A SOP template for field service technicians outlines standardized procedures to ensure consistent and efficient onsite repairs and maintenance. It provides step-by-step instructions, safety protocols, and quality checks tailored for various field conditions. Using this template helps improve service reliability, technician accountability, and customer satisfaction.

Work order reception and review procedures.

This SOP details the work order reception and review procedures, encompassing the systematic approach to receiving, documenting, and evaluating incoming work orders. It ensures accurate assessment of work requirements, prioritization based on urgency and resources, verification of completeness and clarity, and effective communication between departments. The procedure aims to streamline workflow, minimize errors, and enhance operational efficiency by establishing clear guidelines for timely and thorough review of all work orders.

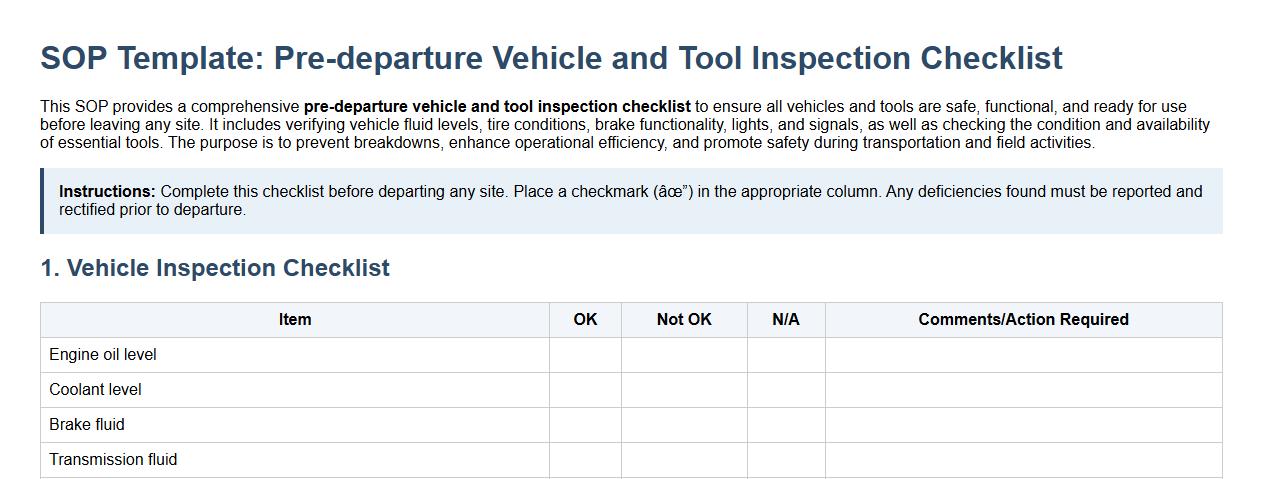

Pre-departure vehicle and tool inspection checklist.

This SOP provides a comprehensive pre-departure vehicle and tool inspection checklist to ensure all vehicles and tools are safe, functional, and ready for use before leaving any site. It includes verifying vehicle fluid levels, tire conditions, brake functionality, lights, and signals, as well as checking the condition and availability of essential tools. The purpose is to prevent breakdowns, enhance operational efficiency, and promote safety during transportation and field activities.

Site arrival safety protocols and customer greeting.

This SOP defines site arrival safety protocols and customer greeting to ensure a secure and welcoming environment. It includes procedures for verifying visitor identities, enforcing safety gear and access regulations, conducting hazard briefings, and providing clear directions upon arrival. Additionally, it outlines polite and professional customer greeting techniques to foster positive first impressions and enhance overall site safety and customer satisfaction.

Standard process for diagnosing equipment issues.

This SOP defines the standard process for diagnosing equipment issues, including initial problem identification, systematic troubleshooting steps, use of diagnostic tools, documentation of findings, communication with maintenance teams, and verification of issue resolution. The goal is to ensure efficient, accurate, and consistent identification of equipment problems to minimize downtime and maintain operational productivity.

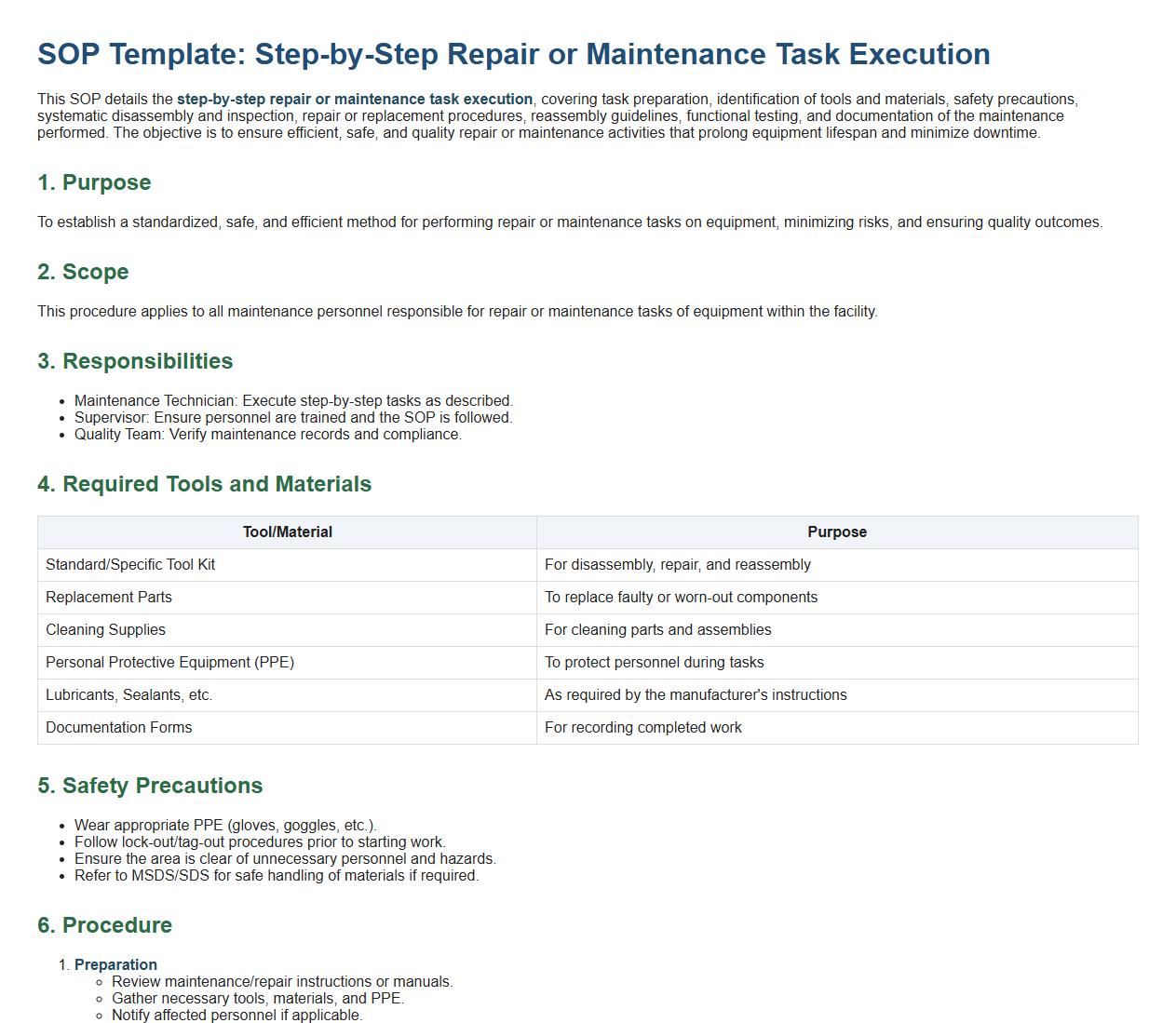

Step-by-step repair or maintenance task execution.

This SOP details the step-by-step repair or maintenance task execution, covering task preparation, identification of tools and materials, safety precautions, systematic disassembly and inspection, repair or replacement procedures, reassembly guidelines, functional testing, and documentation of the maintenance performed. The objective is to ensure efficient, safe, and quality repair or maintenance activities that prolong equipment lifespan and minimize downtime.

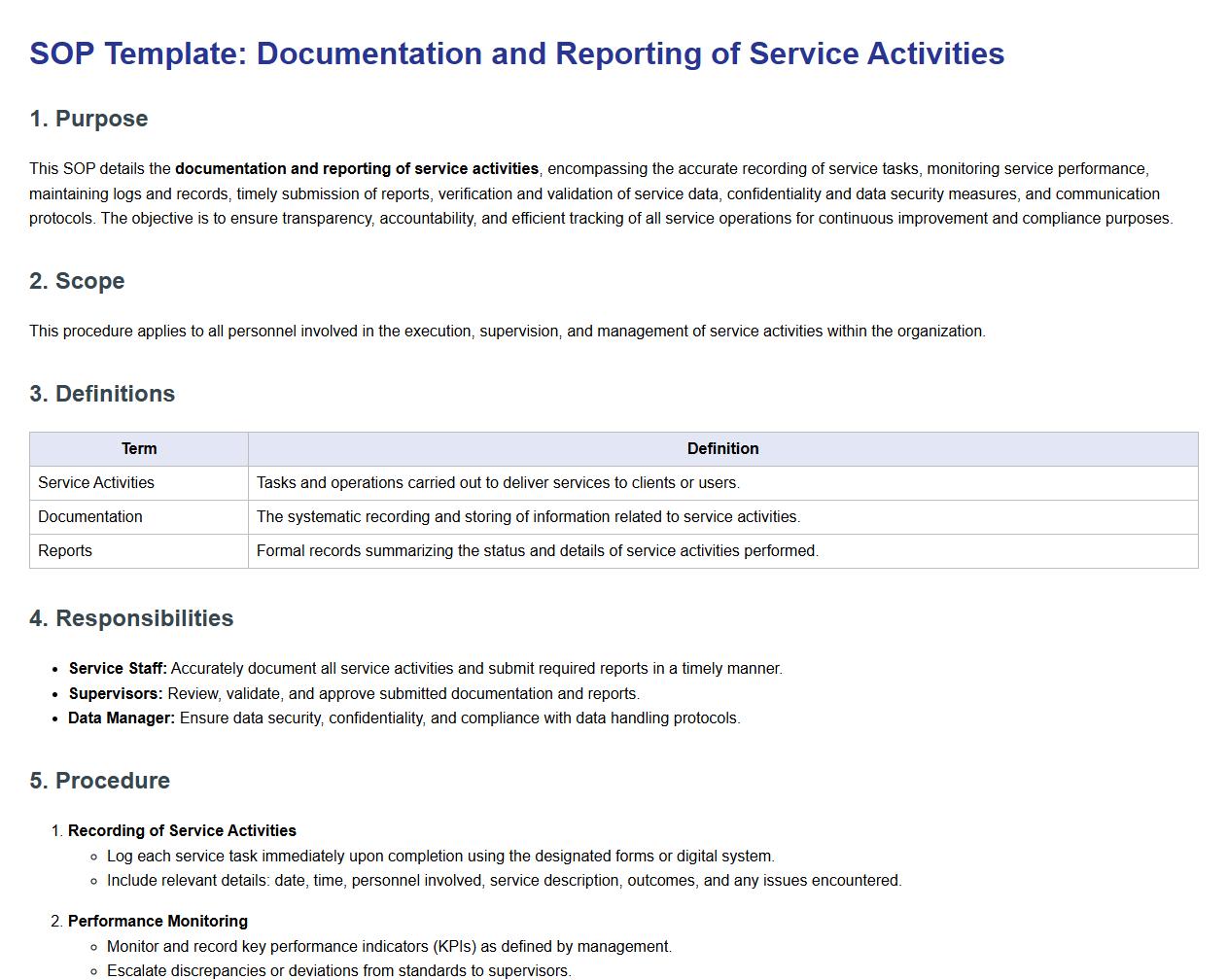

Documentation and reporting of service activities.

This SOP details the documentation and reporting of service activities, encompassing the accurate recording of service tasks, monitoring service performance, maintaining logs and records, timely submission of reports, verification and validation of service data, confidentiality and data security measures, and communication protocols. The objective is to ensure transparency, accountability, and efficient tracking of all service operations for continuous improvement and compliance purposes.

Parts replacement and inventory usage tracking.

This SOP details the process for parts replacement and inventory usage tracking, including procedures for identifying worn or damaged parts, ordering and receiving replacements, updating inventory records, tracking part usage and consumption, conducting regular inventory audits, and ensuring accurate documentation. The goal is to maintain optimal equipment functionality, minimize downtime, and manage inventory efficiently to support ongoing operations.

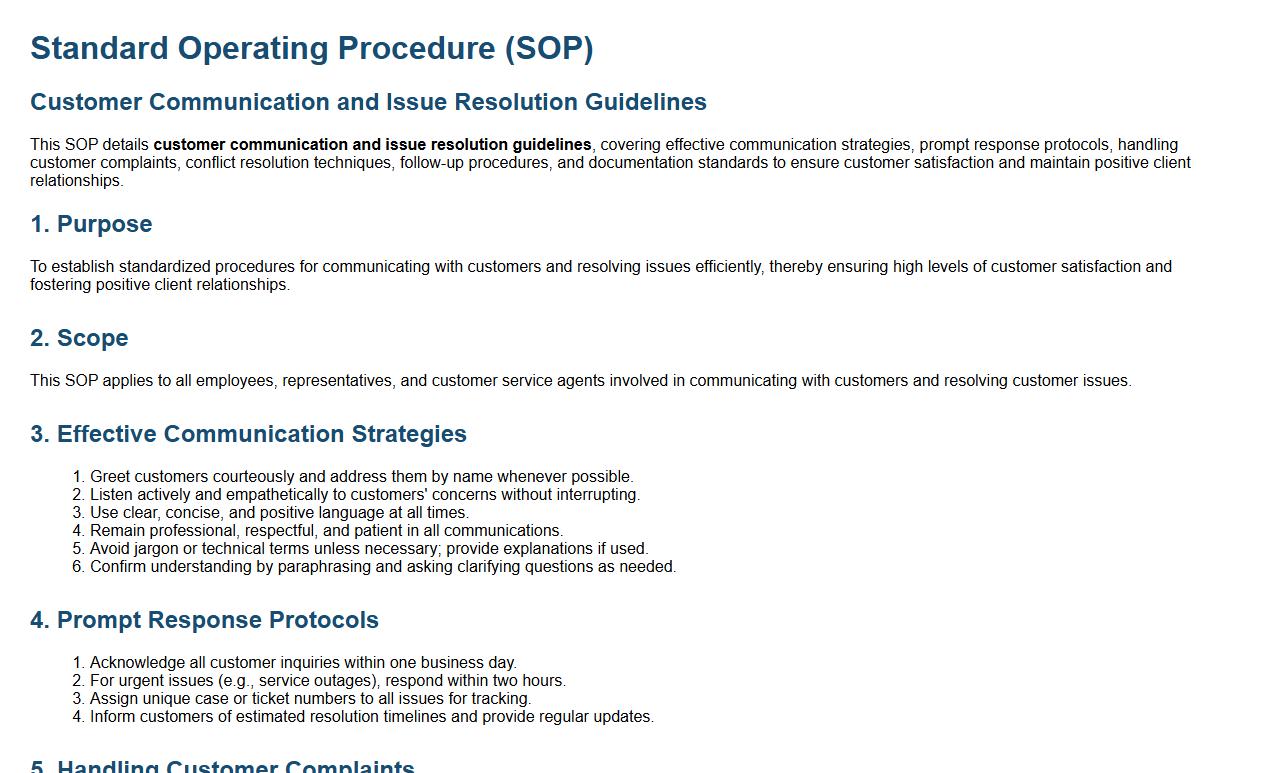

Customer communication and issue resolution guidelines.

This SOP details customer communication and issue resolution guidelines, covering effective communication strategies, prompt response protocols, handling customer complaints, conflict resolution techniques, follow-up procedures, and documentation standards to ensure customer satisfaction and maintain positive client relationships.

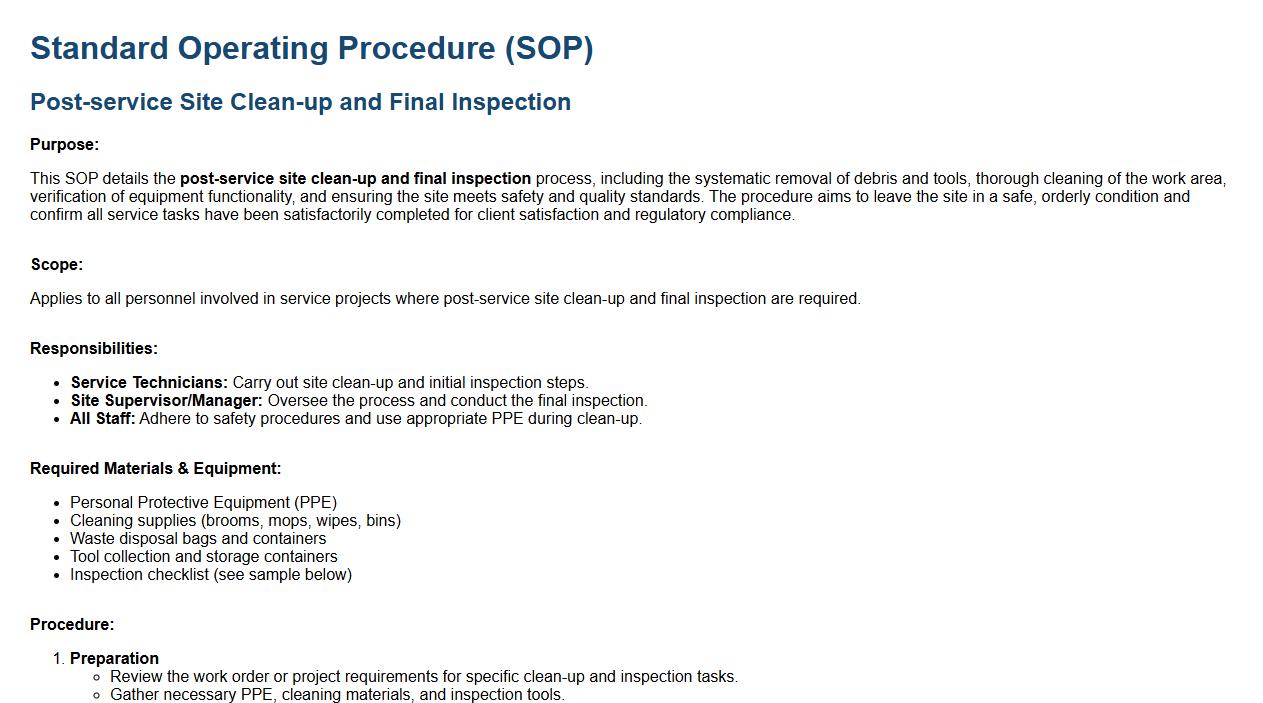

Post-service site clean-up and final inspection.

This SOP details the post-service site clean-up and final inspection process, including the systematic removal of debris and tools, thorough cleaning of the work area, verification of equipment functionality, and ensuring the site meets safety and quality standards. The procedure aims to leave the site in a safe, orderly condition and confirm all service tasks have been satisfactorily completed for client satisfaction and regulatory compliance.

Completion of paperwork and closure of work order.

This SOP details the process for completion of paperwork and closure of work order, including accurate documentation, verification of task completion, final approvals, updating work order status in the system, and archiving records. The goal is to ensure all work is properly recorded, reviewed, and officially closed to maintain operational efficiency and accountability.

What are the critical safety procedures outlined in the SOP that technicians must follow before commencing any fieldwork?

The SOP mandates that technicians conduct a comprehensive risk assessment prior to starting any fieldwork to identify potential hazards. They must ensure all equipment inspections are completed to verify operational safety. Additionally, briefing on safety protocols and emergency response procedures is required before commencing tasks.

How does the SOP define the steps for documenting service activities during and after a field visit?

The SOP requires technicians to maintain a detailed field service log capturing all actions taken and observations during the visit. Technicians must complete a standardized service report immediately after the visit, including any issues encountered and resolutions implemented. This documentation is then submitted electronically to ensure traceability and quality control.

Which communication protocols are specified in the SOP for technicians reporting incidents or equipment malfunctions?

The SOP specifies immediate verbal notification to the designated site supervisor or control center for any incidents or malfunctions. Follow-up written reports must be filed within specified timelines using approved communication channels. Technicians are also instructed to use escalation pathways if initial reports are not addressed promptly.

What are the standard requirements for personal protective equipment (PPE) specified in the SOP for different service environments?

The SOP outlines mandatory PPE guidelines tailored to specific environments, such as gloves, helmets, and eye protection for hazardous areas. Technicians must always verify that PPE complies with industry standards before entering the site. Proper donning and doffing procedures are emphasized to maintain PPE effectiveness and safety.

How does the SOP outline escalation procedures for unresolved technical issues encountered onsite?

The SOP instructs technicians to first attempt onsite troubleshooting following established protocols. If issues remain unresolved, they must escalate the problem to higher-level technical support within a designated timeframe. A formal escalation report is required to document the issue and any actions taken until resolution is reached.