A SOP Template for Machine Calibration in Manufacturing ensures standardized procedures to maintain equipment accuracy and reliability. It outlines step-by-step calibration methods, documentation requirements, and compliance checks to minimize production errors. This template supports quality control by facilitating consistent machine performance and reducing downtime.

Preparation and verification of calibration tools and reference standards.

This SOP details the preparation and verification of calibration tools and reference standards, emphasizing proper selection, inspection, and validation processes to ensure accuracy and reliability in measurement instruments. It includes guidelines for handling, storage, documentation, and periodic verification to maintain traceability and compliance with quality standards, thereby supporting consistent and precise calibration activities.

Pre-calibration equipment inspection and documentation.

This SOP details the process for pre-calibration equipment inspection and documentation, including the verification of equipment condition, ensuring operational readiness, checking calibration standards, and recording inspection results. The procedure aims to guarantee the accuracy and reliability of measurement tools before calibration, maintain equipment integrity, and ensure compliance with quality control standards through thorough documentation.

Safety checks and lockout/tagout procedures.

This SOP details safety checks and lockout/tagout procedures essential for preventing accidental equipment startup during maintenance and repair. It covers the identification of energy sources, proper shutdown and isolation techniques, application of lockout/tagout devices, verification of energy isolation, safe release of stored energy, and communication protocols among workers. The objective is to ensure a safe working environment by minimizing risks associated with hazardous equipment and electrical systems, thereby protecting personnel from potential injuries or fatalities.

Identification and labeling of machine to be calibrated.

This SOP details the process for identification and labeling of machines to be calibrated, including assigning unique identification codes, accurate documentation of machine specifications, clear labeling of calibration status, ensuring traceability throughout the calibration cycle, and maintaining updated calibration records. The objective is to guarantee precise calibration management, prevent errors, and uphold equipment accuracy and compliance with quality standards.

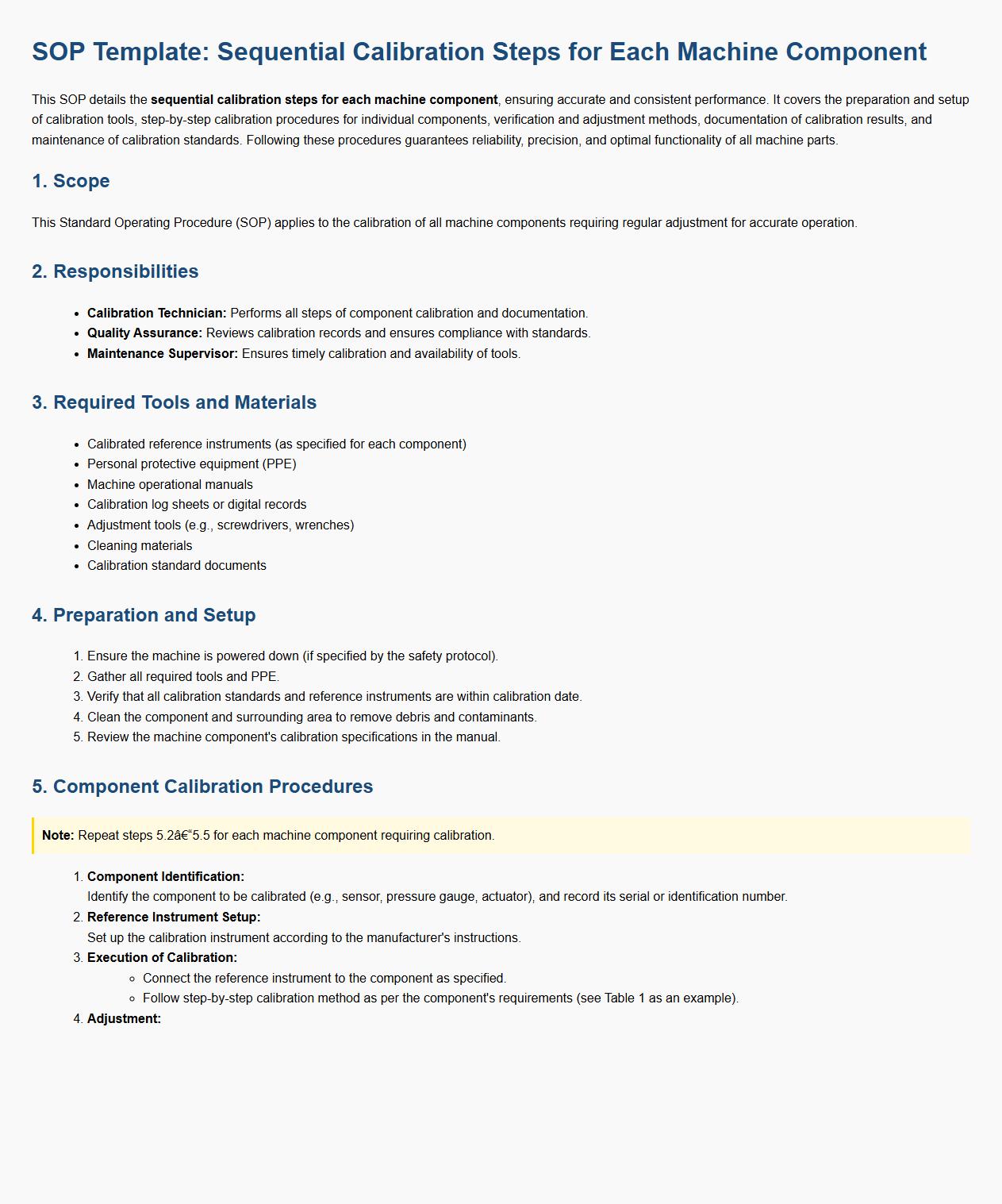

Sequential calibration steps for each machine component.

This SOP details the sequential calibration steps for each machine component, ensuring accurate and consistent performance. It covers the preparation and setup of calibration tools, step-by-step calibration procedures for individual components, verification and adjustment methods, documentation of calibration results, and maintenance of calibration standards. Following these procedures guarantees reliability, precision, and optimal functionality of all machine parts.

Adjustment of equipment settings to meet specified tolerances.

This SOP details the process for adjustment of equipment settings to meet specified tolerances, ensuring precision and compliance with operational standards. It covers the identification of required settings, calibration procedures, verification techniques, documentation of adjustments, and quality control measures to maintain equipment accuracy and performance.

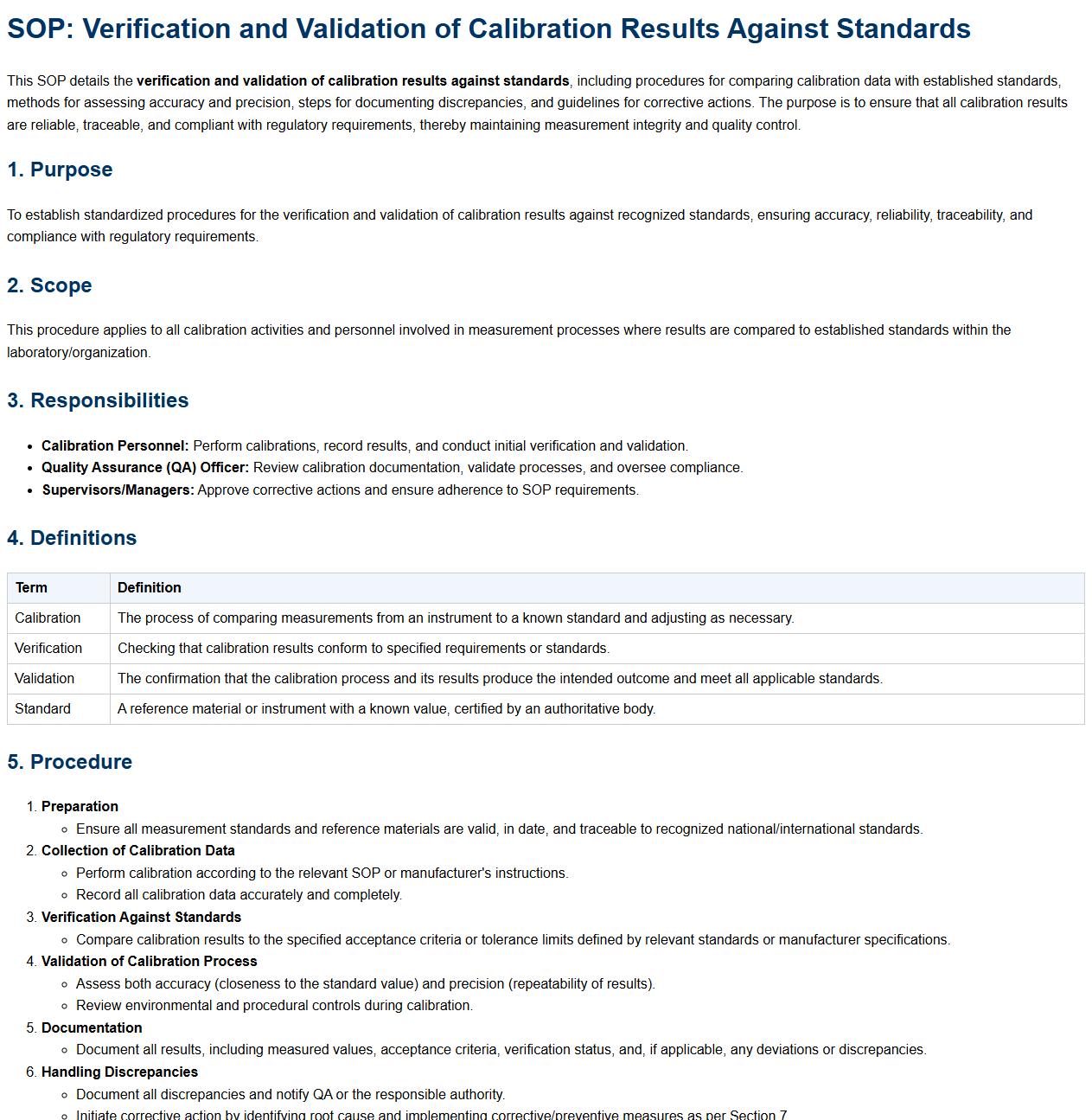

Verification and validation of calibration results against standards.

This SOP details the verification and validation of calibration results against standards, including procedures for comparing calibration data with established standards, methods for assessing accuracy and precision, steps for documenting discrepancies, and guidelines for corrective actions. The purpose is to ensure that all calibration results are reliable, traceable, and compliant with regulatory requirements, thereby maintaining measurement integrity and quality control.

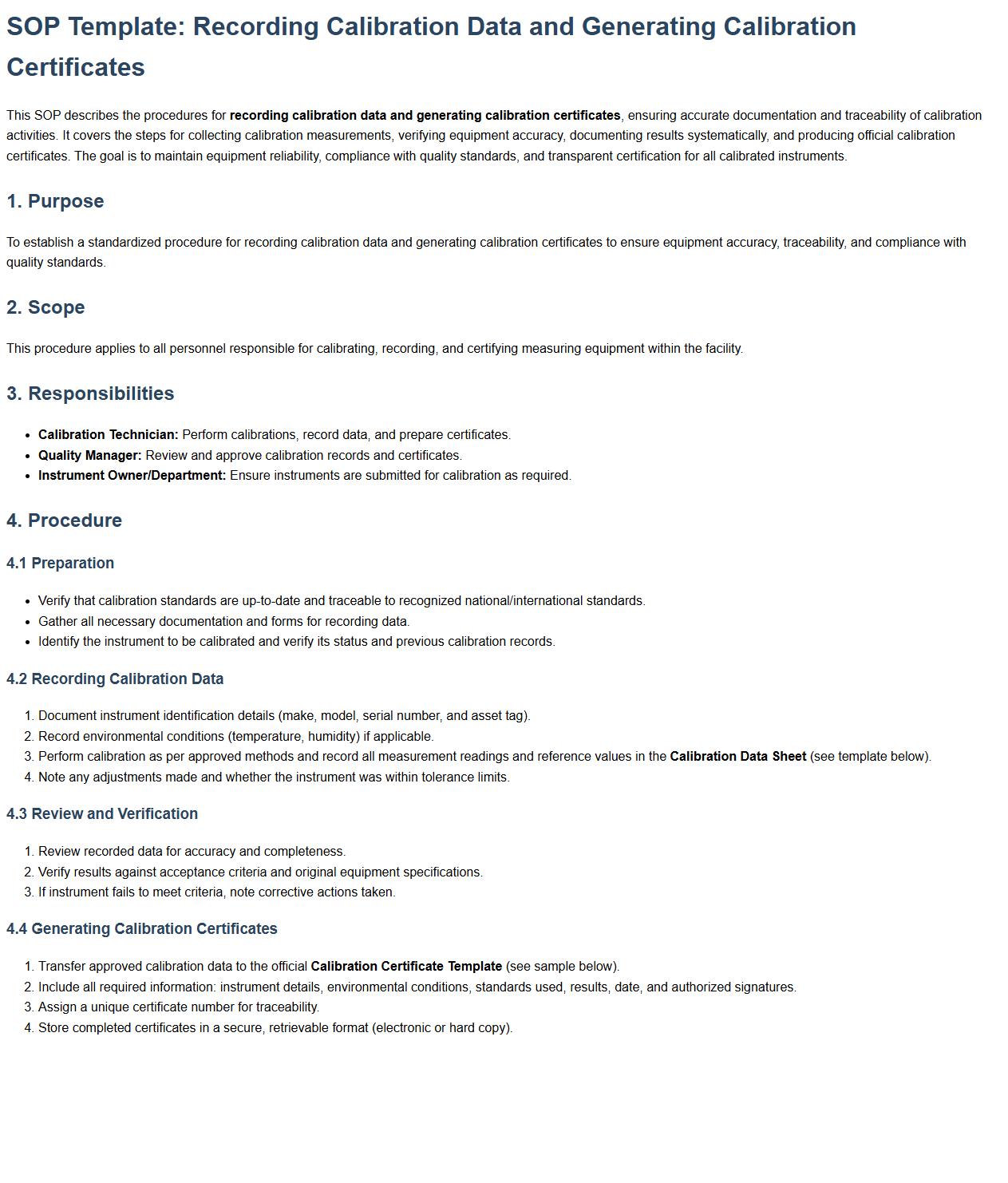

Recording calibration data and generating calibration certificates.

This SOP describes the procedures for recording calibration data and generating calibration certificates, ensuring accurate documentation and traceability of calibration activities. It covers the steps for collecting calibration measurements, verifying equipment accuracy, documenting results systematically, and producing official calibration certificates. The goal is to maintain equipment reliability, compliance with quality standards, and transparent certification for all calibrated instruments.

Communication of calibration status and tagging of equipment.

This SOP outlines the process for communication of calibration status and tagging of equipment to ensure all measuring devices are accurately identified and their calibration validity is clearly communicated. It covers the steps for tagging equipment with calibration status, recording calibration dates, notifying relevant personnel of calibration results, and maintaining documentation to guarantee compliance with quality standards and operational efficiency.

Post-calibration review, sign-off, and scheduling of next calibration.

This SOP details the process for post-calibration review, sign-off, and scheduling of next calibration, ensuring accurate documentation and validation of calibration results. It includes steps for reviewing calibration data, obtaining necessary approvals, formally signing off on completed calibrations, and scheduling the subsequent calibration to maintain equipment accuracy and compliance with quality standards.

What are the key steps outlined in the SOP for machine calibration in manufacturing?

The SOP for machine calibration begins with preparing the machine and calibration tools to ensure readiness. It then requires conducting a series of tests to compare machine output against known standards. Finally, the results must be documented and any adjustments made to align with specified tolerances.

How frequently must machine calibration be performed according to the SOP?

The SOP mandates that machine calibration be performed at regular intervals, typically defined by operational hours or production cycles. Additionally, calibration is required after maintenance or any significant machine repair. Scheduled calibration ensures consistent accuracy and compliance with quality standards.

Which personnel are authorized to conduct and document machine calibration in the SOP?

Only qualified and trained personnel specified in the SOP are authorized to perform machine calibration. These individuals must have documented competency in calibration procedures. Additionally, they are responsible for accurately documenting the calibration results and any corrective actions taken.

What equipment and reference standards are required during the calibration process as per the SOP?

The SOP specifies the use of calibration equipment and reference standards that are traceable to national or international standards. These include precision measuring instruments and certified reference materials. Proper maintenance and certification of these tools are essential for valid calibration outcomes.

What actions should be taken if a machine fails to meet calibration criteria outlined in the SOP?

If a machine fails calibration, the SOP requires immediate investigation to identify the cause of deviation. The machine must be adjusted, repaired, or removed from production until it meets the required standards. All findings and corrective actions must be thoroughly documented to maintain compliance and quality assurance.