A SOP Template for Raw Material Inspection in Manufacturing ensures consistent evaluation of incoming materials to meet quality standards. It outlines step-by-step procedures for inspection, documentation, and acceptance criteria, enhancing traceability and compliance. This template helps minimize defects and supports smooth production processes by verifying raw material integrity before use.

Raw material receiving and documentation verification.

This SOP details the procedures for raw material receiving and documentation verification, encompassing the inspection of incoming materials, verification against purchase orders and delivery documents, quality and quantity checks, proper recording of receipt data, handling of discrepancies or damages, and ensuring compliance with company standards. The process aims to maintain accurate inventory records, ensure material quality, and streamline the supply chain management for uninterrupted production.

Inspection criteria and acceptance sampling procedures.

This SOP defines the inspection criteria and acceptance sampling procedures used to ensure product quality and compliance with specified standards. It covers the methods for selecting sample sizes, the inspection techniques for identifying defects, the criteria for acceptance or rejection, and the documentation requirements. This procedure aims to maintain consistency in quality control, minimize risks of non-conforming products, and support efficient decision-making in the production and supply chain processes.

Visual inspection for packaging integrity and labeling accuracy.

This SOP defines the process for conducting visual inspection for packaging integrity and labeling accuracy, focusing on ensuring that all packaging is free from defects such as tears, dents, or contamination, and that labels are correctly applied, legible, and match product specifications. The procedure aims to maintain product quality, comply with regulatory standards, and prevent mislabeling or packaging errors that could affect consumer safety and brand reputation.

Physical and chemical property testing protocols.

This SOP defines physical and chemical property testing protocols, detailing the standardized procedures for accurately evaluating the physical characteristics and chemical compositions of materials. It covers sample preparation, testing methods, instrumentation calibration, data collection, analysis, quality control measures, and reporting. The goal is to ensure consistent, reliable, and reproducible results that meet industry and regulatory standards for product development, quality assurance, and compliance purposes.

Identification and segregation of non-conforming materials.

This SOP describes the process for the identification and segregation of non-conforming materials to ensure quality control and prevent defective products from reaching customers. It includes procedures for detecting non-conformities, labeling and isolating affected materials, documenting discrepancies, and initiating corrective actions. The goal is to maintain product integrity, comply with quality standards, and facilitate continuous improvement within the production process.

Recording inspection results and traceability requirements.

This SOP details the recording inspection results and traceability requirements, covering the systematic documentation of inspection findings, procedures for ensuring accuracy and completeness, methods for maintaining traceability of products and processes, and compliance with regulatory standards. The goal is to enhance quality control, enable effective tracking of product history, and support accountability and transparency throughout the production and inspection cycle.

Handling and storage of accepted and rejected materials.

This SOP details the procedures for the handling and storage of accepted and rejected materials, ensuring proper segregation, identification, and storage to maintain material integrity and prevent contamination. It covers the inspection, documentation, and appropriate placement of accepted materials for production use, as well as the secure and compliant storage of rejected materials for rework, disposal, or return. Adherence to these guidelines helps maintain operational efficiency and compliance with quality and safety standards.

Communication and reporting of inspection outcomes.

This SOP details the communication and reporting of inspection outcomes, covering the procedures for documenting inspection findings, timely reporting to relevant stakeholders, utilizing standardized reporting formats, ensuring accuracy and clarity in communication, addressing identified issues or non-compliance, and maintaining records for accountability and continuous improvement. The objective is to facilitate effective information flow and prompt decision-making based on inspection results.

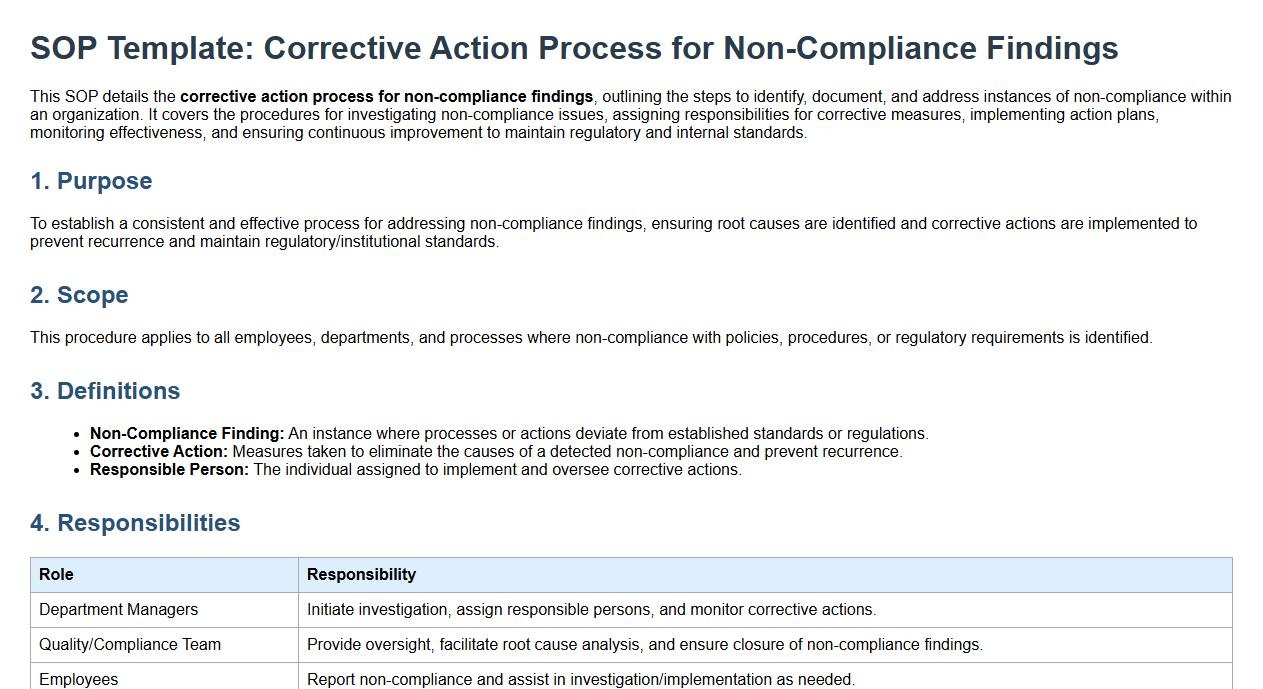

Corrective action process for non-compliance findings.

This SOP details the corrective action process for non-compliance findings, outlining the steps to identify, document, and address instances of non-compliance within an organization. It covers the procedures for investigating non-compliance issues, assigning responsibilities for corrective measures, implementing action plans, monitoring effectiveness, and ensuring continuous improvement to maintain regulatory and internal standards.

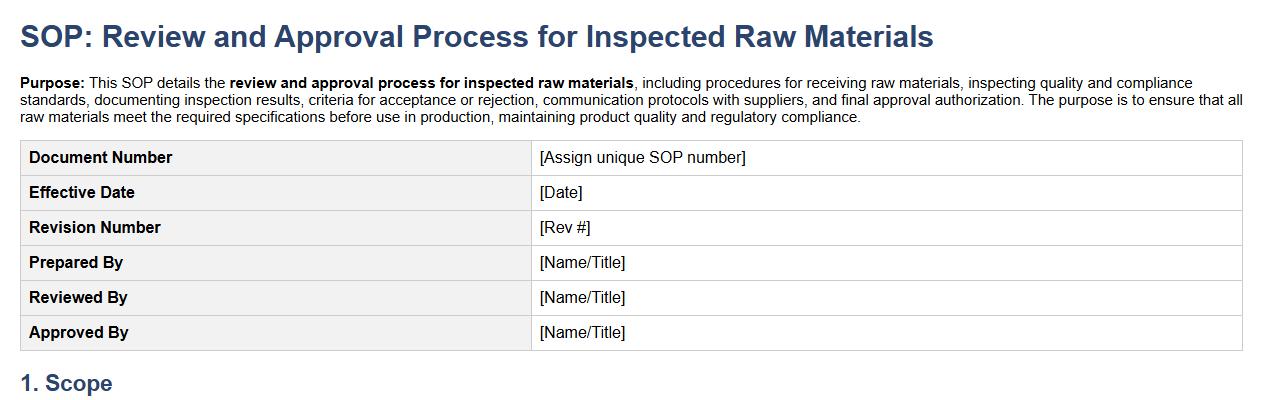

Review and approval process for inspected raw materials.

This SOP details the review and approval process for inspected raw materials, including procedures for receiving raw materials, inspecting quality and compliance standards, documenting inspection results, criteria for acceptance or rejection, communication protocols with suppliers, and final approval authorization. The purpose is to ensure that all raw materials meet the required specifications before use in production, maintaining product quality and regulatory compliance.

What are the acceptance criteria for raw material quality during inspection?

The acceptance criteria for raw material quality are based on predefined specifications such as physical properties, chemical composition, and moisture content. Materials must meet these standards to ensure consistency and safety in production. Any deviations from these criteria typically result in rejection or further testing.

Which specific documents or records must be reviewed or completed during raw material inspection?

Key documents include certificates of analysis (COA), delivery receipts, and inspection checklists. Reviewing these ensures traceability and compliance with quality standards. Accurate record-keeping is essential for audits and quality control verification.

What steps should be taken if non-conforming raw materials are identified?

Non-conforming raw materials must be segregated immediately to prevent contamination of the production line. A non-conformance report (NCR) should be initiated, detailing the issue and corrective actions. Further evaluation or disposal is conducted according to quality management procedures.

Who is responsible for conducting and verifying raw material inspections per SOP?

The designated quality control personnel are responsible for carrying out and verifying inspections according to the standard operating procedure (SOP). Supervisors may also review inspection results for compliance. Accountability ensures adherence to quality standards and regulatory requirements.

How should raw material samples be collected, labeled, and stored during the inspection process?

Samples must be collected representatively and handled to avoid contamination. Proper labeling includes batch numbers, dates, and inspection status to maintain traceability. Samples should be stored under specified conditions to preserve integrity until testing is completed.