A SOP Template for Manufacturing Raw Material Receiving provides a clear and consistent process for verifying, inspecting, and documenting incoming raw materials. It ensures quality control by outlining specific steps for checking material specifications, packaging integrity, and accurate record-keeping. This template helps maintain compliance with industry standards and supports efficient inventory management.

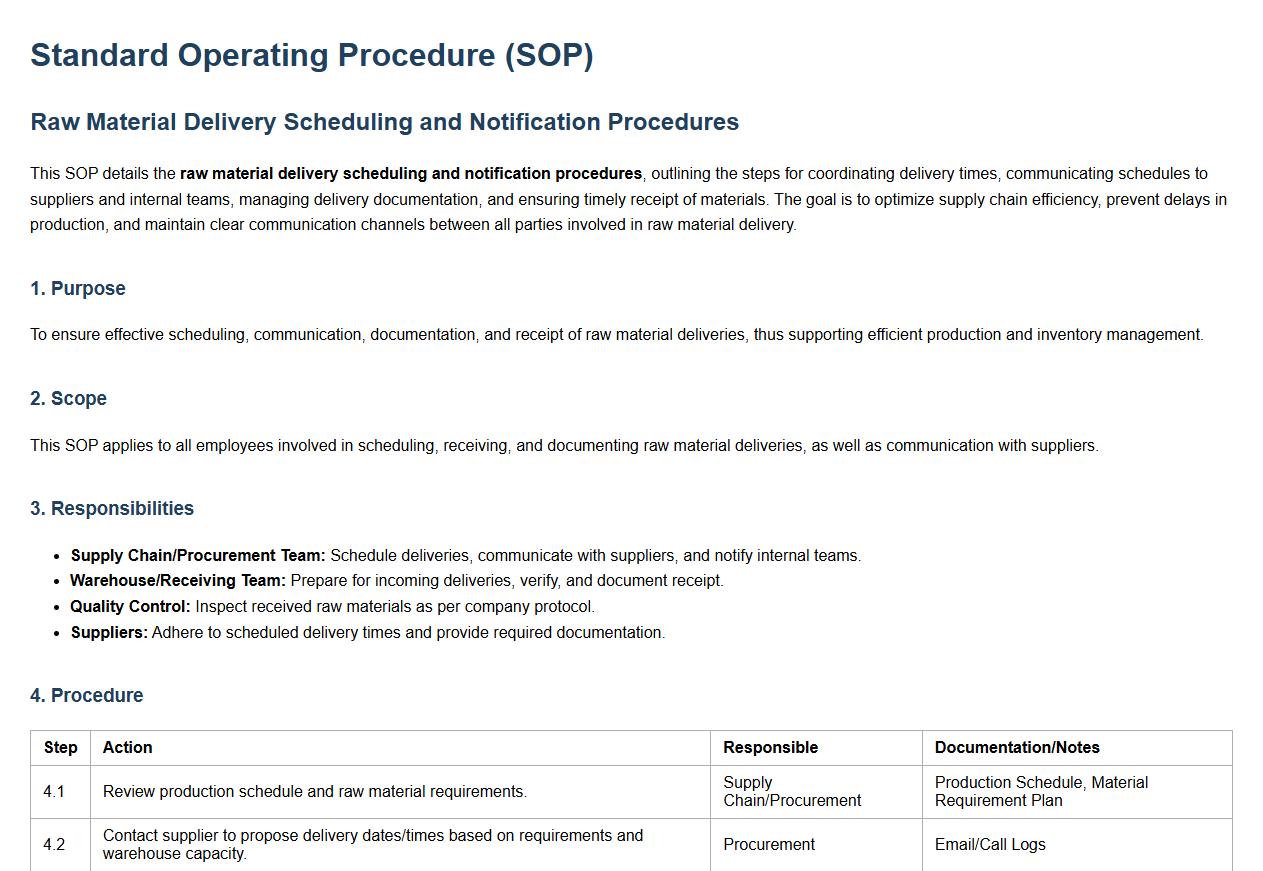

Raw material delivery scheduling and notification procedures.

This SOP details the raw material delivery scheduling and notification procedures, outlining the steps for coordinating delivery times, communicating schedules to suppliers and internal teams, managing delivery documentation, and ensuring timely receipt of materials. The goal is to optimize supply chain efficiency, prevent delays in production, and maintain clear communication channels between all parties involved in raw material delivery.

Supplier documentation and shipment verification.

This SOP details the process for supplier documentation and shipment verification, covering the verification of supplier credentials, review of shipping documents, inspection of received goods, cross-checking quantities and specifications, handling discrepancies, and ensuring compliance with company standards and regulatory requirements. The aim is to maintain accuracy in supply chain operations, prevent errors, and ensure the timely and correct receipt of materials.

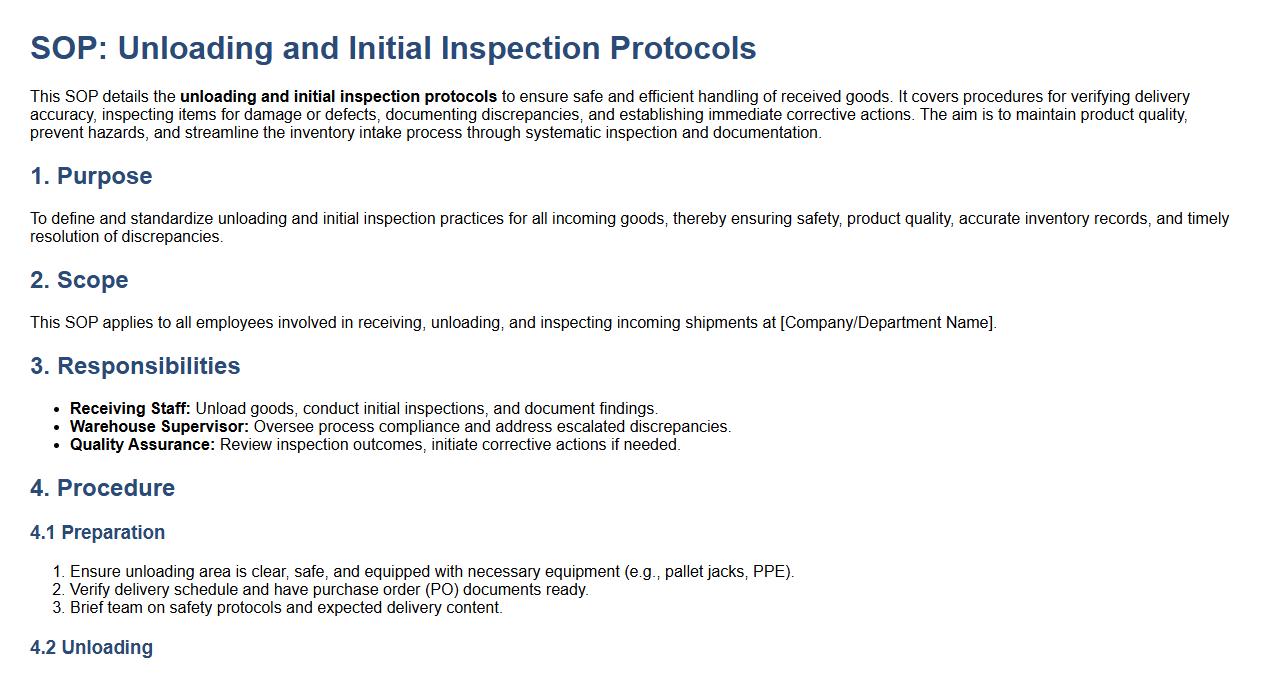

Unloading and initial inspection protocols.

This SOP details the unloading and initial inspection protocols to ensure safe and efficient handling of received goods. It covers procedures for verifying delivery accuracy, inspecting items for damage or defects, documenting discrepancies, and establishing immediate corrective actions. The aim is to maintain product quality, prevent hazards, and streamline the inventory intake process through systematic inspection and documentation.

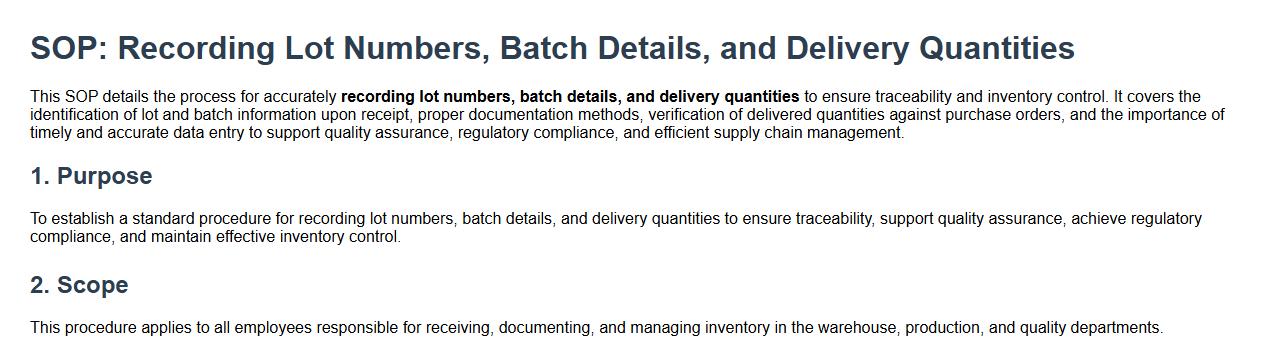

Recording lot numbers, batch details, and delivery quantities.

This SOP details the process for accurately recording lot numbers, batch details, and delivery quantities to ensure traceability and inventory control. It covers the identification of lot and batch information upon receipt, proper documentation methods, verification of delivered quantities against purchase orders, and the importance of timely and accurate data entry to support quality assurance, regulatory compliance, and efficient supply chain management.

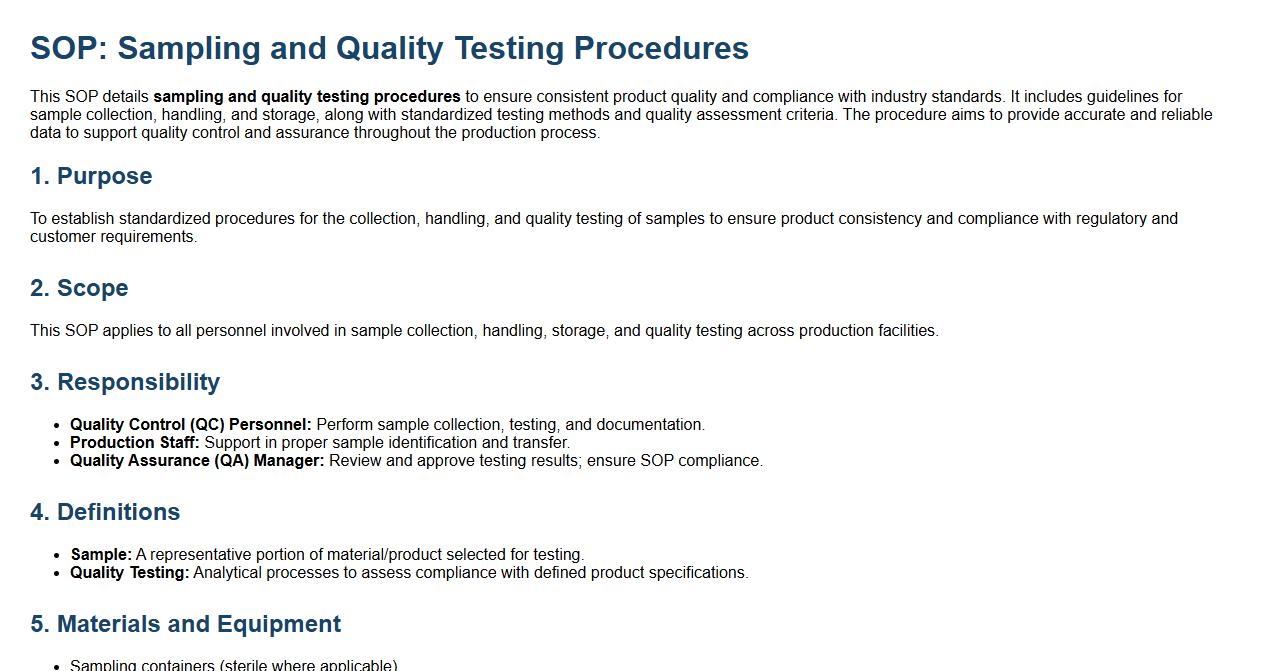

Sampling and quality testing procedures.

This SOP details sampling and quality testing procedures to ensure consistent product quality and compliance with industry standards. It includes guidelines for sample collection, handling, and storage, along with standardized testing methods and quality assessment criteria. The procedure aims to provide accurate and reliable data to support quality control and assurance throughout the production process.

Quarantine and segregation guidelines for non-conforming materials.

This SOP provides detailed quarantine and segregation guidelines for non-conforming materials, ensuring that all materials that do not meet quality standards are properly identified, isolated, and controlled. The procedures include steps for immediate segregation, labeling, documentation, and secure storage of non-conforming items to prevent unintended use or mixing with conforming materials. It also outlines responsibilities for verification, disposition, and corrective action to maintain compliance with quality management systems and regulatory requirements, thereby safeguarding product integrity and operational efficiency.

Inventory labeling and traceability requirements.

This SOP defines inventory labeling and traceability requirements, encompassing standardized labeling procedures, barcode and RFID implementation, batch and lot number assignments, documentation of product movements, and record-keeping protocols. The goal is to ensure accurate tracking of inventory items from receipt to dispatch, facilitating quality control, recall readiness, and regulatory compliance in inventory management systems.

Storage and handling instructions for raw materials.

This SOP provides detailed storage and handling instructions for raw materials, covering proper storage conditions, safe material handling techniques, contamination prevention, inventory management, and compliance with quality standards to ensure the integrity and safety of raw materials throughout the production process.

Documentation, data entry, and receipt acknowledgment.

This SOP details the procedures for documentation, data entry, and receipt acknowledgment, including accurate record-keeping practices, standardized data input methods, verification of entered information, secure storage of documents, and timely acknowledgment of received materials. The goal is to ensure data integrity, traceability, and accountability in organizational processes by implementing consistent and reliable documentation standards.

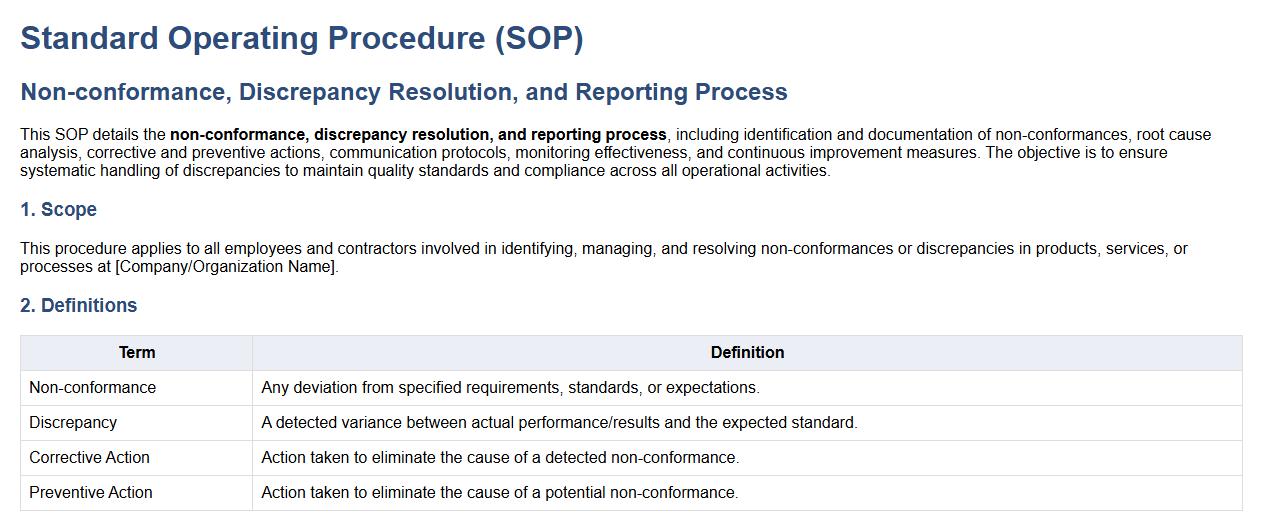

Non-conformance, discrepancy resolution, and reporting process.

This SOP details the non-conformance, discrepancy resolution, and reporting process, including identification and documentation of non-conformances, root cause analysis, corrective and preventive actions, communication protocols, monitoring effectiveness, and continuous improvement measures. The objective is to ensure systematic handling of discrepancies to maintain quality standards and compliance across all operational activities.

What criteria must received raw materials meet before acceptance according to the SOP?

The raw materials must comply with established quality specifications outlined in the SOP. Verification includes checking for correct labeling, proper packaging, and adherence to the required standards. Any deviation from these criteria results in rejection to ensure quality control.

Which documentation is required for verifying and recording each raw material delivery?

Each raw material delivery must be accompanied by a delivery note and a certificate of analysis (CoA). These documents are vital for confirming the material's identity and quality before acceptance. Accurate records of these documents are maintained for traceability and auditing.

What are the specified procedures for inspecting and sampling incoming raw materials?

Inspecting incoming materials involves a thorough visual check and verification against purchase orders as per the SOP. Sampling is conducted using a specified method to ensure representativeness and consistency. Samples are then submitted for laboratory testing to confirm their quality.

How should non-conforming raw materials be handled, segregated, and reported under the SOP?

Non-conforming raw materials must be clearly labeled and segregated in a designated quarantine area to prevent unintended use. The SOP requires immediate reporting to quality assurance for further evaluation. Proper documentation of non-conformance and corrective actions is mandatory.

Who is responsible for reviewing, approving, and storing records of raw material receipt?

The quality control manager or designated personnel is responsible for reviewing and approving raw material receipt records. Approved documentation must be securely stored to maintain data integrity and facilitate audits. The SOP outlines the retention period and access controls for these records.