A SOP Template for Machine Maintenance in Manufacturing provides a standardized framework to ensure consistent and efficient upkeep of machinery. It outlines step-by-step procedures, safety protocols, and scheduling guidelines to minimize downtime and extend equipment lifespan. This template helps manufacturing plants maintain optimal operational performance and reduce unexpected breakdowns.

Preventive maintenance scheduling and planning.

This SOP details the processes for preventive maintenance scheduling and planning, including identification of critical equipment, establishing maintenance intervals, resource allocation, task prioritization, documentation of maintenance activities, and ongoing evaluation of maintenance effectiveness. The goal is to minimize equipment downtime, extend asset life, and ensure operational reliability through systematic and timely preventive maintenance practices.

Daily machine inspection and checklist completion.

This SOP details the process for daily machine inspection and checklist completion to ensure all machinery operates safely and efficiently. It covers pre-operation checks, identification of potential hazards, routine maintenance verification, and documentation requirements. The aim is to prevent equipment failures, enhance workplace safety, and maintain compliance with operational standards through systematic daily inspections and thorough checklist management.

Lubrication, cleaning, and housekeeping procedures.

This SOP details the lubrication, cleaning, and housekeeping procedures necessary to maintain equipment efficiency, ensure a safe working environment, and prolong the lifespan of machinery. It covers scheduled lubrication of moving parts, proper cleaning techniques to prevent contamination and buildup, waste disposal methods, and routine housekeeping practices to keep work areas organized, safe, and compliant with health and safety standards.

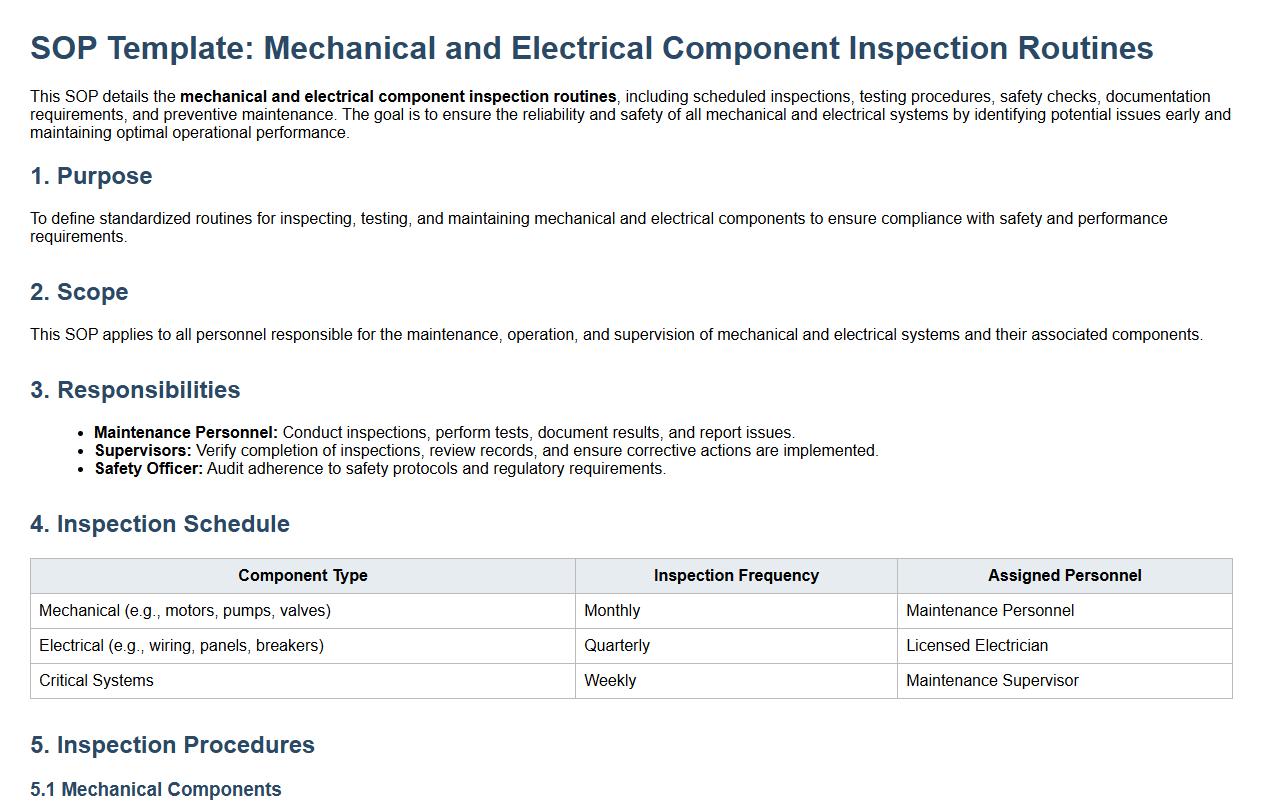

Mechanical and electrical component inspection routines.

This SOP details the mechanical and electrical component inspection routines, including scheduled inspections, testing procedures, safety checks, documentation requirements, and preventive maintenance. The goal is to ensure the reliability and safety of all mechanical and electrical systems by identifying potential issues early and maintaining optimal operational performance.

Replacement and calibration of worn parts and sensors.

This SOP details the replacement and calibration of worn parts and sensors to maintain optimal equipment performance and accuracy. It covers identifying worn components, proper removal and installation techniques, precise calibration procedures, and verification of sensor functionality. Adhering to this SOP ensures consistent operational efficiency, prevents equipment failure, and supports accurate data collection for reliable system performance.

Safety lockout/tagout (LOTO) protocols during maintenance.

This SOP details the Safety lockout/tagout (LOTO) protocols during maintenance to prevent accidental machine startup and ensure worker safety. It covers procedures for identifying energy sources, isolating equipment, applying locks and tags, verifying de-energization, authorized personnel responsibilities, and steps for safely restoring equipment to service. The goal is to minimize risks of injury by controlling hazardous energy during maintenance activities.

Documentation and tracking of maintenance activities.

This SOP details the documentation and tracking of maintenance activities, including procedures for recording maintenance tasks, scheduling regular inspections, tracking repair histories, ensuring compliance with maintenance standards, and utilizing maintenance management systems. The goal is to maintain equipment reliability, minimize downtime, and ensure accurate and accessible records for auditing and continuous improvement.

Emergency breakdown response and reporting process.

This SOP details the emergency breakdown response and reporting process, focusing on immediate actions to address equipment or system failures, steps for safe containment and mitigation of hazards, communication protocols for notifying relevant personnel, documentation requirements for incident analysis, and procedures for restoring normal operations efficiently. The goal is to minimize downtime, ensure staff safety, and facilitate effective incident management through a structured response and thorough reporting system.

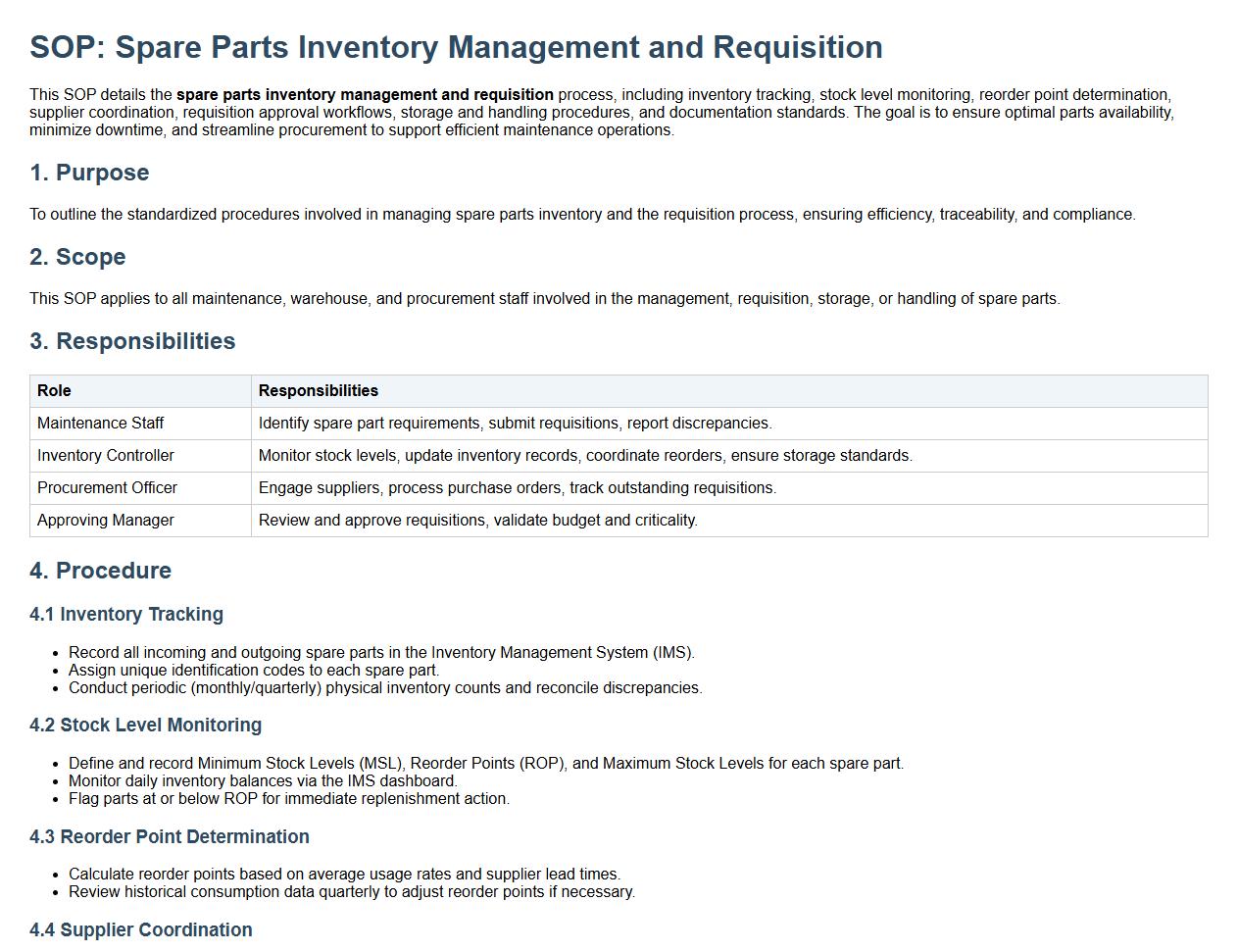

Spare parts inventory management and requisition.

This SOP details the spare parts inventory management and requisition process, including inventory tracking, stock level monitoring, reorder point determination, supplier coordination, requisition approval workflows, storage and handling procedures, and documentation standards. The goal is to ensure optimal parts availability, minimize downtime, and streamline procurement to support efficient maintenance operations.

Training and qualification requirements for maintenance staff.

This SOP details the training and qualification requirements for maintenance staff to ensure all personnel possess the necessary skills and knowledge to perform their duties effectively and safely. It covers mandatory training programs, certification standards, competency assessments, ongoing professional development, and compliance with industry regulations. The objective is to maintain a qualified maintenance team capable of minimizing downtime, preventing equipment failures, and promoting a safe working environment.

Key Steps Outlined in the SOP for Routine Machine Maintenance

The SOP details a structured approach to routine machine maintenance, focusing on inspection, cleaning, and lubrication. Each step ensures machine components are checked for wear and any abnormalities are promptly addressed. This systematic process aims to enhance machine longevity and performance.

Safety Precautions Before Performing Maintenance

The SOP mandates strict adherence to safety protocols including power isolation, lockout-tagout (LOTO), and wearing appropriate personal protective equipment (PPE). These measures prevent accidental machine startup and protect maintenance personnel from injury. Ensuring a hazard-free environment is emphasized as critical before starting any task.

Documentation and Reporting of Completed Maintenance Activities

The SOP requires detailed documentation of all maintenance work using standardized maintenance logs and checklists. This documentation captures the tasks performed, parts replaced, and any anomalies observed. Accurate reporting supports traceability and aids in future troubleshooting and audits.

Responsibility for Verifying Machine Shutdown Procedures

According to the SOP, the maintenance supervisor or lead technician is tasked with verifying proper machine shutdown before maintenance begins. Their role includes ensuring all safety checks and lockout procedures are correctly implemented. This accountability helps maintain a safe work environment and prevents operational errors.

Frequency and Schedule for Preventive Maintenance Mandated in the SOP

The SOP outlines a specific preventive maintenance schedule based on machine type and usage hours, typically ranging from weekly to quarterly intervals. Adhering to these timelines minimizes unexpected breakdowns and optimizes machine reliability. Regular maintenance frequency is adjusted according to operational demands and manufacturer recommendations.