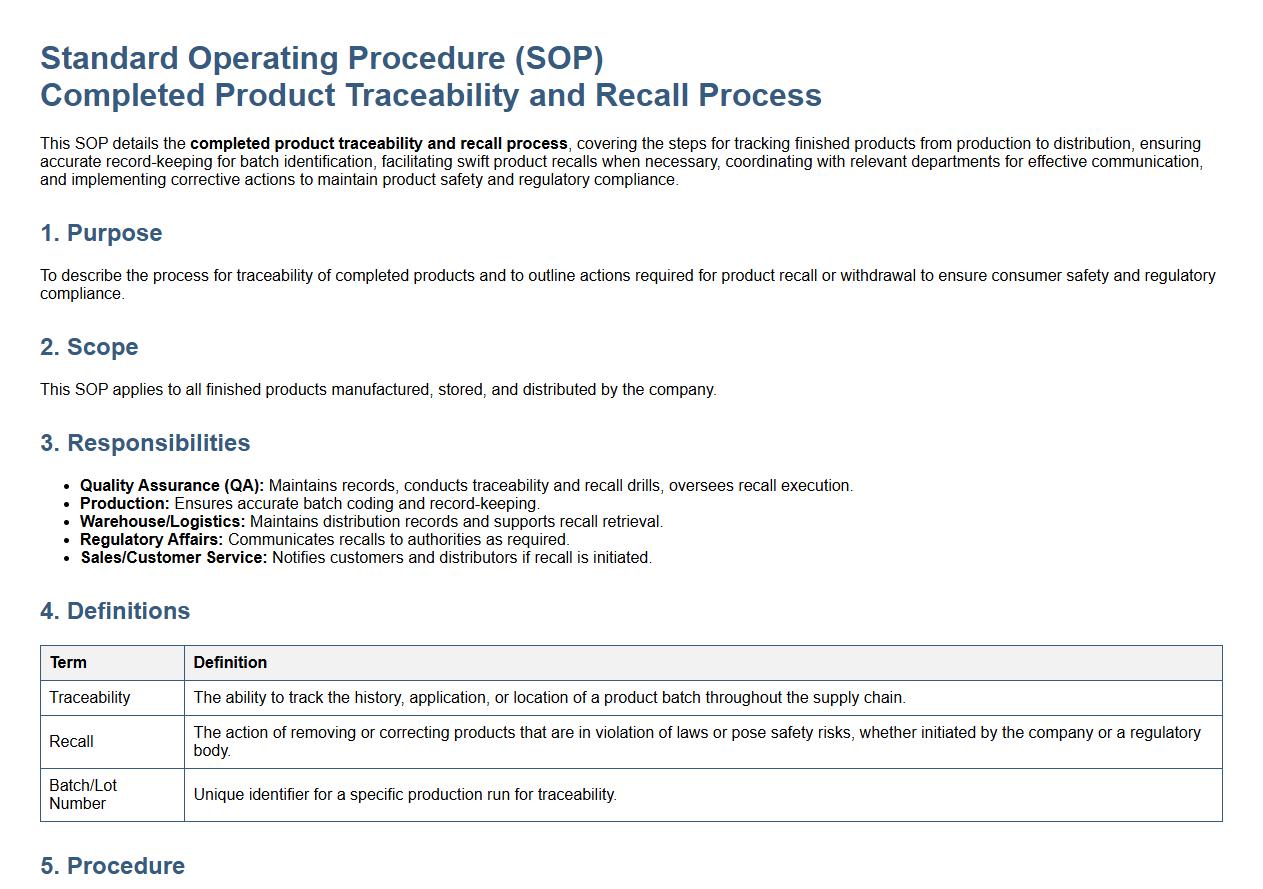

Completed product traceability and recall process.

This SOP details the completed product traceability and recall process, covering the steps for tracking finished products from production to distribution, ensuring accurate record-keeping for batch identification, facilitating swift product recalls when necessary, coordinating with relevant departments for effective communication, and implementing corrective actions to maintain product safety and regulatory compliance.

Correct handling, repackaging, or disposal of expired/damaged goods.

This SOP details the correct handling, repackaging, or disposal of expired/damaged goods, covering procedures for identifying expired or damaged items, safe handling practices to prevent contamination or hazards, proper repackaging techniques to maintain product integrity, and environmentally responsible disposal methods. The goal is to ensure product safety, regulatory compliance, and minimize environmental impact while maintaining workplace hygiene and safety standards.

Documentation and record-keeping of storage and labeling activities.

This SOP details the documentation and record-keeping of storage and labeling activities, emphasizing accurate tracking, proper labeling standards, storage condition monitoring, and timely updates. It ensures compliance with regulatory requirements, enhances inventory management, promotes safety, and facilitates traceability and accountability within storage operations.

What are the key labeling requirements for all food items in storage according to the SOP?

All food items in storage must have clear and legible labels indicating the product name, date received, and expiration date. Labels should be affixed in a consistent location on each container to ensure visibility. The SOP emphasizes the importance of using waterproof and durable labels to prevent damage or smudging during storage.

How does the SOP specify proper storage conditions for different types of food (e.g., perishable vs. non-perishable)?

The SOP outlines specific temperature requirements for perishable foods, typically mandating refrigeration or freezing at appropriate levels to maintain safety. Non-perishable items should be stored in a cool, dry, and well-ventilated area to prevent spoilage. These storage conditions help maintain food quality and safety over time.

What procedures does the SOP mandate for monitoring and documenting food expiration dates?

The SOP requires routine inspection and documentation of expiration dates during regular inventory checks. Food items nearing expiration must be recorded and prioritized for use or disposal according to the first-in, first-out (FIFO) principle. Accurate logs ensure timely removal of expired products to avoid contamination risks.

How does the SOP address the segregation and organization of raw and ready-to-eat foods?

The SOP mandates strict segregation of raw and ready-to-eat foods to prevent cross-contamination. Raw foods are stored on lower shelves or separate compartments to avoid dripping onto higher shelves containing ready-to-eat items. Proper labeling and physical barriers are essential to maintain food safety within storage areas.

What corrective actions are outlined in the SOP if improper storage or labeling is identified during inspections?

The SOP requires immediate corrective action when improper storage or labeling is found, such as re-labeling items or relocating them to the appropriate storage condition. Staff must be notified to prevent recurrence, and a report is generated to document the issue and action taken. Continuous training and audits are emphasized to maintain compliance and food safety standards.