A SOP Template for Manufacturing Employee Training provides a structured framework to ensure consistent and effective onboarding and skill development in manufacturing processes. It outlines step-by-step procedures, safety protocols, and quality standards to enhance employee performance and compliance. Utilizing this template streamlines training efforts while maintaining operational efficiency and reducing errors.

Onboarding process for new manufacturing employees.

This SOP defines the onboarding process for new manufacturing employees, covering initial orientation, safety training, job-specific skill development, introduction to company policies and procedures, assignment of mentors or supervisors, and performance evaluation milestones. The goal is to ensure new hires are effectively integrated into the manufacturing environment, understand their roles and responsibilities, and are equipped to perform their duties safely and efficiently.

Job-specific skills assessment and certification.

This SOP details the process for job-specific skills assessment and certification, including criteria for evaluating employee competencies, standardized testing procedures, certification requirements, record-keeping protocols, and periodic re-assessment to ensure continuous skill development and compliance with industry standards. The aim is to validate and certify the proficiency of personnel in their designated roles to maintain high-quality performance and workplace safety.

Workplace safety and PPE usage instructions.

This SOP provides comprehensive guidelines on workplace safety and PPE usage instructions, covering the proper selection, use, maintenance, and disposal of personal protective equipment. It emphasizes the importance of hazard identification, risk assessment, and compliance with safety standards to minimize occupational injuries and illnesses. The procedures ensure that all employees understand their roles and responsibilities in maintaining a safe work environment through effective PPE practices and safety protocols.

Machine operation and maintenance protocols.

This SOP details machine operation and maintenance protocols, covering proper machine usage, routine inspection and maintenance schedules, safety checks, troubleshooting procedures, and operator training requirements. The goal is to ensure efficient machine performance, reduce downtime, extend equipment lifespan, and maintain a safe working environment by adhering to standardized operational and maintenance practices.

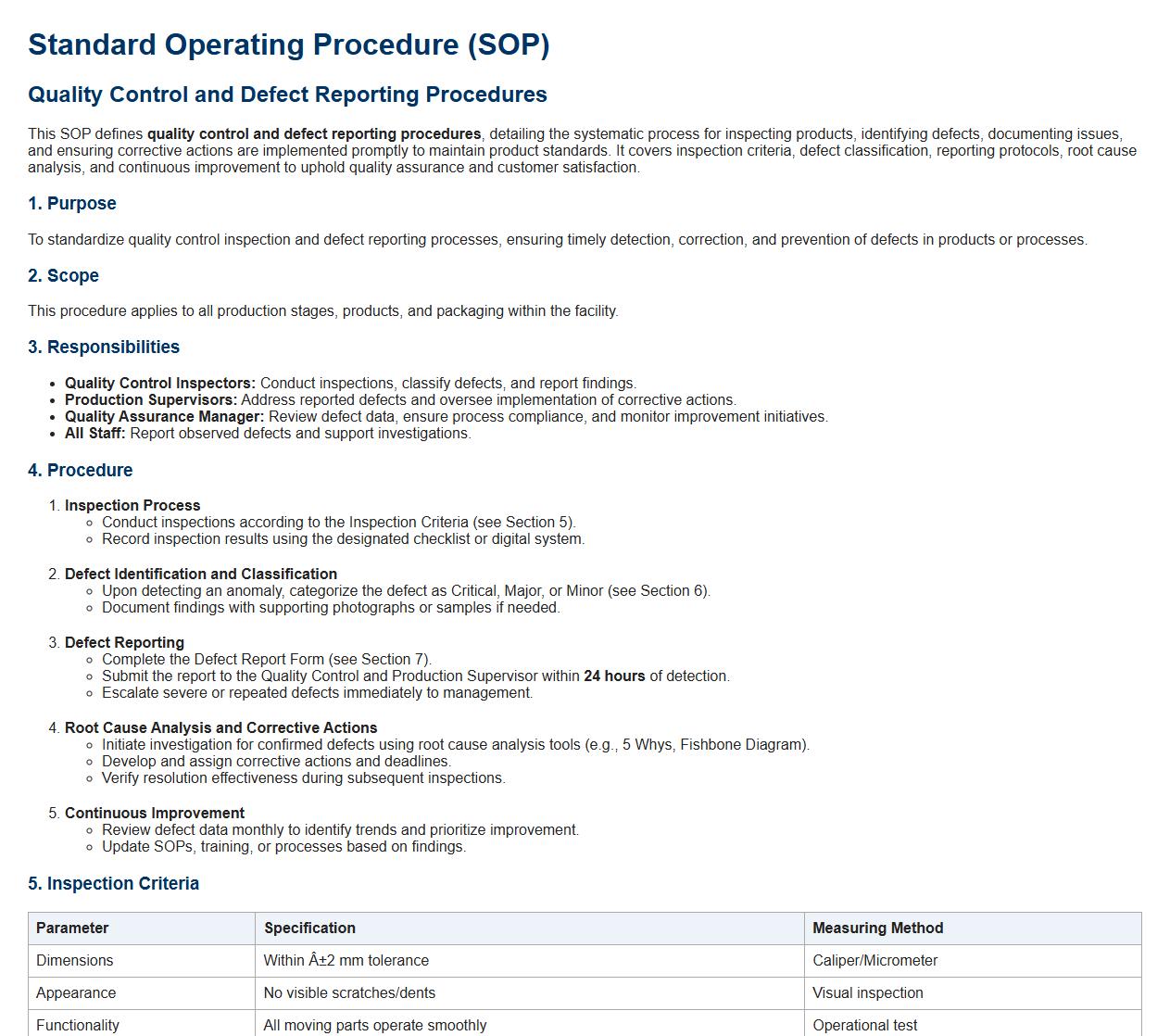

Quality control and defect reporting procedures.

This SOP defines quality control and defect reporting procedures, detailing the systematic process for inspecting products, identifying defects, documenting issues, and ensuring corrective actions are implemented promptly to maintain product standards. It covers inspection criteria, defect classification, reporting protocols, root cause analysis, and continuous improvement to uphold quality assurance and customer satisfaction.

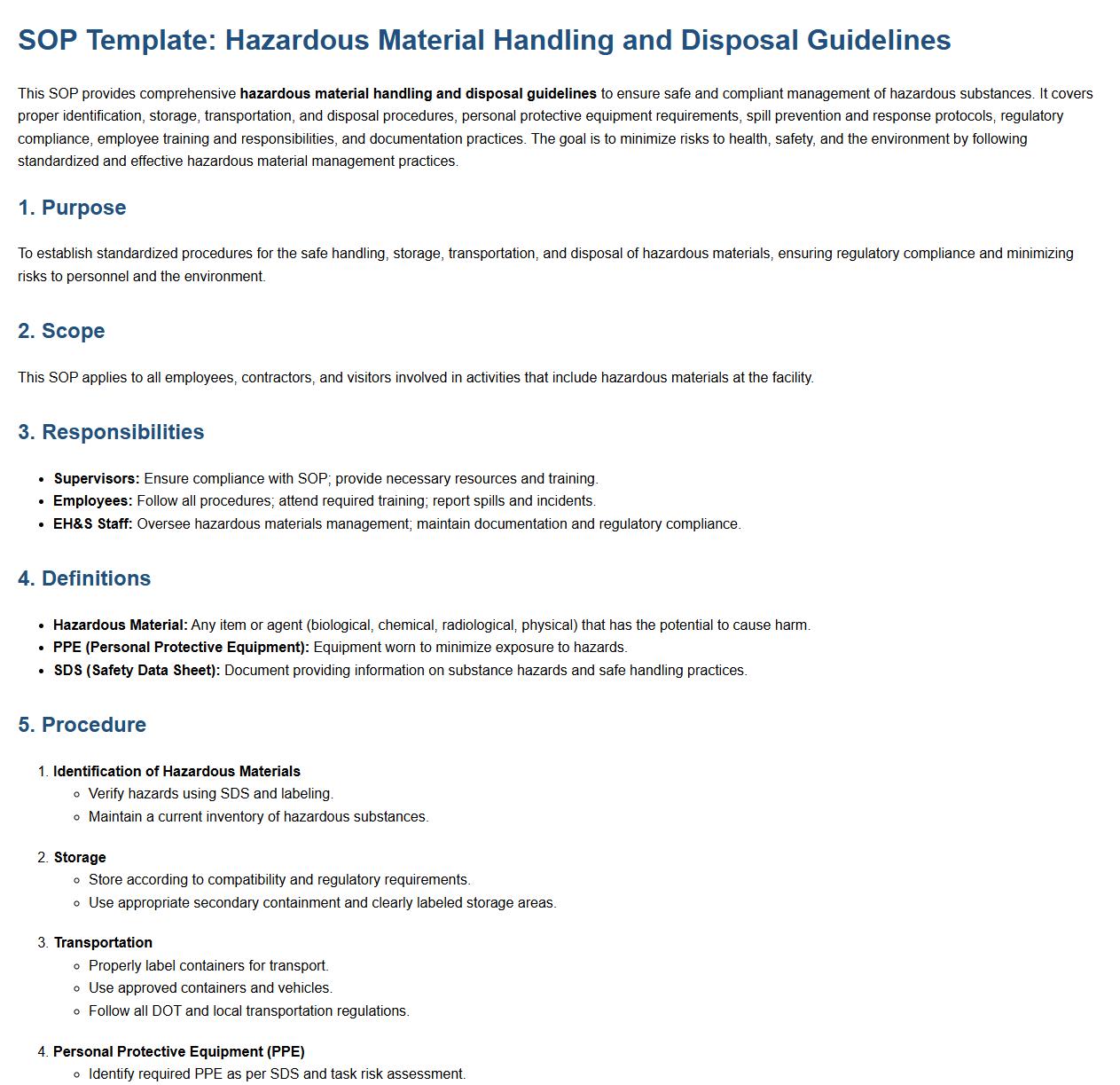

Hazardous material handling and disposal guidelines.

This SOP provides comprehensive hazardous material handling and disposal guidelines to ensure safe and compliant management of hazardous substances. It covers proper identification, storage, transportation, and disposal procedures, personal protective equipment requirements, spill prevention and response protocols, regulatory compliance, employee training and responsibilities, and documentation practices. The goal is to minimize risks to health, safety, and the environment by following standardized and effective hazardous material management practices.

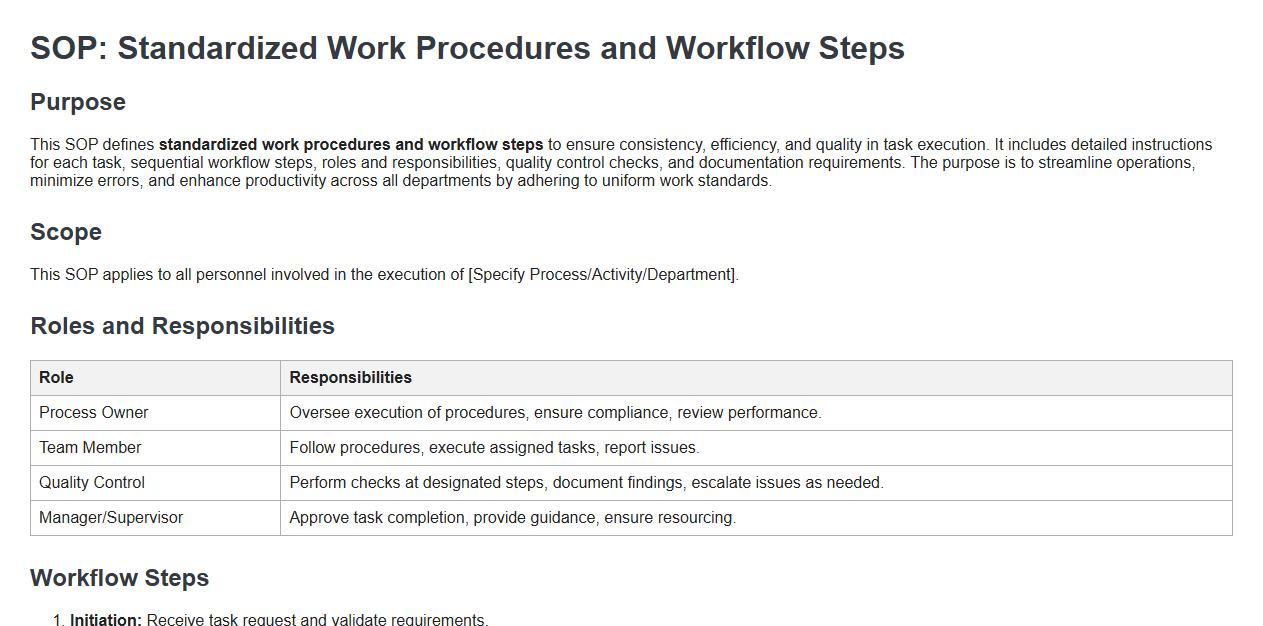

Standardized work procedures and workflow steps.

This SOP defines standardized work procedures and workflow steps to ensure consistency, efficiency, and quality in task execution. It includes detailed instructions for each task, sequential workflow steps, roles and responsibilities, quality control checks, and documentation requirements. The purpose is to streamline operations, minimize errors, and enhance productivity across all departments by adhering to uniform work standards.

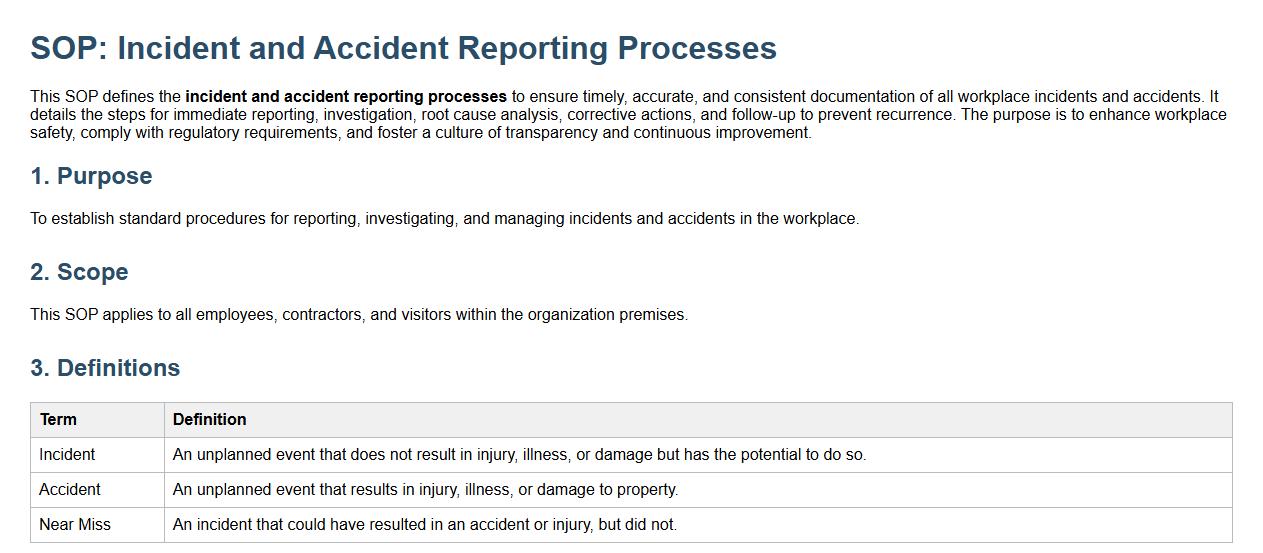

Incident and accident reporting processes.

This SOP defines the incident and accident reporting processes to ensure timely, accurate, and consistent documentation of all workplace incidents and accidents. It details the steps for immediate reporting, investigation, root cause analysis, corrective actions, and follow-up to prevent recurrence. The purpose is to enhance workplace safety, comply with regulatory requirements, and foster a culture of transparency and continuous improvement.

Continuous improvement and retraining program.

This SOP describes the continuous improvement and retraining program, focusing on regularly updating employee skills, assessing training effectiveness, implementing feedback mechanisms, and fostering a culture of ongoing professional development. The program aims to enhance workforce competence, adapt to evolving industry standards, and ensure high performance and safety by systematically reviewing processes and delivering targeted retraining sessions.

Performance evaluation and feedback documentation.

This SOP details the process for performance evaluation and feedback documentation, including setting performance criteria, conducting evaluations, providing constructive feedback, documenting outcomes, and ensuring continuous employee development. The goal is to enhance workforce productivity, foster professional growth, and maintain transparent communication between employees and management.

What are the key objectives outlined in the SOP for Manufacturing Employee Training?

The key objectives of the SOP focus on ensuring all manufacturing employees acquire the necessary skills and knowledge to perform their duties safely and efficiently. It aims to maintain high product quality and compliance with regulatory standards. Additionally, the SOP emphasizes continuous improvement through regular evaluation and refresher training.

Which employee roles are mandated to undergo training according to the SOP?

The SOP mandates training for all manufacturing floor employees, including operators, supervisors, and quality control personnel. It also requires training for new hires and any employees transferring to different roles within manufacturing. Trainers and management staff involved in process oversight are included to ensure uniform competency.

How does the SOP define the process for documenting training completion and competency assessment?

The SOP requires detailed documentation of each training session, including participant names, dates, and training topics. Competency assessments must be performed and recorded to verify employee understanding and skill acquisition. These records are maintained in an accessible training database for audit and review purposes.

What frequency and methods of training are required as per the SOP?

The SOP stipulates initial training upon hire and mandatory annual refresher courses to maintain compliance and skill levels. Training methods include classroom instruction, hands-on practical sessions, and e-learning modules. The approach is designed to accommodate varying learning styles and reinforce critical procedures regularly.

What procedures are included in the SOP for updating training content following process or regulatory changes?

The SOP mandates a formal review process to update training materials whenever significant process changes or new regulatory requirements arise. Training content must be revised and approved by subject matter experts prior to reimplementation. Employees must be promptly retrained to ensure ongoing compliance and operational effectiveness.