A SOP Template for Retail Order Fulfillment streamlines the process of managing customer orders from receipt to delivery, ensuring accuracy and efficiency. This template outlines clear steps for order verification, inventory checks, packaging, and shipment to maintain consistent service quality. Utilizing a standardized SOP reduces errors, improves customer satisfaction, and supports effective workforce training.

Order receipt and verification process.

The order receipt and verification process ensures accurate and timely handling of incoming orders by systematically confirming order details, verifying customer information, and cross-checking product availability. This process minimizes errors, enhances customer satisfaction, and streamlines workflow by providing clear steps for order acknowledgment, validation, and documentation.

Order entry and customer information validation.

This SOP details the order entry and customer information validation process, including accurate data capture, verification of customer details, validation of product availability, pricing accuracy, and confirmation protocols. The aim is to ensure precise order processing, minimize errors, enhance customer satisfaction, and streamline communication between sales and fulfillment departments.

Inventory stock level check and allocation.

This SOP details the process for inventory stock level check and allocation, covering regular stock assessments, accurate recording of inventory quantities, setting reorder thresholds, prioritizing stock distribution based on demand and availability, preventing stockouts and overstock situations, coordinating with procurement and warehouse teams, and maintaining comprehensive documentation to ensure efficient inventory management and optimal resource utilization.

Picking list generation and item location identification.

This SOP details the process for picking list generation and item location identification to optimize order fulfillment efficiency. It covers the systematic creation of accurate picking lists based on customer orders, the use of inventory management systems to pinpoint item locations within the warehouse, and procedures to verify item availability. This ensures timely and precise order preparation, reducing errors and improving overall warehouse productivity.

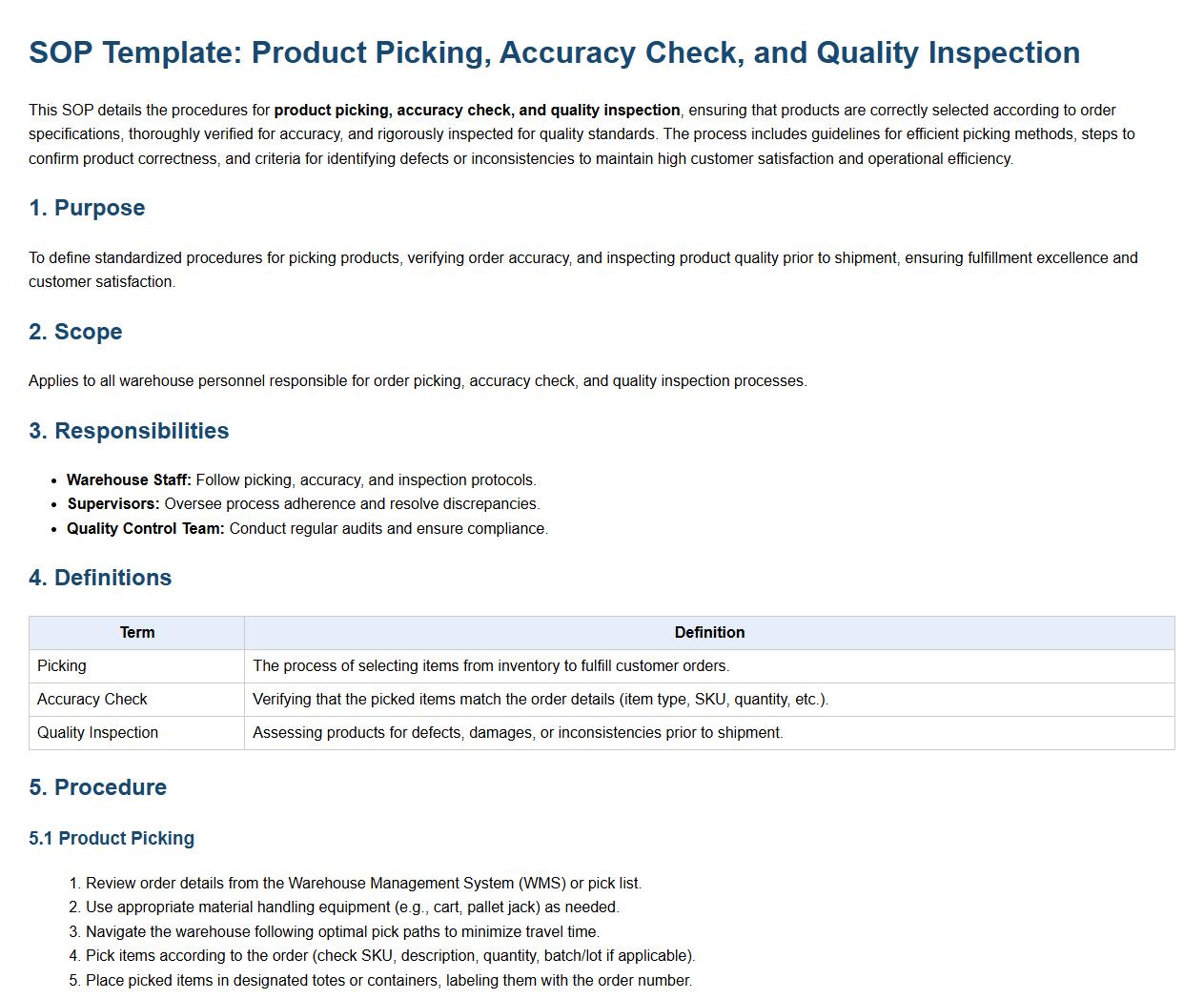

Product picking, accuracy check, and quality inspection.

This SOP details the procedures for product picking, accuracy check, and quality inspection, ensuring that products are correctly selected according to order specifications, thoroughly verified for accuracy, and rigorously inspected for quality standards. The process includes guidelines for efficient picking methods, steps to confirm product correctness, and criteria for identifying defects or inconsistencies to maintain high customer satisfaction and operational efficiency.

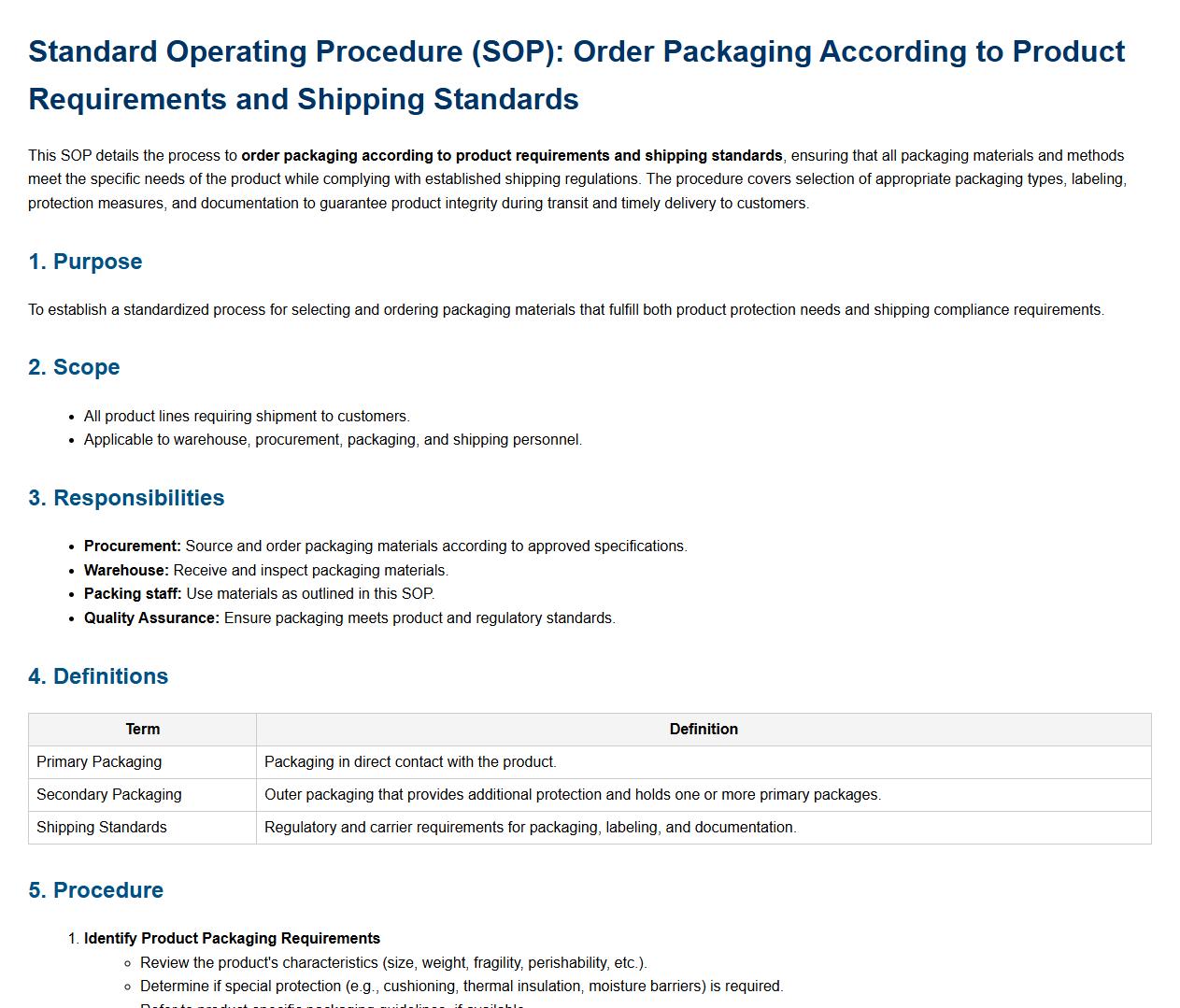

Order packaging according to product requirements and shipping standards.

This SOP details the process to order packaging according to product requirements and shipping standards, ensuring that all packaging materials and methods meet the specific needs of the product while complying with established shipping regulations. The procedure covers selection of appropriate packaging types, labeling, protection measures, and documentation to guarantee product integrity during transit and timely delivery to customers.

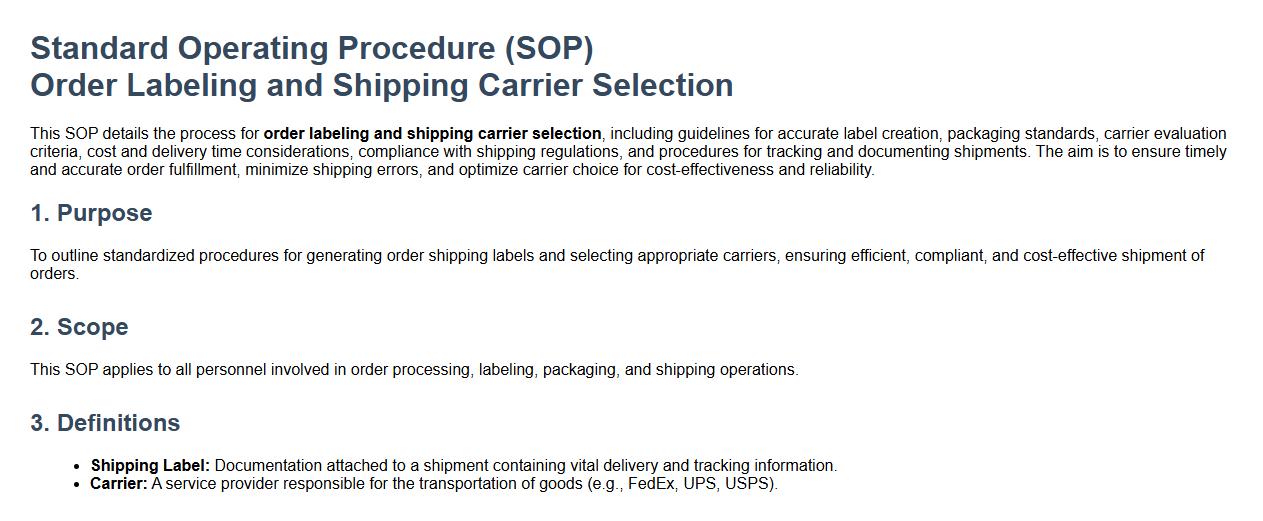

Order labeling and shipping carrier selection.

This SOP details the process for order labeling and shipping carrier selection, including guidelines for accurate label creation, packaging standards, carrier evaluation criteria, cost and delivery time considerations, compliance with shipping regulations, and procedures for tracking and documenting shipments. The aim is to ensure timely and accurate order fulfillment, minimize shipping errors, and optimize carrier choice for cost-effectiveness and reliability.

Order dispatch and handover to shipping provider.

This SOP details the order dispatch and handover to shipping provider process, including order verification, packaging standards, labeling requirements, documentation preparation, coordination with shipping partners, and confirmation of handover. The goal is to ensure accurate, timely, and secure transfer of orders to the shipping provider, facilitating efficient delivery and maintaining customer satisfaction.

Order confirmation and tracking communication to customer.

This SOP details the process for order confirmation and tracking communication to customers, ensuring timely and accurate updates about order status. It includes verifying order details, sending immediate confirmation emails, providing tracking information once the order ships, managing customer inquiries related to order status, and ensuring consistent, clear, and professional communication throughout the order fulfillment process to enhance customer satisfaction and trust.

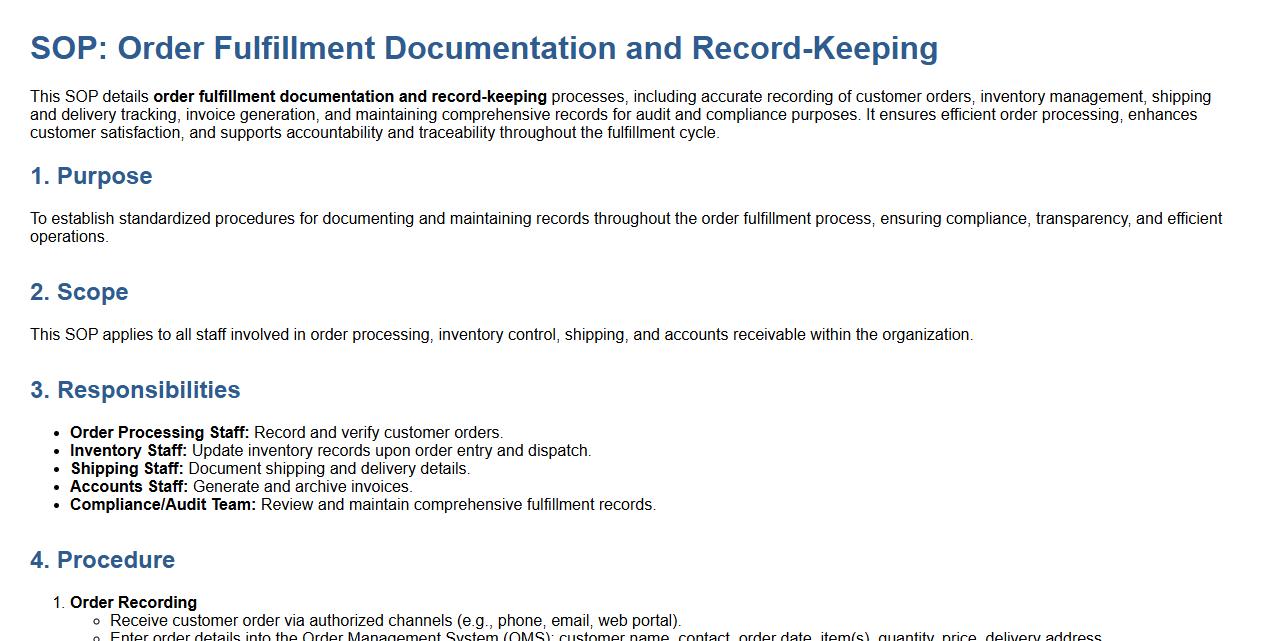

Order fulfillment documentation and record-keeping.

This SOP details order fulfillment documentation and record-keeping processes, including accurate recording of customer orders, inventory management, shipping and delivery tracking, invoice generation, and maintaining comprehensive records for audit and compliance purposes. It ensures efficient order processing, enhances customer satisfaction, and supports accountability and traceability throughout the fulfillment cycle.

What are the primary steps outlined in the SOP for processing retail orders from receipt to delivery?

The SOP begins with the order receipt stage, ensuring all customer details are accurately captured. Next is the order processing, where inventory is checked, and items are picked and packed. Finally, the delivery phase involves coordinating shipment and confirming order arrival with the customer.

Which roles and responsibilities are defined within the order fulfillment process according to the SOP?

The SOP clearly defines roles such as order processors who handle order entry and verification. Warehouse staff are responsible for picking and packing items efficiently. Delivery personnel ensure timely and secure order dispatch and customer handoff.

What quality control measures are specified in the SOP to ensure order accuracy and customer satisfaction?

The SOP mandates double-checking order details during processing to reduce errors. It includes regular inventory audits to maintain stock accuracy. Customer feedback is systematically collected to enhance service quality and address any issues promptly.

How does the SOP address exceptions, such as out-of-stock items or order cancellations?

Out-of-stock items trigger an immediate notification protocol to inform customers about alternatives or delays. The SOP includes clear steps for order cancellation processing to ensure refunds and documentation are handled efficiently. It also outlines escalation procedures for unresolved order exceptions.

What documentation or records are mandated by the SOP to track each stage of retail order fulfillment?

The SOP requires maintaining detailed order logs capturing each transaction step from receipt to delivery. Inventory movement is recorded through packing slips and shipment tracking documents. Customer communications and exception reports are also systematically archived for accountability and auditing.