A SOP Template for Manufacturing Downtime Response provides a structured framework to quickly address and resolve production interruptions, minimizing losses and ensuring safety. This template outlines clear steps for identifying downtime causes, executing corrective actions, and documenting the entire process for continuous improvement. Implementing this SOP enhances operational efficiency and supports consistent manufacturing performance.

Initial incident detection and immediate reporting procedures.

This SOP details initial incident detection and immediate reporting procedures, including identifying potential safety hazards, recognizing incidents promptly, assessing the severity of the situation, and ensuring rapid communication to appropriate personnel. The aim is to minimize risk, ensure swift response, and maintain workplace safety by establishing clear guidelines for early detection and timely incident reporting.

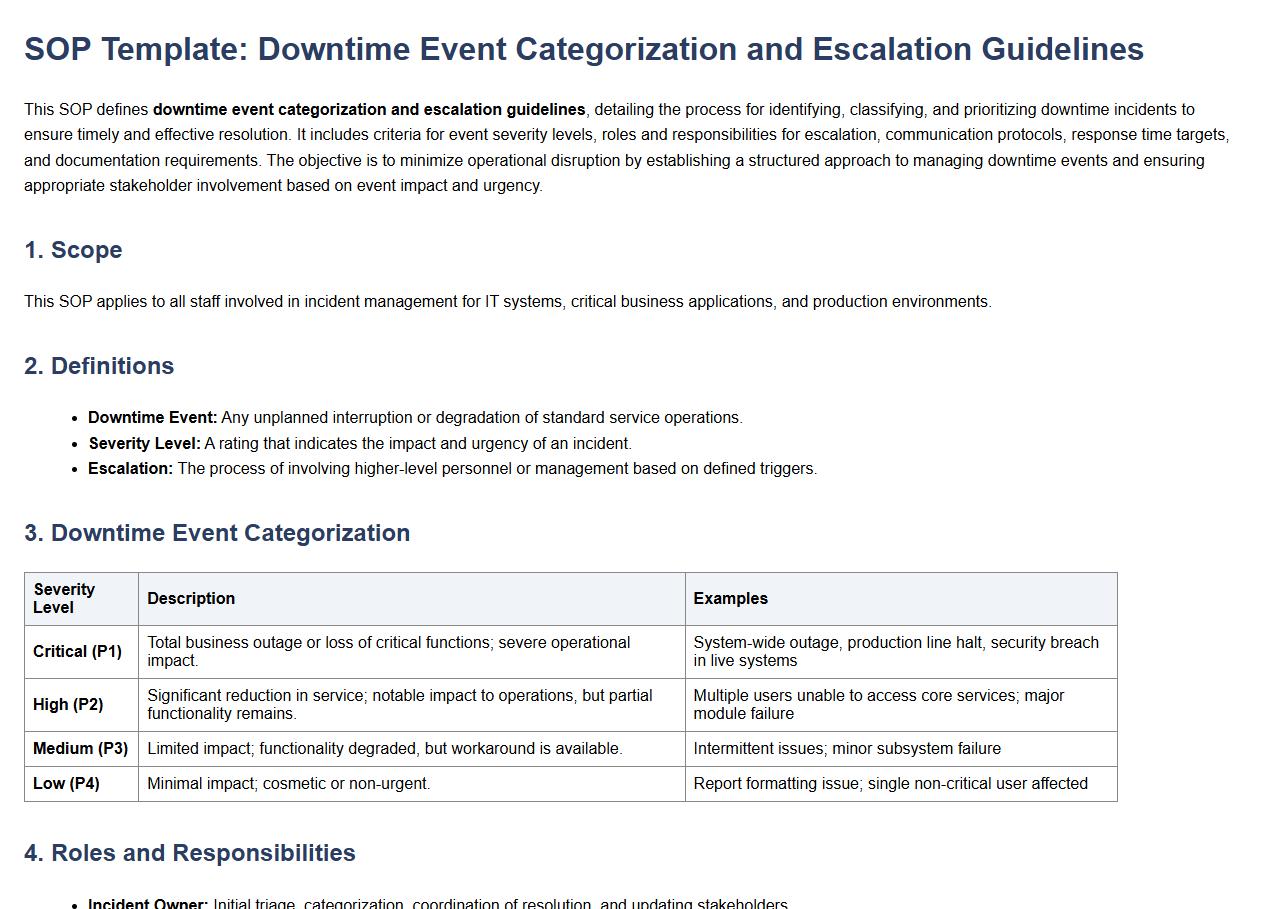

Downtime event categorization and escalation guidelines.

This SOP defines downtime event categorization and escalation guidelines, detailing the process for identifying, classifying, and prioritizing downtime incidents to ensure timely and effective resolution. It includes criteria for event severity levels, roles and responsibilities for escalation, communication protocols, response time targets, and documentation requirements. The objective is to minimize operational disruption by establishing a structured approach to managing downtime events and ensuring appropriate stakeholder involvement based on event impact and urgency.

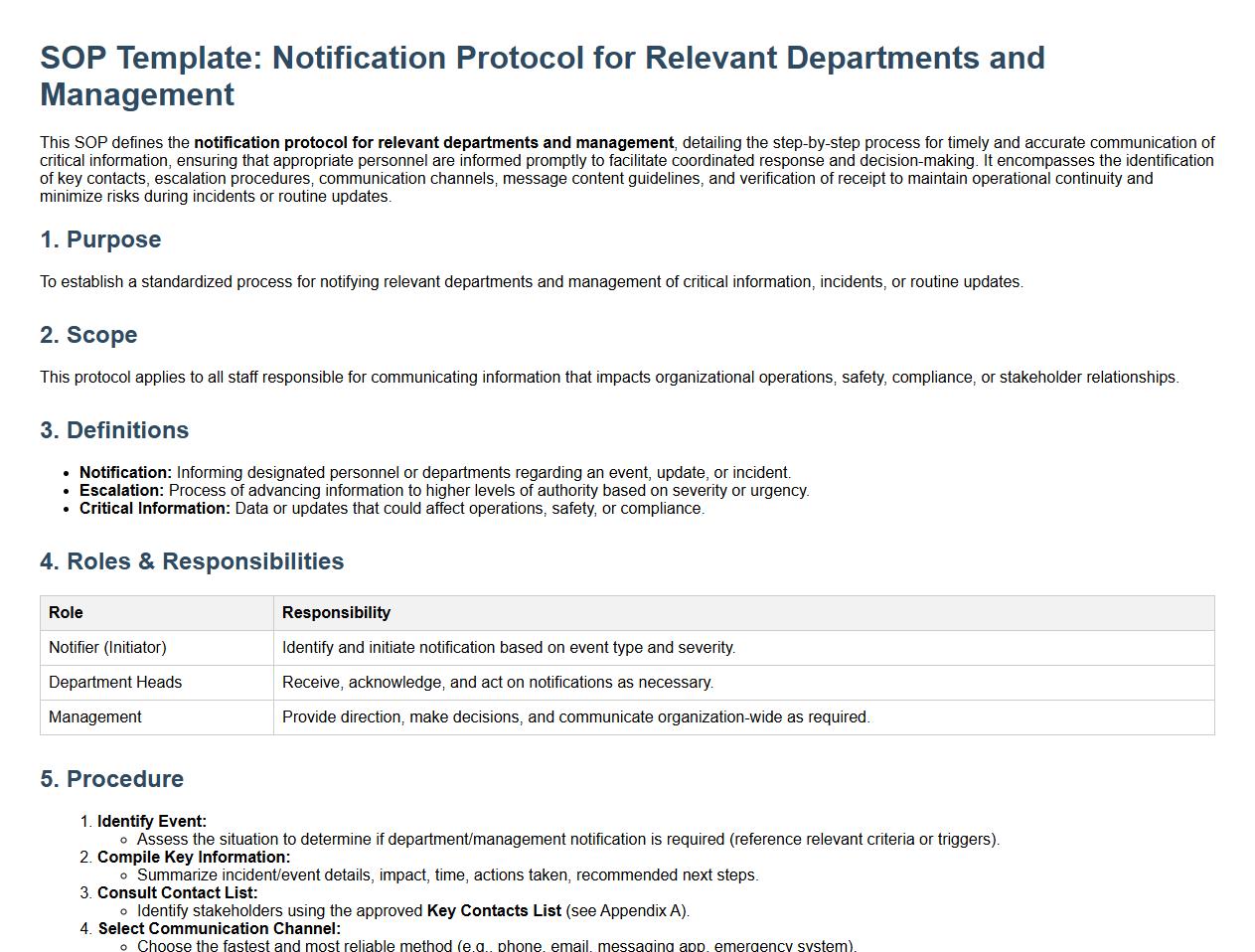

Notification protocol for relevant departments and management.

This SOP defines the notification protocol for relevant departments and management, detailing the step-by-step process for timely and accurate communication of critical information, ensuring that appropriate personnel are informed promptly to facilitate coordinated response and decision-making. It encompasses the identification of key contacts, escalation procedures, communication channels, message content guidelines, and verification of receipt to maintain operational continuity and minimize risks during incidents or routine updates.

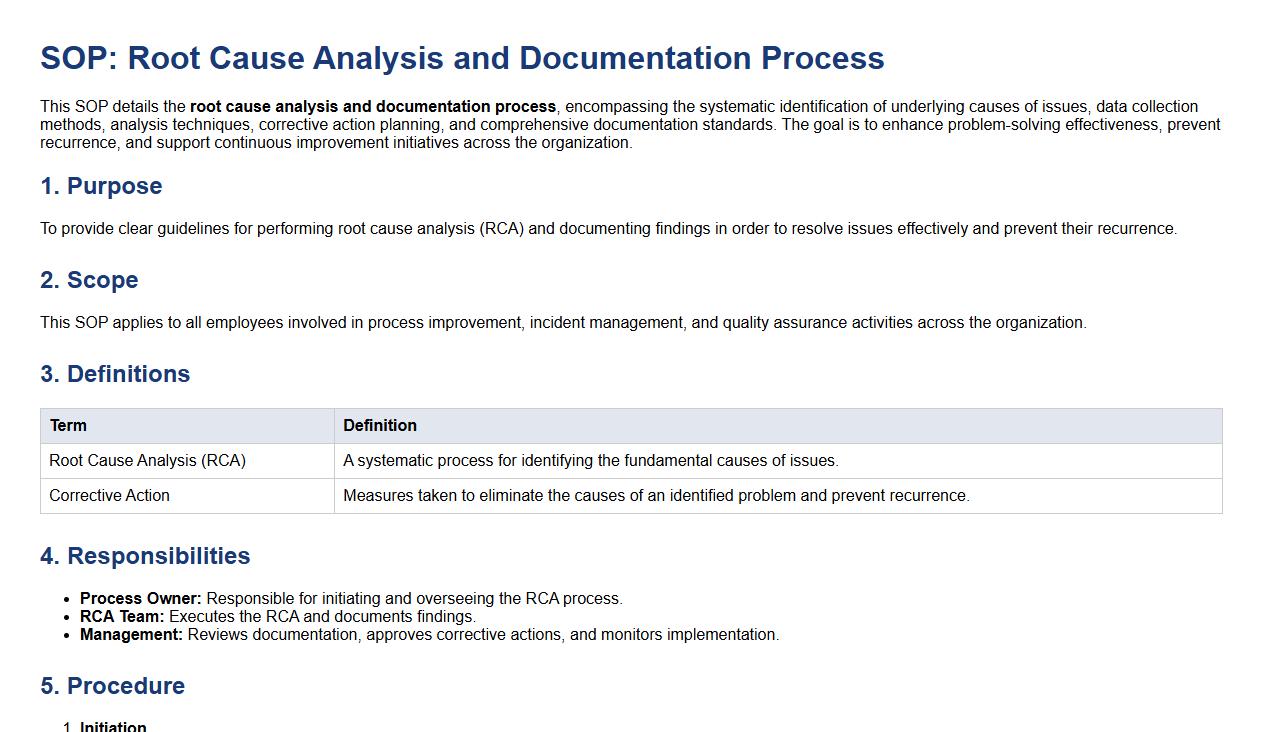

Root cause analysis and documentation process.

This SOP details the root cause analysis and documentation process, encompassing the systematic identification of underlying causes of issues, data collection methods, analysis techniques, corrective action planning, and comprehensive documentation standards. The goal is to enhance problem-solving effectiveness, prevent recurrence, and support continuous improvement initiatives across the organization.

Temporary containment and safety measures.

This SOP describes temporary containment and safety measures essential for managing hazardous situations, preventing spills, and ensuring workplace safety. It outlines procedures for setting up temporary barriers, containment units, and safety zones to mitigate risks during maintenance, repairs, or emergency incidents. The document emphasizes proper equipment use, hazard communication, personnel protection, and timely removal of temporary measures to restore normal operations safely.

Detailed troubleshooting and corrective action steps.

This SOP provides a comprehensive guide for detailed troubleshooting and corrective action steps, including identifying potential issues, systematically diagnosing problems, implementing effective solutions, verifying resolution, and documenting corrective measures. The goal is to enhance problem-solving efficiency, minimize downtime, and ensure consistent operational performance through structured troubleshooting protocols and corrective actions.

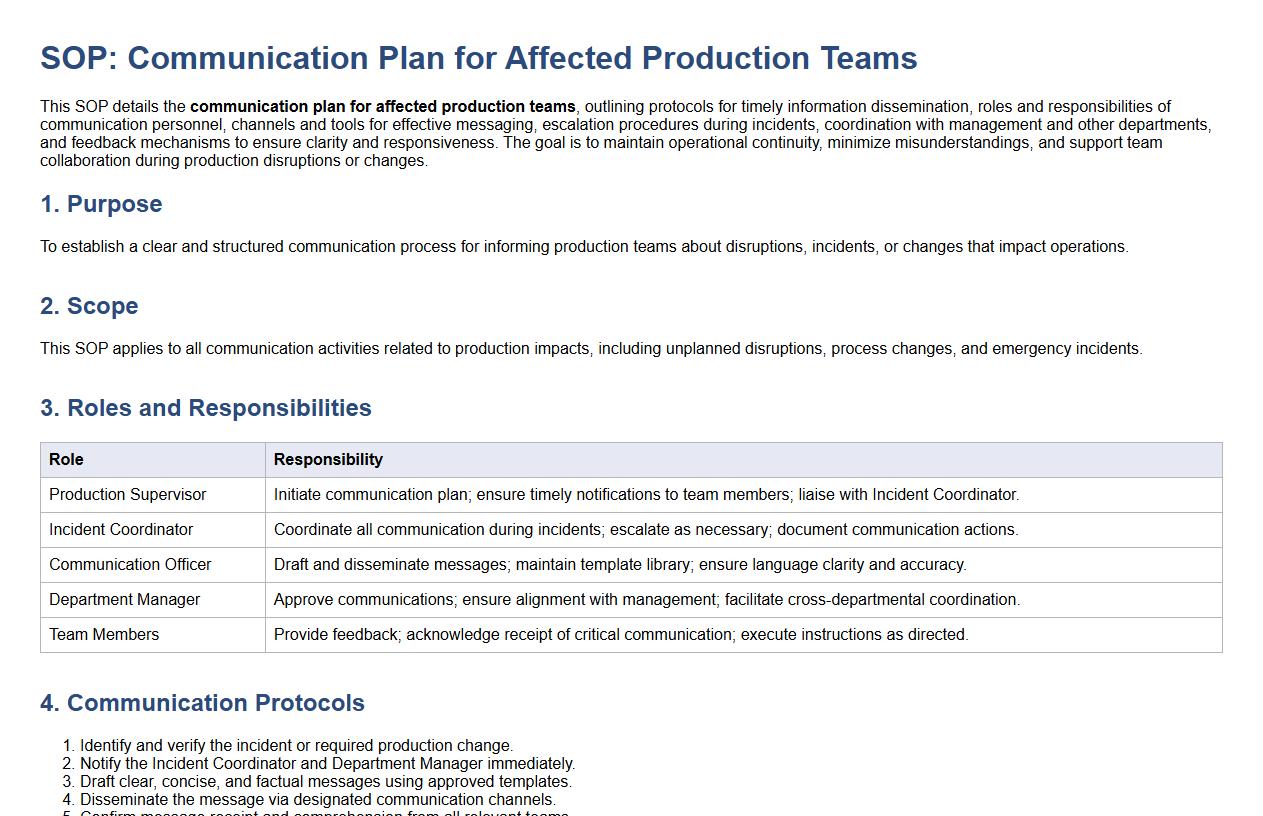

Communication plan for affected production teams.

This SOP details the communication plan for affected production teams, outlining protocols for timely information dissemination, roles and responsibilities of communication personnel, channels and tools for effective messaging, escalation procedures during incidents, coordination with management and other departments, and feedback mechanisms to ensure clarity and responsiveness. The goal is to maintain operational continuity, minimize misunderstandings, and support team collaboration during production disruptions or changes.

Downtime tracking and incident logging requirements.

This SOP details the downtime tracking and incident logging requirements, including the procedures for accurately recording downtime events, identifying causes, documenting incident details, analyzing impact on operations, and implementing corrective actions. The goal is to ensure systematic monitoring of equipment performance and incidents to minimize operational disruptions and enhance overall efficiency.

Post-incident review and restoration of operations.

This SOP details the post-incident review and restoration of operations, focusing on the systematic evaluation of incidents to identify root causes, implement corrective actions, and restore normal business functions efficiently. It includes procedures for incident documentation, team debriefing, assessment of operational impacts, communication protocols, restoration planning, and continuous improvement to enhance organizational resilience and prevent recurrence.

Continuous improvement and preventive action procedures.

This SOP defines continuous improvement and preventive action procedures, focusing on identifying opportunities for process enhancement, analyzing root causes of issues, implementing corrective and preventive measures, monitoring effectiveness of actions taken, and fostering a culture of ongoing quality improvement. Its aim is to proactively address potential problems, minimize risks, and enhance overall operational performance through systematic review and improvement cycles.

What are the primary steps outlined in the SOP for responding to unplanned manufacturing downtime?

The SOP mandates an immediate assessment of the downtime cause to mitigate impact quickly. Next, the affected machinery or process should be isolated to prevent further disruptions. Finally, a corrective action plan must be implemented promptly and monitored for effectiveness.

Who is responsible for initiating downtime reporting according to the SOP?

The operator present at the time of the incident is primarily responsible for initiating downtime reporting. They must notify the shift supervisor without delay to ensure timely intervention. The SOP emphasizes rapid communication to minimize downtime effects.

What communication protocols are specified in the SOP during a downtime event?

The SOP requires that all downtime events be reported through a structured communication chain, starting from the operator to management. Notifications must include downtime duration and suspected causes. Regular updates are mandated until the issue is resolved.

How does the SOP define criteria for classifying downtime severity levels?

Downtime severity levels are classified based on duration, impact on production, and safety risks. Minor downtime involves less than 30 minutes with minimal impact, whereas major downtime exceeds one hour or affects critical operations. This classification helps prioritize response efforts effectively.

What documentation requirements are mandated by the SOP after downtime resolution?

Post-resolution documentation must include a detailed downtime report outlining root causes and corrective actions taken. The SOP also requires records of involved personnel and timestamps for all key events. These documents support continuous improvement and audit compliance.