A SOP Template for Manufacturing Equipment Calibration provides a structured framework to ensure consistent and accurate calibration processes. This template outlines step-by-step procedures, responsibilities, and documentation requirements to maintain equipment precision and compliance with industry standards. Using this template helps reduce errors, enhance quality control, and ensure regulatory adherence in manufacturing operations.

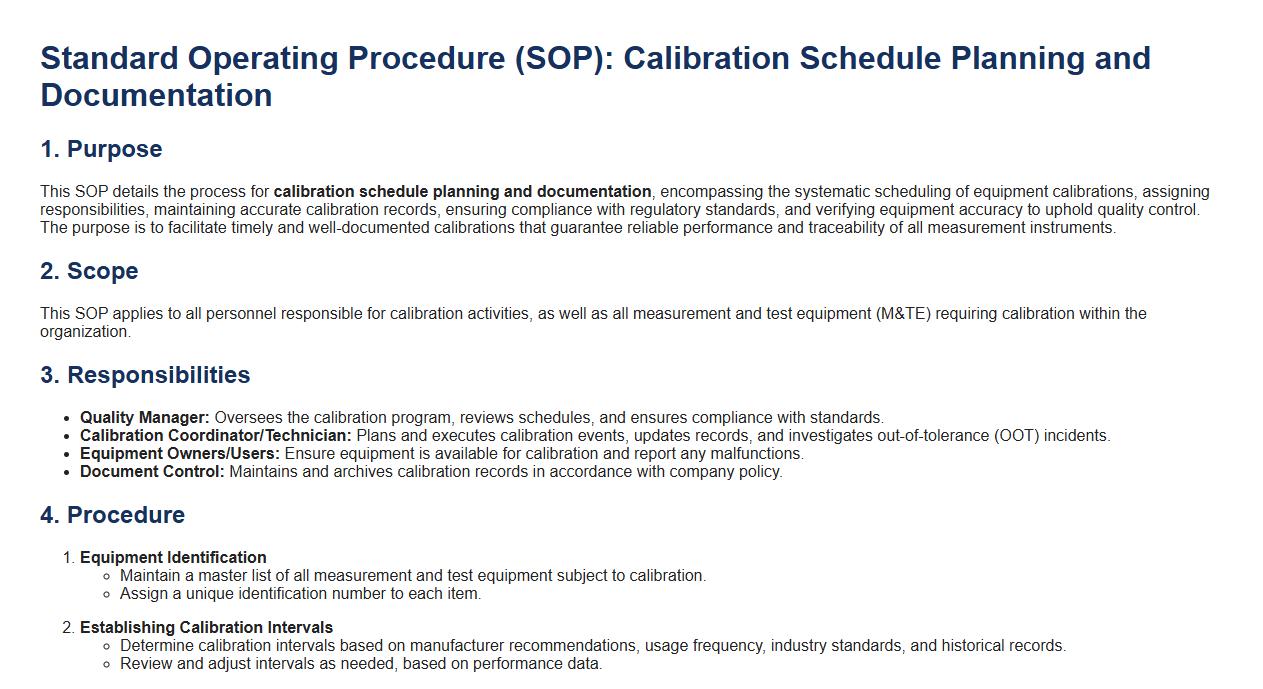

Calibration schedule planning and documentation.

This SOP details the process for calibration schedule planning and documentation, encompassing the systematic scheduling of equipment calibrations, assigning responsibilities, maintaining accurate calibration records, ensuring compliance with regulatory standards, and verifying equipment accuracy to uphold quality control. The purpose is to facilitate timely and well-documented calibrations that guarantee reliable performance and traceability of all measurement instruments.

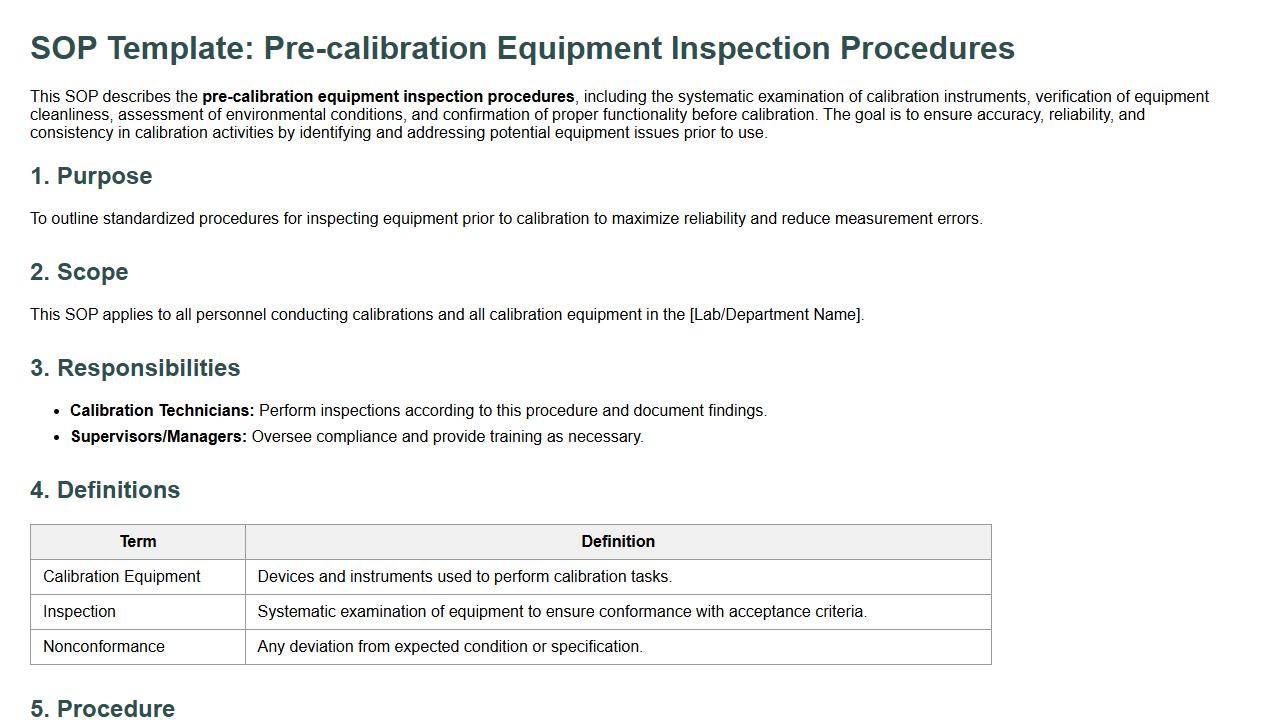

Pre-calibration equipment inspection procedures.

This SOP describes the pre-calibration equipment inspection procedures, including the systematic examination of calibration instruments, verification of equipment cleanliness, assessment of environmental conditions, and confirmation of proper functionality before calibration. The goal is to ensure accuracy, reliability, and consistency in calibration activities by identifying and addressing potential equipment issues prior to use.

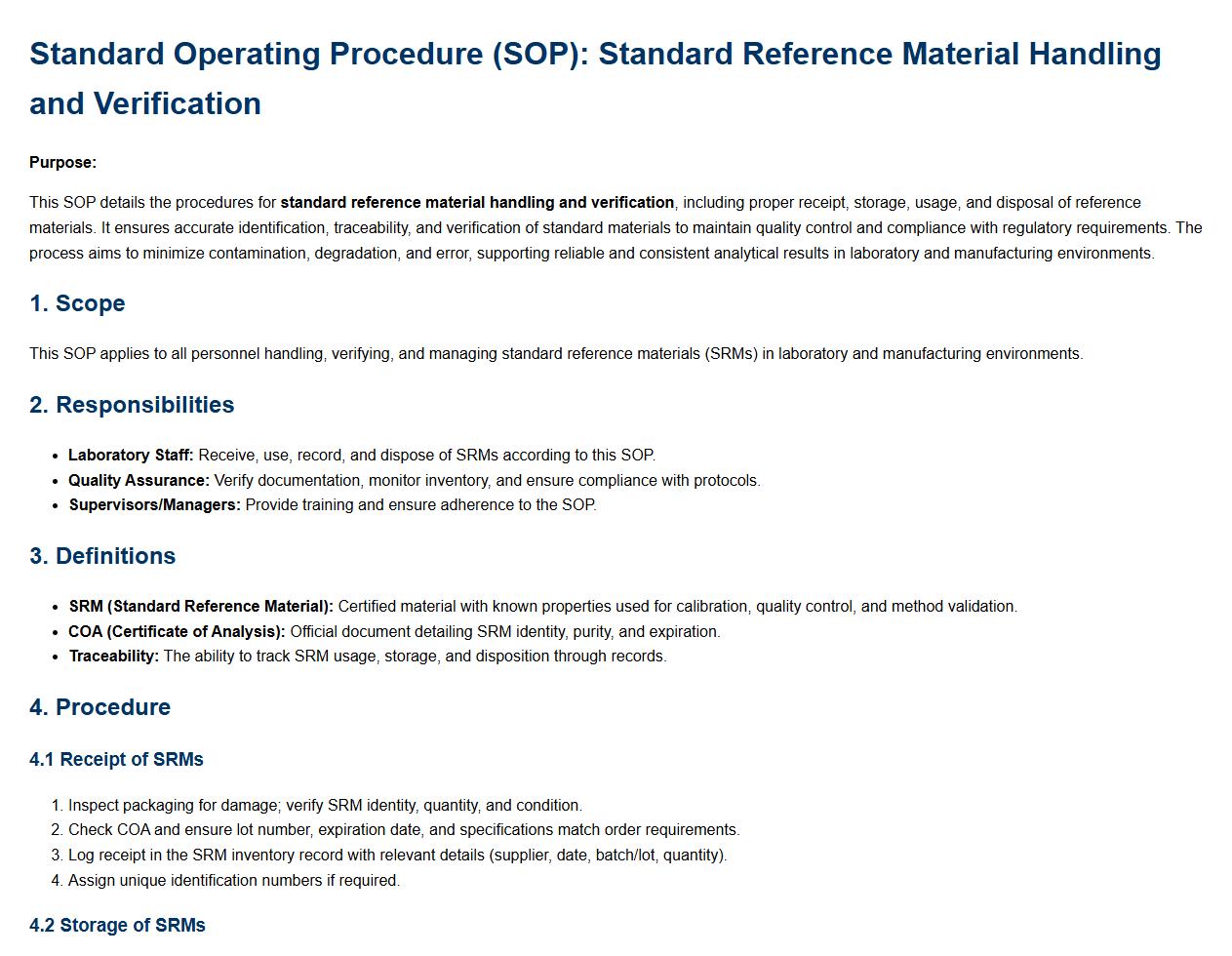

Standard reference material handling and verification.

This SOP details the procedures for standard reference material handling and verification, including proper receipt, storage, usage, and disposal of reference materials. It ensures accurate identification, traceability, and verification of standard materials to maintain quality control and compliance with regulatory requirements. The process aims to minimize contamination, degradation, and error, supporting reliable and consistent analytical results in laboratory and manufacturing environments.

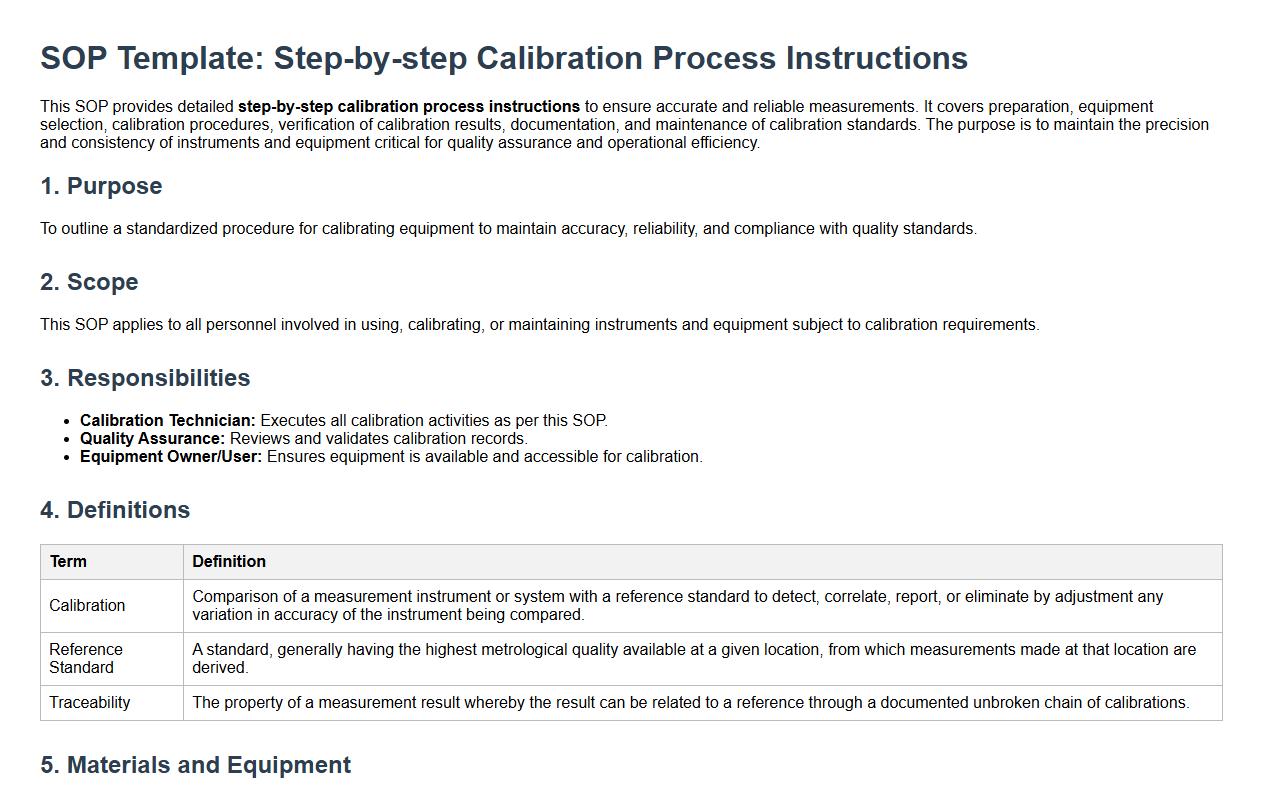

Step-by-step calibration process instructions.

This SOP provides detailed step-by-step calibration process instructions to ensure accurate and reliable measurements. It covers preparation, equipment selection, calibration procedures, verification of calibration results, documentation, and maintenance of calibration standards. The purpose is to maintain the precision and consistency of instruments and equipment critical for quality assurance and operational efficiency.

Calibration environment preparation and control.

This SOP details the procedures for calibration environment preparation and control, focusing on creating and maintaining optimal conditions for accurate calibration processes. It includes guidelines for temperature, humidity, cleanliness, and equipment setup to ensure reliable and precise measurement results. Proper environment control minimizes measurement errors and enhances the consistency and traceability of calibration activities.

Recording calibration measurements and deviations.

This SOP details the process for recording calibration measurements and deviations, ensuring accurate documentation of instrument calibrations, identifying discrepancies from standard values, and maintaining traceability for quality control and compliance. It covers the methods for measuring, recording data, analyzing deviations, and implementing corrective actions to uphold the reliability and precision of calibrated instruments.

Post-calibration equipment labeling and sealing.

This SOP defines the process for post-calibration equipment labeling and sealing, detailing the standardized steps to accurately label calibrated instruments and securely seal them to prevent unauthorized adjustments. It ensures traceability, maintains calibration integrity, and supports compliance with quality management systems by specifying label content, sealing methods, and documentation requirements.

Non-conformance identification and corrective action.

This SOP details the process for non-conformance identification and corrective action, encompassing the detection, documentation, and evaluation of non-conforming products or processes. It outlines procedures for initiating corrective actions, root cause analysis, implementation of remedial measures, and verification of effectiveness to ensure continuous improvement and compliance with quality standards.

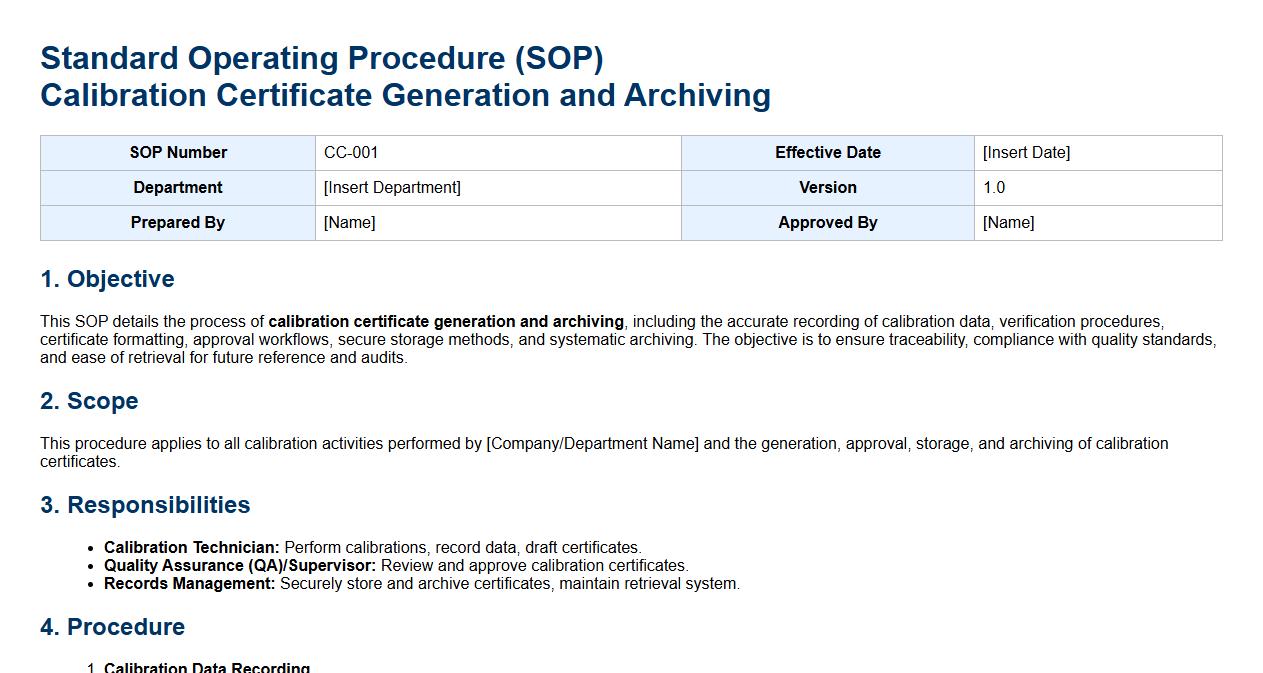

Calibration certificate generation and archiving.

This SOP details the process of calibration certificate generation and archiving, including the accurate recording of calibration data, verification procedures, certificate formatting, approval workflows, secure storage methods, and systematic archiving. The objective is to ensure traceability, compliance with quality standards, and ease of retrieval for future reference and audits.

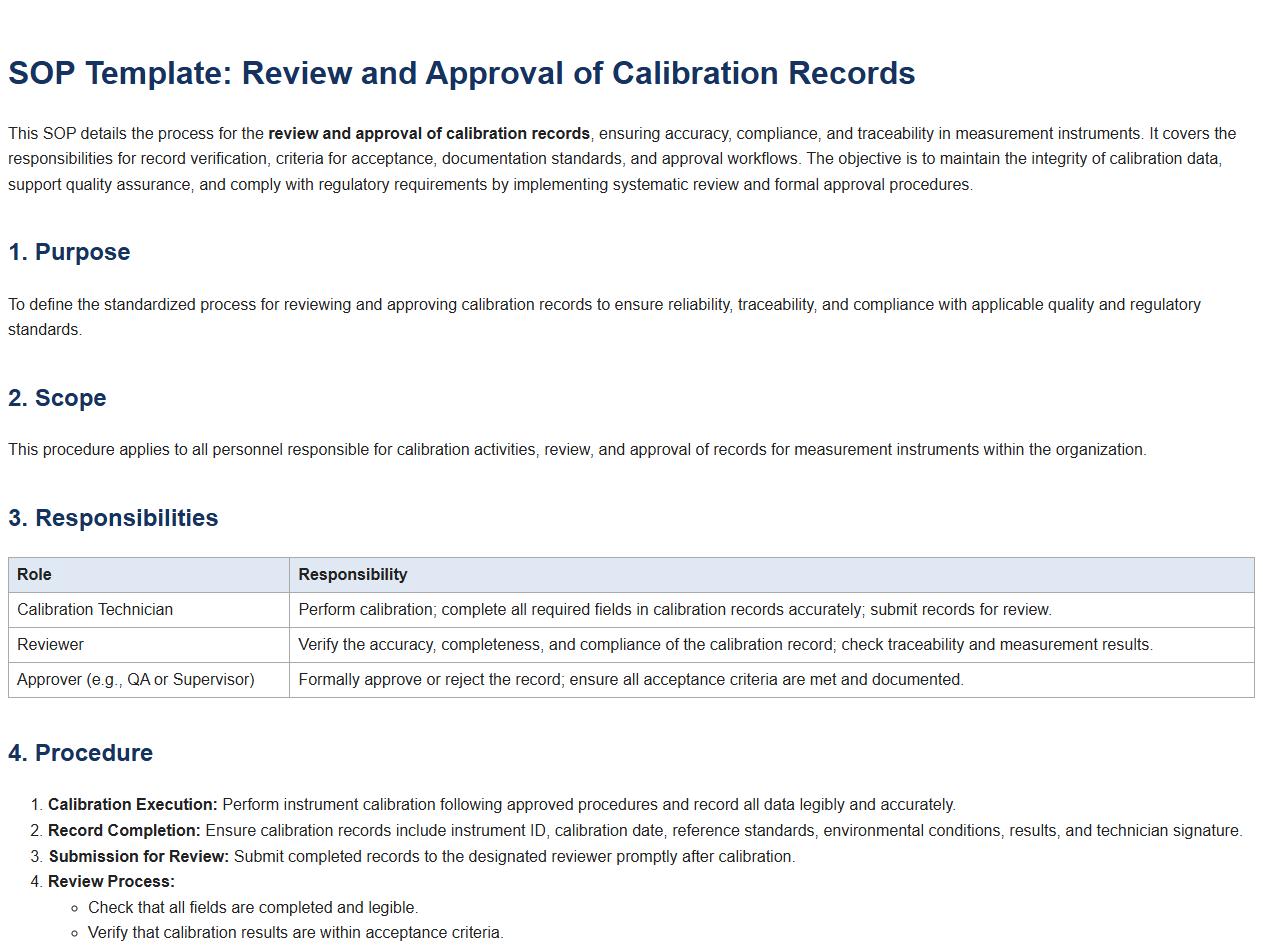

Review and approval of calibration records.

This SOP details the process for the review and approval of calibration records, ensuring accuracy, compliance, and traceability in measurement instruments. It covers the responsibilities for record verification, criteria for acceptance, documentation standards, and approval workflows. The objective is to maintain the integrity of calibration data, support quality assurance, and comply with regulatory requirements by implementing systematic review and formal approval procedures.

What is the primary objective of the SOP for Manufacturing Equipment Calibration?

The primary objective of the SOP for Manufacturing Equipment Calibration is to ensure all equipment used in production operates within specified tolerances. This guarantees product quality and compliance with industry standards. Accurate calibration minimizes errors and maintains process reliability.

Which personnel roles are responsible for executing and documenting equipment calibration?

The roles responsible for executing and documenting equipment calibration typically include calibration technicians, quality control personnel, and equipment operators. These individuals ensure calibration is performed correctly and records are accurately maintained. Accountability in these roles is key to upholding calibration integrity.

What are the frequency and criteria for scheduling regular equipment calibrations?

Regular equipment calibration must be scheduled based on manufacturer recommendations, usage frequency, and regulatory requirements. Typically, calibration intervals range from monthly to annually, depending on equipment criticality. Adhering to these schedules prevents drift and maintains equipment accuracy.

What procedures must be followed if a piece of equipment fails calibration standards?

If equipment fails calibration, the SOP mandates immediate removal from service and root cause analysis to identify faults. Corrective actions, such as repair or adjustment, must be documented. Recalibration is required before returning the equipment to operation.

How are calibration records maintained, reviewed, and archived according to the SOP?

Calibration records are maintained systematically in digital or physical archives, ensuring traceability and compliance. Regular reviews are conducted by quality assurance teams to verify completeness and accuracy. Archived records must be retained for a specified period per regulatory standards.