A SOP Template for Cleaning Crew Scheduling streamlines the organization of cleaning shifts by outlining clear procedures and timelines. This template ensures efficient allocation of tasks, preventing overlaps and delays while maintaining high standards of cleanliness. Implementing a standardized schedule enhances team coordination and boosts overall productivity.

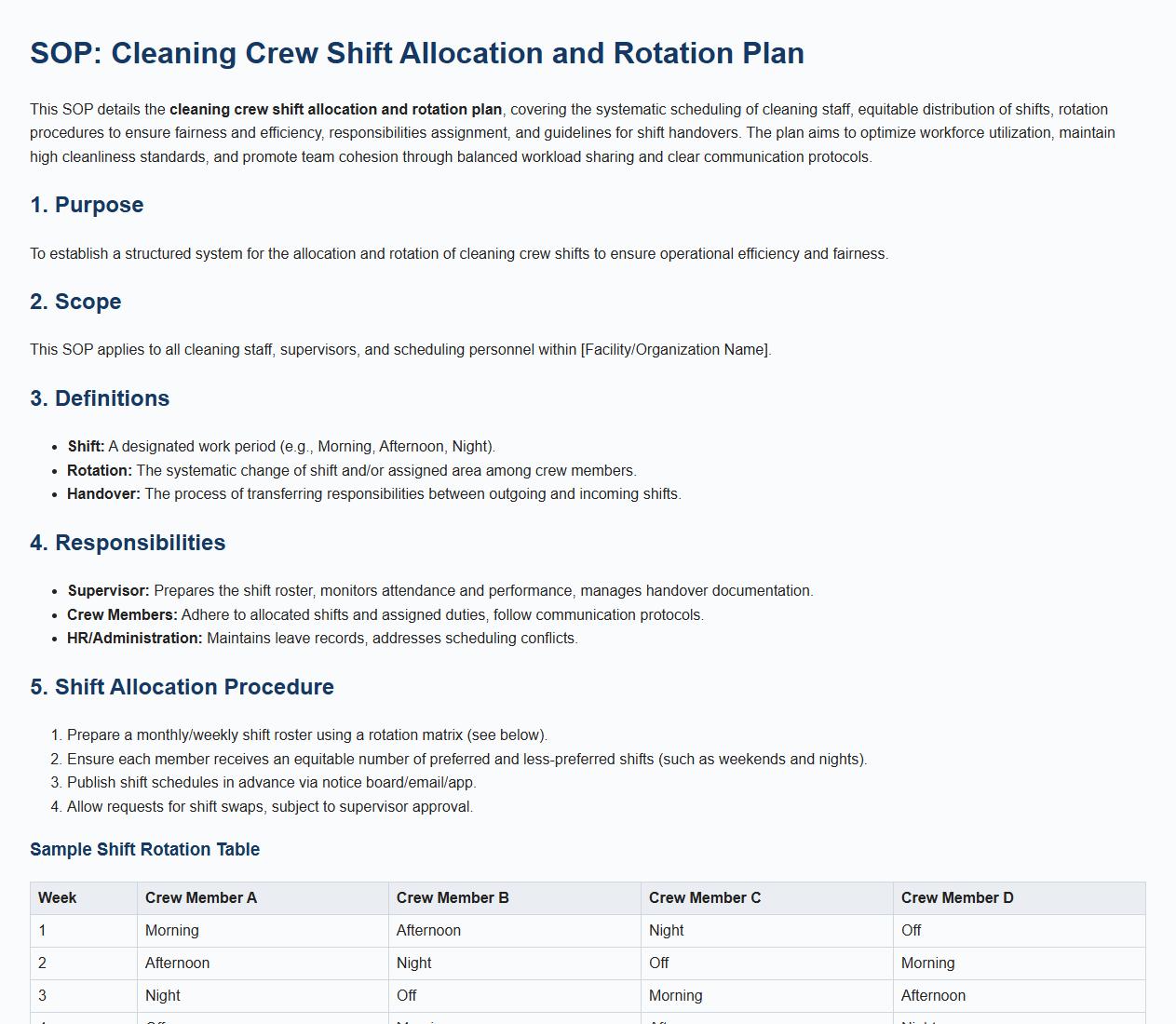

Cleaning crew shift allocation and rotation plan.

This SOP details the cleaning crew shift allocation and rotation plan, covering the systematic scheduling of cleaning staff, equitable distribution of shifts, rotation procedures to ensure fairness and efficiency, responsibilities assignment, and guidelines for shift handovers. The plan aims to optimize workforce utilization, maintain high cleanliness standards, and promote team cohesion through balanced workload sharing and clear communication protocols.

Guidelines for daily and weekly task assignments.

This SOP establishes guidelines for daily and weekly task assignments to ensure efficient workflow and clear responsibility distribution. It includes procedures for planning, prioritizing, and communicating tasks, assigning roles based on skills and availability, monitoring progress, and adjusting assignments as needed. The goal is to enhance productivity, maintain accountability, and support team collaboration through structured task management.

Checklist for equipment and supply inventory before each shift.

This SOP details a comprehensive checklist for equipment and supply inventory before each shift, ensuring all necessary tools, machinery, and materials are accounted for and in proper working condition. It covers verification of inventory levels, inspection for damages or malfunctions, restocking procedures, and documentation requirements to maintain operational efficiency and safety throughout the shift.

Attendance tracking and timekeeping procedures.

This SOP details the attendance tracking and timekeeping procedures, encompassing employee clock-in and clock-out processes, accurate recording of work hours, management of absences and tardiness, verification and approval of timesheets, and integration with payroll systems. The objective is to maintain precise and reliable attendance records to support workforce management, ensure compliance with labor regulations, and facilitate accurate compensation.

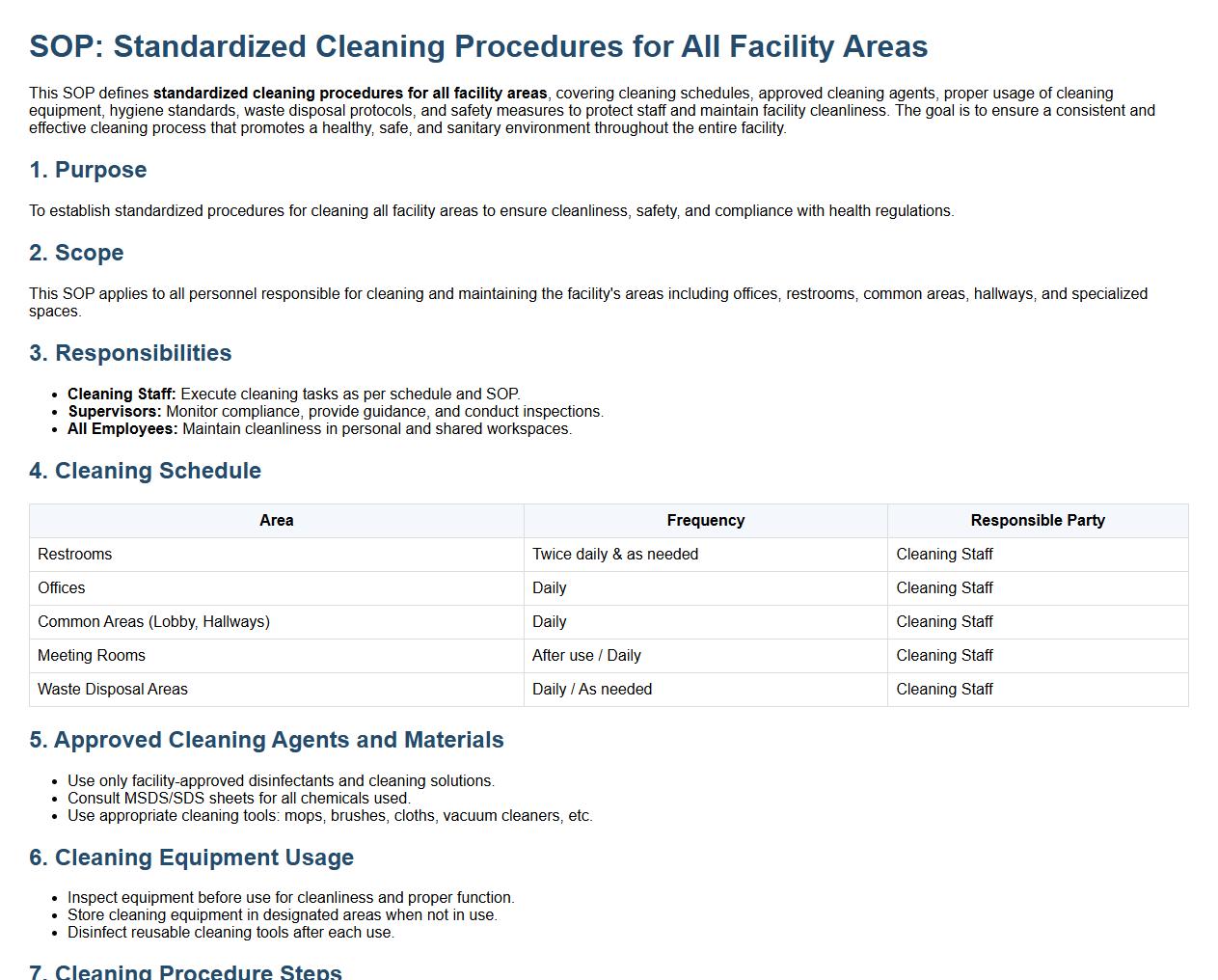

Standardized cleaning procedures for all facility areas.

This SOP defines standardized cleaning procedures for all facility areas, covering cleaning schedules, approved cleaning agents, proper usage of cleaning equipment, hygiene standards, waste disposal protocols, and safety measures to protect staff and maintain facility cleanliness. The goal is to ensure a consistent and effective cleaning process that promotes a healthy, safe, and sanitary environment throughout the entire facility.

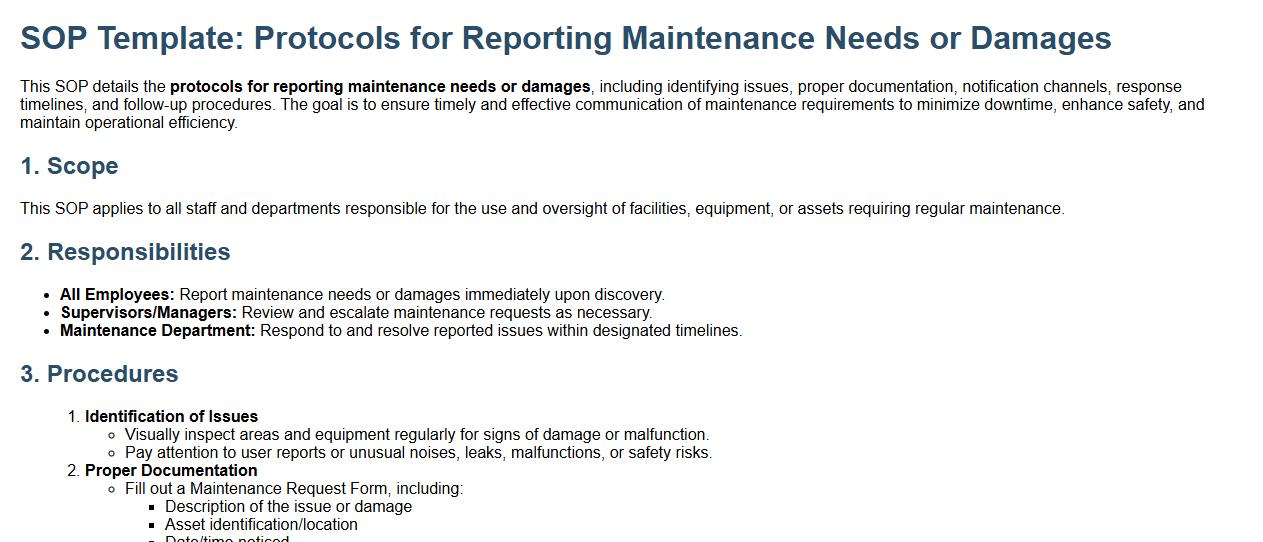

Protocols for reporting maintenance needs or damages.

This SOP details the protocols for reporting maintenance needs or damages, including identifying issues, proper documentation, notification channels, response timelines, and follow-up procedures. The goal is to ensure timely and effective communication of maintenance requirements to minimize downtime, enhance safety, and maintain operational efficiency.

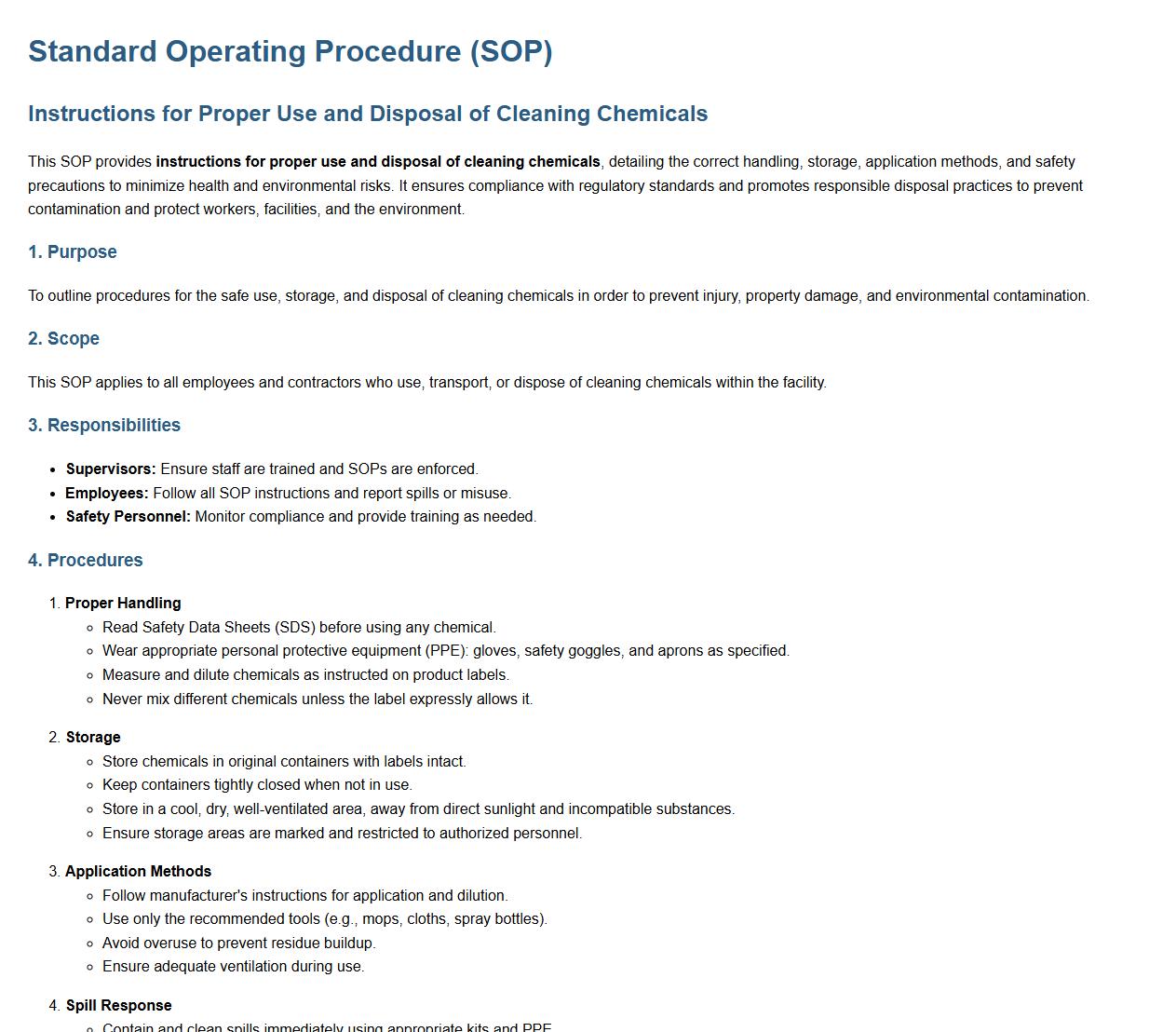

Instructions for proper use and disposal of cleaning chemicals.

This SOP provides instructions for proper use and disposal of cleaning chemicals, detailing the correct handling, storage, application methods, and safety precautions to minimize health and environmental risks. It ensures compliance with regulatory standards and promotes responsible disposal practices to prevent contamination and protect workers, facilities, and the environment.

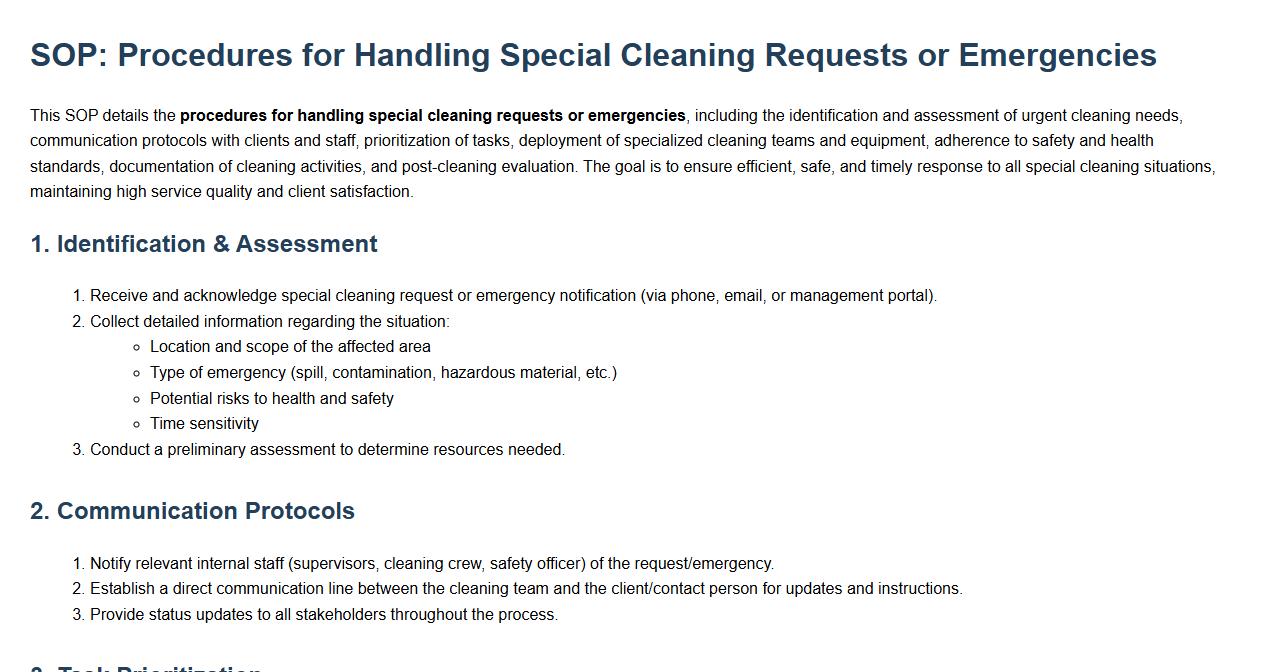

Procedures for handling special cleaning requests or emergencies.

This SOP details the procedures for handling special cleaning requests or emergencies, including the identification and assessment of urgent cleaning needs, communication protocols with clients and staff, prioritization of tasks, deployment of specialized cleaning teams and equipment, adherence to safety and health standards, documentation of cleaning activities, and post-cleaning evaluation. The goal is to ensure efficient, safe, and timely response to all special cleaning situations, maintaining high service quality and client satisfaction.

Guidelines for crew communication and shift handover.

This SOP details guidelines for crew communication and shift handover, emphasizing clear, consistent, and effective information exchange between team members to ensure operational continuity. It covers standardized communication protocols, essential handover documentation, roles and responsibilities during shift changes, methods for reporting incidents or anomalies, and strategies to minimize misunderstandings or errors. The goal is to maintain seamless workflow, enhance safety, and uphold productivity through proper coordination and knowledge transfer.

Performance monitoring and crew feedback documentation.

This SOP details the process for performance monitoring and crew feedback documentation, including setting performance standards, regular evaluation methods, documentation of crew feedback, communication protocols, and continuous improvement strategies. The objective is to ensure accurate tracking of crew performance, foster open communication, and facilitate timely interventions to enhance overall team productivity and morale.

What criteria should be used to prioritize cleaning crew assignments in the scheduling process?

The cleaning crew assignments should be prioritized based on the urgency of cleaning tasks and the specific skills of crew members. Scheduling must consider high-traffic areas that require immediate attention to maintain hygiene standards. Additionally, allocating tasks based on employee availability and workload balance maximizes efficiency.

How does the SOP address shift changes and ensure continuous coverage by the cleaning crew?

The Standard Operating Procedure (SOP) mandates clear shift handovers between crew members to guarantee seamless transitions. Overlapping shifts or designated changeover periods are implemented to prevent gaps in coverage. Documentation of shift changes ensures accountability and continuous cleaning operations.

What steps must be followed when documenting schedule changes or substitutions in the cleaning crew roster?

All schedule changes or substitutions must be recorded promptly in the official roster to maintain accuracy. The SOP requires notifying supervisors and updating digital schedules to reflect any amendments. Proper documentation helps track employee hours and ensures transparency in the scheduling process.

How does the SOP ensure compliance with legal working hour limits and rest periods?

The SOP incorporates legal working hour limits by establishing maximum shift lengths and mandatory rest periods between shifts. Scheduling software may be used to flag violations before finalizing assignments. Regular audits are conducted to enforce adherence to labor laws and protect employee well-being.

What is the protocol for communicating the cleaning schedule and any updates to all relevant personnel?

The cleaning schedule and updates must be communicated through official channels such as email, internal messaging systems, or a centralized scheduling platform. The SOP emphasizes timely notifications to all relevant personnel to avoid any miscommunication. Regular meetings or briefings may also be conducted to reinforce schedule awareness.