The SOP Template for Retail Delivery Receiving ensures a standardized process for verifying and accepting incoming shipments, minimizing errors and discrepancies. It outlines clear steps for inspecting goods, documenting delivery details, and reporting any damages or shortages. This template helps retail businesses maintain inventory accuracy and improve overall supply chain efficiency.

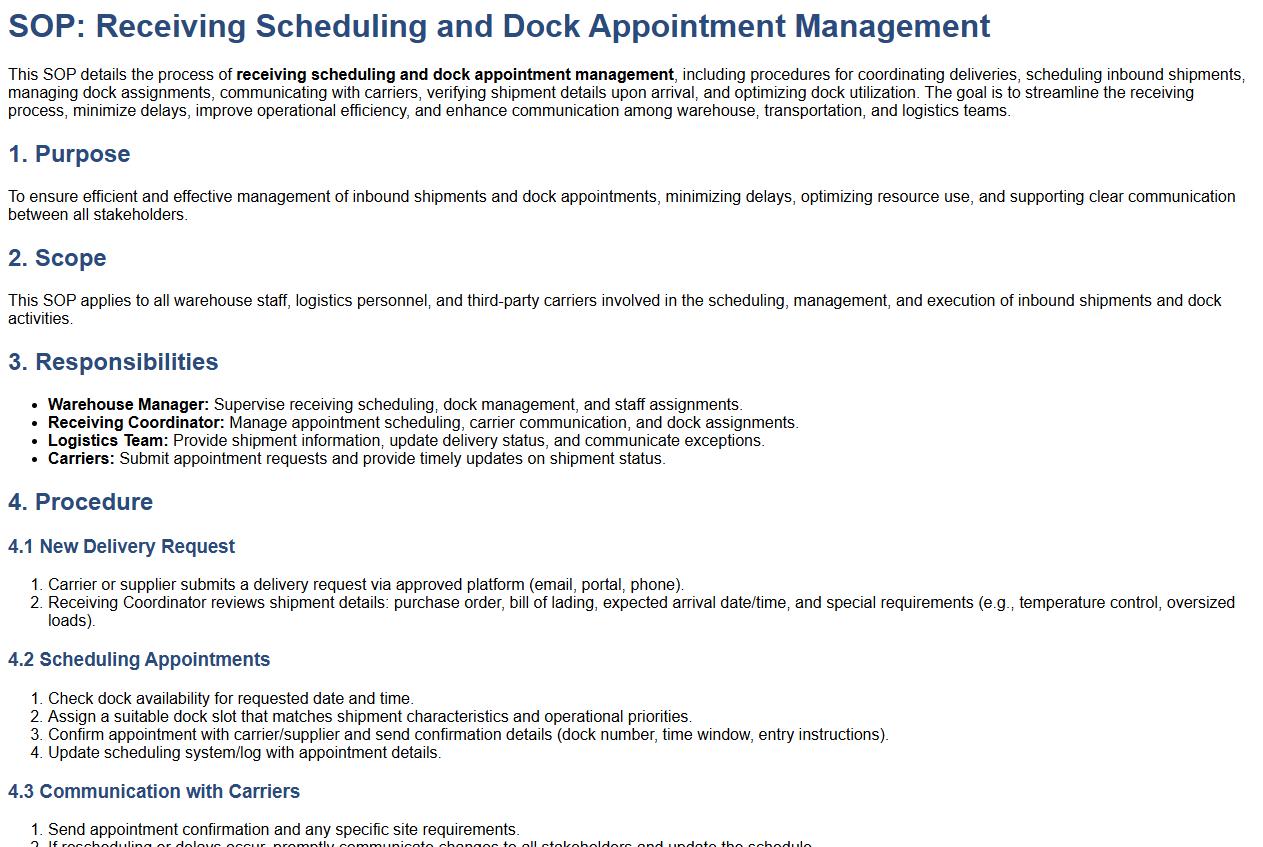

Receiving scheduling and dock appointment management.

This SOP details the process of receiving scheduling and dock appointment management, including procedures for coordinating deliveries, scheduling inbound shipments, managing dock assignments, communicating with carriers, verifying shipment details upon arrival, and optimizing dock utilization. The goal is to streamline the receiving process, minimize delays, improve operational efficiency, and enhance communication among warehouse, transportation, and logistics teams.

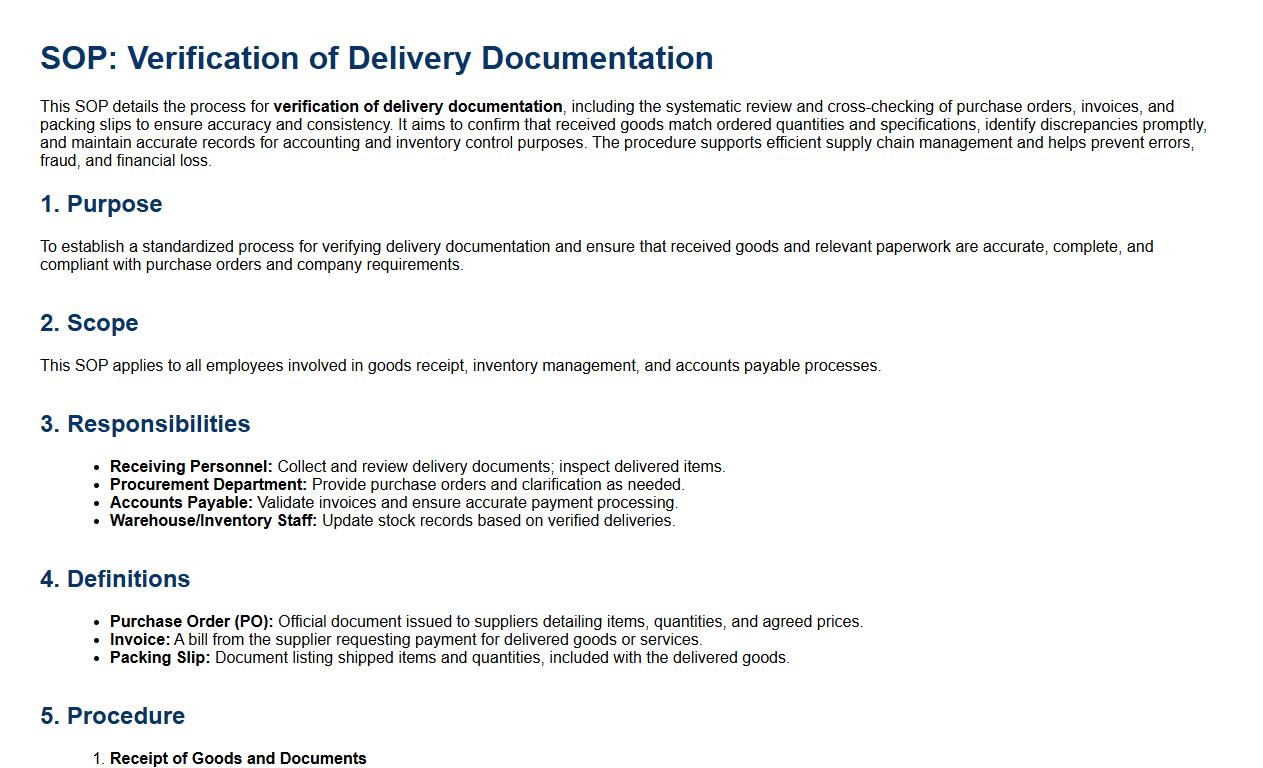

Verification of delivery documentation (purchase orders, invoices, packing slips).

This SOP details the process for verification of delivery documentation, including the systematic review and cross-checking of purchase orders, invoices, and packing slips to ensure accuracy and consistency. It aims to confirm that received goods match ordered quantities and specifications, identify discrepancies promptly, and maintain accurate records for accounting and inventory control purposes. The procedure supports efficient supply chain management and helps prevent errors, fraud, and financial loss.

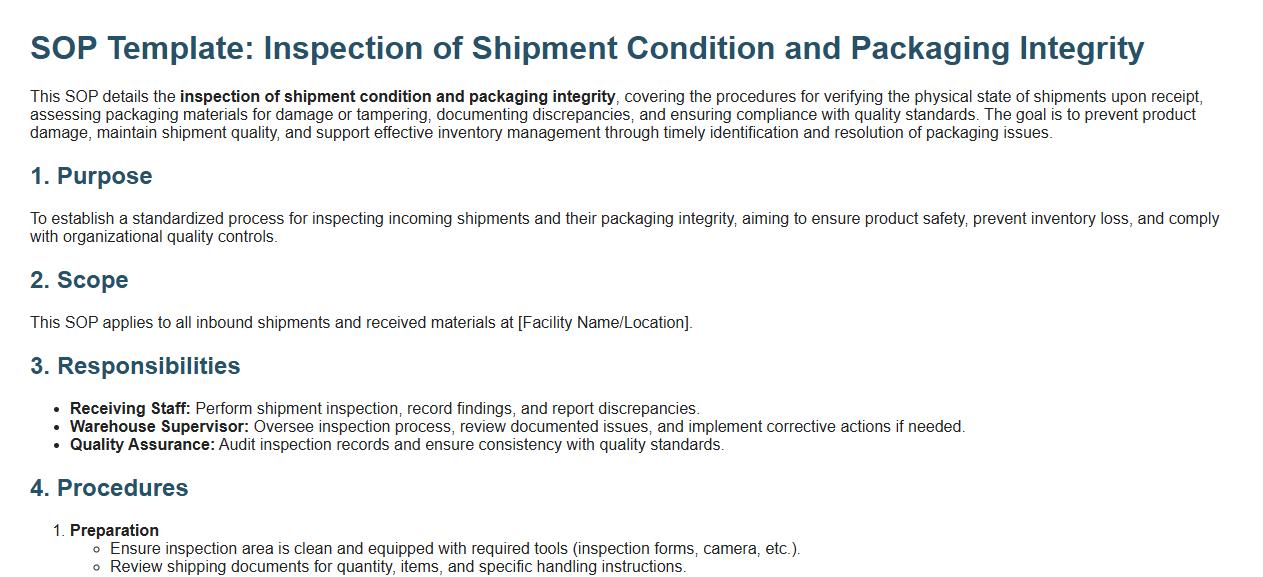

Inspection of shipment condition and packaging integrity.

This SOP details the inspection of shipment condition and packaging integrity, covering the procedures for verifying the physical state of shipments upon receipt, assessing packaging materials for damage or tampering, documenting discrepancies, and ensuring compliance with quality standards. The goal is to prevent product damage, maintain shipment quality, and support effective inventory management through timely identification and resolution of packaging issues.

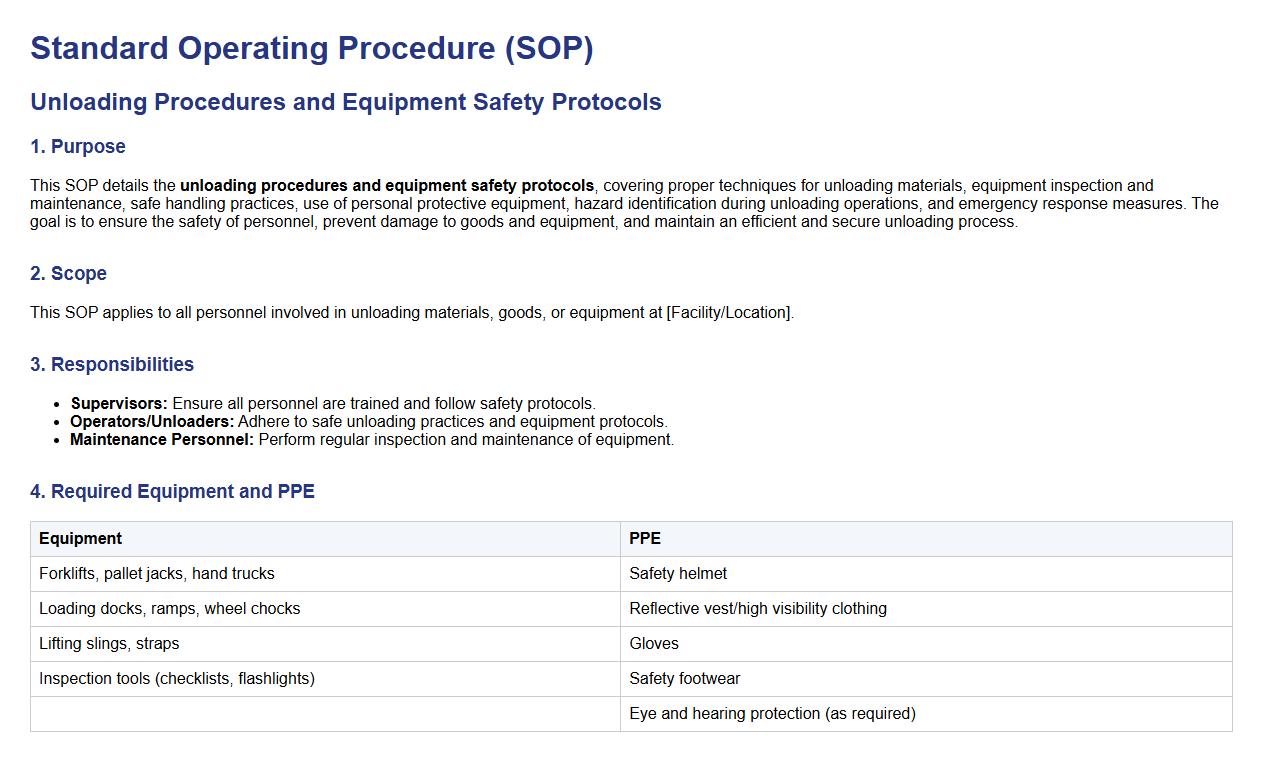

Unloading procedures and equipment safety protocols.

This SOP details the unloading procedures and equipment safety protocols, covering proper techniques for unloading materials, equipment inspection and maintenance, safe handling practices, use of personal protective equipment, hazard identification during unloading operations, and emergency response measures. The goal is to ensure the safety of personnel, prevent damage to goods and equipment, and maintain an efficient and secure unloading process.

Product quantity and quality checks against order details.

This SOP details the process for conducting product quantity and quality checks against order details, including verifying received quantities, inspecting product quality standards, cross-referencing order specifications, documenting discrepancies, and ensuring compliance with customer requirements to maintain accuracy and satisfaction in order fulfillment.

Damaged or missing goods reporting and documentation.

This SOP details the process for damaged or missing goods reporting and documentation, covering identification, reporting protocols, documentation requirements, communication with relevant departments, investigation procedures, and corrective actions. The aim is to ensure accurate tracking, timely resolution, and prevention of future occurrences to maintain inventory integrity and operational efficiency.

Labeling, tagging, and barcode verification process.

This SOP defines the labeling, tagging, and barcode verification process to ensure accurate identification and tracking of products. It covers the standards for applying labels and tags, barcode generation protocols, verification procedures to maintain data integrity, and steps for handling discrepancies. The goal is to streamline inventory management, reduce errors, and improve traceability throughout the supply chain.

Inventory system entry and stock location assignment.

This SOP details the process for inventory system entry and stock location assignment, covering accurate recording of incoming stock, assigning precise storage locations, updating inventory databases, and ensuring traceability of all products. The goal is to maintain organized stock management, streamline retrieval, and enhance inventory accuracy across all warehouse operations.

Cleaning and organization of receiving area post-delivery.

This SOP details the cleaning and organization of the receiving area post-delivery, including the removal of packaging materials, proper disposal of waste, sanitization of surfaces, arrangement of received goods, inspection for damages, and maintenance of a safe, efficient, and clutter-free environment to facilitate smooth operations and compliance with safety standards.

Record-keeping and reporting for audit and compliance purposes.

This SOP details the processes for record-keeping and reporting for audit and compliance purposes, ensuring accurate documentation of all relevant activities, maintaining organized records, adhering to regulatory requirements, and facilitating timely reporting to auditors and authorities. This procedure supports transparency, accountability, and legal compliance within the organization.

What is the primary purpose of the Retail Delivery Receiving SOP?

The primary purpose of the Retail Delivery Receiving SOP is to ensure a standardized process for receiving goods at retail locations. It aims to maintain accuracy in delivery acceptance and safeguard inventory integrity. This SOP helps in minimizing errors and discrepancies during the receiving process.

Which personnel are authorized to receive and inspect deliveries according to the SOP?

Only authorized personnel, typically trained receiving clerks or designated staff, are permitted to receive and inspect retail deliveries. These individuals are responsible for verifying shipment contents against purchase orders. Proper authorization ensures accountability and proper handling of goods.

What specific documentation must be completed and verified during the receiving process per the SOP?

The key documentation includes delivery receipts, inspection forms, and inventory logs. Personnel must verify quantities, item descriptions, and condition against the purchase order and delivery manifest. Accurate record-keeping is critical to track inventory and resolve potential disputes.

What steps must be followed for reporting discrepancies or damages found upon delivery?

Any discrepancies or damages must be documented immediately with photographs and written reports. The receiving staff should notify their supervisor and the supplier promptly to initiate claims or corrective actions. Timely reporting minimizes financial loss and ensures product quality standards.

What are the required procedures for storing received goods as outlined in the SOP?

Received goods must be stored according to specified protocols that ensure proper handling, categorization, and rotation. Items should be placed in designated areas with appropriate labeling, ensuring easy accessibility and stock control. Proper storage extends product shelf life and supports efficient inventory management.