A SOP Template for Retail Vendor Receiving and Delivery ensures standardized procedures for handling incoming shipments and verifying product quality. It outlines clear steps for inspecting goods, documenting discrepancies, and managing inventory updates to maintain operational efficiency. This template helps minimize errors and improve communication between receiving personnel and vendors.

Vendor delivery scheduling and appointment procedures.

This SOP describes the vendor delivery scheduling and appointment procedures, including the process for requesting delivery slots, coordinating delivery times, confirming appointments with vendors, managing delivery documentation, and handling late or missed deliveries. The goal is to ensure efficient and organized receipt of goods, minimize disruptions to operations, and maintain clear communication between vendors and receiving personnel.

Receiving dock and unloading protocols.

This SOP details receiving dock and unloading protocols, covering procedures for safely receiving shipments, inspecting incoming goods, proper unloading techniques, equipment usage such as forklifts and pallet jacks, documentation and verification of deliveries, managing hazardous materials, maintaining dock safety, and coordination with warehouse and inventory teams. The goal is to ensure efficient, accurate, and safe handling of incoming products while minimizing damage and ensuring compliance with safety regulations.

Verification of shipment against purchase orders and invoices.

This SOP details the verification of shipment against purchase orders and invoices, covering the procedures to ensure accuracy and consistency between received shipments, purchase orders, and invoices. It includes steps for inspecting quantities, product descriptions, and pricing to prevent discrepancies, facilitate proper inventory management, and ensure payment accuracy. The SOP aims to streamline the receiving process, enhance accountability, and support effective procurement and financial controls.

Inspection of products for quality and damages.

This SOP details the process for inspection of products for quality and damages, covering visual checks, functional testing, identification of defects, documentation of findings, and protocols for handling non-conforming products. The purpose is to ensure that all products meet established quality standards before distribution, thereby reducing customer complaints and enhancing overall product reliability.

Product count accuracy and discrepancy recording.

This SOP establishes standardized procedures for ensuring product count accuracy and discrepancy recording. It includes methods for conducting precise product counts, verifying inventory data, identifying and documenting discrepancies, investigating causes of variances, and implementing corrective actions. The goal is to maintain accurate inventory records, improve operational efficiency, and minimize losses due to counting errors or misreports.

Proper documentation and record-keeping of received goods.

This SOP defines the process for proper documentation and record-keeping of received goods, including the verification of delivery documents, inspection of goods, accurate entry of received items into inventory systems, filing and storage of delivery records, and regular audits to ensure data accuracy. The objective is to maintain a reliable and transparent record-keeping system that supports inventory management, financial accuracy, and traceability of all received shipments.

Guidelines for product labeling and barcoding.

This SOP provides comprehensive guidelines for product labeling and barcoding, covering label design specifications, barcode standards, placement requirements, quality control measures, and compliance with regulatory requirements. The objective is to ensure accurate product identification, enhance inventory management, and facilitate seamless tracking throughout the supply chain by implementing standardized labeling and barcode practices.

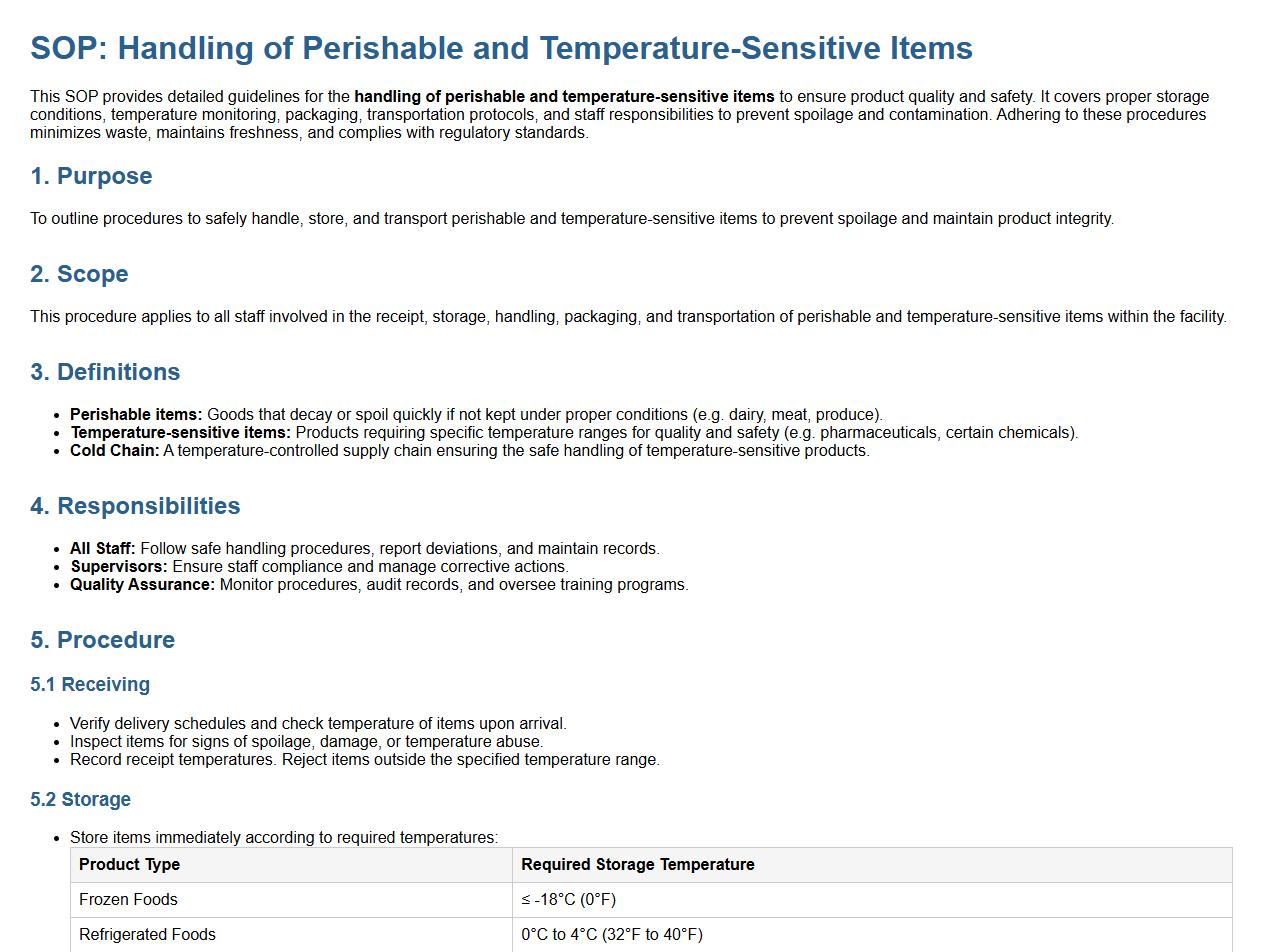

Handling of perishable and temperature-sensitive items.

This SOP provides detailed guidelines for the handling of perishable and temperature-sensitive items to ensure product quality and safety. It covers proper storage conditions, temperature monitoring, packaging, transportation protocols, and staff responsibilities to prevent spoilage and contamination. Adhering to these procedures minimizes waste, maintains freshness, and complies with regulatory standards.

Return and refusal process for non-compliant deliveries.

This SOP details the return and refusal process for non-compliant deliveries, including identification of non-compliance criteria, documentation requirements, communication protocols with suppliers, handling and segregation of non-compliant goods, return authorization procedures, and proper record-keeping for tracking returned shipments. The goal is to ensure efficient handling of deliveries that do not meet quality or contractual standards, minimizing disruptions and maintaining supply chain integrity.

Health, safety, and security procedures during vendor receiving.

This SOP details health, safety, and security procedures during vendor receiving, encompassing the verification of vendor credentials, proper use of personal protective equipment (PPE), safe unloading and handling of goods, adherence to site-specific safety protocols, monitoring for potential security risks, maintaining clear communication between vendors and staff, ensuring compliance with health regulations, and documenting all receiving activities. The objective is to safeguard employees, protect company assets, and maintain a secure and healthy receiving environment.

What is the primary objective of the SOP for Retail Vendor Receiving and Delivery?

The primary objective of the SOP for Retail Vendor Receiving and Delivery is to establish a consistent and efficient process for handling incoming shipments. This ensures accurate inventory management and timely delivery to the retail locations. It aims to minimize errors and optimize vendor coordination.

Which documents must be verified and processed during the receiving stage as per this SOP?

During the receiving stage, the purchase order, delivery receipt, and packing list must be carefully verified and processed. These documents ensure that the quantities and items received match the vendor's shipment. Proper documentation is crucial for accurate record-keeping and inventory validation.

What are the standard procedures for inspecting and reporting shipment discrepancies?

The standard procedures include a thorough inspection of goods against the packing list for any damages or quantity mismatches. Any discrepancies must be immediately documented and reported to the relevant department using the designated discrepancy report form. Prompt reporting helps in quick resolution and accountability.

Who is responsible for ensuring compliance with delivery schedules and location protocols?

The logistics manager or designated receiving supervisor is responsible for ensuring compliance with delivery schedules and location protocols. They coordinate with vendors and internal teams to maintain smooth operations. This role is critical for avoiding delays and ensuring proper handling at the retail site.

What are the required steps for documenting and escalating issues related to damaged or missing goods?

Issues related to damaged or missing goods must be immediately documented using the incident report form. The report should include detailed descriptions, photographs, and supporting evidence. Escalation to the procurement and quality control departments follows to initiate claims or corrective actions.