A SOP Template for Manufacturing Safety Procedures ensures consistent implementation of safety protocols across production lines, minimizing workplace hazards. This template provides clear, step-by-step instructions for handling equipment and emergency situations, enhancing overall operational safety. Using a standardized format helps maintain compliance with industry regulations and promotes a safe working environment.

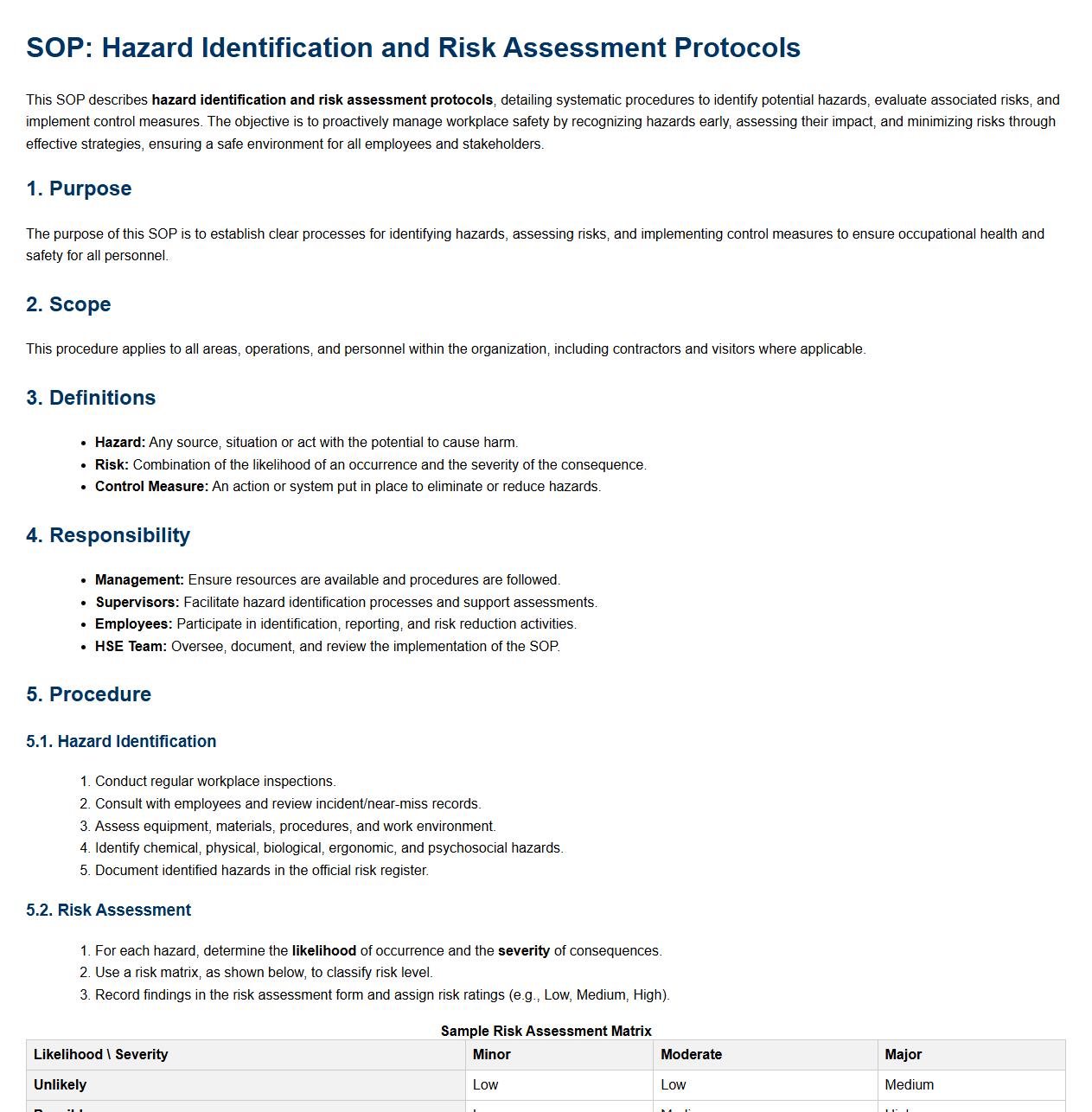

Hazard identification and risk assessment protocols.

This SOP describes hazard identification and risk assessment protocols, detailing systematic procedures to identify potential hazards, evaluate associated risks, and implement control measures. The objective is to proactively manage workplace safety by recognizing hazards early, assessing their impact, and minimizing risks through effective strategies, ensuring a safe environment for all employees and stakeholders.

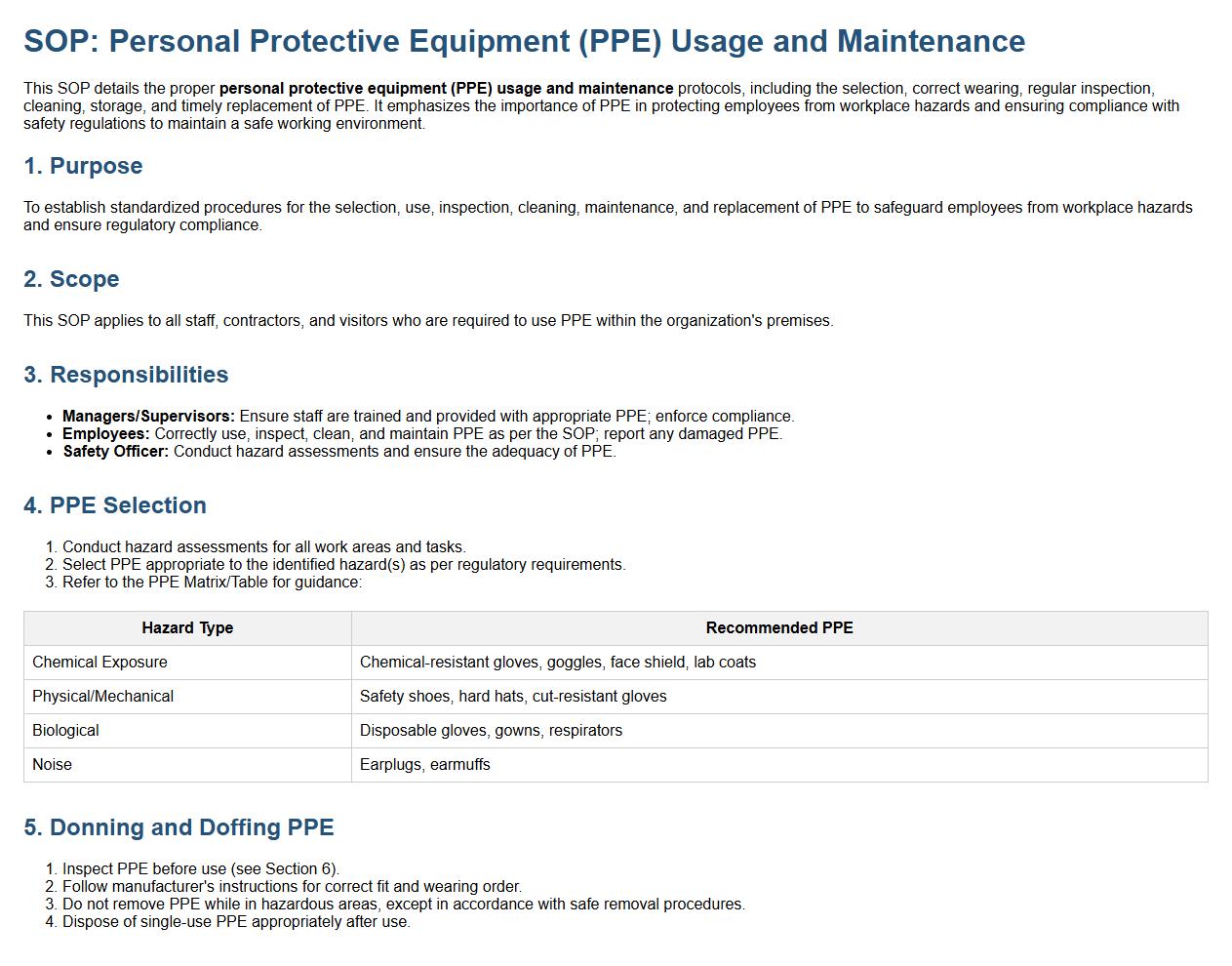

Personal protective equipment (PPE) usage and maintenance.

This SOP details the proper personal protective equipment (PPE) usage and maintenance protocols, including the selection, correct wearing, regular inspection, cleaning, storage, and timely replacement of PPE. It emphasizes the importance of PPE in protecting employees from workplace hazards and ensuring compliance with safety regulations to maintain a safe working environment.

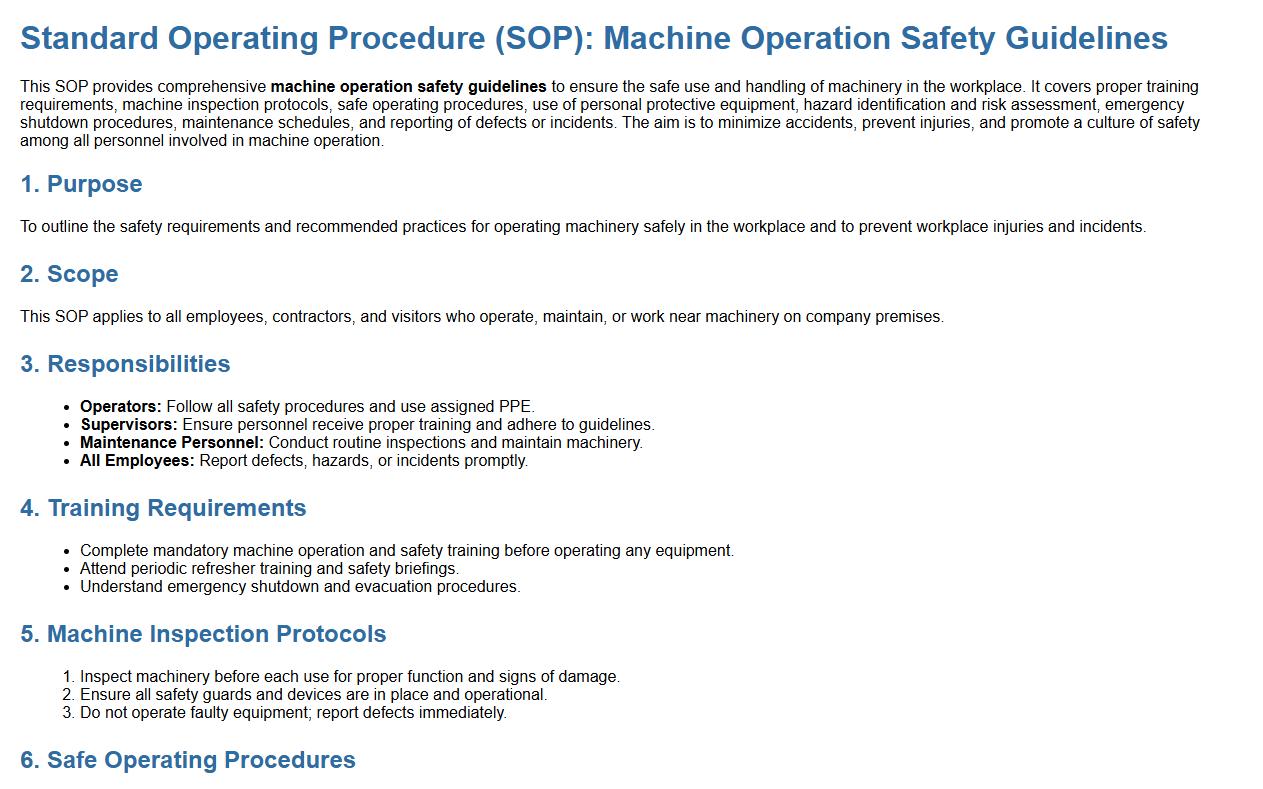

Machine operation safety guidelines.

This SOP provides comprehensive machine operation safety guidelines to ensure the safe use and handling of machinery in the workplace. It covers proper training requirements, machine inspection protocols, safe operating procedures, use of personal protective equipment, hazard identification and risk assessment, emergency shutdown procedures, maintenance schedules, and reporting of defects or incidents. The aim is to minimize accidents, prevent injuries, and promote a culture of safety among all personnel involved in machine operation.

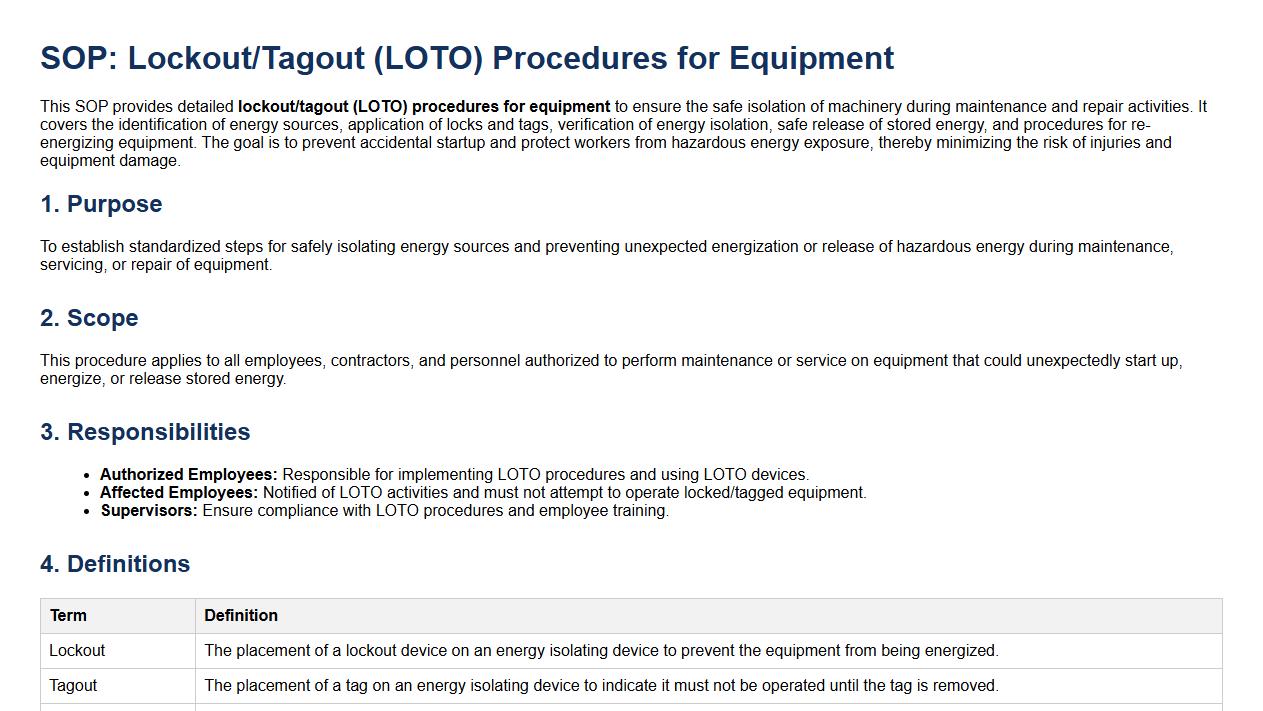

Lockout/tagout (LOTO) procedures for equipment.

This SOP provides detailed lockout/tagout (LOTO) procedures for equipment to ensure the safe isolation of machinery during maintenance and repair activities. It covers the identification of energy sources, application of locks and tags, verification of energy isolation, safe release of stored energy, and procedures for re-energizing equipment. The goal is to prevent accidental startup and protect workers from hazardous energy exposure, thereby minimizing the risk of injuries and equipment damage.

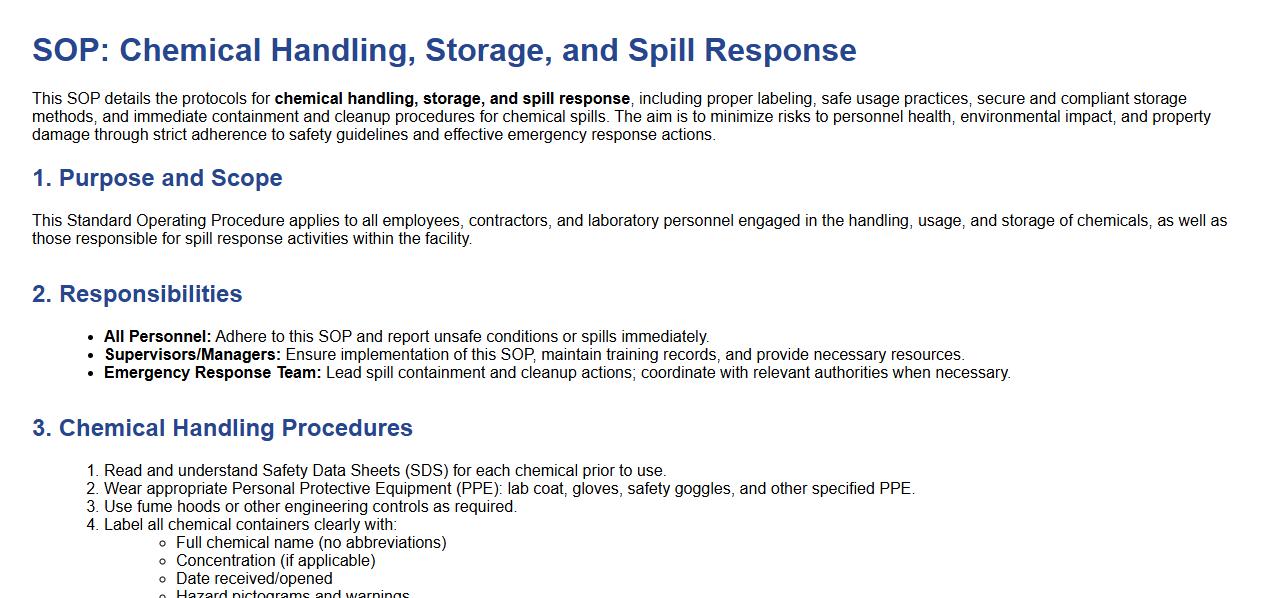

Chemical handling, storage, and spill response.

This SOP details the protocols for chemical handling, storage, and spill response, including proper labeling, safe usage practices, secure and compliant storage methods, and immediate containment and cleanup procedures for chemical spills. The aim is to minimize risks to personnel health, environmental impact, and property damage through strict adherence to safety guidelines and effective emergency response actions.

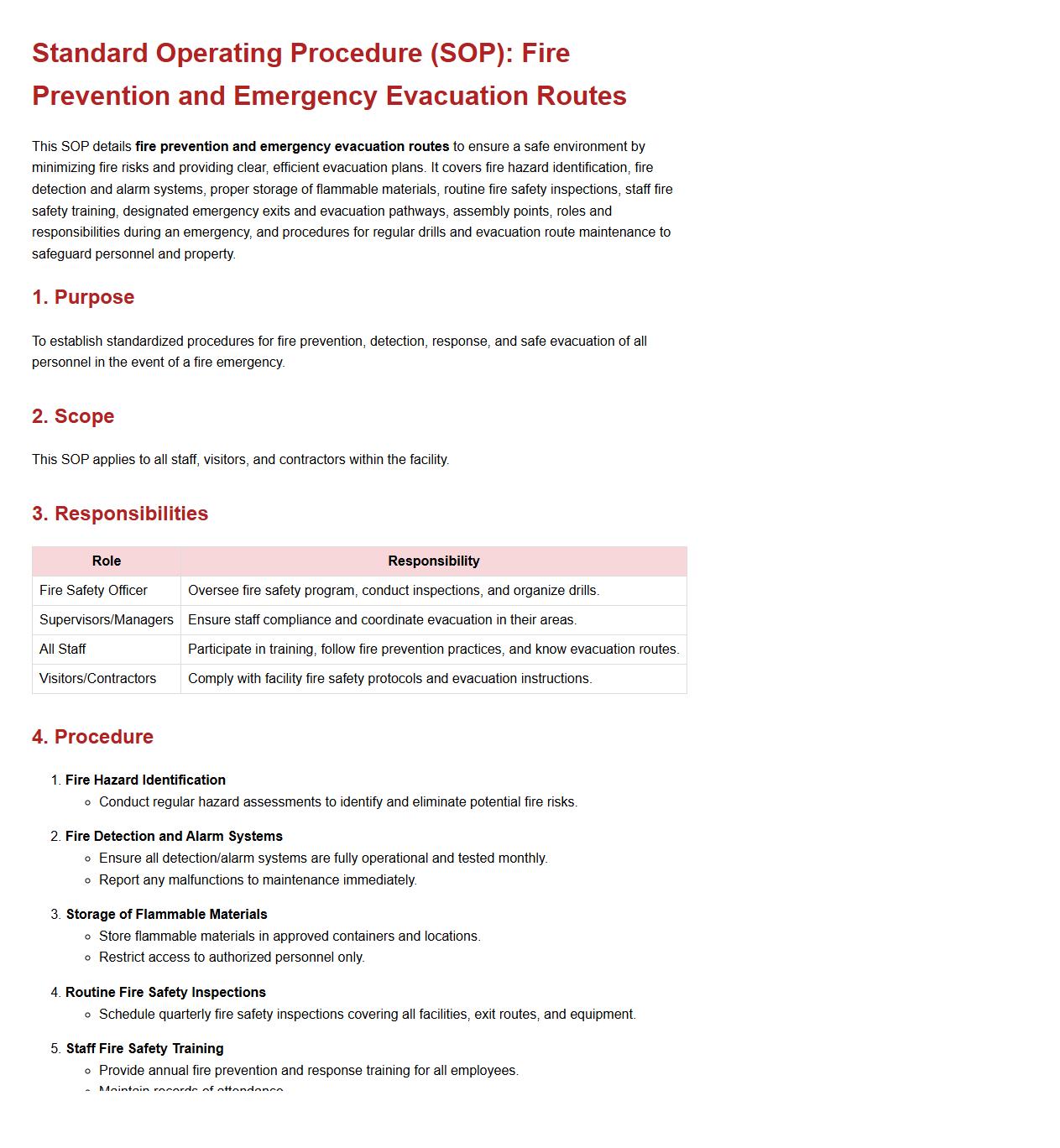

Fire prevention and emergency evacuation routes.

This SOP details fire prevention and emergency evacuation routes to ensure a safe environment by minimizing fire risks and providing clear, efficient evacuation plans. It covers fire hazard identification, fire detection and alarm systems, proper storage of flammable materials, routine fire safety inspections, staff fire safety training, designated emergency exits and evacuation pathways, assembly points, roles and responsibilities during an emergency, and procedures for regular drills and evacuation route maintenance to safeguard personnel and property.

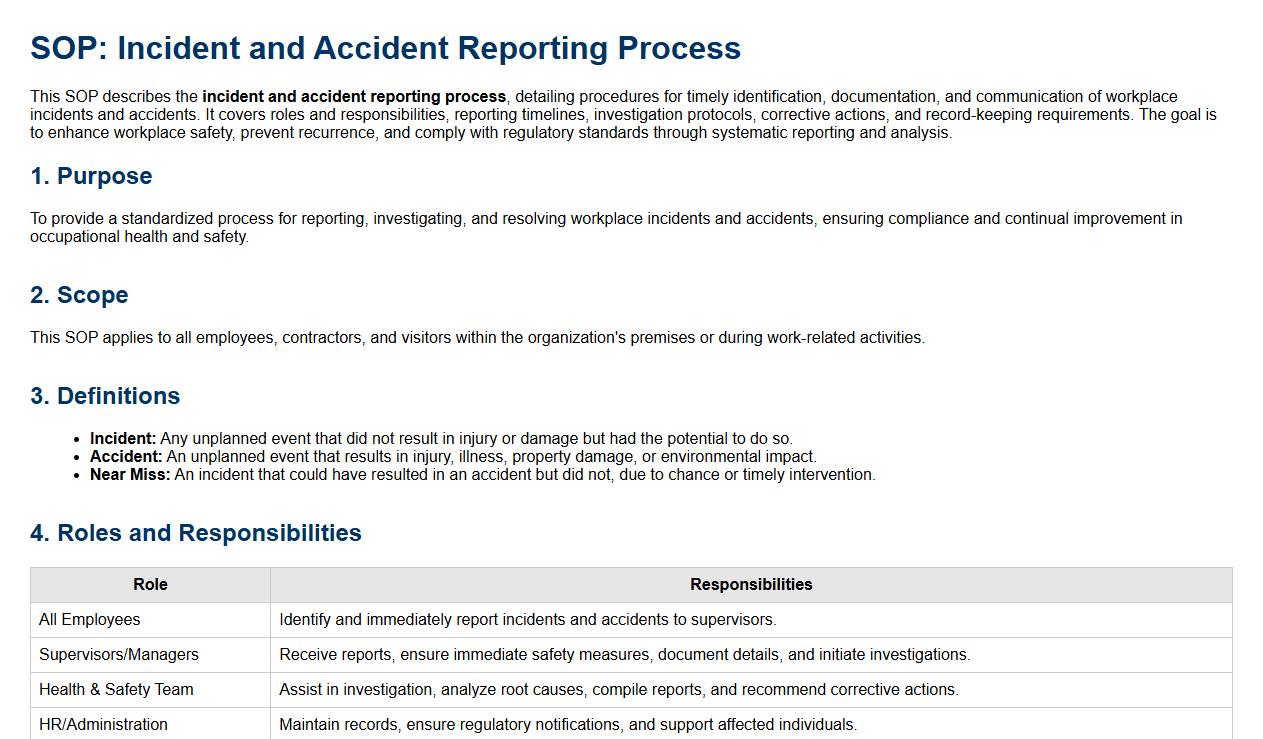

Incident and accident reporting process.

This SOP describes the incident and accident reporting process, detailing procedures for timely identification, documentation, and communication of workplace incidents and accidents. It covers roles and responsibilities, reporting timelines, investigation protocols, corrective actions, and record-keeping requirements. The goal is to enhance workplace safety, prevent recurrence, and comply with regulatory standards through systematic reporting and analysis.

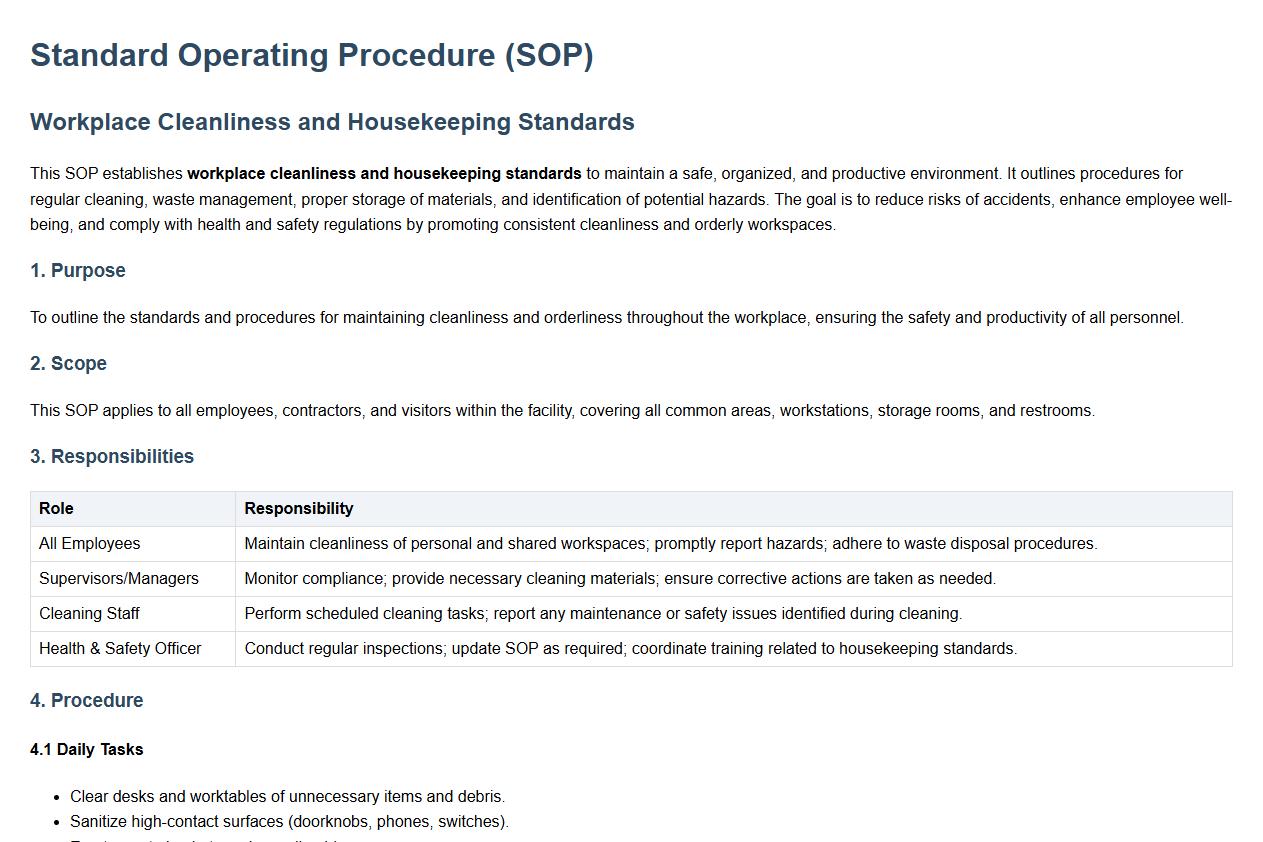

Workplace cleanliness and housekeeping standards.

This SOP establishes workplace cleanliness and housekeeping standards to maintain a safe, organized, and productive environment. It outlines procedures for regular cleaning, waste management, proper storage of materials, and identification of potential hazards. The goal is to reduce risks of accidents, enhance employee well-being, and comply with health and safety regulations by promoting consistent cleanliness and orderly workspaces.

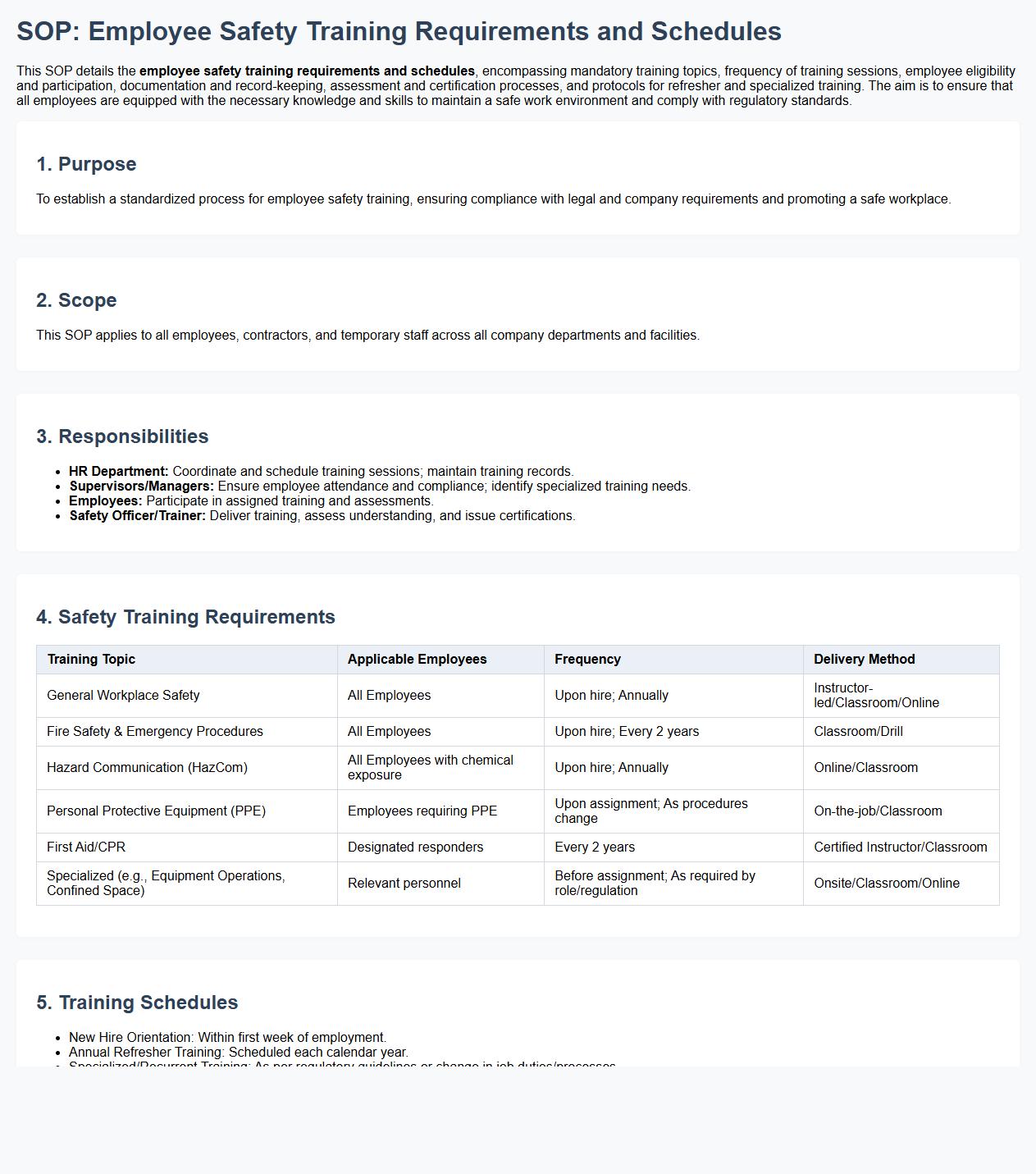

Employee safety training requirements and schedules.

This SOP details the employee safety training requirements and schedules, encompassing mandatory training topics, frequency of training sessions, employee eligibility and participation, documentation and record-keeping, assessment and certification processes, and protocols for refresher and specialized training. The aim is to ensure that all employees are equipped with the necessary knowledge and skills to maintain a safe work environment and comply with regulatory standards.

First aid response and medical emergency procedures.

This SOP details the first aid response and medical emergency procedures necessary to effectively manage injuries and health crises within the workplace. It covers the immediate assessment of the injured or ill person, the provision of appropriate first aid, activation of emergency medical services, communication protocols, and documentation of incidents. The procedures ensure swift, organized, and compliant responses to medical emergencies, promoting the health and safety of all employees and visitors.

What is the primary objective of the Manufacturing Safety Procedures SOP?

The primary objective of the Manufacturing Safety Procedures SOP is to establish a comprehensive framework that ensures the safety and well-being of all personnel involved in manufacturing activities. It aims to minimize workplace accidents and promote compliance with regulatory safety standards. By standardizing safety practices, the SOP enhances overall operational efficiency and risk management.

Which personal protective equipment (PPE) is mandated by the SOP for specific manufacturing tasks?

The SOP mandates the use of personal protective equipment (PPE) such as safety helmets, gloves, goggles, and steel-toed boots for designated manufacturing tasks. It specifies PPE requirements based on task risk assessments to safeguard workers from hazards like chemical exposure and mechanical injuries. Proper PPE usage is emphasized to prevent accidents and ensure compliance with safety protocols.

How does the SOP dictate the reporting and documentation of on-site accidents or near-misses?

The SOP requires immediate reporting and thorough documentation of all on-site accidents and near-misses to designated safety officers. Incident reports must include detailed descriptions, root cause analysis, and corrective actions taken to prevent recurrence. This systematic approach ensures transparency and continuous improvement in workplace safety management.

What are the procedural steps for the safe handling and disposal of hazardous materials according to the SOP?

The SOP outlines strict procedural steps for the safe handling and disposal of hazardous materials, including proper labeling, use of PPE, and containment measures. It mandates secure storage in designated areas to prevent leaks and contamination. Disposal must comply with environmental regulations and be conducted through authorized channels to ensure safety and legal adherence.

Which emergency response actions are outlined in the SOP for equipment malfunction or fire?

The SOP details critical emergency response actions such as immediate shutdown of faulty equipment, activation of fire alarms, and evacuation procedures. It emphasizes prompt communication with emergency responders and use of fire suppression equipment where applicable. These measures are designed to safeguard personnel and minimize damage during equipment malfunctions or fires.