A SOP template for incident reporting in manufacturing ensures consistent documentation of workplace incidents, enhancing safety and compliance. This structured format facilitates clear communication of incident details, root causes, and corrective actions. Implementing such a template helps reduce risks and supports continuous improvement in manufacturing processes.

Incident identification and initial response procedures.

This SOP details the incident identification and initial response procedures, focusing on promptly recognizing incidents, assessing potential risks, securing the area to prevent further harm, notifying appropriate personnel, and initiating immediate corrective actions. The objective is to minimize damage, ensure safety, and enable an effective response to any incident within the organization.

Immediate workplace safety assessment and hazard control.

This SOP establishes the process for immediate workplace safety assessment and hazard control, focusing on the rapid identification, evaluation, and mitigation of potential hazards in the work environment. It ensures prompt responses to safety risks through systematic inspections, hazard documentation, and implementation of control measures to protect employees and maintain a safe workplace. The procedure emphasizes continuous monitoring, corrective actions, and communication to prevent accidents and promote overall occupational health and safety.

Notification process for supervisors and management.

This SOP details the notification process for supervisors and management, including immediate reporting protocols, escalation procedures, communication channels, documentation requirements, and follow-up actions. The goal is to ensure timely and effective communication of critical information to the appropriate supervisory and managerial personnel to facilitate prompt decision-making and resolution.

Detailed incident documentation and evidence collection guidelines.

This SOP provides detailed incident documentation and evidence collection guidelines to ensure accurate, thorough, and systematic recording of incidents. It covers procedures for capturing factual information, preserving physical evidence, maintaining chain of custody, and ensuring confidentiality. The goal is to support effective incident investigation, legal compliance, and continuous improvement in safety and operational practices.

Witness statement collection protocol.

This SOP details the witness statement collection protocol, covering the procedures for identifying, interviewing, and documenting witness accounts, ensuring accuracy and reliability in statements, maintaining confidentiality and legal compliance, securing evidence, and proper storage and handling of collected statements to support investigations and organizational accountability.

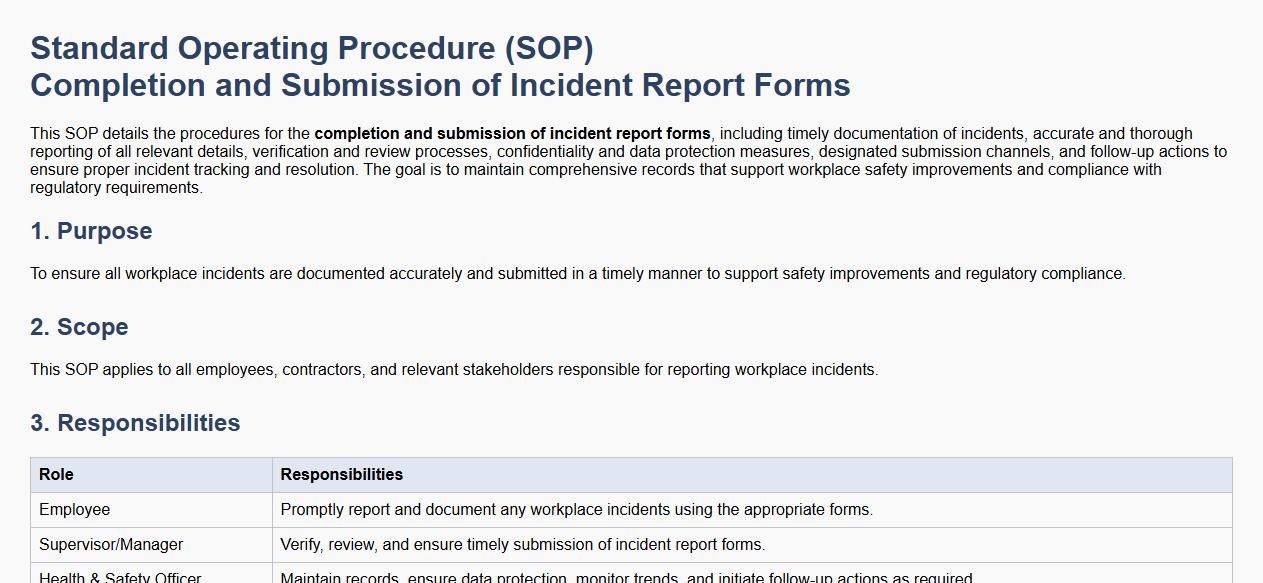

Completion and submission of incident report forms.

This SOP details the procedures for the completion and submission of incident report forms, including timely documentation of incidents, accurate and thorough reporting of all relevant details, verification and review processes, confidentiality and data protection measures, designated submission channels, and follow-up actions to ensure proper incident tracking and resolution. The goal is to maintain comprehensive records that support workplace safety improvements and compliance with regulatory requirements.

Incident escalation and external authority notification (if required).

This SOP defines the process for incident escalation and external authority notification, detailing the criteria for escalating incidents within the organization, the roles and responsibilities of personnel involved in the escalation, and the procedures for notifying external authorities when necessary. It ensures timely and effective communication to manage incidents appropriately, comply with legal requirements, and minimize potential impacts.

Corrective and preventive action planning steps.

This SOP details the corrective and preventive action planning steps to identify, analyze, and address non-conformities or potential issues within processes. It includes procedures for root cause analysis, development of effective corrective actions to eliminate existing problems, implementation of preventive measures to avoid recurrence, and continuous monitoring to ensure the effectiveness of these actions. The goal is to enhance process reliability, improve quality outcomes, and maintain compliance with organizational standards.

Follow-up investigation and root cause analysis procedures.

This SOP details the follow-up investigation and root cause analysis procedures, encompassing steps to systematically identify underlying issues after an incident, methods for data collection and analysis, techniques to determine contributing factors, documentation requirements, corrective action planning, and monitoring of implemented solutions. The goal is to ensure thorough investigations that prevent recurrence and promote continuous improvement in safety and operational efficiency.

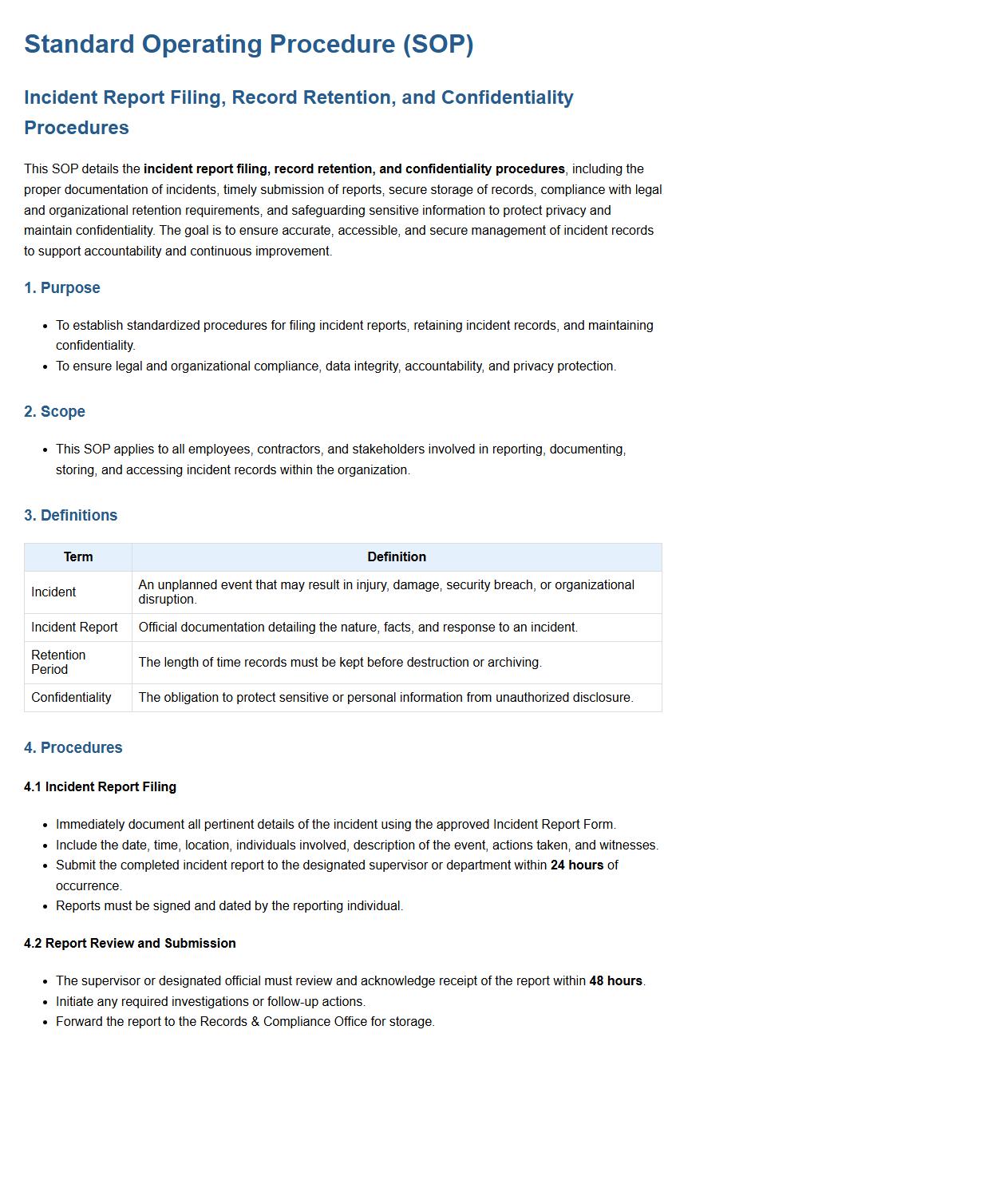

Incident report filing, record retention, and confidentiality procedures.

This SOP details the incident report filing, record retention, and confidentiality procedures, including the proper documentation of incidents, timely submission of reports, secure storage of records, compliance with legal and organizational retention requirements, and safeguarding sensitive information to protect privacy and maintain confidentiality. The goal is to ensure accurate, accessible, and secure management of incident records to support accountability and continuous improvement.

Key Steps Involved in the Incident Reporting Process According to the SOP

The incident reporting process begins with the immediate identification and notification of the incident. Next, detailed documentation of the incident is required using standardized forms. Finally, the report is reviewed and analyzed to implement corrective actions and prevent recurrence.

Responsibility for Initiating and Documenting an Incident Report as Per the SOP

The responsibility for initiating the incident report lies with the employee or individual who first identifies the incident. Documentation must be completed promptly and accurately by the designated personnel. Supervisors or managers often oversee the review and final submission of the report.

Types of Incidents Required to Be Reported Under the SOP Guidelines

The SOP mandates reporting of all incidents that affect safety, security, or operational procedures. This includes accidents, near-misses, equipment failures, and any suspicious activity. Reporting ensures risks are mitigated and compliance with regulatory standards is maintained.

Information That Must Be Included in an Incident Report as Specified in the SOP

The incident report must include the date, time, and location of the incident. It should detail the individuals involved, a description of what occurred, and any immediate corrective actions taken. Additionally, witness statements and any photographic evidence should be attached if applicable.

Timelines and Escalation Procedures Outlined in the SOP for Reporting and Addressing Incidents

The SOP specifies that incidents must be reported immediately or within a defined timeframe, typically 24 hours. Escalation procedures require notifying supervisors, safety officers, and management depending on incident severity. Prompt investigation and resolution are mandatory to comply with organizational policies.