A SOP Template for Shutdown and Restart of Manufacturing Equipment provides a detailed, step-by-step guide to ensure safe and efficient procedures are followed during equipment downtime. It outlines essential safety protocols, operational checks, and troubleshooting measures to minimize risks and production delays. This template helps standardize processes, improve compliance, and maintain equipment integrity throughout the shutdown and restart phases.

Equipment shutdown preparation checklist.

This SOP provides a comprehensive equipment shutdown preparation checklist designed to ensure safe and efficient shutdown procedures. It covers steps such as notifying relevant personnel, securing machinery, disconnecting power sources, inspecting equipment for issues, documenting shutdown status, and performing final safety checks. The checklist aims to prevent damage, enhance operational safety, and maintain equipment integrity during shutdown processes.

Step-by-step equipment shutdown procedure.

This SOP details the step-by-step equipment shutdown procedure to ensure the safe and efficient powering down of machinery. It includes pre-shutdown inspections, systematic power-off sequences, securing and locking equipment, and post-shutdown safety checks. The procedure aims to minimize equipment damage, prevent accidents, and maintain workplace safety during shutdown operations.

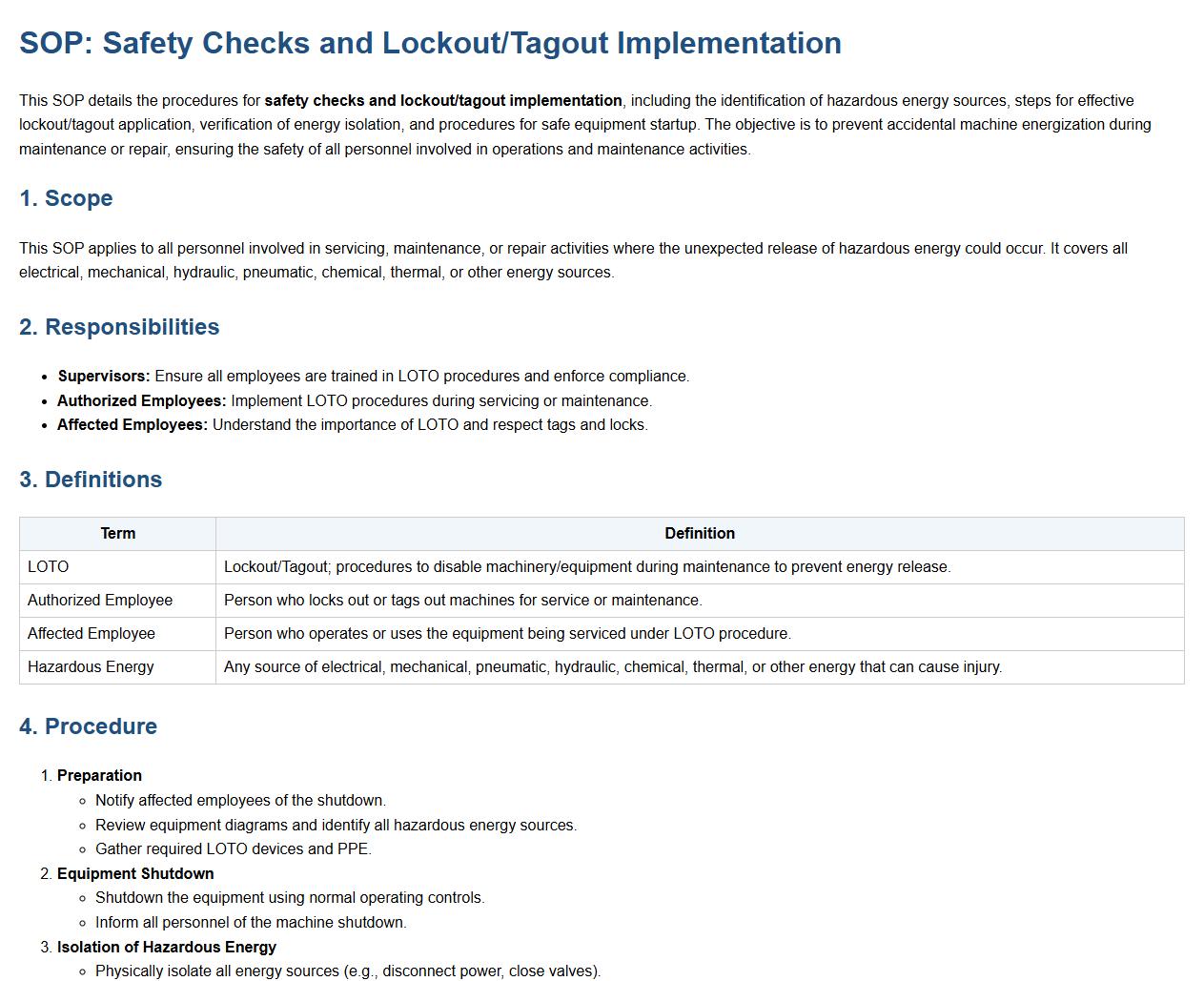

Safety checks and lockout/tagout implementation.

This SOP details the procedures for safety checks and lockout/tagout implementation, including the identification of hazardous energy sources, steps for effective lockout/tagout application, verification of energy isolation, and procedures for safe equipment startup. The objective is to prevent accidental machine energization during maintenance or repair, ensuring the safety of all personnel involved in operations and maintenance activities.

Power and utility disconnection process.

This SOP details the power and utility disconnection process, outlining the necessary steps to safely disconnect electrical, gas, water, and other utilities. It covers pre-disconnection planning, notification procedures, verification of isolation, risk assessments, use of appropriate personal protective equipment, and final confirmation of successful disconnection. The goal is to ensure safety, prevent damage, and maintain compliance with regulatory requirements during utility shutdowns.

Equipment cleaning and inspection post-shutdown.

This SOP details the procedures for equipment cleaning and inspection post-shutdown, ensuring all machinery and tools are thoroughly cleaned, inspected for damage or wear, and properly maintained after operational downtime. The objective is to maintain equipment longevity, ensure safety, and prevent malfunctions prior to the next use, following standardized cleaning methods, safety checks, and documentation protocols.

Documentation and reporting of shutdown status.

This SOP details the documentation and reporting of shutdown status, ensuring accurate and timely recording of shutdown events, monitoring of operational status during shutdowns, and effective communication with relevant stakeholders. It aims to provide a clear framework for tracking shutdown progress, identifying issues, and facilitating coordinated responses to minimize downtime and enhance operational efficiency.

Restart pre-check and inspection protocol.

This SOP defines the restart pre-check and inspection protocol, ensuring all equipment and systems are thoroughly examined before resuming operations. It includes step-by-step procedures to verify functionality, safety compliance, and readiness of machinery, electrical systems, and safety devices. The protocol aims to prevent malfunctions, reduce downtime, and maintain workplace safety by enforcing standardized inspection criteria and documentation prior to restart.

Safe power and utility reconnection process.

This SOP defines the safe power and utility reconnection process to ensure the secure restoration of electrical, gas, water, and other utility services after maintenance, outages, or emergencies. It covers risk assessment, verification of equipment integrity, proper isolation and lockout-tagout procedures, step-by-step reconnection protocols, testing and monitoring of systems, communication with relevant personnel, and compliance with regulatory safety standards. The aim is to prevent accidents, equipment damage, and ensure a safe working environment during utility restoration activities.

Gradual equipment start-up sequence.

This SOP describes the gradual equipment start-up sequence to ensure safe and efficient activation of machinery. It includes step-by-step instructions for powering on equipment gradually, monitoring system responses, checking operational parameters, and minimizing mechanical stress. This procedure aims to prevent equipment damage, reduce wear and tear, enhance safety for operators, and optimize machinery performance during start-up phases.

Post-restart monitoring and performance verification.

This SOP outlines the procedures for post-restart monitoring and performance verification to ensure system stability and optimal functionality after a restart. It includes steps for continuous monitoring of critical parameters, verification of system performance against predefined benchmarks, identification of anomalies, troubleshooting guidelines, and documentation of outcomes to confirm successful system restoration and prevent future issues.

What are the specific conditions that trigger the initiation of the shutdown process for manufacturing equipment?

The shutdown process for manufacturing equipment is typically initiated when there is an indication of operational malfunctions or safety risks. Scheduled maintenance or inspection requirements also serve as key triggers for the shutdown. Additionally, environmental conditions that could affect equipment performance might necessitate an immediate shutdown.

Which safety measures must be verified before starting the restart procedure?

Before restarting equipment, it is essential to verify that all safety protocols are in place and functional, including emergency stop mechanisms and protective guards. Workers must be trained and made aware of the restart process to prevent accidents. Furthermore, confirming that no personnel are in hazardous areas strengthens the safety before powering the equipment back on.

What documentation is required at each step of the shutdown and restart processes?

Comprehensive documentation is required at each step, detailing the operational status, reason for shutdown, and safety checks performed. Logs should include technician checks, equipment condition reports, and authorization signatures. Maintaining this documentation helps ensure regulatory compliance and facilitates troubleshooting during the restart.

Who is authorized to approve and oversee the shutdown and restart of the equipment?

The authorization and oversight of shutdown and restart procedures are generally assigned to qualified supervisors or equipment managers. These individuals must have a thorough understanding of the machinery and safety protocols. Approval from higher management might be required depending on the criticality of the equipment.

What are the critical checkpoints to confirm equipment integrity post-restart?

Post-restart, critical checkpoints include verifying the operational stability of the equipment and ensuring all safety devices are functioning correctly. It is also vital to perform performance tests to confirm that the machinery operates within specified parameters. Ongoing monitoring during initial operation helps detect any anomalies early.