A SOP Template for Retail Broken/Damaged Goods Handling outlines the standardized process for identifying, documenting, and managing damaged or broken products in a retail environment. It ensures consistent procedures for employees to follow, minimizing loss and improving inventory accuracy. Clear guidelines within the template help streamline reporting, disposal, or return of affected items.

Initial identification and segregation of broken/damaged goods.

This SOP details the process for the initial identification and segregation of broken/damaged goods, ensuring timely recognition, accurate documentation, and appropriate separation of defective items from good inventory to prevent distribution errors and maintain product quality standards.

Documentation and logging of damaged items (SKU, quantity, date, cause).

This SOP details the documentation and logging of damaged items, specifying the process for accurately recording the SKU, quantity, date, and cause of damage. It aims to ensure consistent tracking and accountability of damaged inventory to aid in inventory management, loss prevention, and effective reporting for quality control and operational improvements.

Immediate reporting to store supervisor or manager.

This SOP emphasizes the importance of immediate reporting to the store supervisor or manager to ensure timely communication of incidents, concerns, or operational issues. Prompt notification allows for quick decision-making, effective problem resolution, and maintaining store safety and efficiency. It is essential for all employees to understand their responsibility in reporting matters without delay to support a well-managed and secure store environment.

Photographic evidence and condition assessment procedure.

This SOP details the photographic evidence and condition assessment procedure, which includes guidelines for capturing clear and accurate images, documenting physical conditions, and ensuring proper storage and presentation of photographic records. The procedure aims to provide reliable visual documentation to support inspections, evaluations, and decision-making processes across various applications.

Secure storage and labeling of damaged goods in designated area.

This SOP details the procedures for secure storage and labeling of damaged goods in a designated area, ensuring proper identification, segregation, and protection from further damage. It includes steps for accurately labeling items, safely moving damaged products to the approved storage location, maintaining clear records, and minimizing risks to personnel and inventory integrity. The goal is to facilitate efficient handling, prevent contamination or mix-ups, and support effective inventory management and disposal processes.

Customer return/refund/exchange processing protocol.

This SOP details the customer return, refund, and exchange processing protocol, covering the steps for handling return requests, verifying product conditions, approving or denying returns, issuing refunds or exchanges, documenting transactions, and communicating with customers. The goal is to ensure efficient, transparent, and customer-friendly management of returns and refunds while maintaining company policies and minimizing losses.

Disposal and waste management procedures according to store policy.

This SOP defines disposal and waste management procedures in accordance with store policy, covering the proper segregation, handling, and disposal of waste materials. It ensures compliance with environmental regulations, promotes recycling and waste reduction, and maintains a clean and safe store environment by outlining roles, responsibilities, and documentation requirements for effective waste management.

Supplier notification and claims submission process (if applicable).

This SOP details the supplier notification and claims submission process, covering the timely communication with suppliers regarding order discrepancies, damaged goods, or service issues, the documentation requirements for claims, the submission procedures, and follow-up actions to ensure resolution. The process aims to maintain clear, efficient, and effective interactions with suppliers to address and resolve issues promptly, minimizing business disruptions and ensuring compliance with contractual terms.

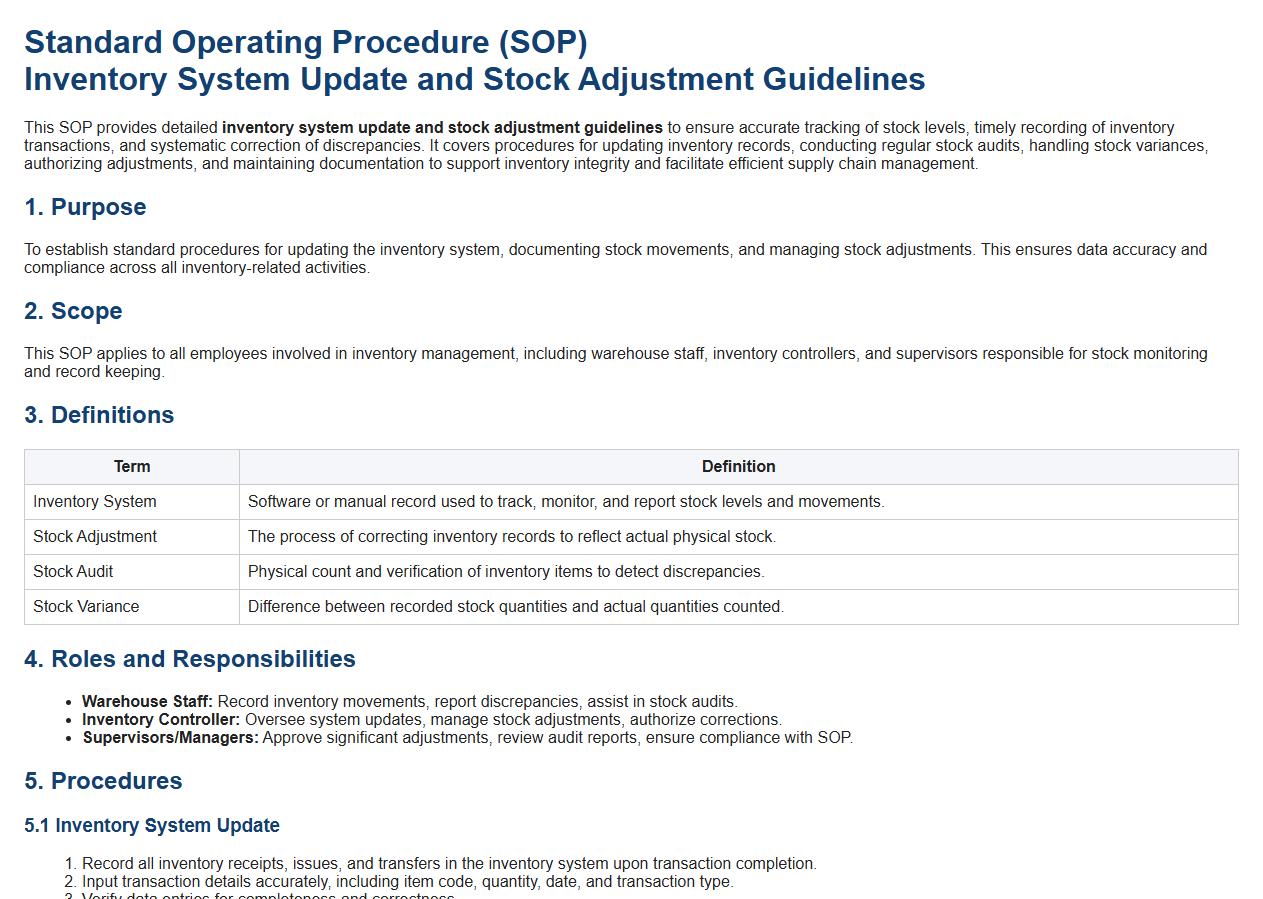

Inventory system update and stock adjustment guidelines.

This SOP provides detailed inventory system update and stock adjustment guidelines to ensure accurate tracking of stock levels, timely recording of inventory transactions, and systematic correction of discrepancies. It covers procedures for updating inventory records, conducting regular stock audits, handling stock variances, authorizing adjustments, and maintaining documentation to support inventory integrity and facilitate efficient supply chain management.

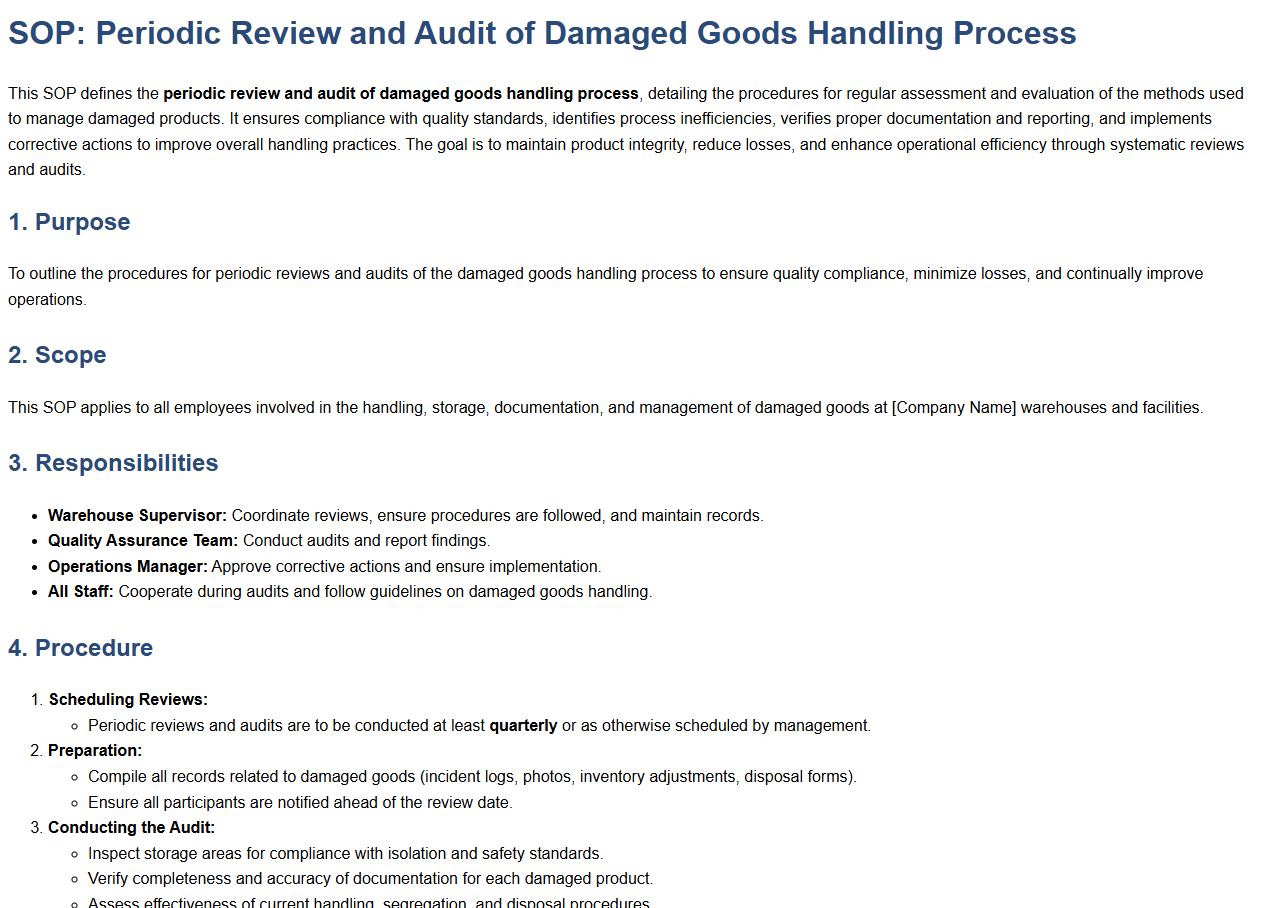

Periodic review and audit of damaged goods handling process.

This SOP defines the periodic review and audit of damaged goods handling process, detailing the procedures for regular assessment and evaluation of the methods used to manage damaged products. It ensures compliance with quality standards, identifies process inefficiencies, verifies proper documentation and reporting, and implements corrective actions to improve overall handling practices. The goal is to maintain product integrity, reduce losses, and enhance operational efficiency through systematic reviews and audits.

What criteria determine when a retail item is classified as broken or damaged under the SOP?

The SOP classifies an item as broken or damaged if it exhibits visible defects that impair its functionality or aesthetic value. Examples include cracks, missing parts, or packaging tears that compromise product integrity. The item's condition is assessed against predefined quality standards to decide its classification.

Which specific procedures must staff follow immediately upon discovering broken or damaged goods?

Staff must promptly isolate the damaged items to prevent their sale or distribution. They are required to notify their supervisor and document the issue according to the SOP guidelines. Additionally, staff must ensure the affected goods are moved to designated holding areas to avoid confusion with sellable inventory.

What documentation is required for reporting and recording damaged merchandise in compliance with the SOP?

The SOP mandates the completion of a damage report form detailing the item's description, extent of damage, and discovery date. Photographic evidence is often required to support the report for record accuracy. This documentation is essential for inventory adjustment and insurance claims processing.

How does the SOP specify the segregation, storage, or disposal of broken/damaged goods?

Broken or damaged goods must be segregated from saleable stock and stored separately in clearly marked areas. The SOP outlines protocols for secure storage to prevent further damage or loss. Disposal procedures typically require authorization, ensuring environmentally compliant and accountable handling.

Who is responsible for reviewing, authorizing, and finalizing actions regarding broken/damaged goods according to the SOP?

The responsibility for reviewing and authorizing actions lies with designated management personnel or quality control supervisors. These individuals assess the damage reports and determine the appropriate resolution, including repair, return, or disposal. Final decisions are formally documented to maintain compliance and accountability.