A SOP Template for Packaging and Labeling in Manufacturing streamlines the process by providing clear, standardized instructions to ensure product consistency and compliance with regulatory requirements. It includes detailed steps for packaging materials, labeling specifications, and quality checks to prevent errors and maintain safety standards. Implementing this template enhances operational efficiency and guarantees that products meet both company and industry guidelines.

Raw material inspection and acceptance procedures.

This SOP details the raw material inspection and acceptance procedures, including criteria for quality assessment, verification of supplier documentation, sampling methods, contamination checks, and compliance with specifications. The goal is to ensure that all incoming raw materials meet predefined standards to maintain product quality and safety throughout the production process.

Packaging material storage and handling guidelines.

This SOP provides comprehensive packaging material storage and handling guidelines to ensure the safe and efficient management of packaging materials. It covers proper storage conditions, inventory control, handling procedures, and safety measures to prevent damage, contamination, and workplace hazards. The goal is to maintain the quality of packaging materials, optimize storage space, and promote a safe working environment for all personnel involved in packaging operations.

Pre-operation equipment checks and sanitation protocols.

This SOP details pre-operation equipment checks and sanitation protocols, including routine inspections for functionality and safety, cleaning procedures to maintain hygiene standards, verification of calibration and settings, identification and reporting of defects, and proper documentation practices. The goal is to ensure all equipment is safe, clean, and ready for effective use, minimizing risks of contamination and operational failures.

Product packaging process steps and line clearance.

This SOP details the product packaging process steps and line clearance, encompassing the preparation and setup of packaging materials, step-by-step guidelines for efficient and accurate packaging operations, inspection and verification of product quality before packaging, proper labeling and coding procedures, and thorough line clearance protocols to prevent contamination or product mix-ups. The aim is to ensure consistency, safety, and compliance throughout the packaging process, enhancing product integrity and traceability.

Label printing, verification, and storage controls.

This SOP details the procedures for label printing, verification, and storage controls, covering the accurate generation of labels, thorough verification processes to ensure label correctness and compliance, and secure storage methods to maintain label integrity and prevent mix-ups. The objective is to guarantee precise product identification, traceability, and consistency throughout production and distribution phases.

Package sealing and integrity inspection procedures.

This SOP details package sealing and integrity inspection procedures to ensure that all packaging meets quality and safety standards. It covers the methods for verifying seal strength, detecting packaging defects, and maintaining product protection during storage and transportation. The goal is to prevent contamination, spoilage, and product damage by implementing consistent inspection protocols and corrective actions when necessary.

Label application, positioning, and adhesion standards.

This SOP details the label application, positioning, and adhesion standards to ensure consistent, accurate placement and secure attachment of labels on products. It covers proper label alignment, surface preparation, adhesive requirements, environmental conditions for application, and inspection procedures to maintain product quality and compliance with regulatory guidelines.

Finished goods batch coding and traceability requirements.

This SOP details the finished goods batch coding and traceability requirements, covering the procedures for assigning batch codes, maintaining accurate records, ensuring product traceability throughout the supply chain, and facilitating efficient recall processes. It aims to enhance product quality control, regulatory compliance, and customer safety by implementing standardized coding and documentation practices for all finished goods.

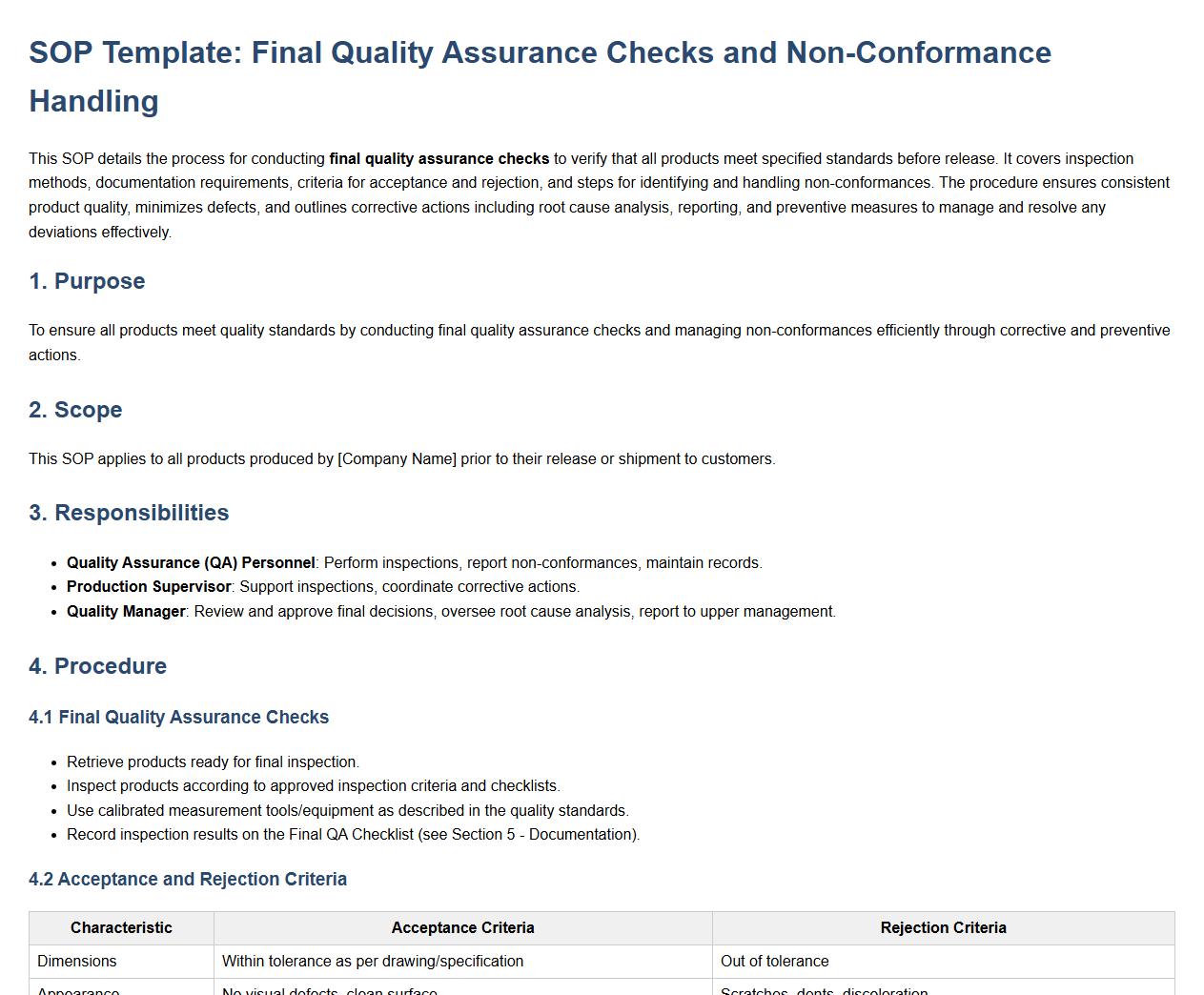

Final quality assurance checks and non-conformance handling.

This SOP details the process for conducting final quality assurance checks to verify that all products meet specified standards before release. It covers inspection methods, documentation requirements, criteria for acceptance and rejection, and steps for identifying and handling non-conformances. The procedure ensures consistent product quality, minimizes defects, and outlines corrective actions including root cause analysis, reporting, and preventive measures to manage and resolve any deviations effectively.

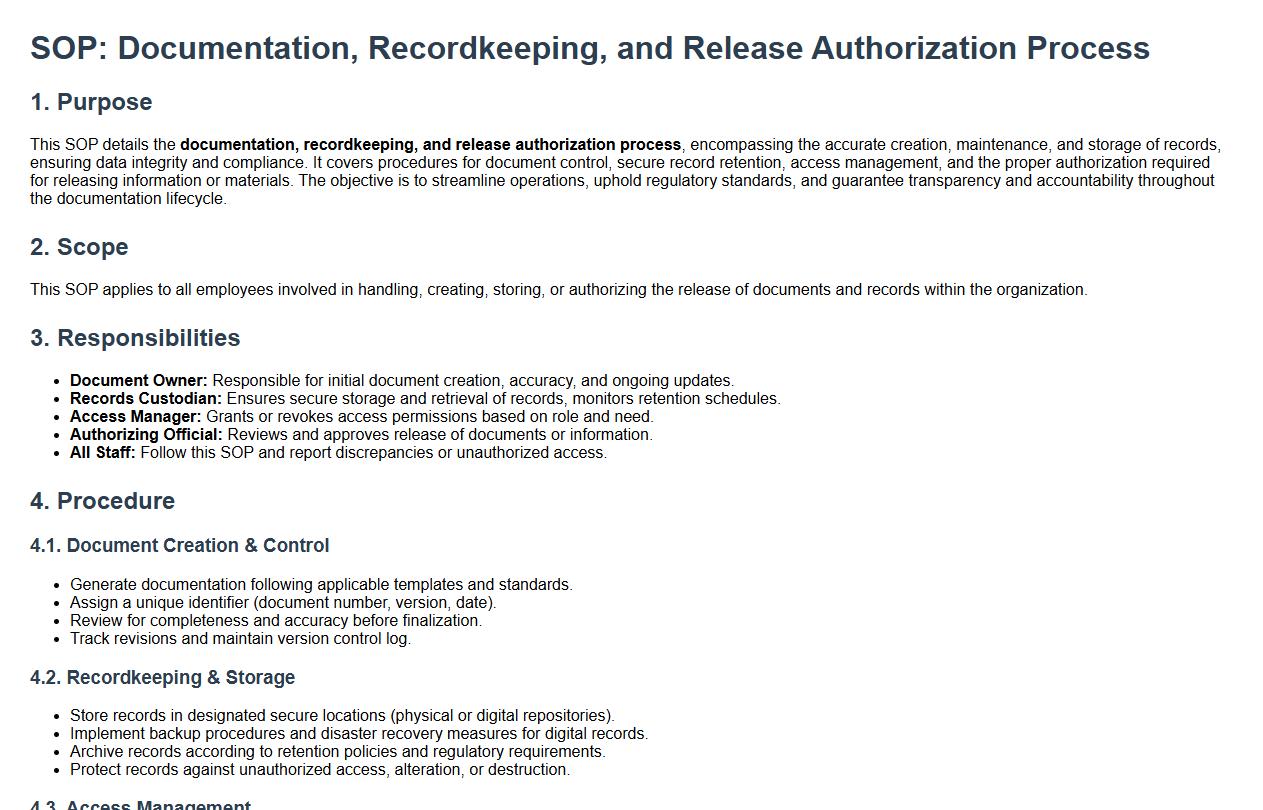

Documentation, recordkeeping, and release authorization process.

This SOP details the documentation, recordkeeping, and release authorization process, encompassing the accurate creation, maintenance, and storage of records, ensuring data integrity and compliance. It covers procedures for document control, secure record retention, access management, and the proper authorization required for releasing information or materials. The objective is to streamline operations, uphold regulatory standards, and guarantee transparency and accountability throughout the documentation lifecycle.

What are the critical steps outlined in the SOP for ensuring accurate packaging and labeling in manufacturing?

The SOP highlights verification of packaging components before use, ensuring all materials match approved specifications. It mandates a thorough review process for labeling information to confirm accuracy and compliance with regulatory standards. Additionally, the SOP requires proper training for personnel involved in packaging and labeling to minimize errors.

How does the SOP address traceability and batch identification requirements during packaging?

The SOP enforces the use of unique batch numbers and production codes on all packaging to maintain product traceability. It specifies that all batches must be recorded in a centralized system to enable quick identification in case of recalls. This procedure ensures accountability and facilitates seamless tracking throughout the supply chain.

What quality control measures are mandated by the SOP to verify label integrity and correctness?

The SOP requires conducting visual inspections and barcode verification to ensure labels are correctly applied and legible. It also mandates periodic sampling and testing of packaged products to verify label adherence and content accuracy. These steps are essential for maintaining product safety and regulatory compliance.

Which types of packaging materials and labeling formats are specified as compliant in the SOP?

The SOP lists approved packaging materials that meet durability and safety standards for the specific product category. It details acceptable labeling formats, including label size, font type, and color schemes, to ensure consistency. Compliance with these specifications minimizes risks of damage and misidentification during handling and distribution.

What procedures does the SOP specify for managing and reporting packaging or labeling discrepancies?

The SOP outlines a clear protocol for documenting and notifying supervisors immediately upon discovery of any packaging or labeling discrepancies. It requires containment measures to prevent further distribution of affected products and initiates an investigation to determine root causes. Corrective actions must be implemented and recorded to avoid recurrence of issues.