A SOP Template for Professional Laundry Services ensures consistent quality and operational efficiency by providing clear, step-by-step instructions for every stage of the laundry process. It helps staff maintain hygiene standards, handle fabrics correctly, and operate equipment safely. This template streamlines training and guarantees customer satisfaction through reliable service delivery.

Laundry intake and item tagging procedures.

This SOP details the laundry intake and item tagging procedures, covering the proper methods for receiving laundry items, inspecting for damages or stains, accurately tagging each item with identification labels, and documenting the intake process to ensure efficient tracking and handling of laundry throughout the cleaning cycle. The goal is to maintain organization, prevent loss or mix-ups, and enhance overall laundry service quality.

Sorting and pre-treatment of laundry.

This SOP details the sorting and pre-treatment of laundry, covering the proper categorization of fabrics by color, type, and soil level, the identification and removal of stains, the selection of suitable pre-treatment solutions, and the safe handling of soiled materials. The procedure ensures efficient laundering, fabric protection, and hygiene standards by minimizing cross-contamination and preparing laundry for optimal cleaning results.

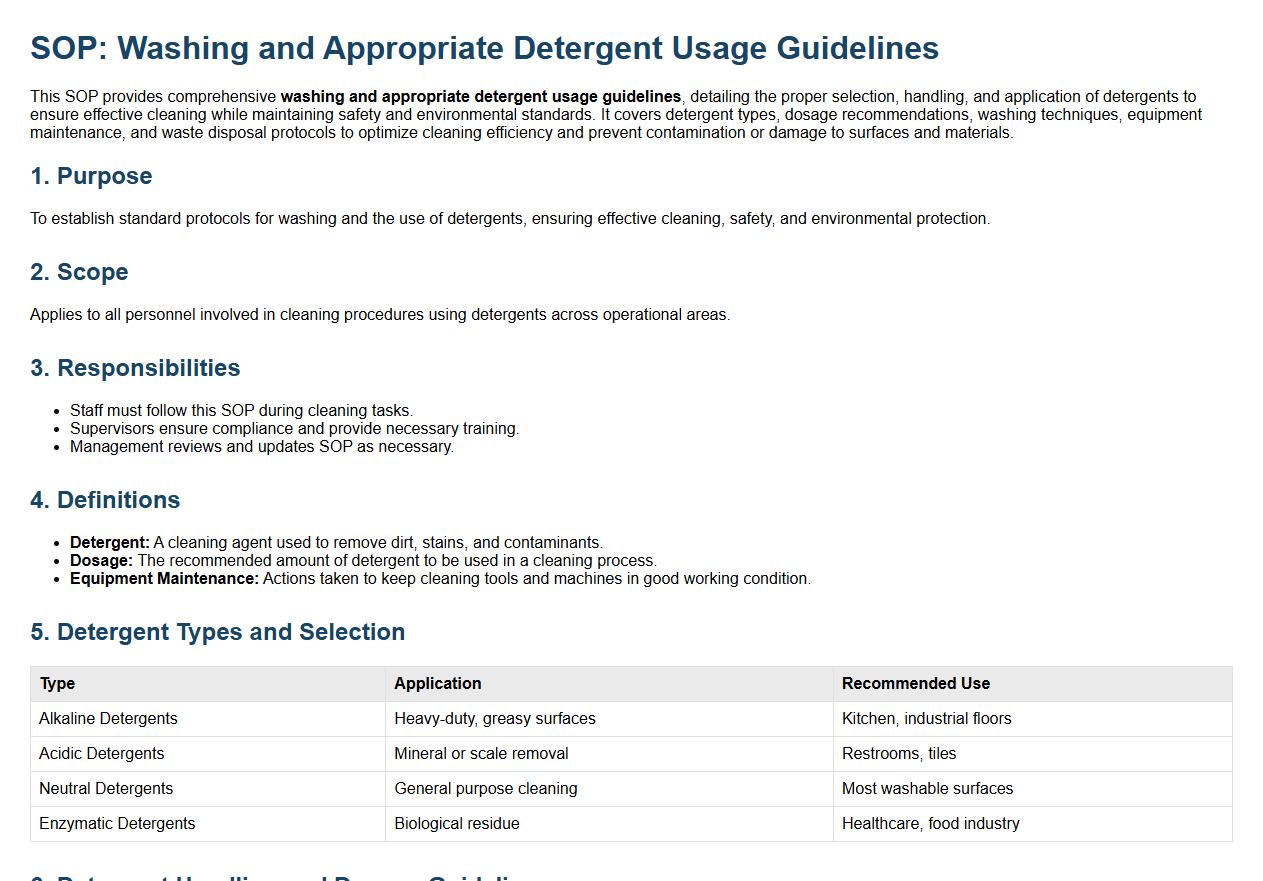

Washing and appropriate detergent usage guidelines.

This SOP provides comprehensive washing and appropriate detergent usage guidelines, detailing the proper selection, handling, and application of detergents to ensure effective cleaning while maintaining safety and environmental standards. It covers detergent types, dosage recommendations, washing techniques, equipment maintenance, and waste disposal protocols to optimize cleaning efficiency and prevent contamination or damage to surfaces and materials.

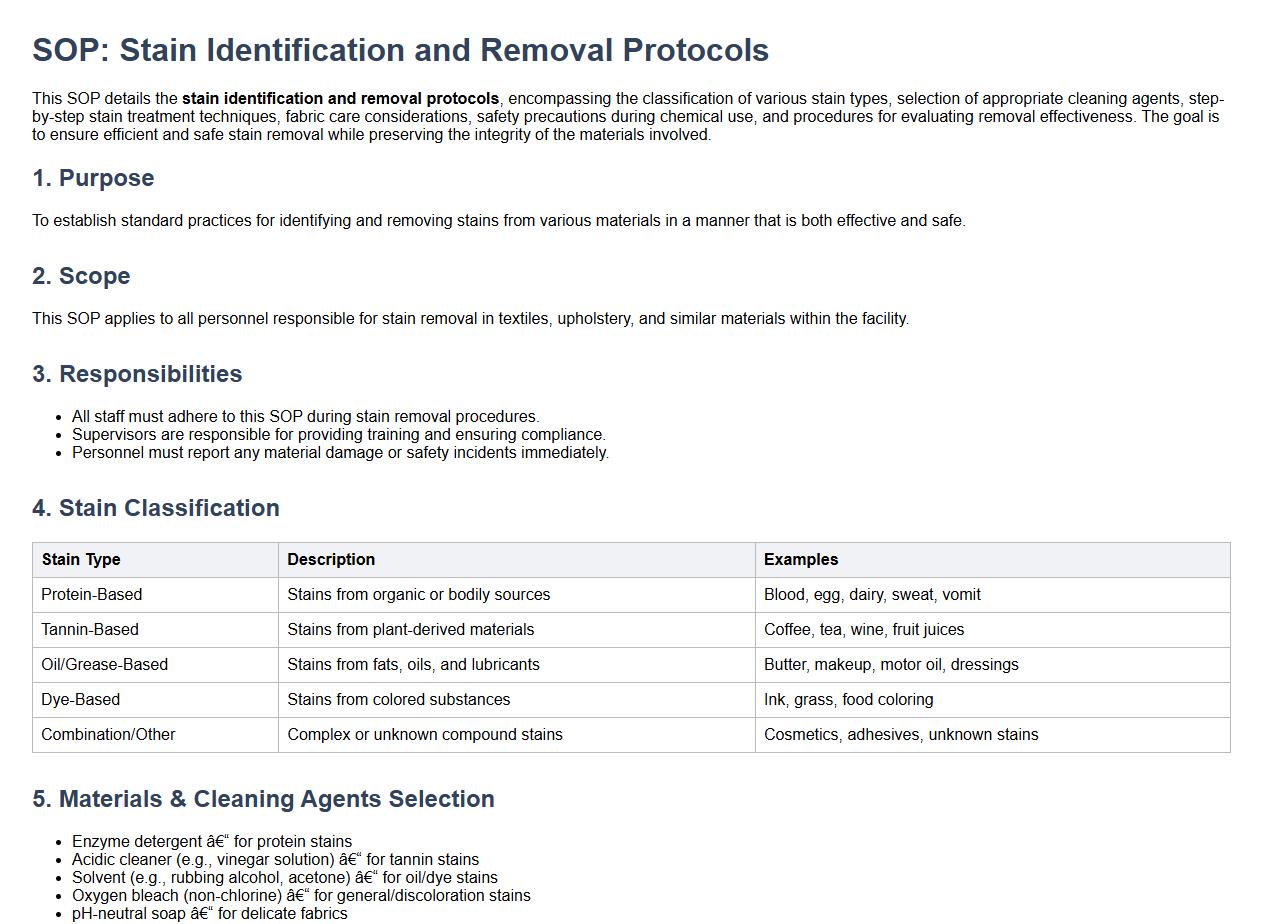

Stain identification and removal protocols.

This SOP details the stain identification and removal protocols, encompassing the classification of various stain types, selection of appropriate cleaning agents, step-by-step stain treatment techniques, fabric care considerations, safety precautions during chemical use, and procedures for evaluating removal effectiveness. The goal is to ensure efficient and safe stain removal while preserving the integrity of the materials involved.

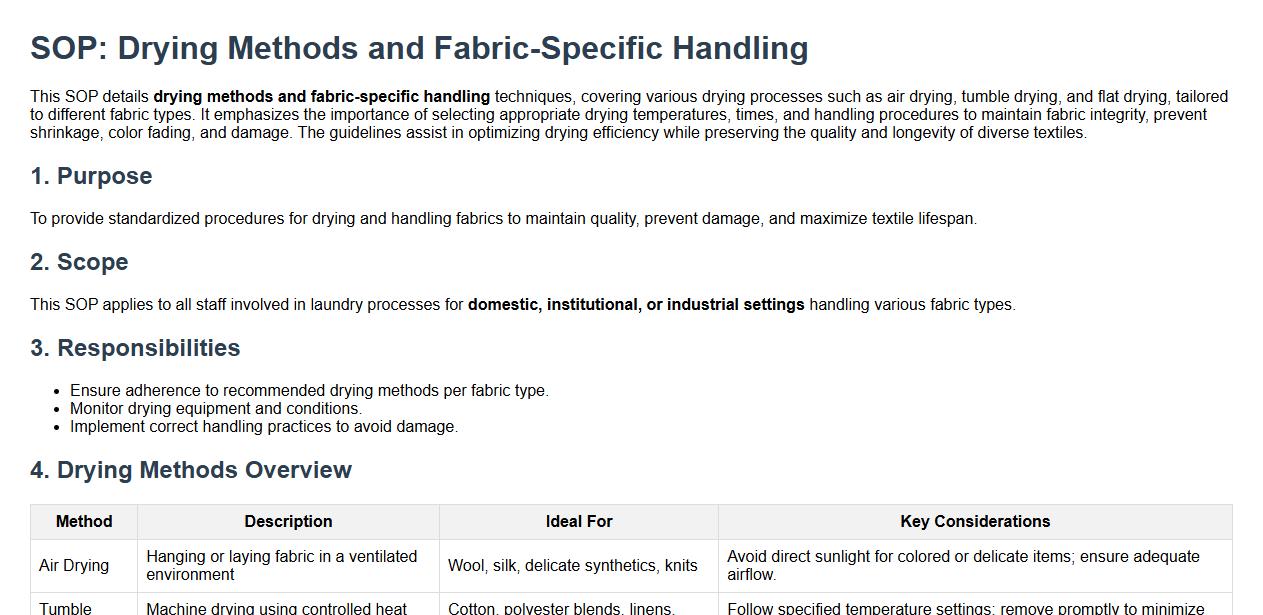

Drying methods and fabric-specific handling.

This SOP details drying methods and fabric-specific handling techniques, covering various drying processes such as air drying, tumble drying, and flat drying, tailored to different fabric types. It emphasizes the importance of selecting appropriate drying temperatures, times, and handling procedures to maintain fabric integrity, prevent shrinkage, color fading, and damage. The guidelines assist in optimizing drying efficiency while preserving the quality and longevity of diverse textiles.

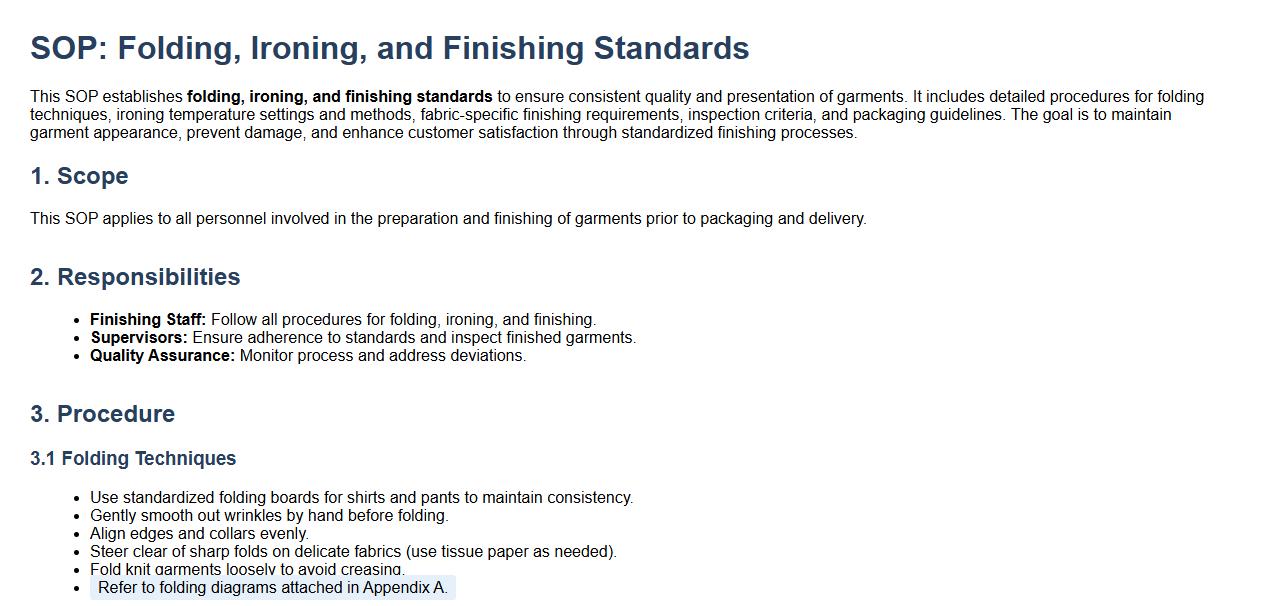

Folding, ironing, and finishing standards.

This SOP establishes folding, ironing, and finishing standards to ensure consistent quality and presentation of garments. It includes detailed procedures for folding techniques, ironing temperature settings and methods, fabric-specific finishing requirements, inspection criteria, and packaging guidelines. The goal is to maintain garment appearance, prevent damage, and enhance customer satisfaction through standardized finishing processes.

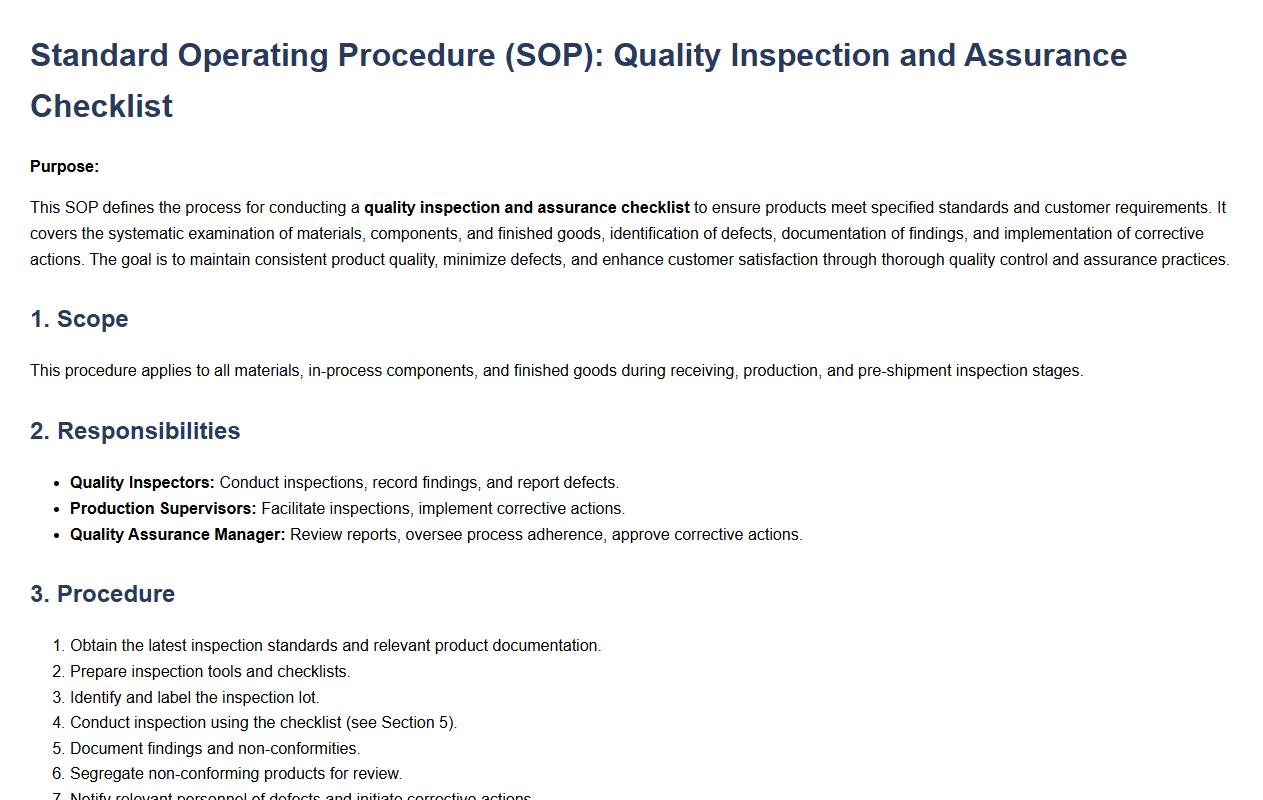

Quality inspection and assurance checklist.

This SOP defines the process for conducting a quality inspection and assurance checklist to ensure products meet specified standards and customer requirements. It covers the systematic examination of materials, components, and finished goods, identification of defects, documentation of findings, and implementation of corrective actions. The goal is to maintain consistent product quality, minimize defects, and enhance customer satisfaction through thorough quality control and assurance practices.

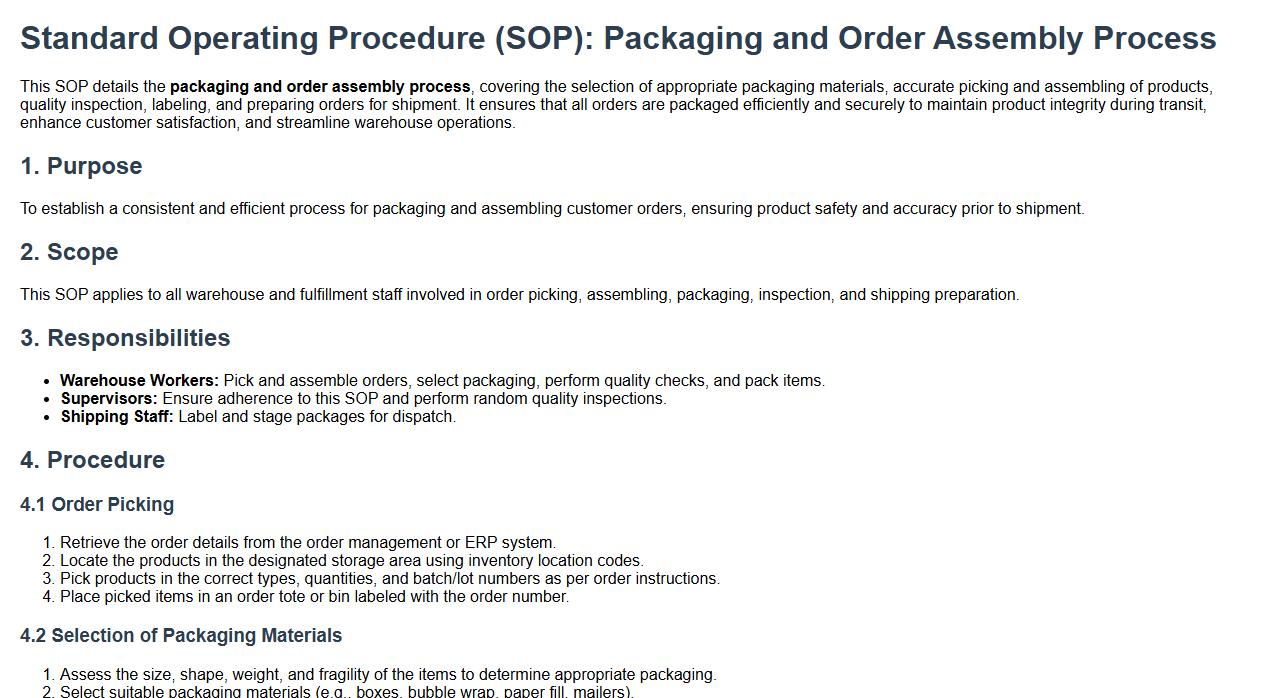

Packaging and order assembly process.

This SOP details the packaging and order assembly process, covering the selection of appropriate packaging materials, accurate picking and assembling of products, quality inspection, labeling, and preparing orders for shipment. It ensures that all orders are packaged efficiently and securely to maintain product integrity during transit, enhance customer satisfaction, and streamline warehouse operations.

Lost and damaged item resolution procedure.

This SOP defines the lost and damaged item resolution procedure, detailing the steps for reporting, investigating, and resolving incidents involving lost or damaged items. It includes guidelines for documenting occurrences, assessing responsibility, communicating with relevant parties, and implementing corrective actions to prevent recurrence. The objective is to ensure timely and effective resolution while minimizing operational disruptions and maintaining accountability.

Laundry delivery and customer feedback process.

This SOP details the laundry delivery and customer feedback process, covering the steps for timely and accurate delivery of laundry services, customer communication protocols, feedback collection methods, handling customer complaints, and continuous service improvement. The goal is to enhance customer satisfaction by ensuring efficient delivery operations and addressing customer concerns promptly.

What are the primary objectives and scope defined in the SOP for Professional Laundry Services?

The primary objective of the SOP is to ensure consistent and high-quality laundry service delivery. It defines the entire scope from receiving soiled items to the final distribution of clean laundry. This SOP aims to optimize operational efficiency while maintaining hygiene standards.

Which safety and hygiene protocols must staff follow during all stages of laundry handling?

Staff must adhere to strict safety and hygiene protocols including wearing protective gear and regular hand washing. Contaminated items should be handled with care to prevent cross-contamination. Proper disinfection of work areas and equipment is mandatory at each stage.

How are different fabric types and stains identified, sorted, and processed according to the SOP?

The SOP mandates identifying fabric types through labeling and visual inspection for accurate sorting of laundry. Stains are categorized by type to apply the most effective pre-treatment methods. Proper sorting ensures tailored washing cycles that protect fabric integrity.

What procedures are outlined for machine operation, maintenance, and routine equipment checks in the laundry workflow?

The SOP details standard steps for safe machine operation including correct loading and cycle selection. It also requires routine maintenance schedules to prevent breakdowns and ensure optimal performance. Regular equipment inspections are documented to guarantee operational reliability.

What documentation, recordkeeping, and quality assurance measures are required by the SOP for service accountability?

Accurate recordkeeping is essential to track laundry batches, including input and output logs. Quality assurance checks are conducted to verify cleanliness and compliance with service standards. The SOP demands maintaining detailed documentation for audit and accountability purposes.