A SOP Template for Packaging Process in Manufacturing outlines standardized procedures to ensure consistency, quality, and safety during packaging operations. It includes detailed steps for material handling, equipment use, and quality checks to minimize errors and maintain compliance with industry standards. This template serves as a crucial guide for training staff and enhancing operational efficiency.

Incoming materials inspection and verification.

This SOP details the incoming materials inspection and verification process, ensuring that all received materials meet specified quality standards and compliance requirements. It covers procedures for verifying shipment accuracy, checking for damages or defects, confirming documentation and certifications, and recording inspection results. The goal is to prevent defective or incorrect materials from entering production and to maintain consistent product quality and operational efficiency.

Workspace preparation and sanitization procedures.

This SOP details the workspace preparation and sanitization procedures, encompassing steps for cleaning and organizing work areas, proper use of disinfectants, waste disposal protocols, equipment sanitization, employee hygiene practices, and maintaining a safe and healthy environment. The objective is to prevent contamination, ensure compliance with health standards, and promote overall workplace safety and efficiency.

Packaging equipment setup and calibration.

This SOP details the procedures for packaging equipment setup and calibration, including initial equipment assembly, adjustment of operational parameters, calibration of sensors and scales, verification of packaging accuracy, and routine maintenance checks. The objective is to ensure that packaging machinery operates efficiently and consistently, maintaining product quality and compliance with industry standards.

Product quality checks prior to packaging.

This SOP details the product quality checks prior to packaging, outlining procedures for inspecting product consistency, verifying compliance with quality standards, identifying defects or damages, conducting weight and dimension measurements, ensuring proper labeling, and validating packaging materials. The objective is to maintain high product quality, prevent defective items from reaching customers, and uphold brand reputation through systematic quality control before packaging.

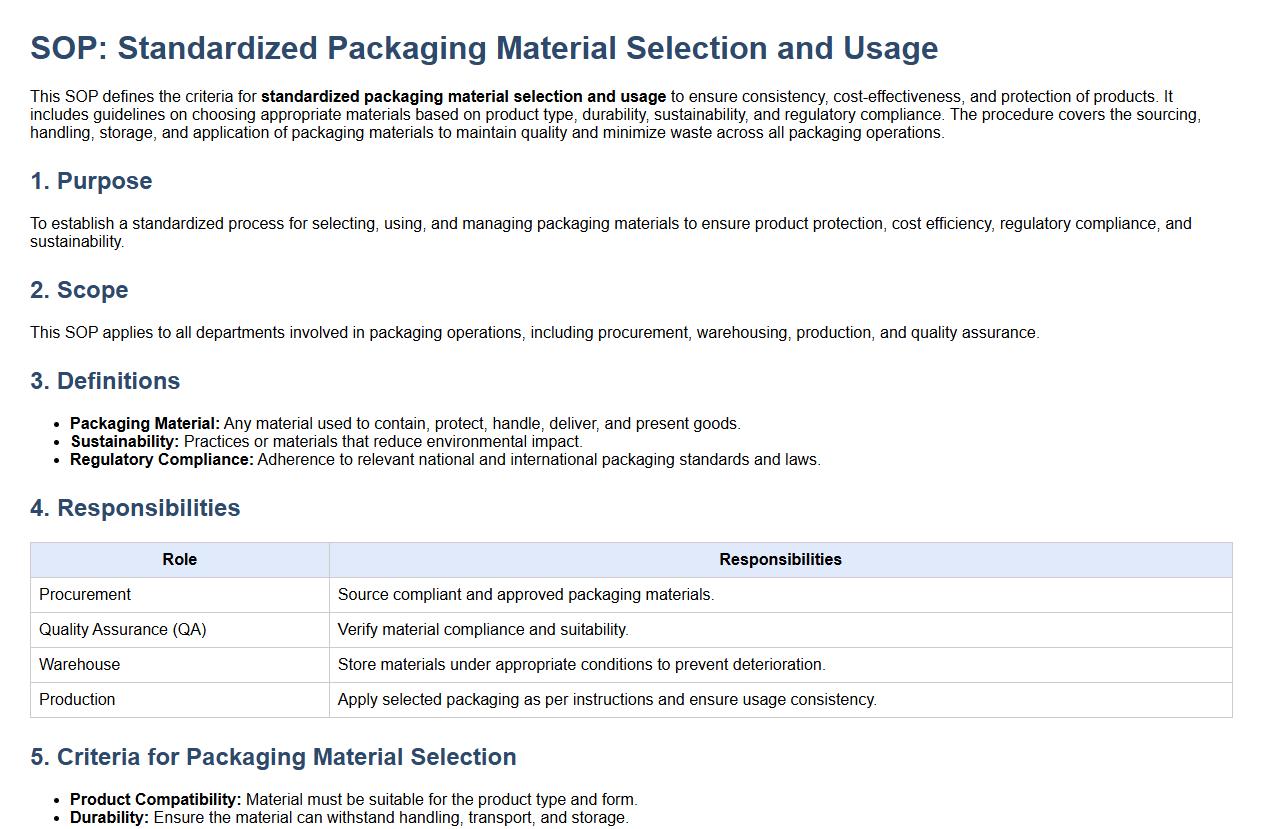

Standardized packaging material selection and usage.

This SOP defines the criteria for standardized packaging material selection and usage to ensure consistency, cost-effectiveness, and protection of products. It includes guidelines on choosing appropriate materials based on product type, durability, sustainability, and regulatory compliance. The procedure covers the sourcing, handling, storage, and application of packaging materials to maintain quality and minimize waste across all packaging operations.

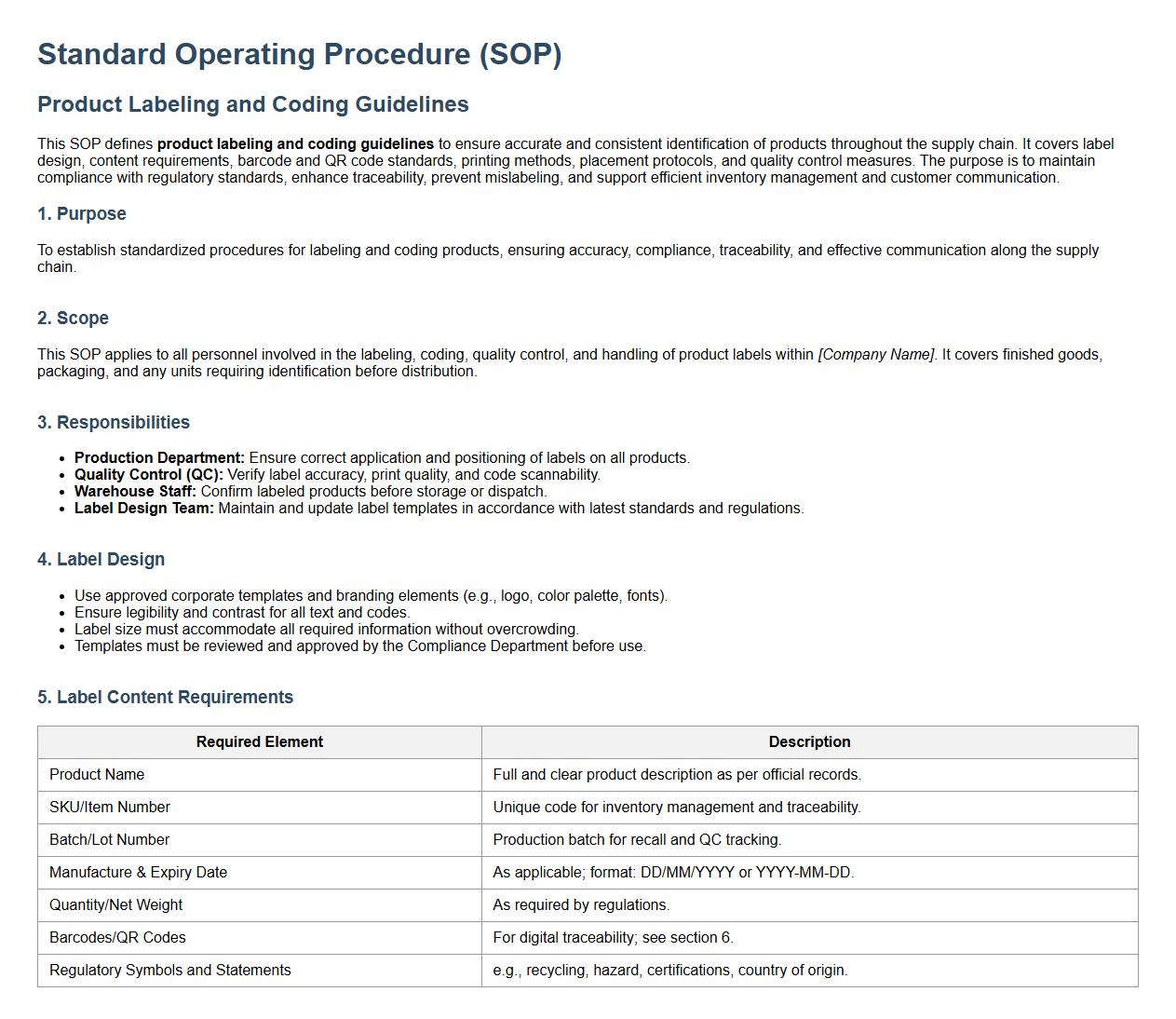

Product labeling and coding guidelines.

This SOP defines product labeling and coding guidelines to ensure accurate and consistent identification of products throughout the supply chain. It covers label design, content requirements, barcode and QR code standards, printing methods, placement protocols, and quality control measures. The purpose is to maintain compliance with regulatory standards, enhance traceability, prevent mislabeling, and support efficient inventory management and customer communication.

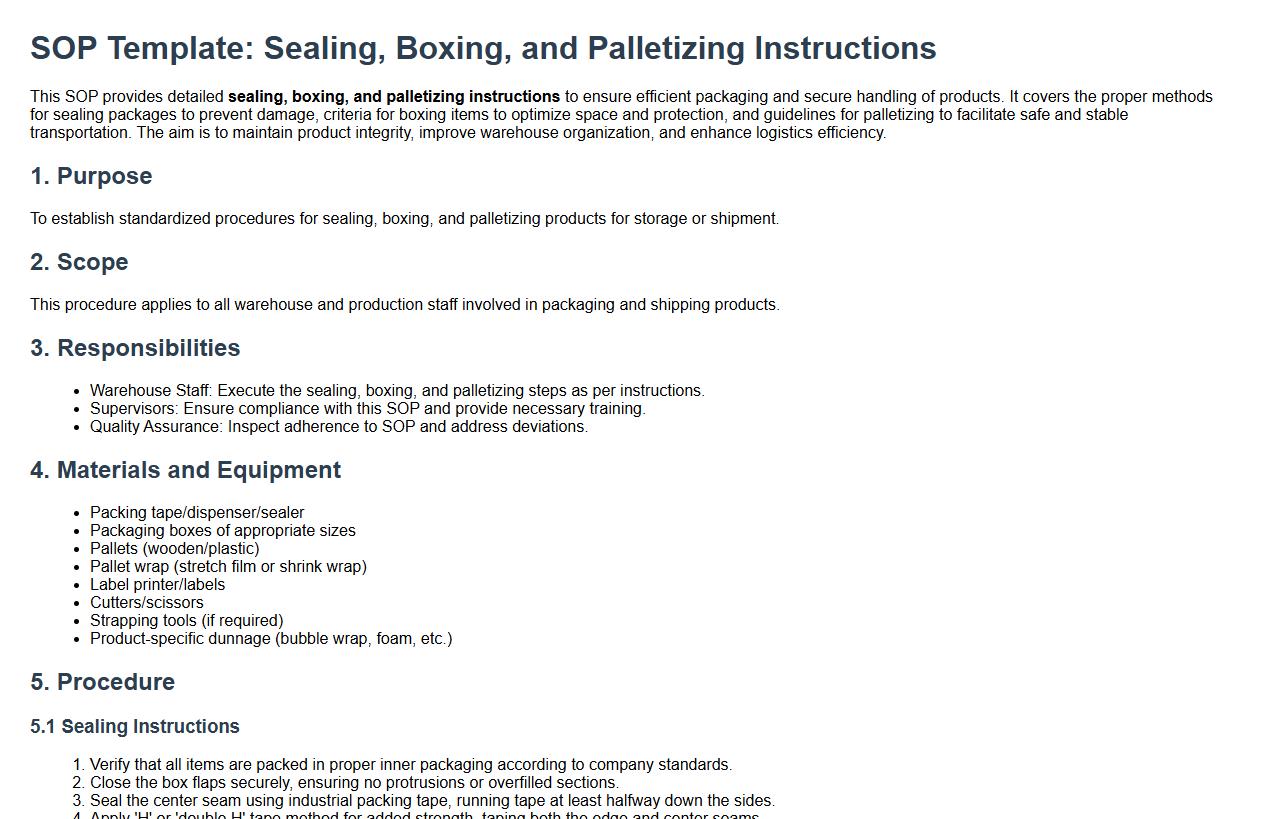

Sealing, boxing, and palletizing instructions.

This SOP provides detailed sealing, boxing, and palletizing instructions to ensure efficient packaging and secure handling of products. It covers the proper methods for sealing packages to prevent damage, criteria for boxing items to optimize space and protection, and guidelines for palletizing to facilitate safe and stable transportation. The aim is to maintain product integrity, improve warehouse organization, and enhance logistics efficiency.

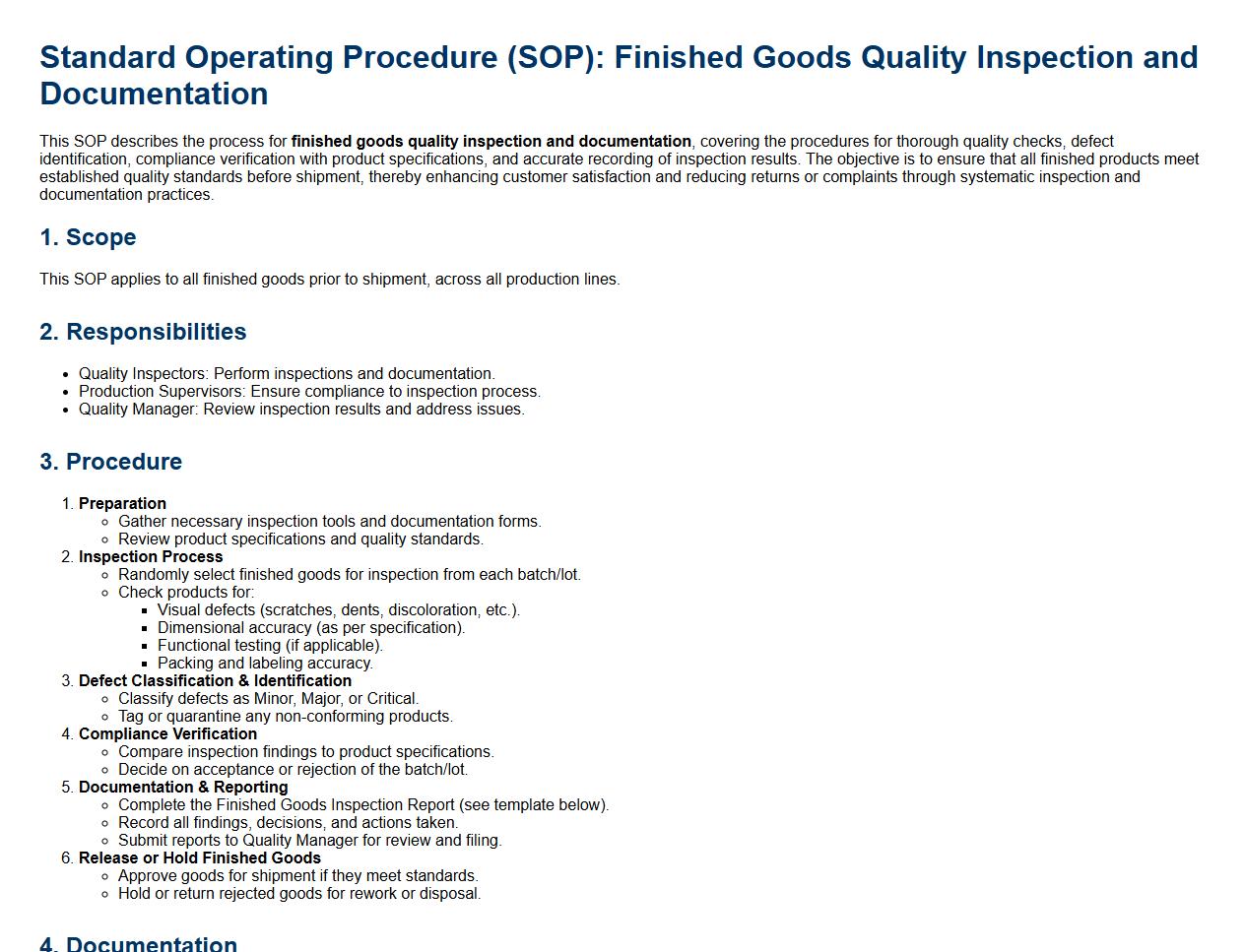

Finished goods quality inspection and documentation.

This SOP describes the process for finished goods quality inspection and documentation, covering the procedures for thorough quality checks, defect identification, compliance verification with product specifications, and accurate recording of inspection results. The objective is to ensure that all finished products meet established quality standards before shipment, thereby enhancing customer satisfaction and reducing returns or complaints through systematic inspection and documentation practices.

Storage and staging requirements for packaged goods.

This SOP defines the storage and staging requirements for packaged goods, ensuring proper handling, organization, and protection of products before distribution. It covers guidelines for temperature control, shelf life management, inventory rotation, packaging integrity, space optimization, and safety protocols to maintain product quality and prevent damage or contamination during storage and staging processes.

Waste disposal and cleanup procedures.

This SOP details waste disposal and cleanup procedures to ensure safe, efficient, and environmentally responsible management of waste materials. It covers waste segregation, proper disposal methods, handling hazardous waste, spill response, and cleanup protocols. The goal is to minimize environmental impact, maintain workplace safety, and comply with regulatory requirements by implementing standardized procedures for waste collection, transportation, and disposal.

Key Steps in the Packaging Process

The SOP outlines the preparation of all packaging materials to ensure readiness. It emphasizes the step-by-step assembly and sealing of products according to standardized guidelines. Finally, it mandates a final inspection before moving products to storage or shipment.

Quality Control Checks in Packaging

The SOP specifies regular visual inspections to detect defects such as mislabeling or damage. It requires periodic weight and dimension verification to ensure package standards are met. Additionally, the document enforces the use of sampling methods for batch quality validation.

Safety and Hygiene Requirements

The SOP mandates workers to wear appropriate personal protective equipment (PPE) throughout the packaging operations. It requires strict adherence to sanitization and cleanliness standards within the packaging area. Moreover, it highlights regular training on hygiene practices to prevent contamination.

Proper Labeling and Documentation Procedures

The SOP defines that every package must have a clear, accurate label indicating product details and batch numbers. It instructs maintaining detailed documentation logs for traceability and quality tracking. The process includes verifying all labels against documentation before final sealing.

Handling and Reporting Deviations

The SOP describes immediate isolation of affected batches when deviations are detected. It mandates prompt documentation and reporting of any irregularities to supervisors. Corrective actions must be implemented as per protocol with follow-up reviews to prevent recurrence.