A SOP Template for Order Fulfillment in Manufacturing streamlines the entire process by clearly outlining each step from order receipt to product delivery. This template ensures consistent quality, minimizes errors, and enhances efficiency by standardizing workflows. Implementing a well-structured SOP helps manufacturing teams meet customer expectations and maintain timely order processing.

Order receipt and verification process.

This SOP describes the order receipt and verification process, including the procedures for receiving customer orders, verifying order details for accuracy and completeness, checking inventory availability, confirming pricing and payment terms, and recording orders into the system. The purpose is to ensure accurate and timely processing of customer orders, minimize errors, and improve overall customer satisfaction by maintaining clear communication and documentation throughout the order verification workflow.

Order entry and data validation procedures.

This SOP details the order entry and data validation procedures, encompassing accurate order capturing, customer information verification, product and quantity confirmation, pricing and discount validation, data accuracy checks, error detection and correction methods, order approval workflows, and system update protocols. The goal is to ensure efficient and error-free order processing, maintain data integrity, and enhance customer satisfaction through reliable and consistent order management practices.

Inventory availability check and allocation guidelines.

This SOP details the procedures for inventory availability check and allocation guidelines, including steps for verifying stock levels, prioritizing allocation based on demand and urgency, coordinating with procurement and warehouse teams, and maintaining accurate inventory records. The objective is to ensure optimal inventory management, reduce stockouts, and improve order fulfillment efficiency.

Order picking and material handling instructions.

This SOP details order picking and material handling instructions, covering efficient and accurate picking processes, proper handling techniques to prevent product damage, safety protocols during material transport, use of handling equipment, inventory verification, packing guidelines, and shipping preparation. The goal is to optimize order fulfillment accuracy, enhance workplace safety, and maintain product integrity throughout the material handling workflow.

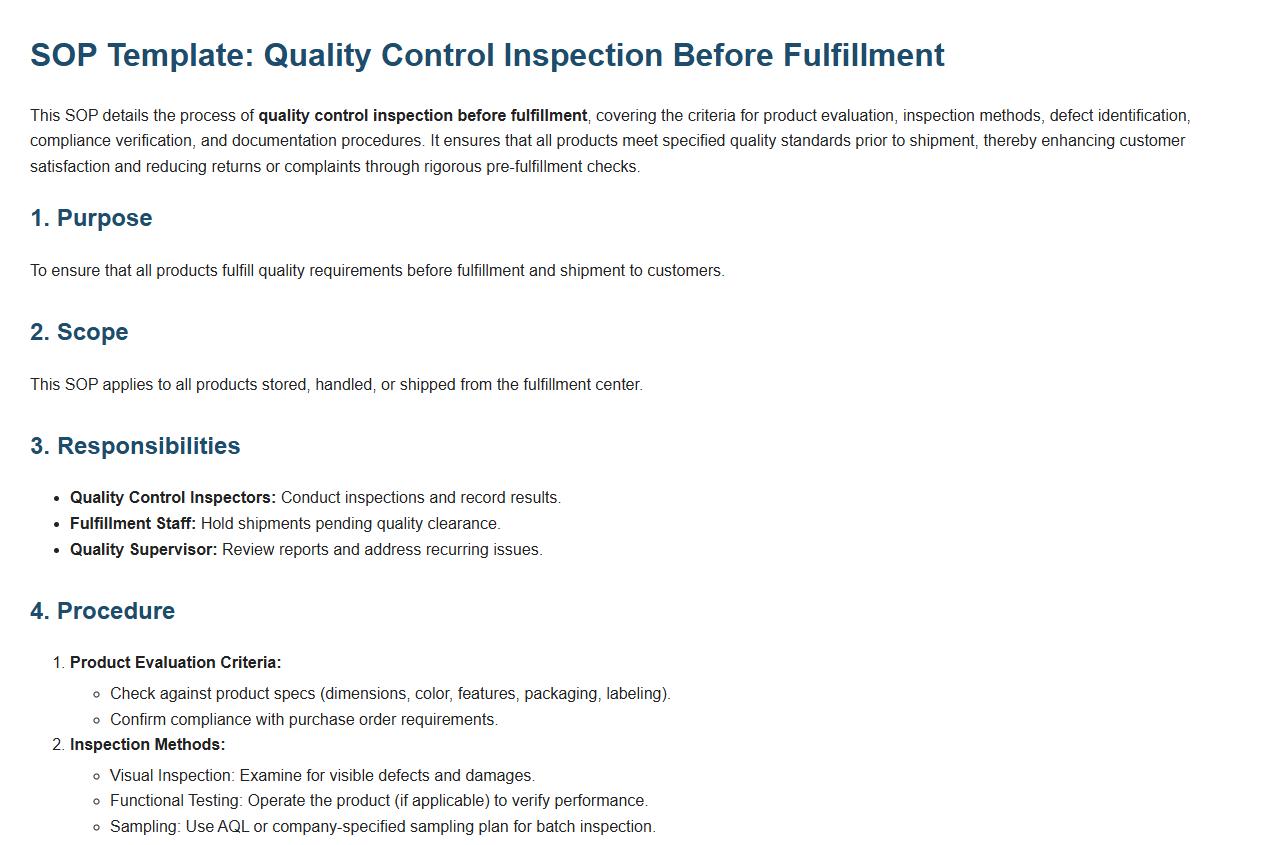

Quality control inspection before fulfillment.

This SOP details the process of quality control inspection before fulfillment, covering the criteria for product evaluation, inspection methods, defect identification, compliance verification, and documentation procedures. It ensures that all products meet specified quality standards prior to shipment, thereby enhancing customer satisfaction and reducing returns or complaints through rigorous pre-fulfillment checks.

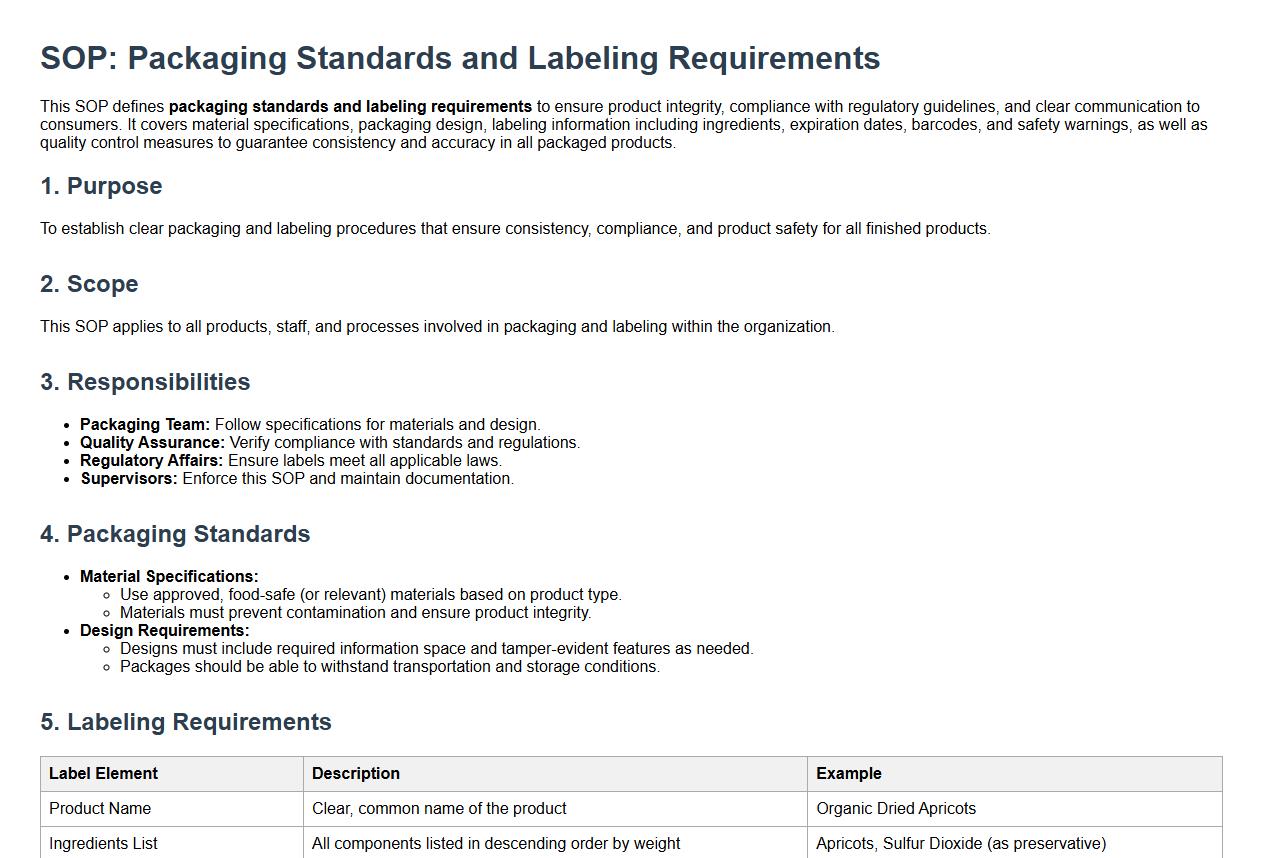

Packaging standards and labeling requirements.

This SOP defines packaging standards and labeling requirements to ensure product integrity, compliance with regulatory guidelines, and clear communication to consumers. It covers material specifications, packaging design, labeling information including ingredients, expiration dates, barcodes, and safety warnings, as well as quality control measures to guarantee consistency and accuracy in all packaged products.

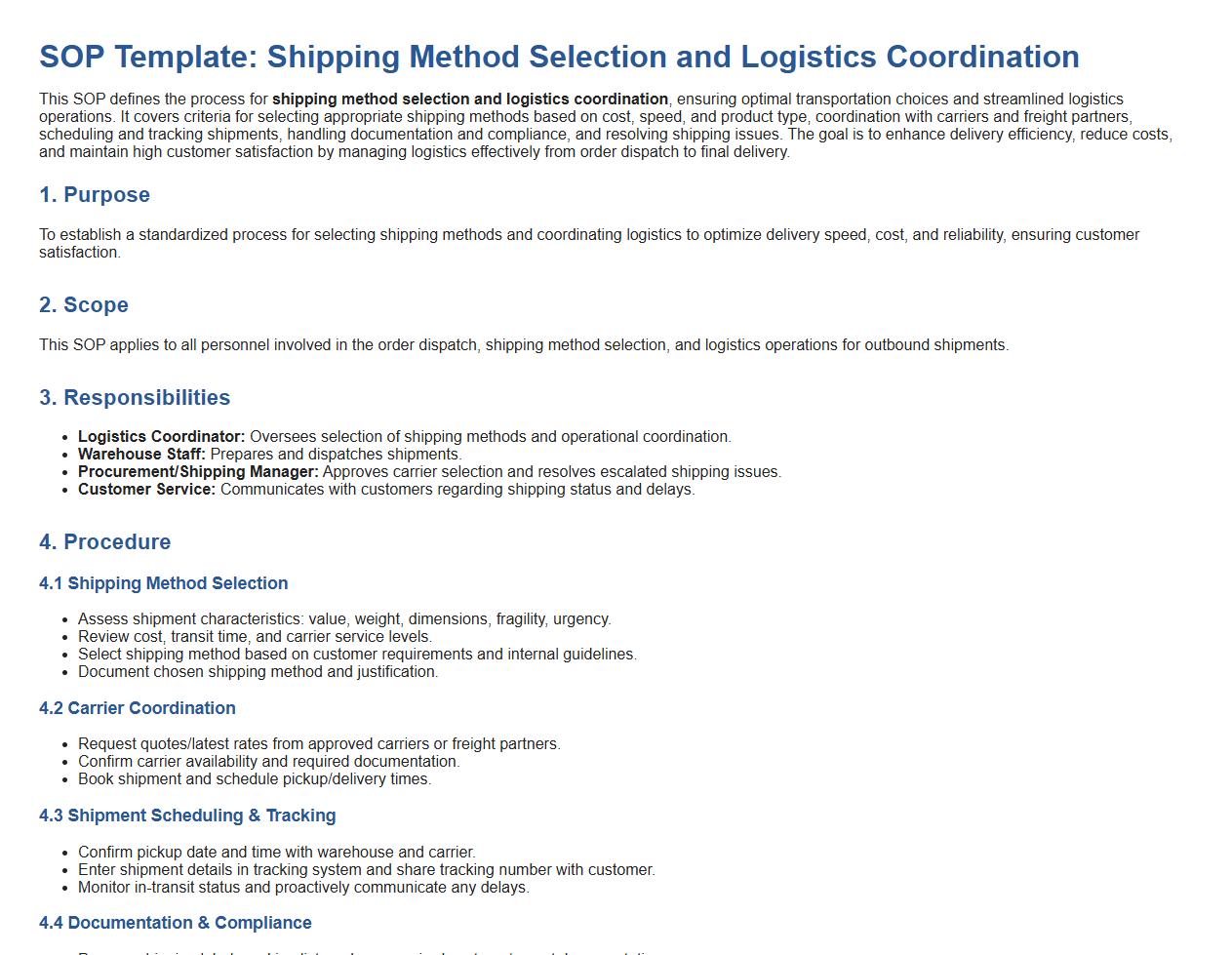

Shipping method selection and logistics coordination.

This SOP defines the process for shipping method selection and logistics coordination, ensuring optimal transportation choices and streamlined logistics operations. It covers criteria for selecting appropriate shipping methods based on cost, speed, and product type, coordination with carriers and freight partners, scheduling and tracking shipments, handling documentation and compliance, and resolving shipping issues. The goal is to enhance delivery efficiency, reduce costs, and maintain high customer satisfaction by managing logistics effectively from order dispatch to final delivery.

Order dispatch and shipment tracking procedures.

This SOP describes order dispatch and shipment tracking procedures, including order verification, packaging and labeling standards, carrier selection, shipment scheduling, real-time tracking updates, handling of delays or damages, and communication with customers. The aim is to ensure accurate, timely dispatch of orders and provide transparent shipment tracking for improved customer satisfaction and operational efficiency.

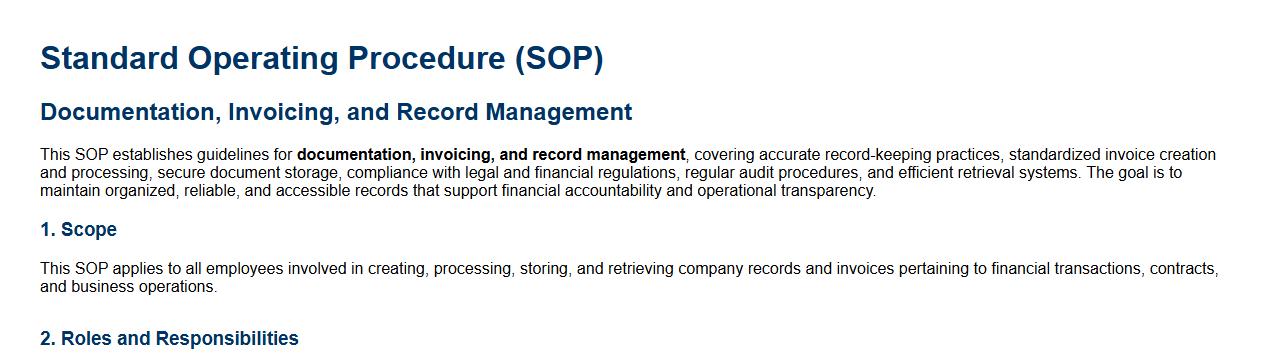

Documentation, invoicing, and record management.

This SOP establishes guidelines for documentation, invoicing, and record management, covering accurate record-keeping practices, standardized invoice creation and processing, secure document storage, compliance with legal and financial regulations, regular audit procedures, and efficient retrieval systems. The goal is to maintain organized, reliable, and accessible records that support financial accountability and operational transparency.

Order status communication and customer notification process.

This SOP details the order status communication and customer notification process, covering steps to inform customers about order confirmations, processing updates, shipping details, delays, and delivery status. It aims to enhance customer satisfaction by ensuring timely, accurate, and consistent communication throughout the order fulfillment cycle.

What are the essential steps outlined in the SOP for processing customer orders in manufacturing?

The SOP for processing customer orders begins with order receipt and verification to ensure all details are accurate. Next, production planning is initiated to schedule manufacturing activities based on the order specifications. Finally, the order moves to fulfillment, including packaging and shipping, ensuring timely delivery to the customer.

Which departments are responsible for each stage in the order fulfillment process as per the SOP?

The Sales Department handles order receipt and validation to confirm customer requirements. The Production Department oversees manufacturing scheduling and execution to meet quality standards. Lastly, the Logistics Department manages packaging, shipment, and delivery to complete the order fulfillment process.

How does the SOP ensure accuracy and traceability from order receipt to product shipment?

The SOP mandates the use of a centralized order tracking system that logs every step from order entry to shipment. Each product batch is assigned a unique identifier to maintain clear traceability. This system ensures all stakeholders can verify order status and history, minimizing errors and improving accountability.

What quality control measures are mandated by the SOP during order fulfillment?

The SOP requires quality inspections at multiple stages, including raw material receipt, in-process checks, and final product evaluation. It also includes standardized testing procedures to confirm product compliance with specifications. These measures guarantee that only products meeting strict quality standards reach the customer.

How does the SOP handle exceptions or discrepancies in inventory during order processing?

The SOP outlines a protocol for inventory discrepancy reporting to immediately flag any stock shortages or mismatches. It requires cross-departmental communication to resolve issues swiftly, including procurement adjustments if necessary. This process helps prevent delays and maintains smooth order fulfillment despite inventory challenges.