A SOP Template for Manufacturing Process Improvement standardizes procedures to enhance efficiency and maintain quality in production. It provides clear, step-by-step instructions to reduce errors, streamline workflows, and ensure compliance with industry standards. This template serves as a foundational tool for continuous operational excellence and consistent output.

Process mapping and workflow analysis.

This SOP provides a comprehensive guide for process mapping and workflow analysis, detailing the steps to identify, document, and analyze business processes to improve efficiency and effectiveness. It covers the creation of process flowcharts, identification of bottlenecks, evaluation of process performance, and recommendations for optimization. The goal is to enhance operational transparency, streamline workflows, and support continuous improvement initiatives within the organization.

Identification and documentation of current process baseline.

This SOP details the identification and documentation of current process baseline, encompassing the systematic assessment of existing workflows, data collection on performance metrics, evaluation of process efficiency and effectiveness, and comprehensive recording of all findings. The objective is to establish a clear and accurate baseline that serves as a reference point for future process improvements, performance tracking, and benchmarking activities.

Root cause analysis of process inefficiencies.

This SOP provides a systematic approach for conducting root cause analysis of process inefficiencies, focusing on identifying underlying issues affecting operational performance. It covers data collection methods, analysis techniques such as cause-and-effect diagrams and the 5 Whys, prioritization of root causes, implementation of corrective actions, and ongoing monitoring to ensure continuous process improvement. The goal is to enhance efficiency, reduce waste, and improve overall productivity by addressing the fundamental causes of inefficiencies.

Definition of process improvement goals and objectives.

This SOP details the definition of process improvement goals and objectives, focusing on establishing clear, measurable, and achievable targets to enhance operational efficiency, quality, and productivity. It guides the identification of key performance indicators, alignment with organizational strategy, stakeholder involvement, and the prioritization of improvement initiatives to drive continuous improvement and achieve desired business outcomes.

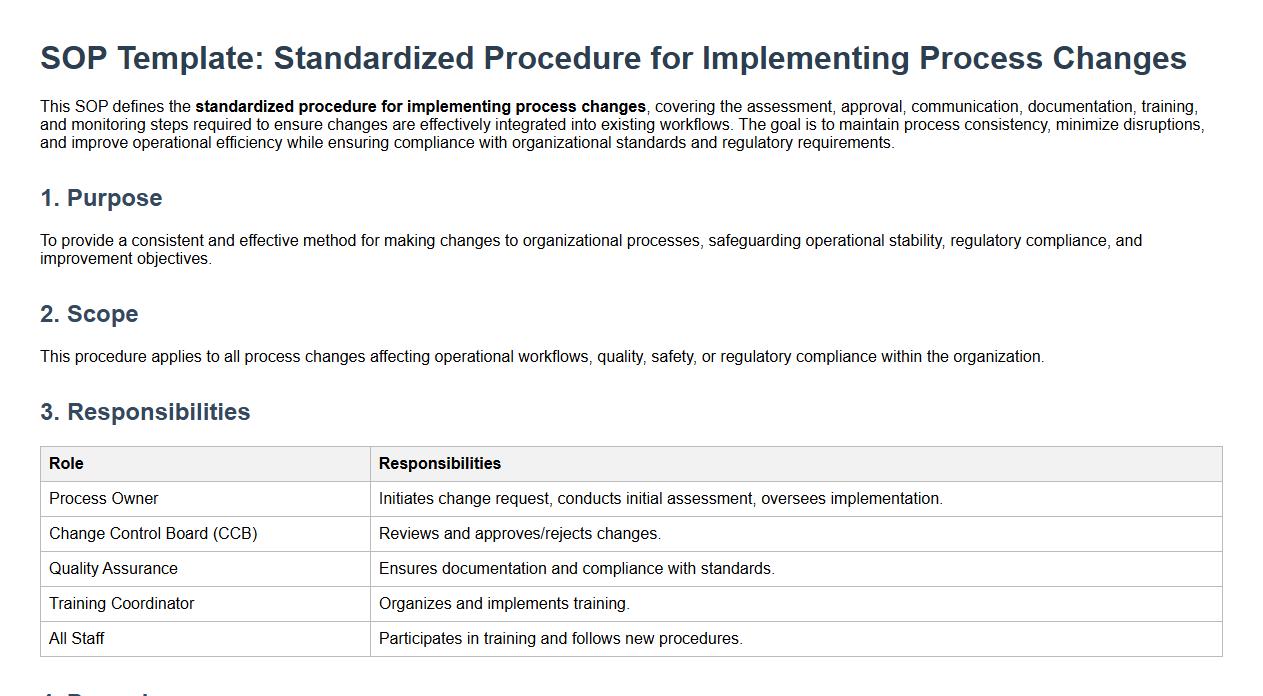

Standardized procedure for implementing process changes.

This SOP defines the standardized procedure for implementing process changes, covering the assessment, approval, communication, documentation, training, and monitoring steps required to ensure changes are effectively integrated into existing workflows. The goal is to maintain process consistency, minimize disruptions, and improve operational efficiency while ensuring compliance with organizational standards and regulatory requirements.

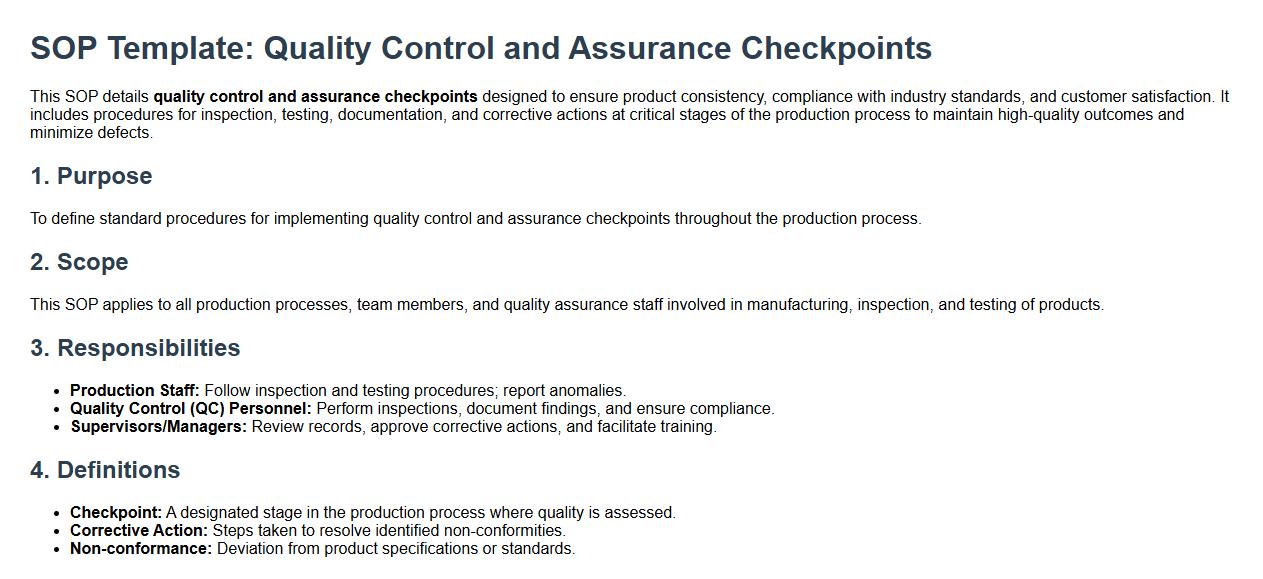

Quality control and assurance checkpoints.

This SOP details quality control and assurance checkpoints designed to ensure product consistency, compliance with industry standards, and customer satisfaction. It includes procedures for inspection, testing, documentation, and corrective actions at critical stages of the production process to maintain high-quality outcomes and minimize defects.

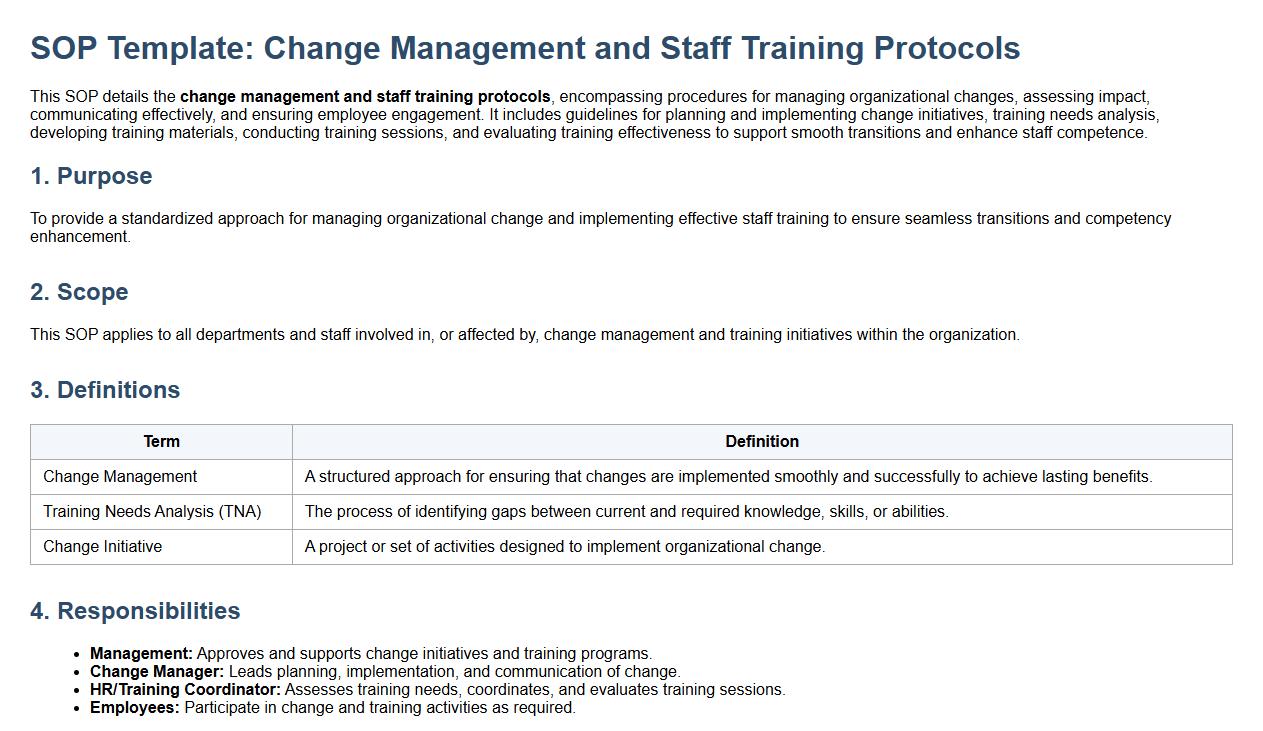

Change management and staff training protocols.

This SOP details the change management and staff training protocols, encompassing procedures for managing organizational changes, assessing impact, communicating effectively, and ensuring employee engagement. It includes guidelines for planning and implementing change initiatives, training needs analysis, developing training materials, conducting training sessions, and evaluating training effectiveness to support smooth transitions and enhance staff competence.

Performance measurement and KPI tracking.

This SOP details the processes for performance measurement and KPI tracking, including defining relevant key performance indicators, data collection methods, analysis techniques, reporting protocols, and regular review cycles. The objective is to ensure accurate monitoring of organizational performance, facilitate informed decision-making, and drive continuous improvement through systematic tracking and evaluation of critical metrics.

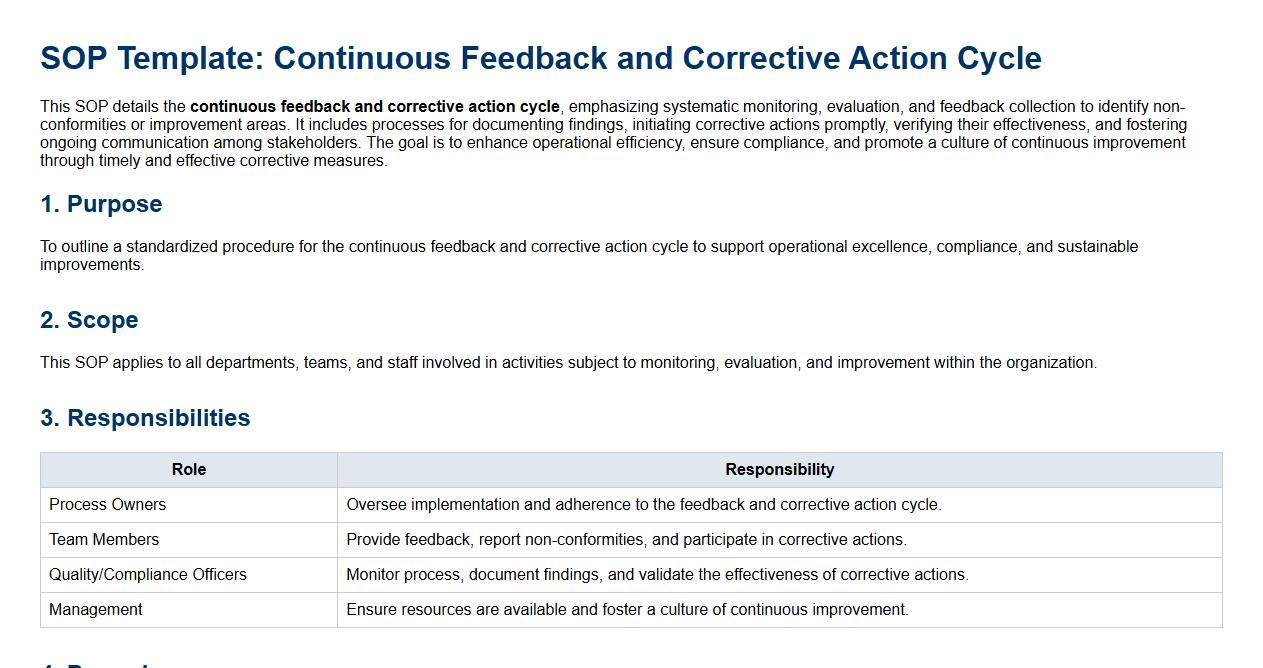

Continuous feedback and corrective action cycle.

This SOP details the continuous feedback and corrective action cycle, emphasizing systematic monitoring, evaluation, and feedback collection to identify non-conformities or improvement areas. It includes processes for documenting findings, initiating corrective actions promptly, verifying their effectiveness, and fostering ongoing communication among stakeholders. The goal is to enhance operational efficiency, ensure compliance, and promote a culture of continuous improvement through timely and effective corrective measures.

Documentation and communication of process updates.

This SOP details the documentation and communication of process updates, ensuring that all changes to procedures are accurately recorded, effectively communicated to relevant stakeholders, and consistently maintained. It covers methods for updating process documents, approval workflows, communication channels, and timelines for distributing updates to promote transparency, compliance, and operational efficiency within the organization.

What is the primary objective of the SOP for Manufacturing Process Improvement?

The primary objective of the SOP is to ensure consistent enhancement of manufacturing processes, aiming to increase efficiency and product quality. It serves as a guideline to systematically identify, analyze, and implement improvements. This process helps in reducing waste, minimizing costs, and meeting customer satisfaction requirements effectively.

Which key performance indicators (KPIs) are monitored according to the SOP?

The SOP mandates monitoring critical KPIs such as production yield, cycle time, and defect rates to evaluate process efficiency. It also tracks equipment utilization and downtime to detect bottlenecks. These metrics provide actionable insights to drive continuous process improvements.

What roles and responsibilities are defined in the SOP for implementing process improvements?

The SOP clearly defines roles such as Process Engineers, Quality Assurance personnel, and Production Supervisors in the improvement cycle. Each role is responsible for specific tasks including identifying issues, validating solutions, and overseeing implementation. Collaborative teamwork ensures accountability and effective execution.

What documentation and record-keeping requirements are mandated by the SOP?

The SOP requires meticulous documentation of all process changes, including detailed improvement plans, validation results, and approval records. It emphasizes maintaining traceability to ensure compliance with internal and external standards. Proper record-keeping supports audit readiness and continuous performance tracking.

How does the SOP address risk assessment and control during process changes?

The SOP incorporates a structured risk assessment approach to identify potential hazards before implementing any process change. It mandates control measures to mitigate identified risks and prevent negative impacts on quality or safety. Continuous monitoring ensures that risks remain controlled throughout the improvement cycle.