A SOP Template for Manufacturing Product Inspection provides a standardized framework to ensure consistent quality control during the production process. It outlines specific inspection criteria, methods, and documentation procedures to identify defects and maintain product standards. Utilizing this template improves efficiency, reduces errors, and supports compliance with industry regulations.

Pre-inspection material verification and documentation.

This SOP details the process for pre-inspection material verification and documentation, ensuring all materials are accurately identified, verified against specifications, and properly recorded before inspection. It covers procedures for checking material quality, quantity, and compliance with project requirements, as well as maintaining thorough documentation to support traceability and accountability in the inspection process.

Inspection tool and equipment calibration procedures.

This SOP details the inspection tool and equipment calibration procedures, covering the steps for regular inspection, calibration scheduling, calibration standards, documentation requirements, calibration equipment maintenance, and corrective actions for non-compliance. The procedure ensures accuracy, reliability, and compliance of measurement tools and equipment used in quality control and production processes, thereby maintaining operational efficiency and product quality.

Detailed step-by-step product inspection process.

This SOP details the product inspection process through a comprehensive step-by-step approach, ensuring each product meets quality standards. It covers initial visual checks, measurement verification, functional testing, defect identification, documentation of findings, and final approval or rejection criteria. The goal is to maintain consistent product quality, reduce defects, and enhance customer satisfaction by following a standardized inspection methodology.

Sample selection and handling instructions.

This SOP details sample selection and handling instructions to ensure the integrity and reliability of samples collected for analysis. It includes guidelines for proper sample identification, collection techniques, preservation methods, and transportation procedures. The objective is to minimize contamination, degradation, and errors during sample processing, thereby maintaining the accuracy of subsequent test results and analyses.

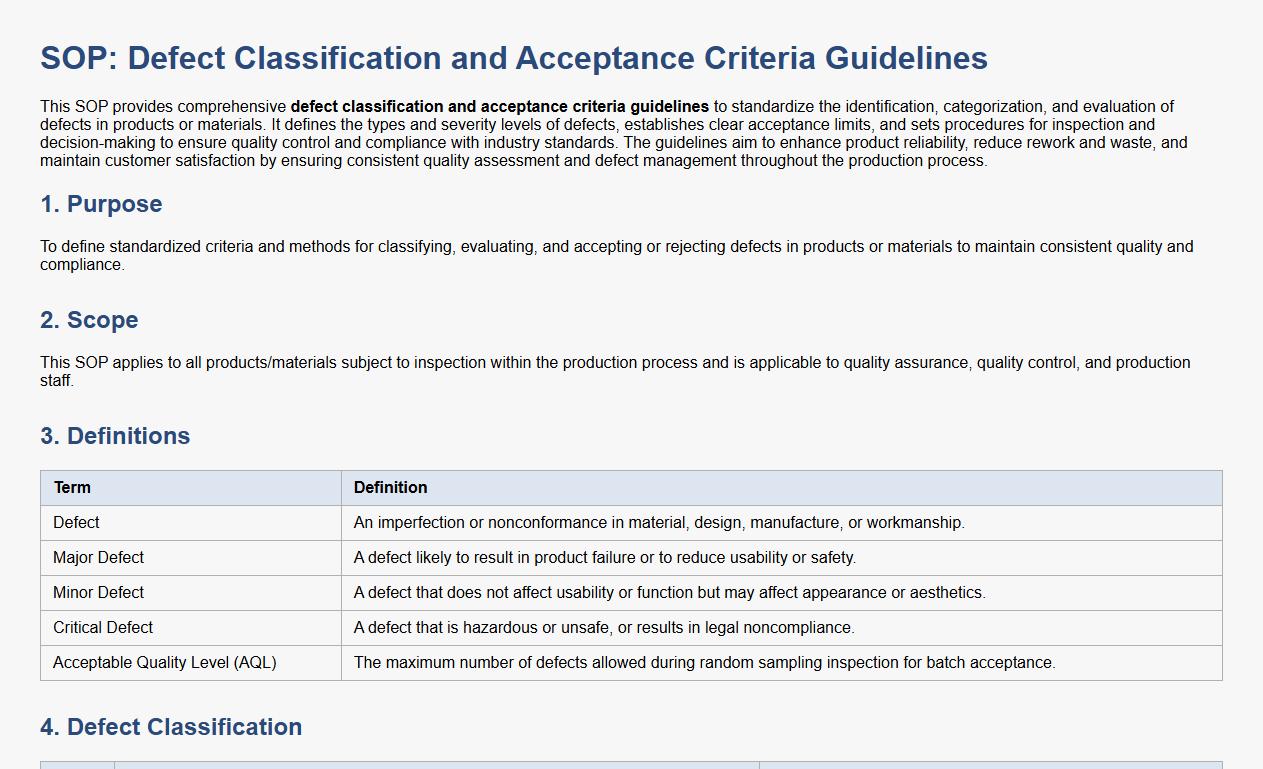

Defect classification and acceptance criteria guidelines.

This SOP provides comprehensive defect classification and acceptance criteria guidelines to standardize the identification, categorization, and evaluation of defects in products or materials. It defines the types and severity levels of defects, establishes clear acceptance limits, and sets procedures for inspection and decision-making to ensure quality control and compliance with industry standards. The guidelines aim to enhance product reliability, reduce rework and waste, and maintain customer satisfaction by ensuring consistent quality assessment and defect management throughout the production process.

Recording, photographing, and reporting inspection findings.

This SOP details the procedures for recording, photographing, and reporting inspection findings. It includes guidelines on accurately documenting observations, capturing clear and relevant photographic evidence, and compiling comprehensive reports. The goal is to ensure thorough and consistent communication of inspection results to support effective decision-making and follow-up actions.

Non-conformance identification and escalation procedure.

This SOP defines the process for non-conformance identification and escalation, detailing steps for recognizing deviations from standards, documenting incidents, and escalating issues to appropriate levels of management. It aims to ensure timely detection, accurate reporting, and effective resolution of non-conformances to maintain quality, compliance, and continuous improvement across operations.

Product rework or rejection handling process.

This SOP defines the product rework or rejection handling process, detailing the procedures for identifying, segregating, and documenting non-conforming products. It includes steps for analyzing the root cause of defects, deciding on appropriate rework actions or rejection, implementing corrective measures, and ensuring compliance with quality standards. The objective is to maintain product quality, minimize waste, and ensure customer satisfaction by effectively managing rejected or rework-required products within the production workflow.

Final inspection approval and sign-off steps.

This SOP details the final inspection approval and sign-off steps, covering the process for verifying that all project requirements and quality standards have been met, documenting inspection results, obtaining necessary approvals from designated authorities, ensuring compliance with regulatory and company standards, resolving any outstanding issues, and officially signing off to confirm project completion. The purpose is to guarantee that all aspects of the project have been thoroughly reviewed and formally approved before final delivery or launch.

Inspection records retention and data management protocol.

This SOP details the inspection records retention and data management protocol, encompassing the procedures for systematic documentation, secure storage, timely retrieval, and authorized disposal of inspection records. It ensures compliance with regulatory requirements, maintains data integrity and confidentiality, facilitates efficient audits, and supports continuous improvement through accurate record-keeping and data analysis.

What are the critical steps outlined in the SOP for conducting manufacturing product inspections?

The SOP emphasizes the initial preparation stage, which includes gathering all necessary tools and inspection checklists. Following preparation, inspectors perform a systematic examination of products based on specified criteria. The final step involves documenting the inspection results and ensuring any non-conformities are addressed promptly.

Which personnel are responsible for each stage of the product inspection process according to the SOP?

Quality Control Inspectors are primarily responsible for performing the product inspections. Supervisors oversee the inspection process and ensure compliance with SOP guidelines. Additionally, the production team is involved in rectifying any identified issues post-inspection.

What predefined criteria must a product meet to pass inspection as per the SOP?

The SOP lists specific quality benchmarks including dimensional accuracy, functionality, and aesthetic standards. Products must also meet safety and regulatory requirements to pass the inspection. Consistency with documented manufacturing specifications is a critical condition for approval.

How does the SOP specify the documentation and reporting requirements during product inspections?

The SOP mandates that all inspection data be recorded on standardized forms immediately after evaluation. Reports must include detailed findings, inspector comments, and the final verdict on product acceptance. These records are then submitted to management for review and further action.

What procedures does the SOP mandate when a product fails to meet inspection standards?

Upon failure, the SOP requires immediate segregation of the defective product to prevent further processing. A root cause analysis must be conducted to identify issues and implement corrective actions. The incident, along with corrective measures, must be thoroughly documented and escalated to the quality assurance team.