A SOP Template for Quality Control in Manufacturing standardizes procedures to ensure consistent product quality and compliance with industry standards. It outlines step-by-step processes for inspection, testing, and documentation, reducing errors and improving efficiency. This template serves as a critical tool for training and maintaining quality assurance across production lines.

Quality assurance incoming raw materials inspection.

This SOP details the quality assurance incoming raw materials inspection process, focusing on the systematic evaluation of raw materials upon receipt to ensure they meet predefined quality standards. It covers procedures for sampling, testing, verification against specifications, documentation of inspection results, and handling of non-conforming materials. The goal is to maintain product quality and production efficiency by preventing substandard raw materials from entering the manufacturing process.

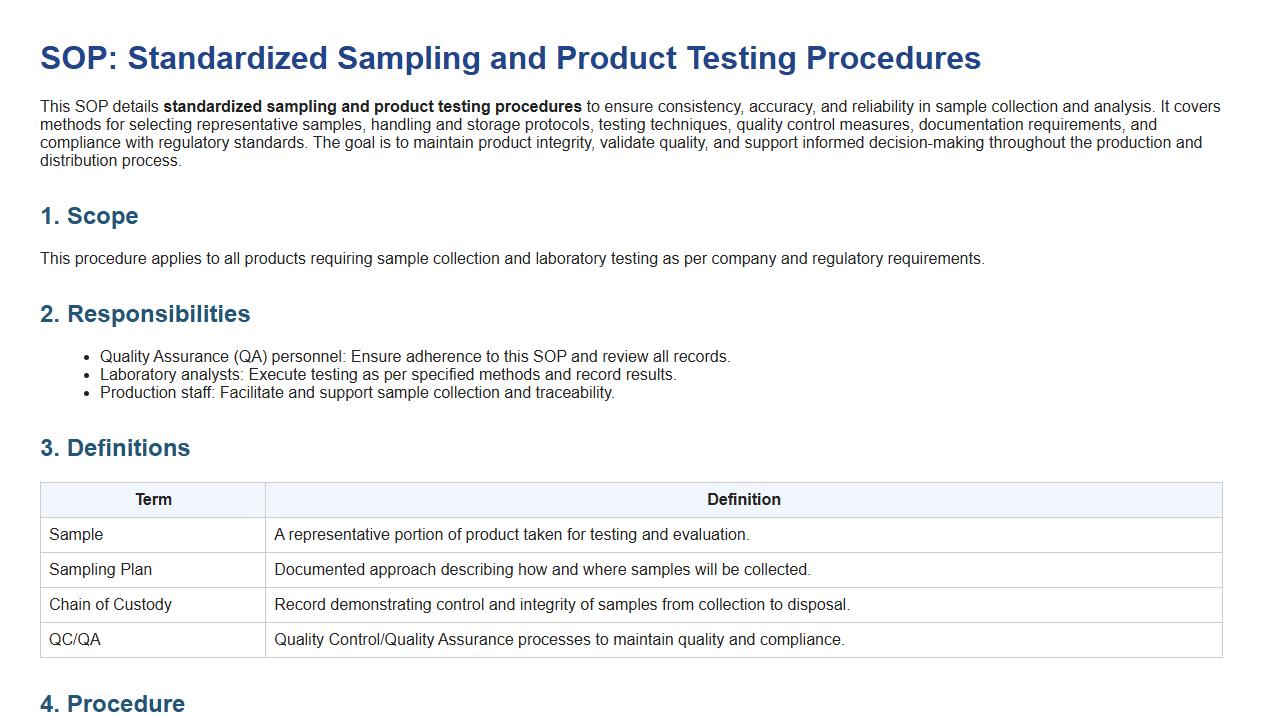

Standardized sampling and product testing procedures.

This SOP details standardized sampling and product testing procedures to ensure consistency, accuracy, and reliability in sample collection and analysis. It covers methods for selecting representative samples, handling and storage protocols, testing techniques, quality control measures, documentation requirements, and compliance with regulatory standards. The goal is to maintain product integrity, validate quality, and support informed decision-making throughout the production and distribution process.

Production line in-process quality checks.

This SOP details the procedures for production line in-process quality checks, including the frequency and methods of inspection, criteria for product acceptance, documentation requirements, and corrective actions for non-conforming items. The purpose is to ensure consistent product quality throughout the manufacturing process, minimize defects, and maintain compliance with industry standards and customer specifications.

Defective product identification and segregation protocol.

This SOP details the defective product identification and segregation protocol, outlining the systematic procedures for detecting, isolating, and managing defective products within the production process. It includes criteria for defect recognition, methods for product segregation to prevent integration with conforming goods, documentation requirements, and communication processes to alert relevant departments. The purpose is to maintain product quality, prevent customer dissatisfaction, and ensure compliance with regulatory standards by effectively controlling defective products.

Corrective action and non-conformance management.

This SOP details the process for corrective action and non-conformance management, covering identification, documentation, investigation, root cause analysis, implementation of corrective measures, monitoring effectiveness, and continuous improvement. It aims to ensure systematic handling of non-conformances to maintain quality standards and prevent recurrence.

Calibration and maintenance of testing equipment.

This SOP details the calibration and maintenance of testing equipment to ensure accuracy, reliability, and optimal performance. It covers procedures for regular calibration schedules, verification of equipment functionality, routine maintenance tasks, documentation of calibration results, and corrective actions for equipment discrepancies. The goal is to maintain integrity in testing processes, minimize equipment downtime, and comply with quality standards.

Finished goods final inspection and release.

This SOP describes the finished goods final inspection and release process, ensuring that all products meet quality standards and specifications before shipment. It covers inspection criteria, documentation requirements, non-conformance handling, approval procedures, and the release authorization to guarantee that only compliant finished goods are dispatched to customers, maintaining product integrity and customer satisfaction.

Documentation and record-keeping requirements.

This SOP details the documentation and record-keeping requirements necessary for maintaining accurate, consistent, and secure records. It covers the types of documents to be maintained, proper methods for documentation, data retention periods, confidentiality protocols, and procedures for reviewing and updating records. Adhering to these guidelines ensures compliance with regulatory standards, supports operational transparency, and facilitates efficient information retrieval and audit readiness.

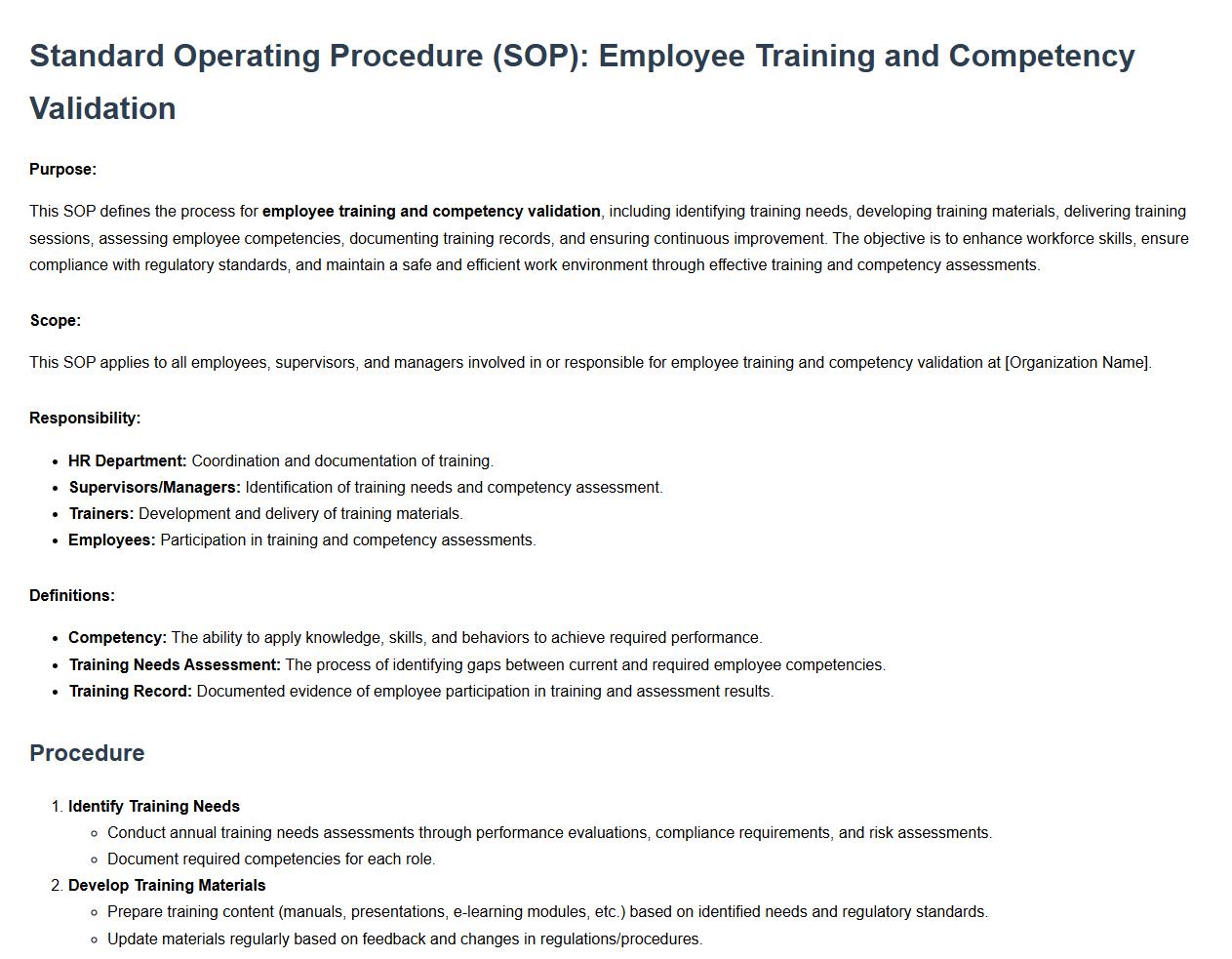

Employee training and competency validation.

This SOP defines the process for employee training and competency validation, including identifying training needs, developing training materials, delivering training sessions, assessing employee competencies, documenting training records, and ensuring continuous improvement. The objective is to enhance workforce skills, ensure compliance with regulatory standards, and maintain a safe and efficient work environment through effective training and competency assessments.

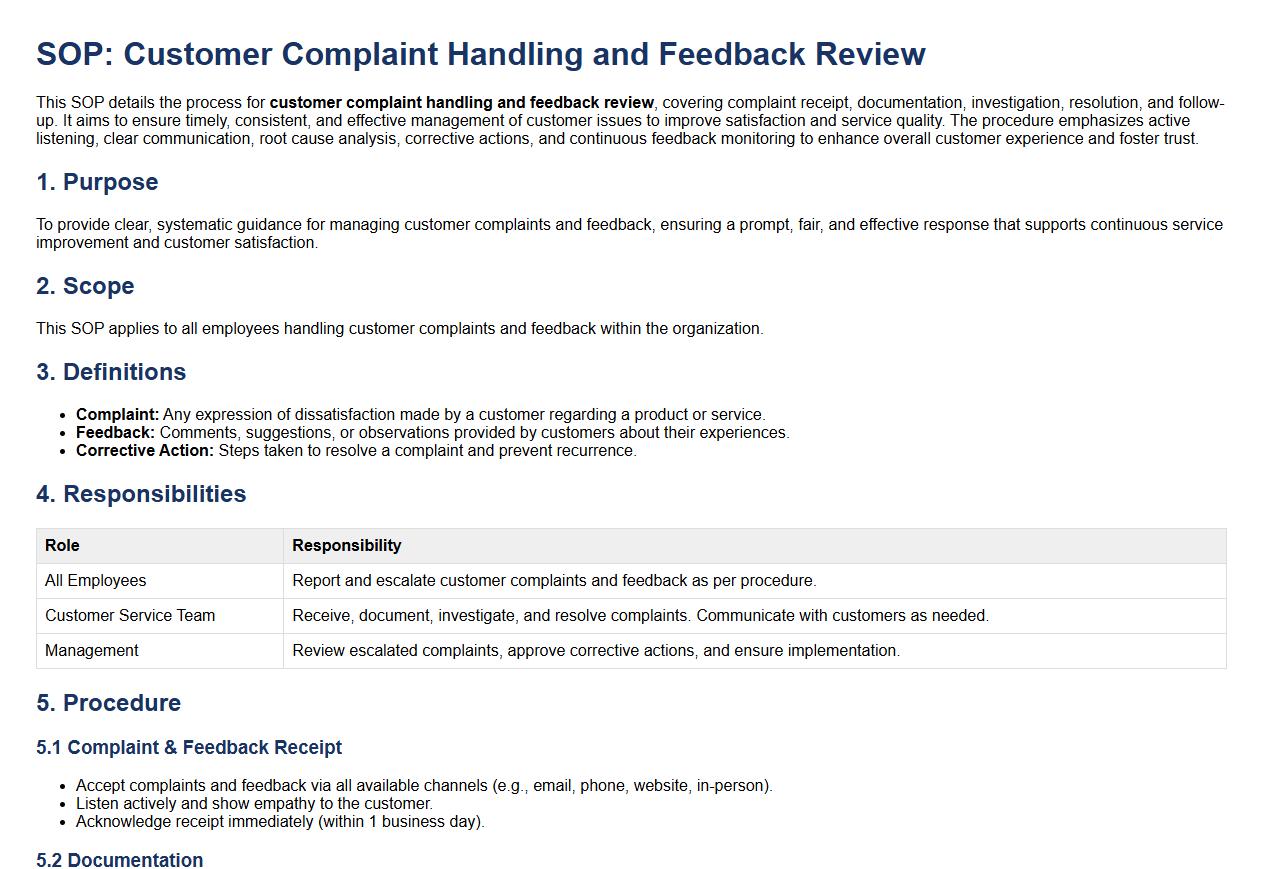

Customer complaint handling and feedback review.

This SOP details the process for customer complaint handling and feedback review, covering complaint receipt, documentation, investigation, resolution, and follow-up. It aims to ensure timely, consistent, and effective management of customer issues to improve satisfaction and service quality. The procedure emphasizes active listening, clear communication, root cause analysis, corrective actions, and continuous feedback monitoring to enhance overall customer experience and foster trust.

What primary objectives does the SOP for Quality Control in Manufacturing aim to achieve?

The SOP for Quality Control in Manufacturing primarily aims to ensure consistent product quality and compliance with industry standards. It focuses on minimizing defects and enhancing overall production efficiency through systematic inspections. Additionally, it fosters continuous improvement and customer satisfaction by adhering to strict quality protocols.

Which critical steps must be documented during quality inspections according to the SOP?

The SOP mandates documenting the inspection criteria, methods, and results with precise detail to maintain traceability. Each step, from sample collection to measurement and analysis, must be recorded to verify compliance. Furthermore, any deviations or abnormalities observed during the inspection process must be clearly noted and reported.

How does the SOP define the roles and responsibilities within the quality control process?

The SOP distinctly assigns roles such as quality inspectors, supervisors, and production staff to uphold accountability in quality control. Inspectors are responsible for conducting tests and recording outcomes, while supervisors oversee compliance and corrective actions. Clear role definitions ensure effective communication and streamlined quality management.

What criteria are used in the SOP to accept or reject manufactured products?

The SOP includes specific acceptance criteria based on dimensional accuracy, functional performance, and conformity to design specifications. Products meeting these predefined standards are accepted for further processing or shipment. Conversely, any items failing to comply with these quality benchmarks are rejected to prevent defective products from reaching customers.

How are non-conformities identified, reported, and managed as per the SOP guidelines?

Non-conformities are identified through regular inspections and testing against established quality standards. Once detected, they are promptly documented in a non-conformance report and communicated to relevant personnel. The SOP outlines corrective actions and monitoring procedures to manage and resolve non-conformities effectively, ensuring product integrity.