A SOP Template for Continuous Improvement in Manufacturing provides a structured framework for standardizing processes aimed at enhancing efficiency and quality. It outlines clear procedures for identifying, analyzing, and implementing improvements to manufacturing operations. This template ensures consistency and supports ongoing operational excellence by promoting systematic evaluation and refinement.

Continuous improvement team formation and roles assignment.

This SOP details the process for continuous improvement team formation and roles assignment, including the selection criteria for team members, defining team objectives, assigning specific roles and responsibilities, establishing communication protocols, setting performance metrics, and scheduling regular review meetings. The goal is to create an effective team structure that drives ongoing operational enhancements and fosters a culture of continuous improvement across the organization.

Identification and documentation of improvement opportunities.

This SOP describes the process for the identification and documentation of improvement opportunities, focusing on systematically recognizing areas for enhancement, recording observations and suggestions, evaluating potential benefits, and communicating findings to relevant stakeholders. The goal is to foster continuous improvement by ensuring that all improvement opportunities are accurately captured, assessed, and tracked for implementation within the organization.

Standardized problem-solving process (e.g., PDCA, DMAIC) guidelines.

This SOP defines the standardized problem-solving process guidelines, including the application of methodologies such as PDCA (Plan-Do-Check-Act) and DMAIC (Define-Measure-Analyze-Improve-Control). It outlines systematic steps for identifying, analyzing, and resolving problems effectively to ensure continuous improvement and consistent results across projects and operations.

Root cause analysis procedures (e.g., 5 Whys, Fishbone Diagram).

This SOP details the root cause analysis procedures, including methodologies such as the 5 Whys and Fishbone Diagram. It provides systematic approaches to identify the underlying causes of problems or incidents by asking iterative questions and visually mapping contributing factors. The purpose is to enable effective problem-solving, prevent recurrence, and improve overall organizational processes through thorough investigation and analysis.

Establishing and tracking key performance indicators (KPIs).

This SOP details the process for establishing and tracking key performance indicators (KPIs) to effectively monitor and evaluate organizational performance. It covers the identification of relevant KPIs aligned with strategic objectives, setting measurable targets, data collection methods, regular monitoring, and reporting procedures. The purpose is to ensure continuous improvement, informed decision-making, and achievement of business goals by systematically tracking and analyzing performance metrics.

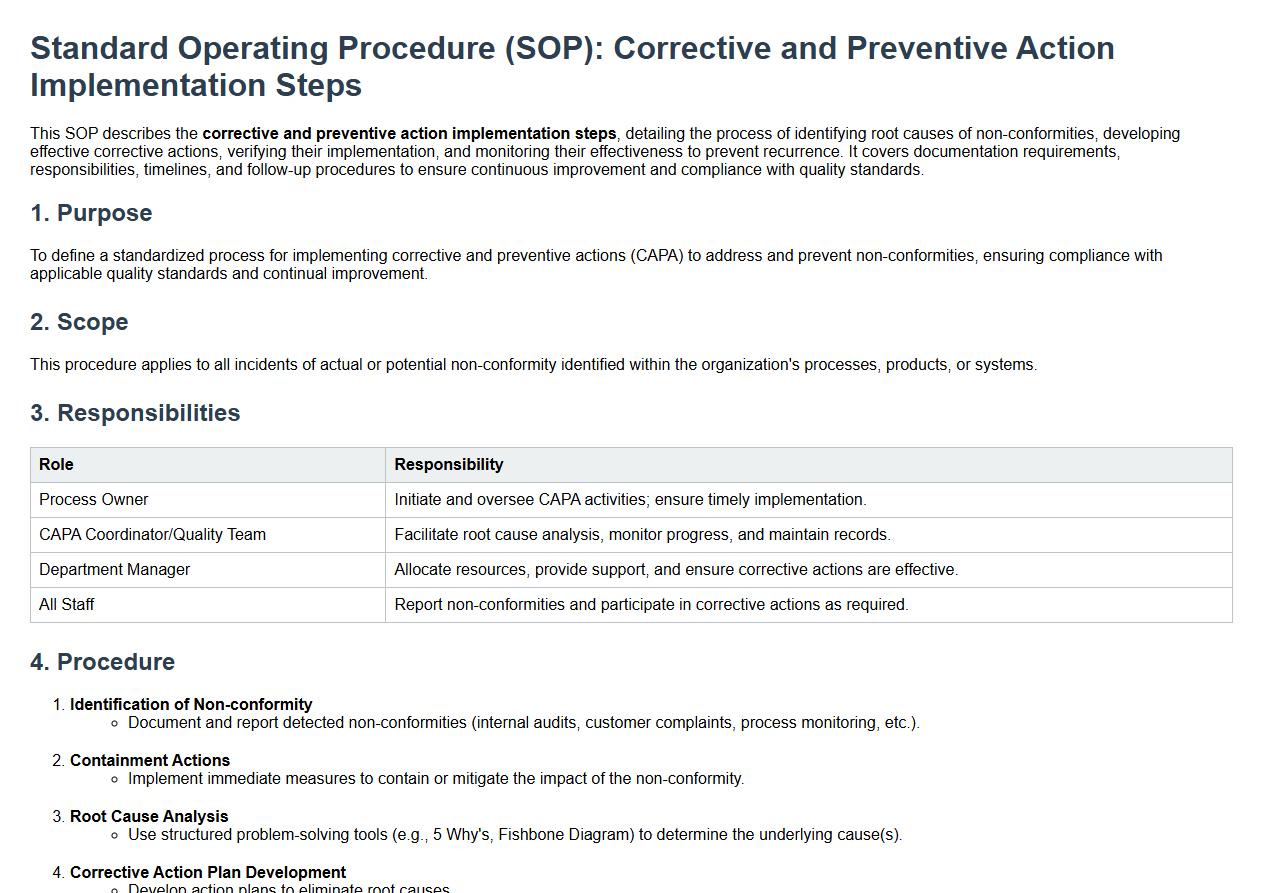

Corrective and preventive action implementation steps.

This SOP describes the corrective and preventive action implementation steps, detailing the process of identifying root causes of non-conformities, developing effective corrective actions, verifying their implementation, and monitoring their effectiveness to prevent recurrence. It covers documentation requirements, responsibilities, timelines, and follow-up procedures to ensure continuous improvement and compliance with quality standards.

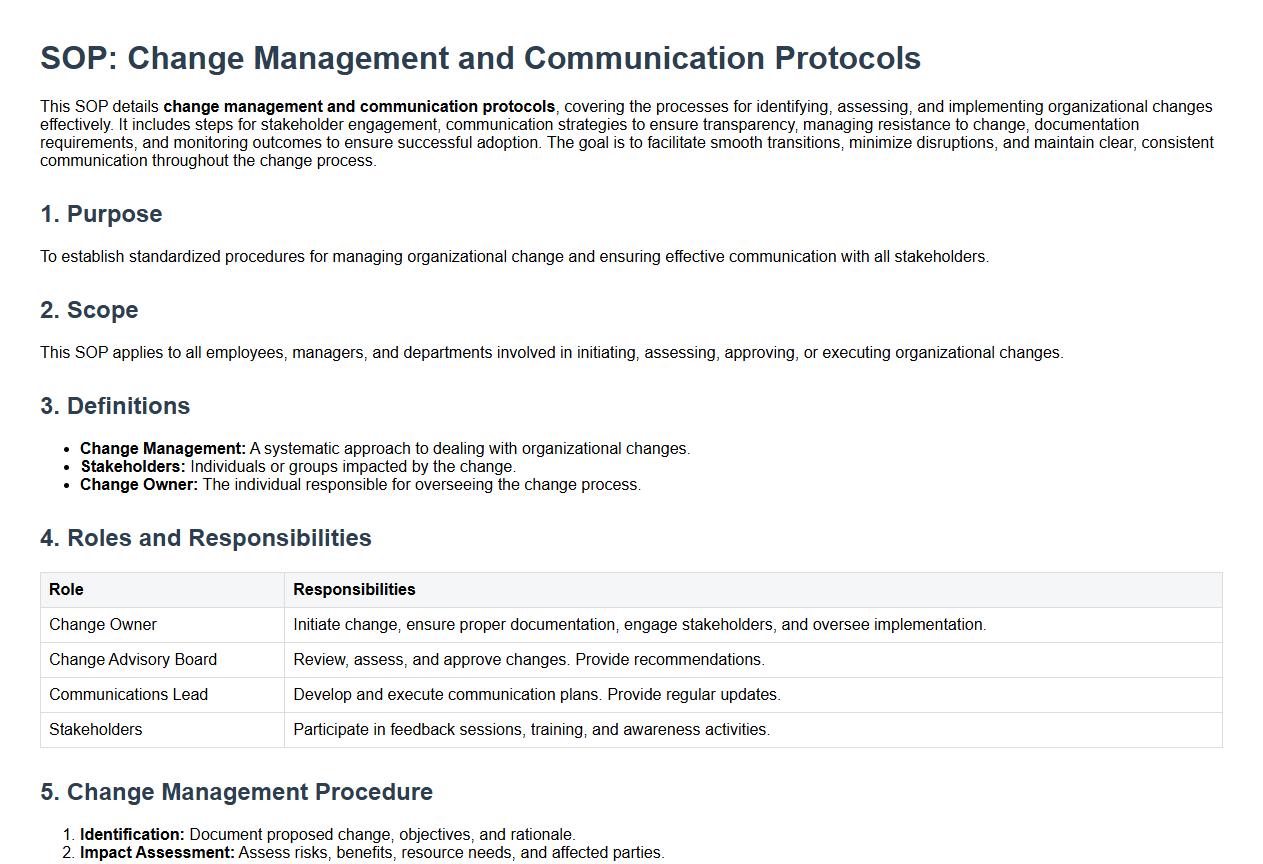

Change management and communication protocols.

This SOP details change management and communication protocols, covering the processes for identifying, assessing, and implementing organizational changes effectively. It includes steps for stakeholder engagement, communication strategies to ensure transparency, managing resistance to change, documentation requirements, and monitoring outcomes to ensure successful adoption. The goal is to facilitate smooth transitions, minimize disruptions, and maintain clear, consistent communication throughout the change process.

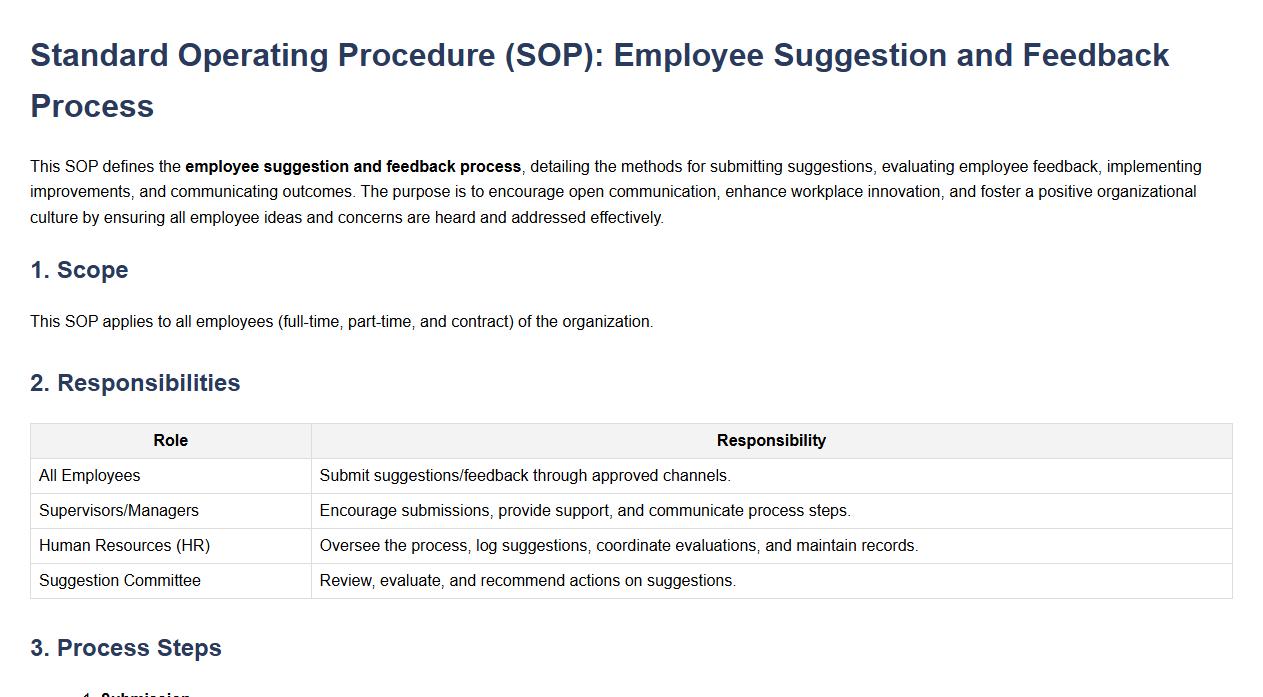

Employee suggestion and feedback process.

This SOP defines the employee suggestion and feedback process, detailing the methods for submitting suggestions, evaluating employee feedback, implementing improvements, and communicating outcomes. The purpose is to encourage open communication, enhance workplace innovation, and foster a positive organizational culture by ensuring all employee ideas and concerns are heard and addressed effectively.

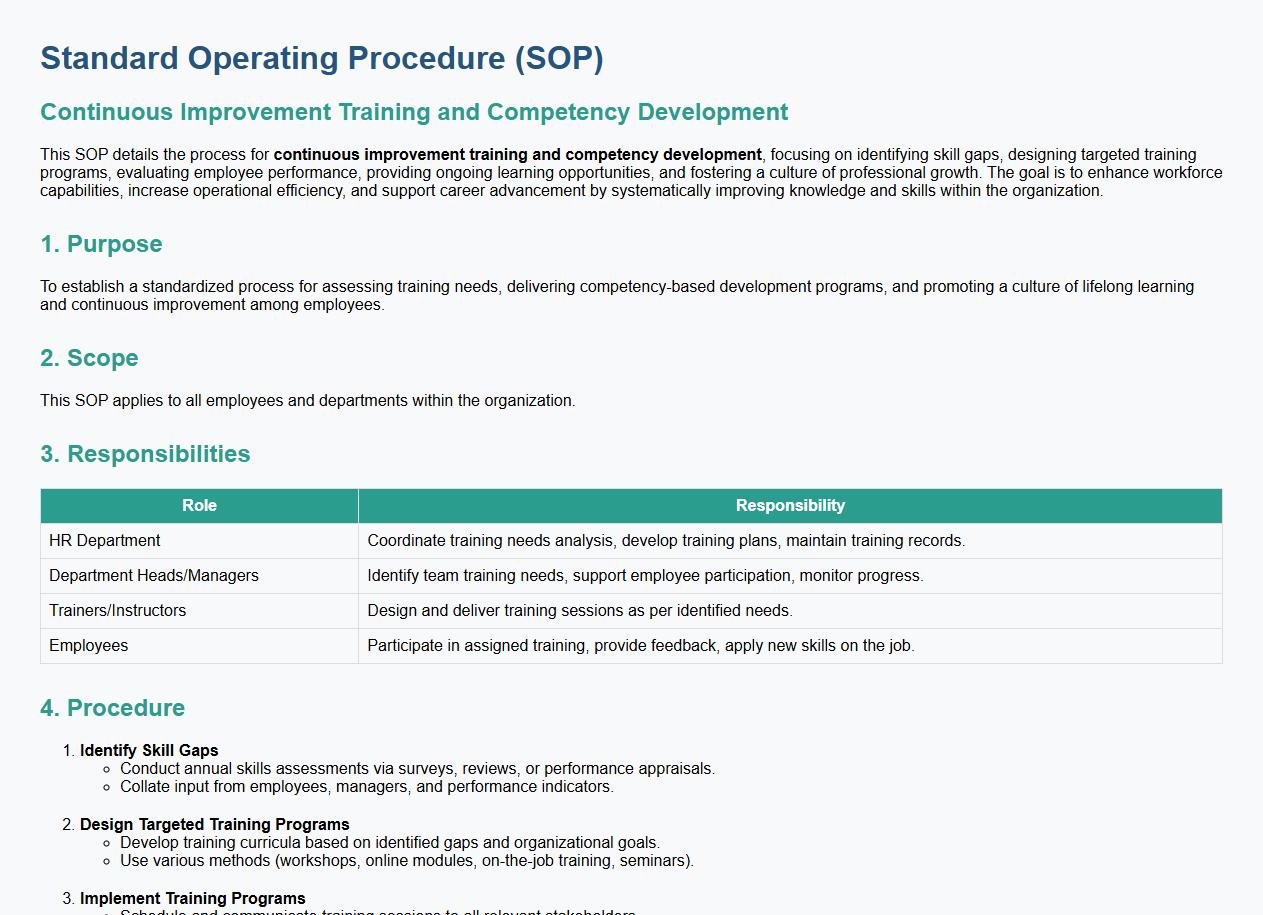

Continuous improvement training and competency development.

This SOP details the process for continuous improvement training and competency development, focusing on identifying skill gaps, designing targeted training programs, evaluating employee performance, providing ongoing learning opportunities, and fostering a culture of professional growth. The goal is to enhance workforce capabilities, increase operational efficiency, and support career advancement by systematically improving knowledge and skills within the organization.

Improvement project follow-up, review, and sustainment checks.

This SOP details the processes for improvement project follow-up, review, and sustainment checks, ensuring continuous evaluation and validation of project outcomes. It encompasses systematic monitoring of project implementation, assessment of achieved improvements against set objectives, identification of deviations or areas needing correction, and establishing sustainment measures to maintain project benefits. The goal is to guarantee long-term success and effectiveness of improvement initiatives through regular reviews and proactive management.

What are the key objectives outlined in the SOP for Continuous Improvement in Manufacturing?

The SOP emphasizes enhancing process efficiency as a primary goal to reduce waste and optimize resource use. It aims to foster a culture of ongoing innovation and employee engagement for sustained growth. Additionally, the SOP targets consistent quality improvement to meet and exceed customer expectations.

Which stakeholders are responsible for executing tasks defined in the SOP?

Manufacturing managers oversee the implementation of improvement initiatives and ensure alignment with production goals. The quality assurance team monitors compliance and effectiveness of process changes. Operators and line workers play a vital role in executing daily tasks and providing practical feedback.

What steps does the SOP specify for identifying and prioritizing improvement opportunities?

The process begins with systematic data collection and analysis from various production metrics. Next, potential improvement areas are evaluated based on impact and feasibility. Finally, a prioritized action plan is developed to address the most critical opportunities first.

How does the SOP define measurement and evaluation of implemented improvements?

The SOP requires establishing clear key performance indicators (KPIs) before implementation. Continuous monitoring through data tracking helps assess improvement effectiveness over time. Post-implementation reviews ensure that desired outcomes are achieved and standardized.

What documentation and reporting procedures are required as per the SOP?

All improvement activities must be documented in standardized forms and logs to maintain traceability. Regular progress reports are generated to update stakeholders and support decision-making. The SOP mandates archiving records for future audits and ongoing process evaluation.