A SOP Template for Product Inspection in Manufacturing provides a standardized framework to ensure consistent quality checks throughout the production process. It outlines detailed inspection criteria, procedures, and documentation requirements to minimize defects and maintain compliance with industry standards. Using this template helps streamline quality control efforts and enhances overall product reliability.

Incoming raw material verification procedures.

This SOP defines the incoming raw material verification procedures to ensure that all raw materials received meet specified quality standards and comply with purchase order requirements. It includes steps for inspecting shipments, verifying documentation, sampling for quality tests, recording discrepancies, and managing non-conforming materials. The purpose is to prevent the use of substandard materials in production, thereby safeguarding product quality and consistency.

Pre-production equipment and tool calibration checklist.

This SOP provides a comprehensive pre-production equipment and tool calibration checklist to ensure all machinery and tools are accurately calibrated before beginning production. It includes procedures for verifying calibration status, adjusting instruments to standard specifications, documenting calibration results, and scheduling regular maintenance. The checklist aims to maintain equipment precision, enhance product quality, and minimize production errors by implementing consistent calibration practices.

Visual inspection guidelines for surface defects.

This SOP provides visual inspection guidelines for surface defects, detailing the procedures for identifying, assessing, and documenting imperfections on various surfaces. It covers the use of proper lighting, magnification tools, and inspection angles to ensure accurate detection of defects such as cracks, scratches, discolorations, and other irregularities. The SOP aims to maintain quality control and prevent defective products from progressing in the production process by establishing standardized inspection criteria and reporting methods.

Dimensional measurement and tolerance verification steps.

This SOP details the dimensional measurement and tolerance verification steps, including the preparation of measurement tools, selection of appropriate instruments, calibration procedures, measurement techniques, data recording, comparison against specified tolerances, and documentation of results. The objective is to ensure accurate and consistent dimensional verification to maintain product quality and conformity with design specifications.

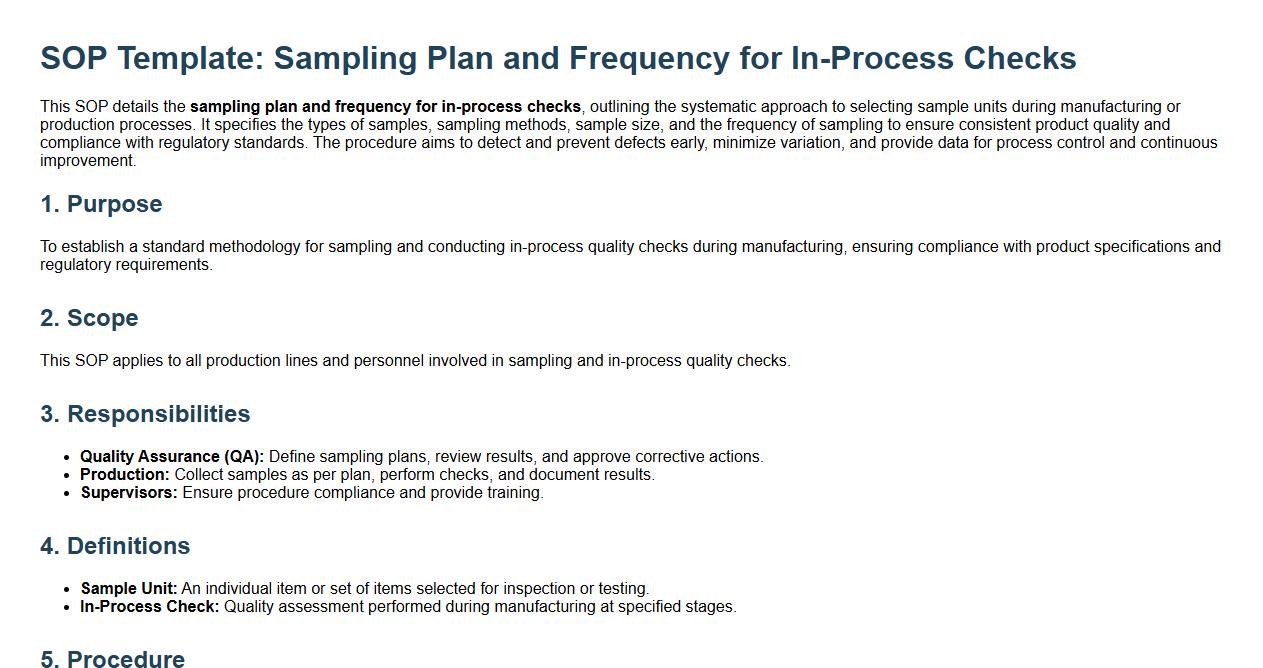

Sampling plan and frequency for in-process checks.

This SOP details the sampling plan and frequency for in-process checks, outlining the systematic approach to selecting sample units during manufacturing or production processes. It specifies the types of samples, sampling methods, sample size, and the frequency of sampling to ensure consistent product quality and compliance with regulatory standards. The procedure aims to detect and prevent defects early, minimize variation, and provide data for process control and continuous improvement.

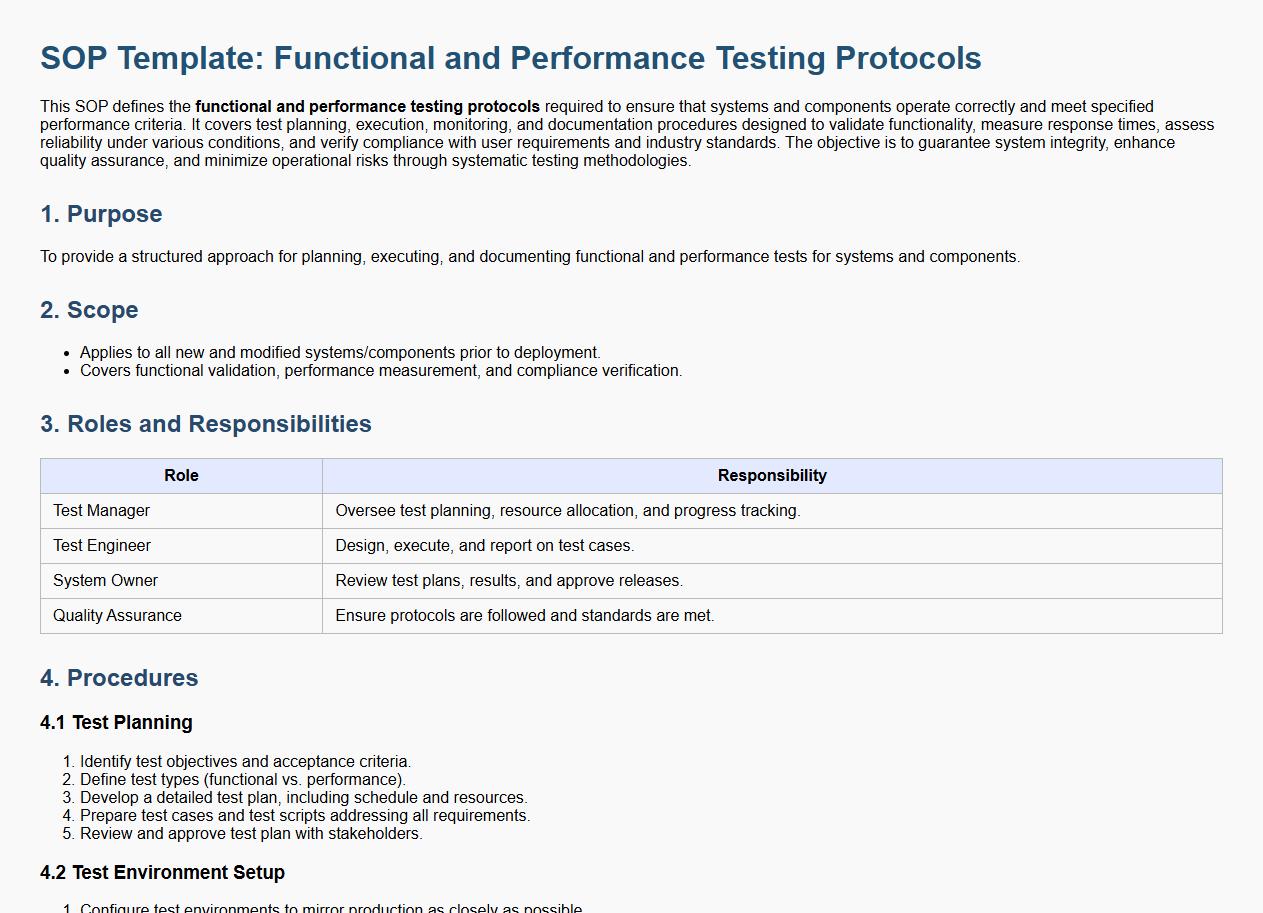

Functional and performance testing protocols.

This SOP defines the functional and performance testing protocols required to ensure that systems and components operate correctly and meet specified performance criteria. It covers test planning, execution, monitoring, and documentation procedures designed to validate functionality, measure response times, assess reliability under various conditions, and verify compliance with user requirements and industry standards. The objective is to guarantee system integrity, enhance quality assurance, and minimize operational risks through systematic testing methodologies.

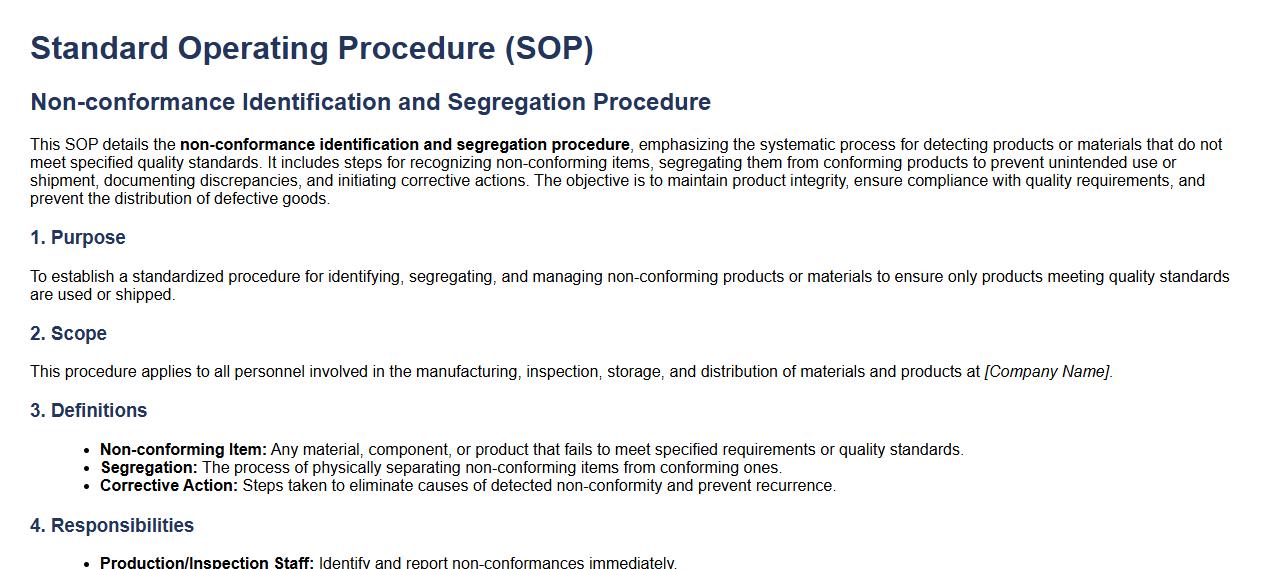

Non-conformance identification and segregation procedure.

This SOP details the non-conformance identification and segregation procedure, emphasizing the systematic process for detecting products or materials that do not meet specified quality standards. It includes steps for recognizing non-conforming items, segregating them from conforming products to prevent unintended use or shipment, documenting discrepancies, and initiating corrective actions. The objective is to maintain product integrity, ensure compliance with quality requirements, and prevent the distribution of defective goods.

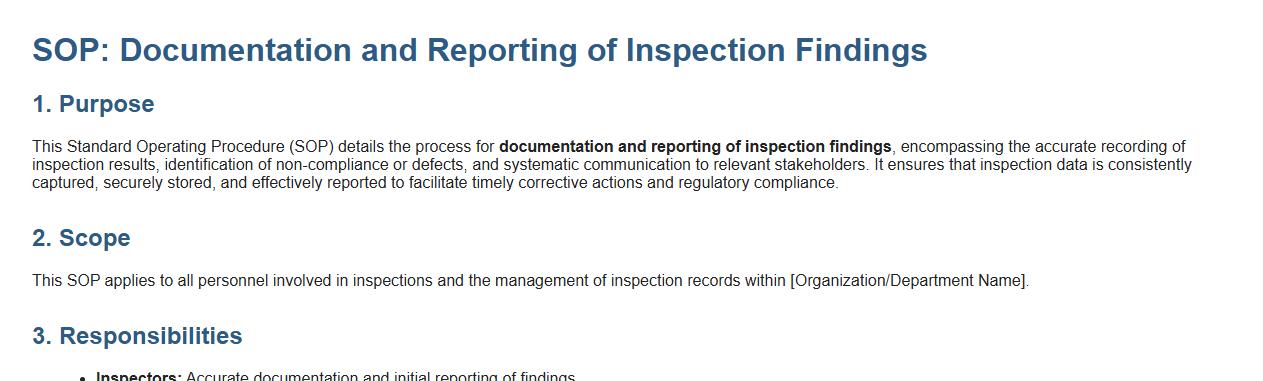

Documentation and reporting of inspection findings.

This SOP details the process for documentation and reporting of inspection findings, encompassing the accurate recording of inspection results, identification of non-compliance or defects, and systematic communication to relevant stakeholders. It ensures that inspection data is consistently captured, securely stored, and effectively reported to facilitate timely corrective actions and regulatory compliance.

Corrective action process for detected defects.

This SOP details the corrective action process for detected defects, encompassing defect identification, root cause analysis, documentation of findings, development and implementation of corrective measures, verification of effectiveness, and continuous monitoring to prevent recurrence. The objective is to ensure timely resolution of defects, enhance product quality, and maintain compliance with industry standards through systematic and proactive corrective actions.

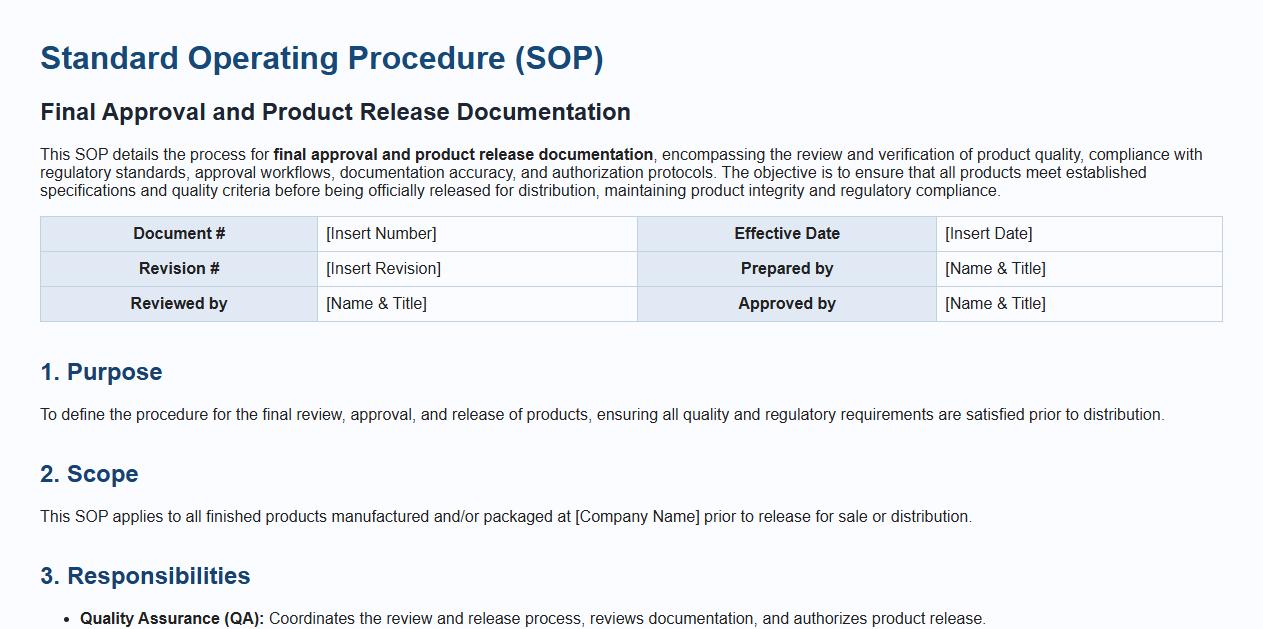

Final approval and product release documentation.

This SOP details the process for final approval and product release documentation, encompassing the review and verification of product quality, compliance with regulatory standards, approval workflows, documentation accuracy, and authorization protocols. The objective is to ensure that all products meet established specifications and quality criteria before being officially released for distribution, maintaining product integrity and regulatory compliance.

Key Objectives Outlined in the SOP for Product Inspection During Manufacturing

The primary objective of the SOP is to ensure consistent product quality through systematic inspection procedures. It aims to identify defects early to prevent faulty products from reaching customers. Additionally, the SOP focuses on maintaining compliance with regulatory and company standards to achieve customer satisfaction.

Specific Inspection Criteria and Quality Standards in the SOP

The SOP mandates adherence to predefined quality benchmarks such as dimensional accuracy, material integrity, and functional performance. Products must meet both internal standards and industry-recognized certifications during inspection. It emphasizes using calibrated measurement tools and verified procedures for reliable assessment.

Responsibility for Conducting and Documenting Product Inspections

The SOP assigns inspection duties to qualified quality control personnel who possess the necessary training and certifications. Inspectors are responsible for meticulously documenting all findings in standardized inspection reports. This documentation supports traceability and accountability throughout the manufacturing process.

Steps for Addressing and Reporting Non-Conforming Products

Upon detecting non-conforming products, the SOP requires immediate segregation to prevent further processing. A formal non-conformance report (NCR) must be generated detailing the issue and corrective actions. The process involves notifying relevant teams to initiate root cause analysis and implement preventive measures.

Frequency and Stages of Product Inspections Defined by the SOP

The SOP outlines inspection frequency at critical manufacturing stages including incoming materials, in-process, and final product evaluations. Regular inspections ensure continuous quality control and early defect detection to minimize rework. Scheduled audits and random checks supplement these to uphold rigorous quality standards.