A SOP template for employee training in manufacturing ensures consistent and thorough instruction on safety protocols, machinery operation, and quality standards. It outlines step-by-step procedures to help new hires quickly adapt and maintain productivity. This structured approach minimizes errors and promotes a safer, more efficient work environment.

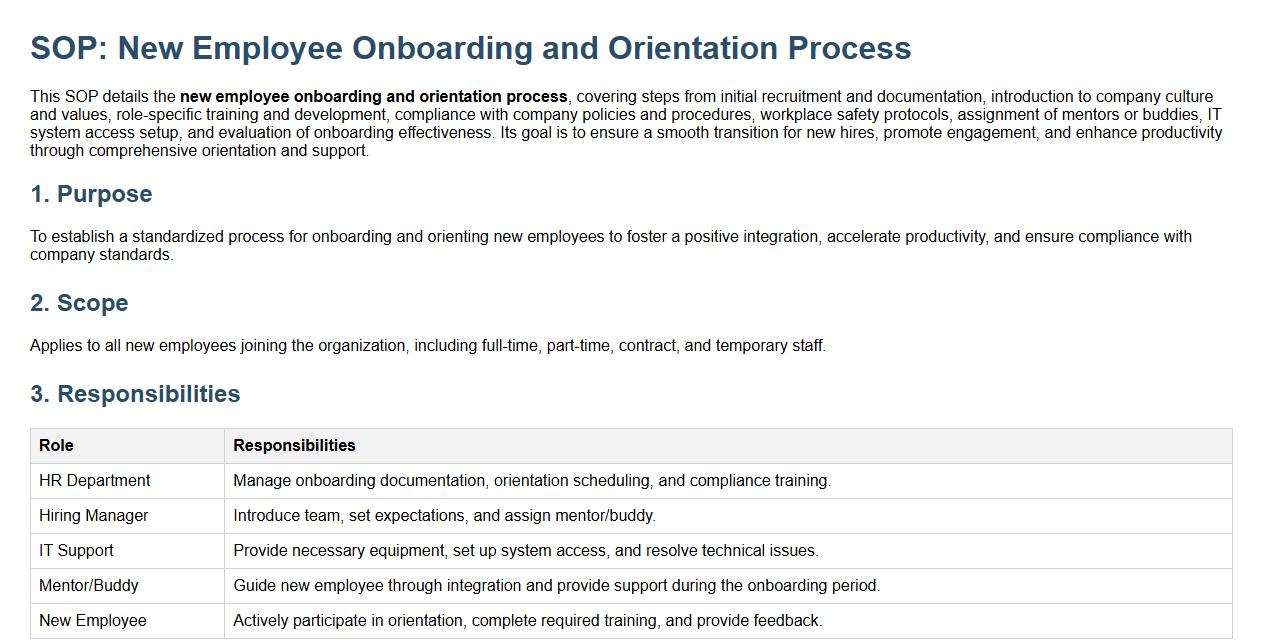

New employee onboarding and orientation process.

This SOP details the new employee onboarding and orientation process, covering steps from initial recruitment and documentation, introduction to company culture and values, role-specific training and development, compliance with company policies and procedures, workplace safety protocols, assignment of mentors or buddies, IT system access setup, and evaluation of onboarding effectiveness. Its goal is to ensure a smooth transition for new hires, promote engagement, and enhance productivity through comprehensive orientation and support.

Job-specific task instruction and demonstration procedures.

This SOP details the job-specific task instruction and demonstration procedures designed to ensure employees receive clear, practical guidance tailored to their unique job roles. It covers step-by-step instructions, live demonstrations, competency evaluations, and ongoing support to enhance skill acquisition, promote safety, and improve overall job performance. The objective is to standardize training methods to increase efficiency and reduce errors in task execution across the organization.

Workplace safety and hazard communication guidelines.

This SOP defines workplace safety and hazard communication guidelines, focusing on identifying and mitigating workplace hazards, proper use of personal protective equipment (PPE), clear labeling and signage of hazardous materials, employee training on hazard recognition, procedures for reporting unsafe conditions, and compliance with regulatory standards. The goal is to create a safe work environment that minimizes risks and ensures effective communication of potential hazards to all employees.

Equipment and machinery operation training steps.

This SOP details the equipment and machinery operation training steps, including the identification of necessary training, preparation of training materials and safety guidelines, hands-on demonstration and practice sessions, assessment of trainee competency, provision of feedback and corrective actions, documentation of training completion, and ongoing evaluation and refresher training to ensure safe and efficient operation of all machinery and equipment on site.

Quality control and inspection protocols for trainees.

This SOP details quality control and inspection protocols for trainees, covering standardized procedures to evaluate trainee performance, consistency in training outcomes, adherence to training guidelines, regular assessment schedules, documentation of inspection results, corrective actions for non-compliance, and continuous improvement strategies. The goal is to maintain high training standards, ensure competency, and support the development of skilled and qualified personnel.

Personal protective equipment (PPE) usage and requirements.

This SOP details the personal protective equipment (PPE) usage and requirements to ensure the safety and health of all employees. It covers the selection, proper use, maintenance, and disposal of PPE, including gloves, helmets, eye protection, respiratory devices, and protective clothing. The document emphasizes compliance with regulatory standards, employee training, and regular inspections to minimize workplace hazards and prevent injuries.

Standardized documentation and record-keeping for training.

This SOP establishes standardized documentation and record-keeping for training, ensuring consistent tracking of trainee progress, training sessions, attendance, assessment results, and certification status. It aims to maintain accurate, organized, and secure records to support compliance, facilitate audits, and enhance the effectiveness of training programs across the organization.

Assessment and competency evaluation procedures.

This SOP details the assessment and competency evaluation procedures, covering the systematic methods for evaluating skills, knowledge, and performance of individuals. It includes planning assessments, selecting appropriate evaluation tools, conducting fair and consistent testing, recording results, providing feedback, and ensuring continuous improvement. The goal is to maintain high standards of competency, support professional development, and ensure compliance with industry requirements.

Continuous skills development and refresher training schedule.

This SOP details the continuous skills development and refresher training schedule, encompassing the planning, implementation, and monitoring of regular training sessions designed to enhance employee competencies, update knowledge on industry best practices, and ensure compliance with safety and operational standards. The schedule aims to promote ongoing professional growth, maintain high performance levels, and adapt to technological advancements and regulatory changes within the organization.

Feedback collection and training effectiveness review process.

This SOP details the feedback collection and training effectiveness review process, encompassing the systematic gathering of participant feedback, evaluation of training objectives achievement, analysis of training methods and materials, identification of improvement areas, and documentation of results. The goal is to ensure continuous enhancement of training programs by measuring their impact and effectiveness in meeting organizational learning goals.

What are the key objectives outlined in the SOP for Employee Training in Manufacturing?

The key objectives in the SOP for Employee Training include ensuring all employees are competent in their roles, enhancing workplace safety, and maintaining compliance with industry standards. It aims to standardize training processes to improve efficiency and product quality. Additionally, the SOP emphasizes continuous skill development to adapt to technological advancements.

Which departments or roles are responsible for implementing and monitoring the training process?

The Human Resources (HR) department typically oversees the overall training program, while the Production and Quality Assurance teams handle role-specific training implementation. Supervisors and team leads are responsible for daily monitoring and ensuring employees complete required sessions. Collaboration among these departments ensures comprehensive training management and accountability.

How does the SOP define the required frequency and types of training for manufacturing employees?

The SOP specifies that training frequency varies based on job complexity, safety requirements, and regulatory guidelines, with mandatory refresher courses conducted annually. Types of training include onboarding, safety protocols, equipment operation, and quality control procedures. This structured approach ensures employees remain updated with best practices and compliance standards.

What documentation or records must be maintained to demonstrate compliance with training SOPs?

Complete and accurate training records must be maintained, including attendance logs, training content, assessment results, and certifications. These documents provide evidence of compliance during audits and regulatory inspections. The SOP mandates secure storage and easy retrieval of records for accountability and continuous improvement.

What procedures are described in the SOP for evaluating the effectiveness of completed employee training sessions?

The SOP outlines procedures such as post-training assessments, performance monitoring, and feedback collection to evaluate training effectiveness. It requires analysis of key performance indicators and error rates to measure improvements linked to training. Continuous review and updates to training content are made based on these evaluations to ensure relevance.